I got my first pcp recently (NP500) and didn,t fire a single shot, i already fully dissambled it. What i noticed is that you can open the transfer port, BUT my question is does it help much?

I think you also need to dril a bigger hole in the Reciever to get maximal result. i am not sure that this is possible without damaging the thread in the hole where you screw in the bolts for securing the barrel. Or you have to make that bigger too, with a bigger bolt and new thread. Another option is to make the channel in the reciever bigger and place a helicol to use the same bolt for the barrel.

@Troy Hammer (what,s your experience or thoughts about these things)

Another thing i noticed that all the O-rings had some damage when placed in a situation where an intersection is with drilled holes.

((for example the two holes for the barrel mounting bolts), (valve block O rings under fillingprobe hole and manometer hole, up airport to the barrel))

Most likely because these holes are not or not enough deburred in the factory.

When you open up airport in the barrel by drilling you will create a little bur on the inside where you absolute don,t want burs (damaging the pellets?slugs).

So at the moment doing some investigation for a good way (tools) to do the deburring perfect ,to prevent damaging the new O rings by the first use.

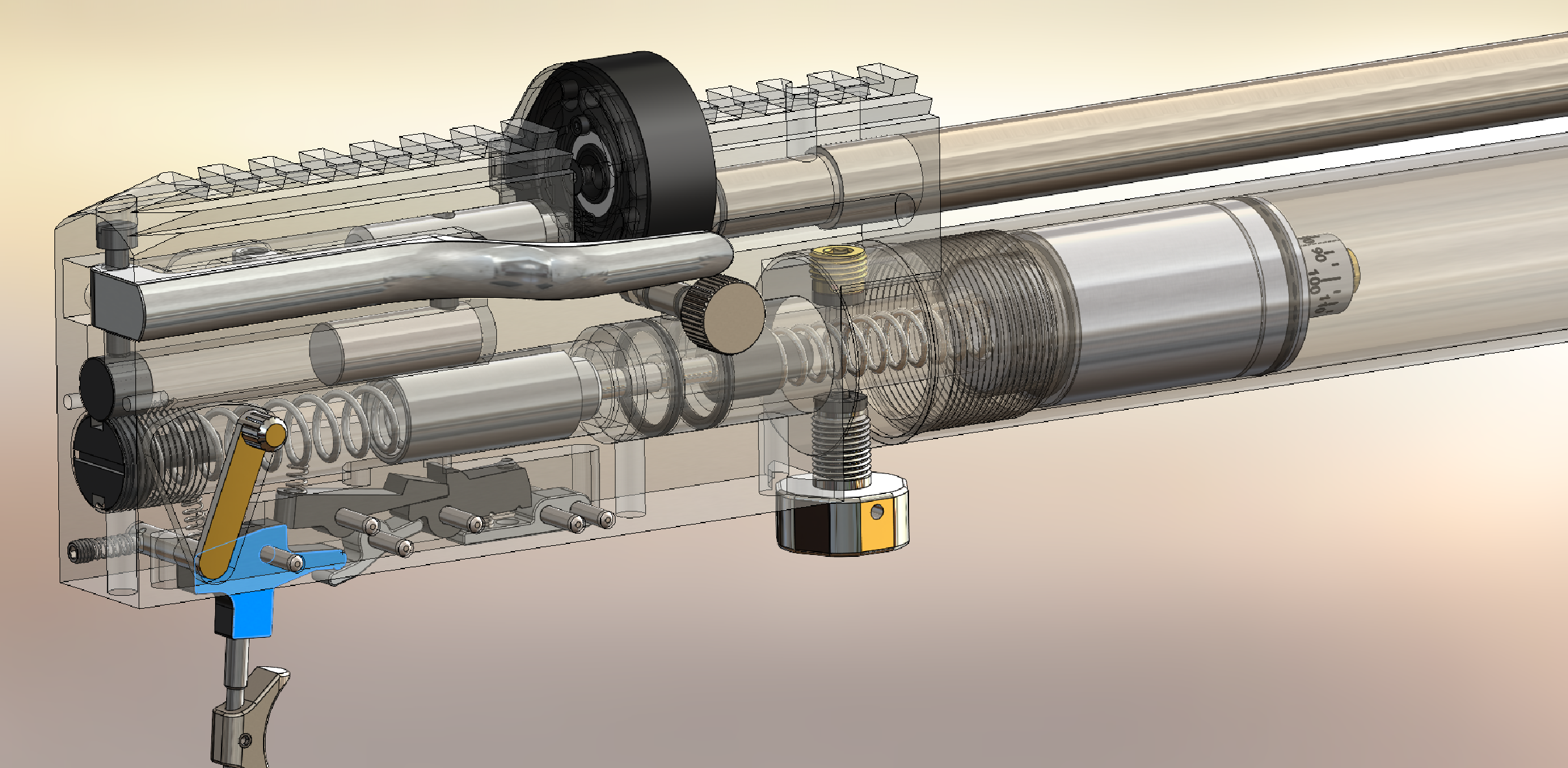

Out of the box i noticed the cocking system felt a kind off grindy, i thought this can be better (saw the raw surface from the outside on the thick part from the needle.

Cleanded, polished and lubed al the parts cocking and hammer system, result i have to be carefull not to hurt fingers because the cocking lever jumps back when i open it

.

Also cleaned,polished and lubed all the contact points from the trigger systym, result very smooth trigger system, also because i removed some big burs from the hammer (location contact point hammer and trigger plate).

Have seen that there is a lot play in the cocking mechanism and the pins (poor quality material) so i think i put some time in this to make some custom pins and other parts (hammer ) on a lathe

During my investigation about the valve tuning i found something thats probably interesting for a lot Kral owners

.

But this is the first investigation, i have to do more.

This is what i found:

https://www.gallagherseals.com/blog/tag/poppet-seal I think this wil make tuning the valve easier and i think quality is better than the original ones from plastic ( with burs).

also opened the valve port.

by disassembling i noticed that the valve was hard to move in the valve block, bij cleaning and lubricating it a bit it moved much easier and smoother.

Thanks to Troy, sharing his knowledge on youtube video where he shows how to disassemble a Kral puncher breaker

.

I saw that it isn,t that complicated as you think and this gave me the trust to disassemble my brand new first PCP airgun

A big question for me is about the slingshot spring system, whith length widht and strenght are the springs?.

Thinking about the hammerspring i have the thought to make it a two stage spring .( a low power smaller diameter in front from the hammer , for half in a small pockethole covered with a springseat on the backside and after that the main hammerspring)

It,s interesting how everything works and i like it to improve things and doing the investigation to accomplish that.

I hope that this will help for others to improve the performance