Thanks, OldSpook,

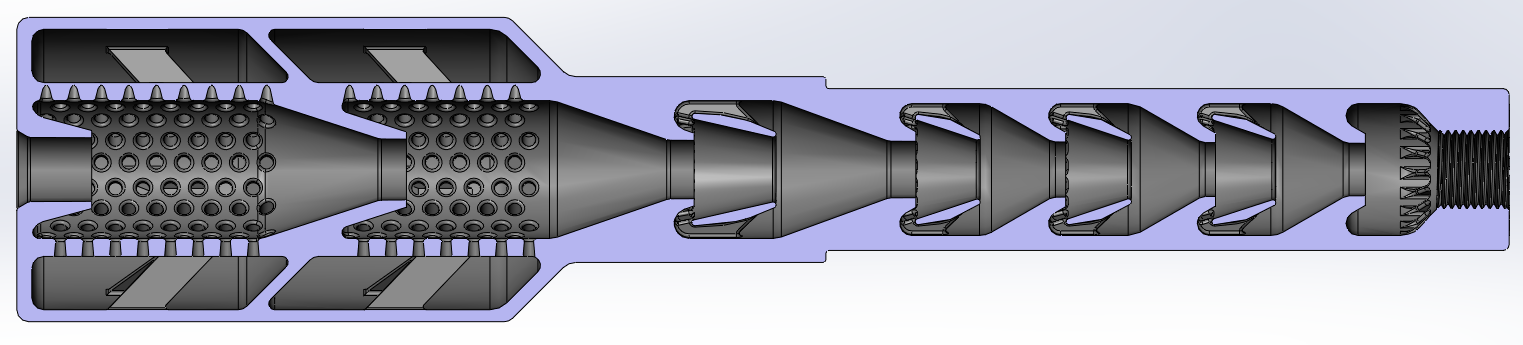

The non Tesla Valve reflex airstripper cone is the first to see muzzle blast, as the pellet uncorks. See image below. Because the reflex volume is small, I spaced the first cone so close to the muzzle that it would act just long enough for the pellet to enter the bore of the cone, and thus be shielded from the initial blast. Air that follows the pellet would encounter the second to fifth cones, all equipped with TV air foils.

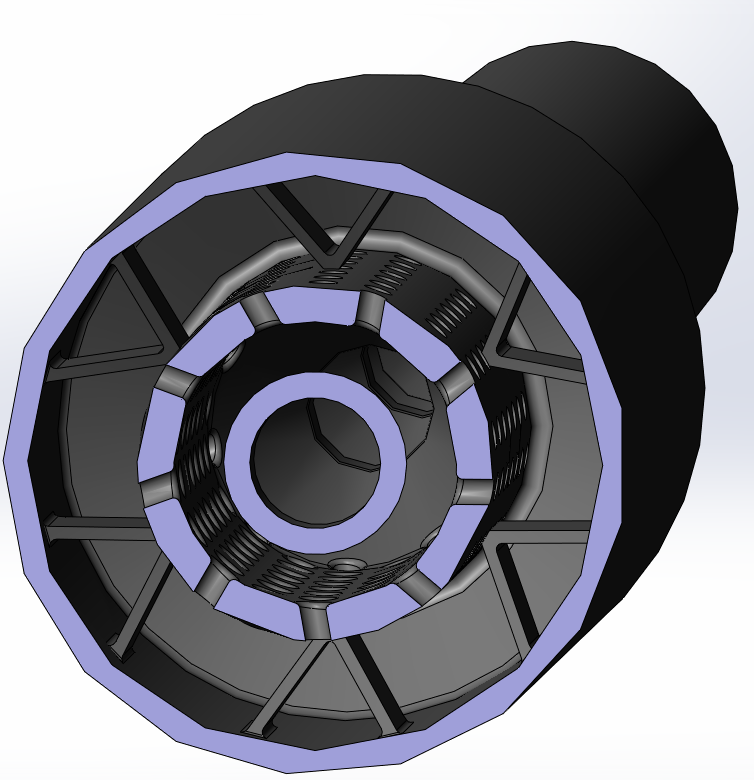

The ID of the printed tube that lives in the shroud is not very large at 27 mm. Perhaps your TV baffle style is more flexible in terms of engineering the bore to bypass ratio; but there is very little room the way I support the airfoil to drive very large flow ratios.

