You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kral Jumbo project. Some observations.

- Thread starter Vetmx

- Start date

After dropping weight on the hammer, I had to turn the SSG in a half turn to get my velocity back to what it was. There was a POI change so that told me the wasted air from the hammer being too heavy was messing with my accuracy. It shot good before, it shoots better now with less vibes and crisper sound.

Upvote 0

@Vetmx, your SSG is inspirational. I just got myself a Jumbo in 6.35 and am going to open up the ports to 5mm once it arrives from Covid-torn Spain. Your nifty SSG concept may yet come in handy ...

I know I will also need to replace the power adjuster wheel/pin to get to that size of port diameter -- inspired for that one by TheBanker4, whose vids I found to be both highly informational and slick. An ordinary guy apparently, but perhaps not? A great forum indeed ...

Interesting to see that, even with the SSG, you still slimmed down your bolt. Was that really necessary / aren't you worried it may become too light ? You had to turn up your power adjuster -- doesn't that make for more stress on the cocking lever I wonder.

By the by, the stock Jumbo bolt and hammer spring combo looks like the same one as my Puncher Pro 6.35 that I regulated with an Audrius (59 EUR). Stock hammer spring OD = 8mm and ID = 6 by the looks of it -- is that accurate ? Once regged (ports open to 4.5mm), the Puncher Pro started having hammer bounce as predicted by Troy Hammer from Annihilator. The shot count went way down. I then found that the bolt was way too heavy (much heavier than the one in the Kral Puncher Breaker). I first tried a heavier hammer spring but that did not help and the cocking became very difficult. I then bit the bullet, drilled open the inside of the bolt and cut it down on both sides -- it became 30% lighter. I also added to the valve spring preload and increased the reg set point to 150 bar. The shot count doubled. The regulated consistency is a nearly 100% 255m/s with the JSB Kings 1.645 gram. It's a wonderful world ...

Any further suggestions ? Please keep posting on your Jumbo adventure, looks like there are more interesting developments in store ...

I know I will also need to replace the power adjuster wheel/pin to get to that size of port diameter -- inspired for that one by TheBanker4, whose vids I found to be both highly informational and slick. An ordinary guy apparently, but perhaps not? A great forum indeed ...

Interesting to see that, even with the SSG, you still slimmed down your bolt. Was that really necessary / aren't you worried it may become too light ? You had to turn up your power adjuster -- doesn't that make for more stress on the cocking lever I wonder.

By the by, the stock Jumbo bolt and hammer spring combo looks like the same one as my Puncher Pro 6.35 that I regulated with an Audrius (59 EUR). Stock hammer spring OD = 8mm and ID = 6 by the looks of it -- is that accurate ? Once regged (ports open to 4.5mm), the Puncher Pro started having hammer bounce as predicted by Troy Hammer from Annihilator. The shot count went way down. I then found that the bolt was way too heavy (much heavier than the one in the Kral Puncher Breaker). I first tried a heavier hammer spring but that did not help and the cocking became very difficult. I then bit the bullet, drilled open the inside of the bolt and cut it down on both sides -- it became 30% lighter. I also added to the valve spring preload and increased the reg set point to 150 bar. The shot count doubled. The regulated consistency is a nearly 100% 255m/s with the JSB Kings 1.645 gram. It's a wonderful world ...

Any further suggestions ? Please keep posting on your Jumbo adventure, looks like there are more interesting developments in store ...

Upvote 0

The short barrel I made definitely required a shorter dwell time. One option was to increase the valve return spring tension on valve components that I don’t trust their quality. But I could actually feel that the hammer was just too heavy during the shot cycle. Maybe it’s just something we develop from owning high end rifles. My gun cocks super easy and smooth. The spring I used is the stock one out of my P15. It was a little larger in diameter than the stock spring so I did make the hole in the hammer just a little bigger. You really want to pay attention to your barrel port if you plan on going 5mm. Like I said before, chamber a pellet then remove the barrel. See if you have room to open it up and not expose the pellets skirt. On my .22, 5mm would expose the pellets skirt a little on the 14.3 and too much on the 18.1gr.

Upvote 0

Thank you Vetmx! I hear you on the barrel port and will watch it like a hawk.

