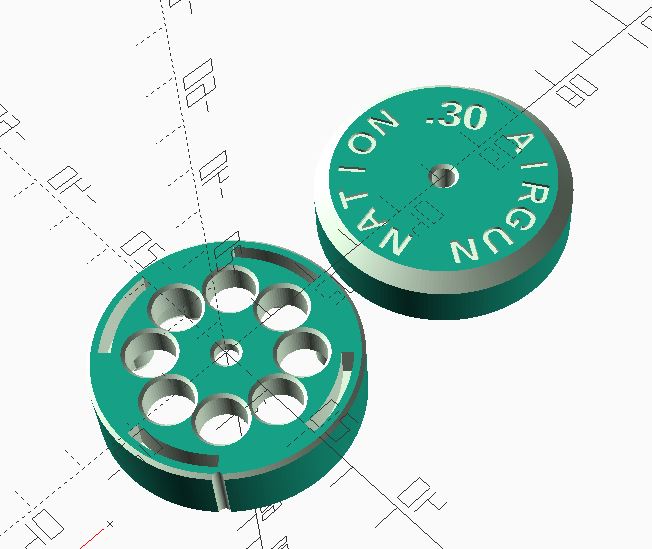

I made the original design in 3 parts for the ease of loading the pellets head first, this version will save material and printing time for the cost of having to load the pellet backward - maybe I will design and post a speedloader for the speedloader later

And the flat upper surface made it possible to imprint the Caliber and name of this very fine Forum (thank you Michael and Moderators!)

Original description recycled:

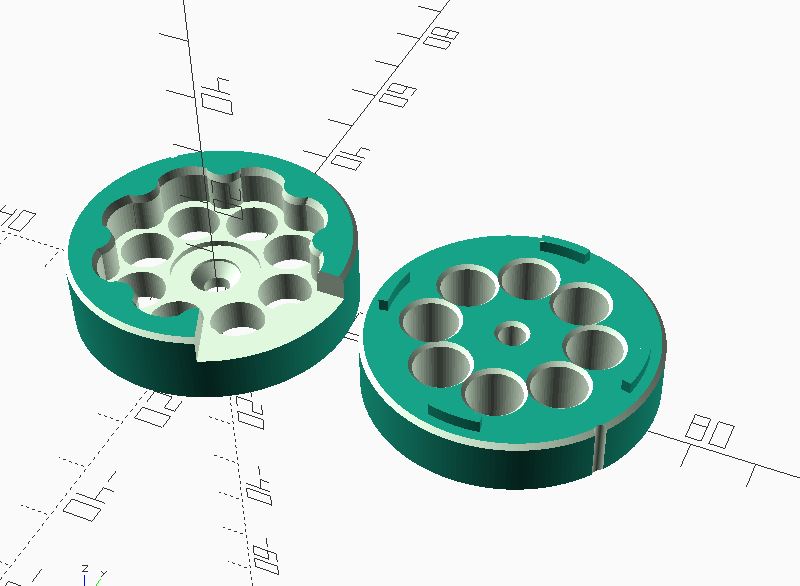

designed as simple as possible, you will only need the3 2 printed parts, one 4 mm x 30 4 mm x 22 screw with counter sunk head, a shim and a lock nut (or 4 mm nut + blue Locktite)

The discs is held i position by friction between the printed parts, the lock nut is used to adjust this friction, no balls and springs

Ad glue to the head of the screw, this will make it stick to the adapter part

Put the parts together, tighten the nut and let the glue settle, when dried, loosen the nut, adjust for friction

The speed loader is fixed by the L2 indexing arm, only one hand needed load, turn clockwise to drop the pellets in mag

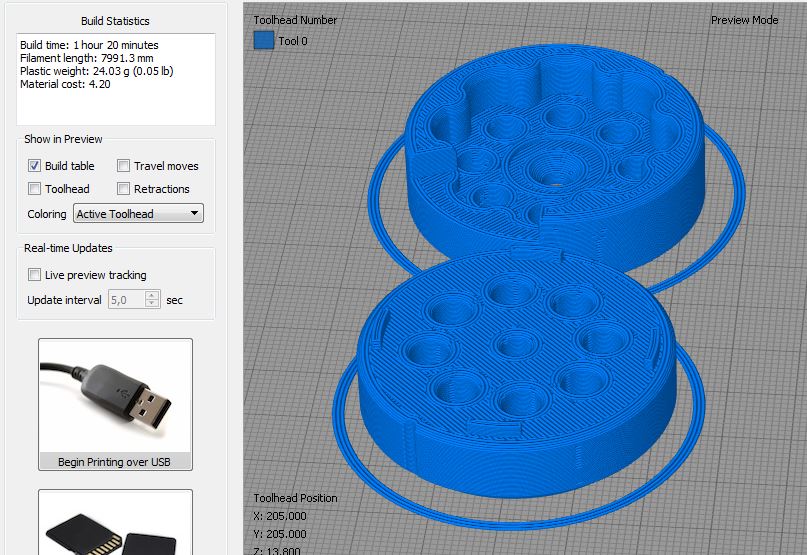

Changes to print settings:

The 4 indexing arm is higher than the base, ad extra cooling at the last part of the print, with my print at layer hight 0.24 that be at layer 53, so my fan settings is 60% from layer 2 and 100% at layer 53

Be kind, print and share with those poor souls that do not own a 3D printer

Edit: .20 cal version added

View attachment L2speedloader_2_disc_AN_Logo_20.1623696815.stl

View attachment L2speedloader_2_disc_AN_Logo_20.1623696815.stl

View attachment L2speedloader_2_disc_AN_Logo_177.1623504383.stl

View attachment L2speedloader_2_disc_AN_Logo_177.1623504383.stl

View attachment L2speedloader_2_disc_AN_Logo_22.1623504406.stl

View attachment L2speedloader_2_disc_AN_Logo_22.1623504406.stl

View attachment L2speedloader_2_disc_AN_Logo_25.1623504439.stl

View attachment L2speedloader_2_disc_AN_Logo_25.1623504439.stl

View attachment L2speedloader_2_disc_AN_Logo_30.1623504482.stl

View attachment L2speedloader_2_disc_AN_Logo_30.1623504482.stl

And the flat upper surface made it possible to imprint the Caliber and name of this very fine Forum (thank you Michael and Moderators!)

Original description recycled:

designed as simple as possible, you will only need the

The discs is held i position by friction between the printed parts, the lock nut is used to adjust this friction, no balls and springs

Ad glue to the head of the screw, this will make it stick to the adapter part

Put the parts together, tighten the nut and let the glue settle, when dried, loosen the nut, adjust for friction

The speed loader is fixed by the L2 indexing arm, only one hand needed load, turn clockwise to drop the pellets in mag

Changes to print settings:

The 4 indexing arm is higher than the base, ad extra cooling at the last part of the print, with my print at layer hight 0.24 that be at layer 53, so my fan settings is 60% from layer 2 and 100% at layer 53

Be kind, print and share with those poor souls that do not own a 3D printer

Edit: .20 cal version added

Upvote 0