I understand that the distance the reverse airflow travels affects its delay, but my mental model does not consider the forward and reverse air flow streams to travel at the same speed: Air following the pellet cannot travel faster than the pellet, because the pellet is in the way. Air that is accelerated by its pressure drop, by expanding somewhat radially (before being directed forwards) can easily travel faster than the pellet. So, the extra distance it might have to travel to "time" the pellet motion might need to be much further than twice the distance the pellet travels.

Now, I hear what you say about the frontal flow destabilizing the pellet, but providing that flow is symmetrical, I see air flowing from the front of the pellet as what normally keeps it stable, on the way to the target. So, in my opinion, providing that air flow is symmetrical, a short duration frontal flow at greater than pellet velocity won't do much more than slow the pellet down a little. Air flowing from behind over a waisted pellet, by contrast tries to flip the pellet over, so it would travel head first into the dominant air stream. The fact that the pellet is spin stabilized prevents that.

Consider the original FX smooth twist barrels achieving an effective spin rate of perhaps 1:48. Pellets fired from such barrels did not depend on spin for stability. On the contrary, the spin was just enough to null out anomalies in the pellet. A side benefit was that they were not prone to long range spiraling that is seen with 1:16 twist rates and pellets starting out at 950+ FPS. With such slow spin rates, it is air traveling from behind the pellet that would destabilize it, hence FX used air strippers to reduce muzzle blast acting on the pellet on all their PCPs with the original smooth twist barrels. Such air strippers are still a good idea.

Now, we are talking about conventional rifling and twist rates, in the case of the OP's PCP. So, that should help keep the pellet stable while it is encountering less than perfect airflow.

Back to my design's TV vent area; I have not tallied up the combined flow area, but just looking at it, it falls short of the ideal 12 to 1 ratio you mentioned. It looks 2:1 at best. I assume that more vent area improves sound suppression, at the cost of accuracy? If so, my TV design probably does not have enough reverse flow to cause much of a concern about accuracy. It also means that sound suppression is not as good as it might be with more aggressive reverse flow. But, the design I offer has four tesla valve stages, rather than one or two.

Each baffle stage, TV or conventional, should strip air from behind the pellet. So, concerns about turbulence destabilizing the pellet is more relevant near the barrel muzzle, and less of a concern towards the moderator muzzle. And my very first baffle in the design under discussion is

not a Tesla Valve.

I get that too slow a pellet may run into the reverse flow of a Tesla Valve. I would argue that unless the pellet velocity was low because a heavy for caliber pellet had been used, such concerns would be overblown: Shooting a conventional pellet at low velocity implies that the pressure and volume of air applied to that pellet was low - possibly due to tuning for low power. As such, the airflow would be weaker and would not outpace the pellet; or if it did would not have much effect on it.

Connected to the above is perhaps something we can agree on: Tesla valves work better, the harder you drive them. As in, higher power for caliber. A detuned PCP shooting through a STO gas diode, or a custom Tesla Valve moderator is likely to seem less impressive with regard to sound suppression, compared to other moderators. But then again, low power PCPs are not that loud to begin with. This is why STO make "high flow" and medium flow" Tesla Valve moderators - to reasonably match them to the power you are shooting at.

What matters ultimately is if this integral insert shroud extension provides the sound suppression Mr.H expects, without increasing group size. If it is a miserable failure with respect to grouping, the first thing I will try, is adding a barrel band type stabilizer. The second is to remove all the tesla valve air foils from my design, and have a conventional baffle version printed, for comparison. If both the TV and non-TV versions group equally poorly, it is probably not my failure to design a good TV that is the cause of the lack of performance.

So, I might have done a poor job, but probably not because of neglecting to consider the factors you mentioned

That said, it is possible that I should have made the TVs longer and used fewer of them.

View attachment 427750