I once messed one up, thankfully only on an Artemis PR900w (aka Diana Stormrider). (Then got a new barrel for 60 bucks and now shooting fine thanks to Robert Lane's gorgeous reg.) Not again though, especially because I am not so sure where I could procure a Kral Jumbo spare pipe in .25 ... !!

My Kral .25 Pro shoots pretty accurate now at 60m, courtesy of the JSB heavy Mk--II (230m/s), the Audrius inline reg, and my lighter/shorter hammer. I also put a bubble level on the scope -- with the highly sculpted stock on the Pro that makes a real difference in accuracy. But it still has a fair bit of action noise emanating from the open breech block ...

Can't wait to tackle the Jumbo. I am secretly hoping that it comes with the same match grade trigger as my cheapy Kral Puncher (350 Eur, 6.35cal). That gun has the same 53cm barrel and the same lighter/big bore hammer as the Puncher Breaker bullpup. But it has the long stock and the smaller 230cc cylinder gives it nice balance. What an amazing tack driver at 60m with JSB King 1.645 gram even in windy conditions ...

I once messed one up, thankfully only on an Artemis PR900w (aka Diana Stormrider). (Then got a new barrel for 60 bucks and now shooting fine thanks to Robert Lane's gorgeous reg.) Not again though, especially because I am not so sure where I could procure a Kral Jumbo spare pipe in .25 ... !!

My Kral .25 Pro shoots pretty accurate now at 60m, courtesy of the JSB heavy Mk--II (230m/s), the Audrius inline reg, and my lighter/shorter hammer. I also put a bubble level on the scope -- with the highly sculpted stock on the Pro that makes a real difference in accuracy. But it still has a fair bit of action noise emanating from the open breech block ...

Can't wait to tackle the Jumbo. I am secretly hoping that it comes with the same match grade trigger as my cheapy Kral Puncher (350 Eur, 6.35cal). That gun has the same 53cm barrel and the same lighter/big bore hammer as the Puncher Breaker bullpup. But it has the long stock and the smaller 230cc cylinder gives it nice balance. What an amazing tack driver at 60m with JSB King 1.645 gram even in windy conditions ...

Upvote 0

Couldn’t leave well enough alone. After shooting for a while with the lighter hammer I still felt the gun was a little hammer heavy. Managed to shave it down to just under 45grams. So I went from 63.5 down to 45 grams. I believe this is it. The difference is worth the effort. The gun no longer feels like a Kral. If you regulate your Kral, you must lighten the hammer.

Upvote 0

Couldn’t leave well enough alone. After shooting for a while with the lighter hammer I still felt the gun was a little hammer heavy. Managed to shave it down to just under 45grams. So I went from 63.5 down to 45 grams. I believe this is it. The difference is worth the effort. The gun no longer feels like a Kral. If you regulate your Kral, you must lighten the hammer.

If you shorten the hammer ⅜" then bore the center to ½" at the same depth you can get about that same weight and not be so tough on tools trying to cut through the case hardened outer steel. I use 2" length springs .48" O.D. .059" wire from Grainger. That keeps the hammer in free flight without the need to build an SSG. The hammer spring adjuster will also still be in full function. I use different spring combos for different calibers and tunes but that spring seems to work best for 25-30fpe in 22cal.

Attachments

Upvote 0

I already faced 1/4' off the back of the hammer and enlarged the hole to accept the next size larger spring. Are you using that combo in regulated Krals? Or are you just trying to get back to a flatter curve on a unregulated gun with big porting?

Upvote 0

I already faced 1/4' off the back of the hammer and enlarged the hole to accept the next size larger spring. Are you using that combo in regulated Krals? Or are you just trying to get back to a flatter curve on a unregulated gun with big porting?

It works on both. It's a free flight hammer. Works almost the exact same as an SSG but with better adjustability. I'm pretty sure I made the first SSG ever to go in to a Kral gun but prefer the adjustability of the free flight hammer.

Upvote 0

Well I must have got lucky with the SSG's I built because I have plenty of adjustability. I went from a 63 gram hammer to 50 then to 45 and was able to maintain my 904fps tune by just turning in the adjuster like the stock one and I still have a bunch of free flight. I can also adjust it in more and achieve the max velocity for my reg setting and still have free flight. At least there are two options with these guns.

