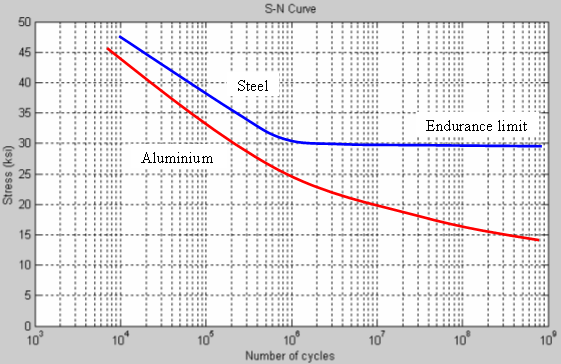

I’m reminded that the CF tanks most of us use are aluminum and are wrapped in CFProperly designed steel tanks don't fatigue and can have a infinite lifespan properly cared for. I would trust them more than CF, but they are too heavy. Aluminum almost never has a infinite lifespan and will in enough cycles eventually fail. The key is to design aluminum tanks strong enough that for all practical use, the number of cycles at a given stress level never gets close the the fatigue limit. What does the curves look like for CF? I don't know, but the deep diving sub makers all use steel not CF, except for the one company in the news for a terrible fatal accident. That sub and a number of problems not only with the CF shell but using windows not rated for the pressure they were subject too. What idiot would get into the sub?

Fatigue limit - Wikipedia

en.wikipedia.org

View attachment 462385

Upvote 0