Thanks, TorqueMaster for paying attention to the "entry" and "exit" measurement designations for the baffle cones. Certainly, if the cones were installed backwards, not only would sound suppression suffer, the air flow down the spigot that then necks down to what should be the baffle inlet is likely to upset the pellet. This alone might explain the poor performance with regards to sound suppression and grouping.

If I understood correctly, even the Huggett attached to the muzzle directly did not do well - unless that was about sound, rather than grouping or point of impact shifts. Now, a 15 mm barrel OD with a chamfer at its stud shoulder, mated to a muffler with a chamfer at the edge of the female thread, leaves very little flat shoulder to overlap between barrel and Huggett. So, it is possible that there was some misalignment with the Huggett directly mounted too. Apart from actual clipping, a large slant in the air flow can push pellets around.

If the Hugget did tend to mount in an angular fashion due an ineffective shoulder, who is to say that it would not mount in a different angle every time it was installed? That could account for shifting POI. Or, perhaps the Huggett could waggle shot to shot, and upset groups. Even if the problem was not airflow related, having something attached to the barrel that is able to migrate shot to shot, is bad for system harmonics.

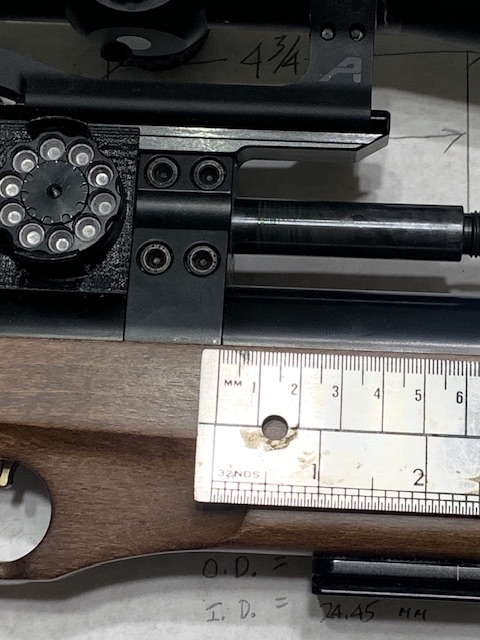

The stock baffle bores seem tight to me, for a system where there is any doubt about shroud droop; but the above observation about baffle reversal is a very significant one.

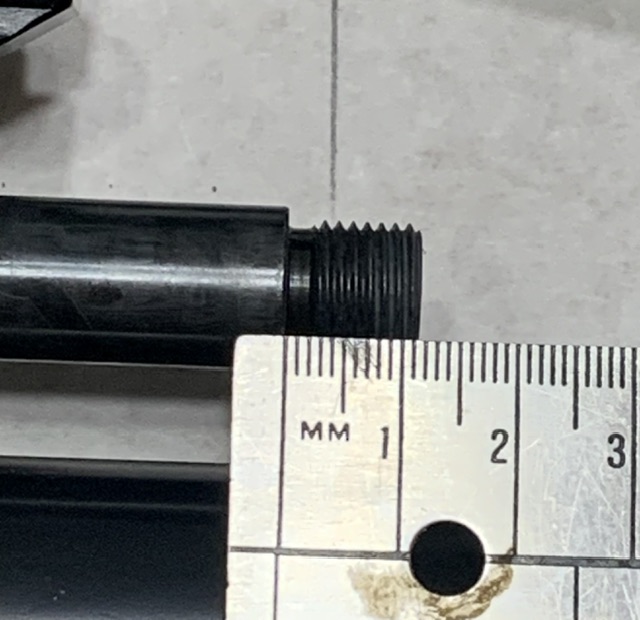

I agree that the shroud endcap thread is most likely 28 x 1 mm. I count at least 8 threads, with a bit more, removed by the two chamfers at either end of the thread - see image below. If there are any doubts, then using any 1 mm pitch thread form as a thread gauge will settle the question. Assuming a proper thread gauge is not on hand.

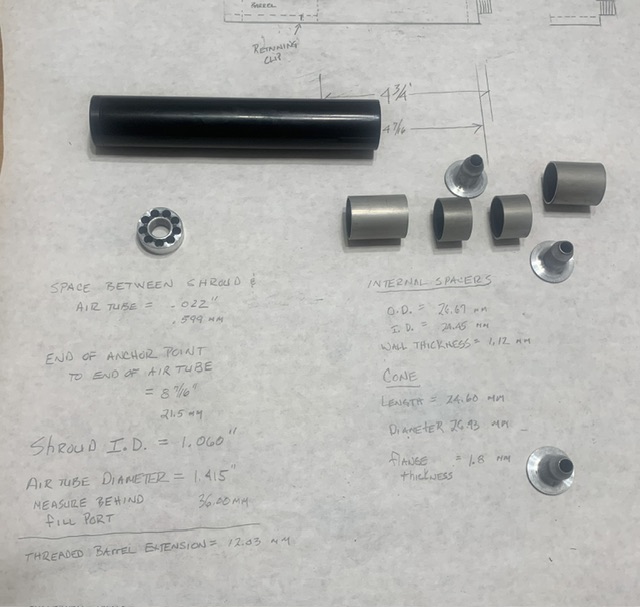

View attachment 427263 All that said, I think this PCP would benefit from a longer and wider expansion volume ahead of the barrel muzzle. Certainly, we can get that to over 8" long at the max print height you can handle. But, rather than being overcome by eagerness as I often am, I think Mr.H should try to see how his airgun shoots with the stock baffles installed with the small ends of the cones pointing at the barrel muzzle. Does it shoot better, and it it quieter? If yes, but not quiet enough, then that seems like a go ahead for this project. I will carry on with a design, regardless. Unless I am told to stop.