Upvote 0

Well I must have got lucky with the SSG's I built because I have plenty of adjustability. I went from a 63 gram hammer to 50 then to 45 and was able to maintain my 904fps tune by just turning in the adjuster like the stock one and I still have a bunch of free flight. I can also adjust it in more and achieve the max velocity for my reg setting and still have free flight. At least there are two options with these guns.

I think you made an excellent SSG and it seems to work perfect. It's a fantastic job. Not taking anything away from your work. Just if someone wants similar results duplicating yours would be more difficult. Just cutting through the case hardened hammer is a job in itself.

Upvote 0

Troy is a busy man and people give him too much poop in my opinion. Alot of folks send thier guns to him and cry because he doesn't email back or keep them in the loop. My advice is if you send him your gun expect him to have it a couple of months. He's a one man factory with alot of demand. By the way the wait is worth it and his prices are fair. I shot one of his tuned guns at my local range and it's a completely different animal than a stock one. He does take a long time and he is hard to get ahold of however he's honest and does good work.

Upvote 0

I think you made an excellent SSG and it seems to work perfect. It's a fantastic job. Not taking anything away from your work. Just if someone wants similar results duplicating yours would be more difficult. Just cutting through the case hardened hammer is a job in itself.

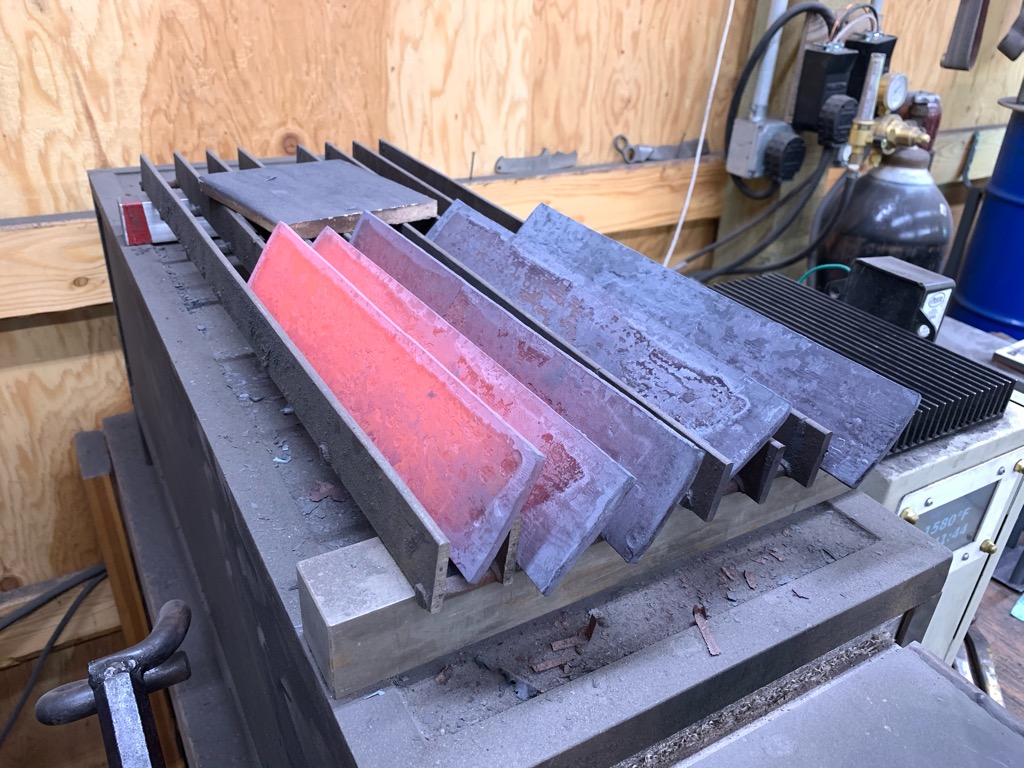

Heat the hammer till red then let it air cool ; repeat 3 times . Will soften the case hardening . When finished machining heat till red and quench in motor oil to harden .

