For some reason I can't understand, or no one wants to divulge entirely. (FX themselves have no comment) No one is selling fx crown hammer weights.

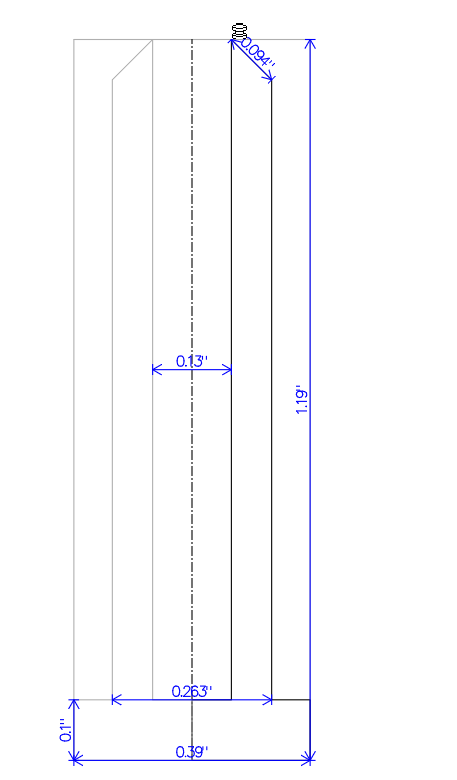

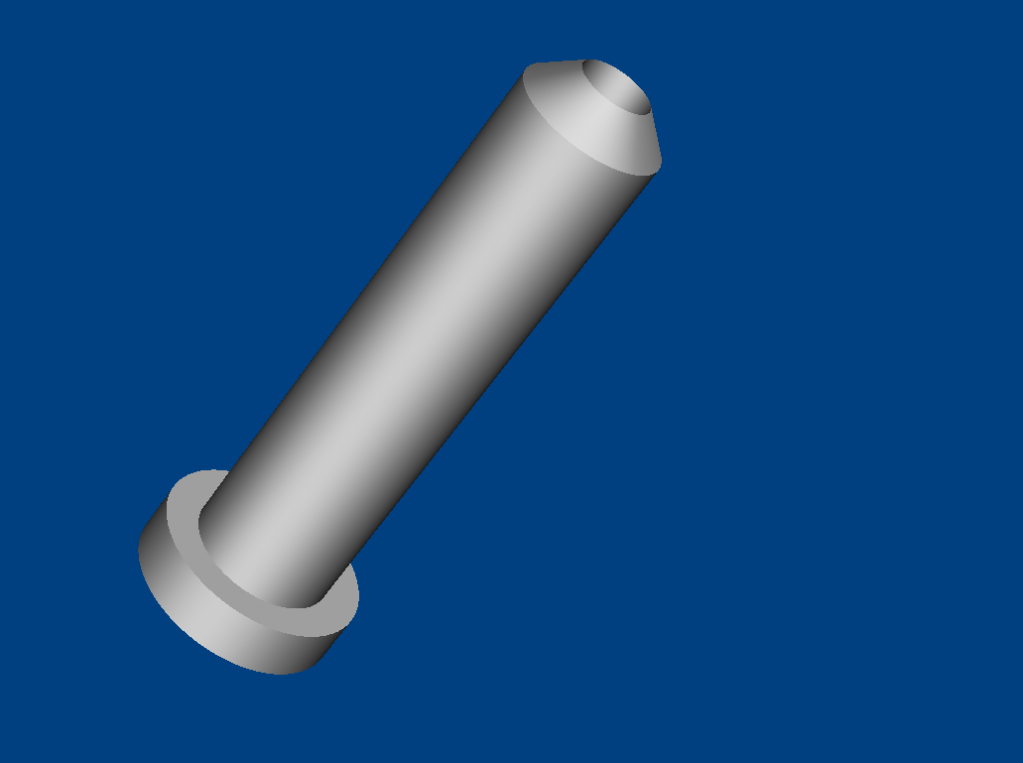

So, it's up to me to make one for myself. Right now I have 3 concerns

#1. Material. I'm wanting to use tool brass (c360). But l I'm wondering if it will deform over time, though I feel it would have to undergo a truly expreme amount of use for this to occur.

#2 Actual weight. I know this was being used for larger calibers and has a weight of roughly 8.25gm. I'll primarily be shooting 22 slugs, so I'm not sure that much weight is needed. But I'm likely going tomake 2 weights. One that I'll modify (for testing), and a final version.

#3 There appears to be a hex shaped recess on the face that butts against the hammer, but I'm not sure what it's for? Mass calculations (for brass and steel) come out close to 8.5gm without the recess, so it can't be very deep....

So, it's up to me to make one for myself. Right now I have 3 concerns

#1. Material. I'm wanting to use tool brass (c360). But l I'm wondering if it will deform over time, though I feel it would have to undergo a truly expreme amount of use for this to occur.

#2 Actual weight. I know this was being used for larger calibers and has a weight of roughly 8.25gm. I'll primarily be shooting 22 slugs, so I'm not sure that much weight is needed. But I'm likely going tomake 2 weights. One that I'll modify (for testing), and a final version.

#3 There appears to be a hex shaped recess on the face that butts against the hammer, but I'm not sure what it's for? Mass calculations (for brass and steel) come out close to 8.5gm without the recess, so it can't be very deep....