Upvote 0

Some case hardening needs a water quench to harden. I would then run it through a few tempering cycles of at least 400° for 2hrs. Also you dont have to heat to red hot. You would be better off doing a sub critical anneal. To do this you heat it to 1200° and let it air cool. This will prevent as much scale build up. Steel starts to black body radiate in the visible spectrum around 900°. So dim the lights and slowly heat it till you just barely see it emitting color. Then let it cool. If you have any issues you could send it to me and I can do it in my heat treating ovens.

Upvote 0

@Vetmx: wow-- looks like you reached Kral Nirvana ... I just wonder what the SSG would do in 6.35 cal ... Would it retain high power without creating too much strain on the cocking action?

@THammer: Troy any views on the higher caliber? What springs would you use there? I just installed the double spring on my 6.35 Artemis P12, a notorious hammer bouncer. And yes, I am now getting 50 shots, 52 Joule. But the cocking has become somewhat harder on the bolt action ... darn there is no free lunch apparently!

(Note: I also had a good result after lightening the hammer in my 6.35 Puncher Pro. In combination with increased reg set point (150 bar) and more valve spring preload, hammer bounce was reduced and shot count doubled. Cocking action remained smooth as well!)

@THammer: Troy any views on the higher caliber? What springs would you use there? I just installed the double spring on my 6.35 Artemis P12, a notorious hammer bouncer. And yes, I am now getting 50 shots, 52 Joule. But the cocking has become somewhat harder on the bolt action ... darn there is no free lunch apparently!

(Note: I also had a good result after lightening the hammer in my 6.35 Puncher Pro. In combination with increased reg set point (150 bar) and more valve spring preload, hammer bounce was reduced and shot count doubled. Cocking action remained smooth as well!)

Upvote 0

I built a hammer from scratch for my P15. I wanted one that I could use the more popular .36 spring size. I had to harden it then temper it. It was a learning experience and it’s been in the gun for years. I drilled my Kral hammer out on my lathe. Didn’t have a boring bar small enough. Hated every minute of it. Almost heated it up to reverse the hardening process but was able to get it done without adding more work.

Parrotculler, caliber doesn’t matter to a hammer spring. It’s all about your reg pressure. If your reg is set at 150b on your .25 and mine is set at 150b on my .22, we both need enough spring to crack the valve with 150b behind it. The difference is your barrel length and it’s volume in .25. Your hammer weight will control your dwell which is different than mine. But that’s a whole different topic. That’s why I took baby steps with this gun. Remember, my barrel is only 15.5” long. Had to go slow and listen to what the gun was telling me over the course of a boatload of shots. Your gun will be different.

Parrotculler, caliber doesn’t matter to a hammer spring. It’s all about your reg pressure. If your reg is set at 150b on your .25 and mine is set at 150b on my .22, we both need enough spring to crack the valve with 150b behind it. The difference is your barrel length and it’s volume in .25. Your hammer weight will control your dwell which is different than mine. But that’s a whole different topic. That’s why I took baby steps with this gun. Remember, my barrel is only 15.5” long. Had to go slow and listen to what the gun was telling me over the course of a boatload of shots. Your gun will be different.

Upvote 0

I built a hammer from scratch for my P15. I wanted one that I could use the more popular .36 spring size. I had to harden it then temper it. It was a learning experience and it’s been in the gun for years. I drilled my Kral hammer out on my lathe. Didn’t have a boring bar small enough. Hated every minute of it. Almost heated it up to reverse the hardening process but was able to get it done without adding more work.

Parrotculler, caliber doesn’t matter to a hammer spring. It’s all about your reg pressure. If your reg is set at 150b on your .25 and mine is set at 150b on my .22, we both need enough spring to crack the valve with 150b behind it. The difference is your barrel length and it’s volume in .25. Your hammer weight will control your dwell which is different than mine. But that’s a whole different topic. That’s why I took baby steps with this gun. Remember, my barrel is only 15.5” long. Had to go slow and listen to what the gun was telling me over the course of a boatload of shots. Your gun will be different.

I appreciate the point made -- yet more air is clearly needed to push a 30+ grain pellet at 250m/s (820fps) out of my .25 pipe than to do the same for a 15 grain pellet out of a .22 ... just stating the obvious maybe ... So I am wondering about some hammer spring specs.

My goals are: power (50FPE/70J), long-range accuracy, shot count, and smooth cocking cycle. I also abhor hammer bounce, such as the uncivilized sounds emanating from my Cometa Orion. At the same time, I do not want a high regulator set point -- 150 bar is my limit. I therefore need to work with plenum size ( I assume I will have 25 cc), valve, ports, valve and hammer springs, and bolt ...

I am already ready to lighten the hammer by 25% and open up the ports to 5mm (pellet skirts allowing), will need to craft a larger-diameter power adjuster pin.

My remaining questions are about spring sizes (OD, ID, length). Hopefully someone can help, at least directionally, based on their own experience:

- the twin hammer spring option: what spring sizes are needed to achieve the above FPE/Joule ? Is cocking likely to remain acceptably light ?

- the SSG option (the version sliding out of the hammer adjustment screw): spring size needed to achieve the above FPE/Joule ? I also wonder if cocking will remain easy.

If the answers are not promising, for the .25 with the desired power, I may need to remain with the factory spring. Perhaps with more valve spring preload to mitigate hammer bounce, but still compromise somewhat on hammer bounce and shot count.

Thanks in advance for views !

Upvote 0

I would never use my valve spring to control hammer bounce. I increase valve spring tension only if I have an issue with my ES. You probably got away with it on your other gun because your hammer was still too heavy. You were fighting hammer bounce from the wrong side of the gun. You put more pressure on the valve with a high reg setting and more valve spring. But then you have to put more effort into cracking the valve with a heavy hammer spring and heavy hammer. Your guns harmonics will feel much better if you don’t have everything fighting each other. Quite a few guns ago I learned to quit being dead set on a power goal. I first take what a gun will give me once properly tuned and go from there. If you go with thammers setup, the spring he listed above is a good place to start. If you go with my SSG, find a Artemis P15 spring or possibly one out of a Gauntlet. Get your porting as close to 5mm as you can and set your reg at 140b. By not setting it at 150 right away, at least you will know you still have some gas left in the tank if you need it. I don’t have any super heavy .22 pellets, that’s what I have a .25 for, but if I did I would shoot some out of my longer barrel to see just how fast my gun would push them. It would give you an idea what my porting and gun is capable of. I fixed the dreaded Orion hammer bounce on my buddies gun. I will let you know what spring to use if I can find my notes or the piece of spring I clipped.

Upvote 0

@Vetmx I sense we are getting to the holy grail of PCP airgunning here, amazing, only Bob Sterne's insights are still missing ...

Do you know if the P15 stock spring resembles the P12, which has a 12mm something OD? Allowing for heavy drilling in the Kral hammer, that would be a stroke of luck because I just replaced my P12 stock spring by a lighter one (same OD, less wire diameter) in a twin spring setup that increased my P12 shot count to 45 ....

I would be in your debt also for any further Cometa remedies. I really have a love-hate relationship with that instrument. Never before spent as much time getting a gun to work -- the only thing not requiring mod was R Lane's reg ... Shroud was a disaster, mag and pellet probe too, trigger was a wobbly joke, and I dunno what I'm gonna do when the valve block o-ring needs to be replaced with that arcane tool ...

Do you know if the P15 stock spring resembles the P12, which has a 12mm something OD? Allowing for heavy drilling in the Kral hammer, that would be a stroke of luck because I just replaced my P12 stock spring by a lighter one (same OD, less wire diameter) in a twin spring setup that increased my P12 shot count to 45 ....

I would be in your debt also for any further Cometa remedies. I really have a love-hate relationship with that instrument. Never before spent as much time getting a gun to work -- the only thing not requiring mod was R Lane's reg ... Shroud was a disaster, mag and pellet probe too, trigger was a wobbly joke, and I dunno what I'm gonna do when the valve block o-ring needs to be replaced with that arcane tool ...

Upvote 0

The stock P15 spring is like 8.5mm diameter. I chose it because I only had to drill out my hammer a little. The spring I put in my buddies Orion was a .36” diameter with .051 or .052” wire. I clipped it short enough to allow the hammer to free flight but can’t remember how short I went. It’s in his gun tuned perfectly so I can’t talk him into taking it apart to measure. I had to turn down the spring guide just a little so it would fit into the spring. I have a Cometa Orion bullpup mini. I went with an external SSG on it with just a slight mod to the stock.

Upvote 0