You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Leshiy 2 explodes

- Thread starter bckyrdsnpr52

- Start date

Please don't...

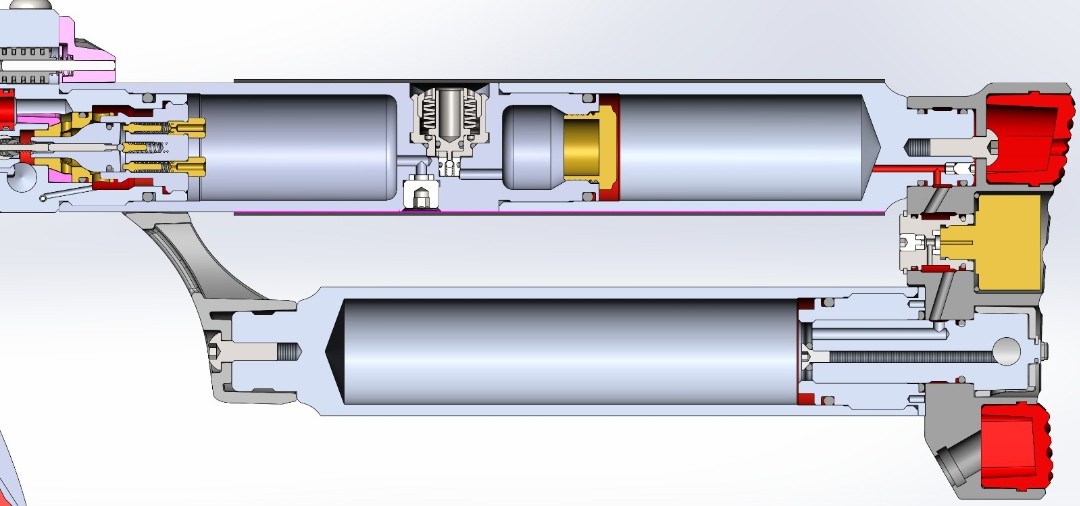

And now to the case, as I mentioned in the latest video, a simple design change would be sufficient to make the gun safer.

I changed the bottom corner to 5mm radius and the highest stress point moves to the threaded portion of the cylinder that is not under pressure and wouldn't be an issue on the actual cylinder.

As you can see to stress riser is gone from the bottom. I suspect a change has been implemented in the machining but can't say anything definitive as I don't have more samples.

So anyone willing to open theirs to take pictures from the cylinders if there is a sharp corner or not would be great.

Marko

Edit: one thing I forgot to mention, look at the material datasheets and see what temperature does to yield strength of the material.

Most aluminum alloys loose strength with heat.

And now to the case, as I mentioned in the latest video, a simple design change would be sufficient to make the gun safer.

I changed the bottom corner to 5mm radius and the highest stress point moves to the threaded portion of the cylinder that is not under pressure and wouldn't be an issue on the actual cylinder.

As you can see to stress riser is gone from the bottom. I suspect a change has been implemented in the machining but can't say anything definitive as I don't have more samples.

So anyone willing to open theirs to take pictures from the cylinders if there is a sharp corner or not would be great.

Marko

Edit: one thing I forgot to mention, look at the material datasheets and see what temperature does to yield strength of the material.

Most aluminum alloys loose strength with heat.

Last edited:

Upvote 0

Now you can send Ed your bill for the work you've done. The whole analysis with proposed solution should be rewarded.

If I may speculate I would say the explosion was initiated in the sharp corner of the air tube.

BTW, I found a drawing of L2 tube posted some time ago by Ed in this thread. It seems the end of the tube is different there - conical - whereas your tube has a flat bottom.

Could you elaborate if that would be better?

If I may speculate I would say the explosion was initiated in the sharp corner of the air tube.

BTW, I found a drawing of L2 tube posted some time ago by Ed in this thread. It seems the end of the tube is different there - conical - whereas your tube has a flat bottom.

Could you elaborate if that would be better?

Last edited:

Upvote 0

"Most aluminum alloys loose strength with heat."

You should correct that sentence to All metal alloys loose strenght with heat. Very basic thing of material design, you should know that.

A question about that cylinder MJP cut in half. If you use that kind of cylinder as intended, only filling to 300bar, when will it break? Safety factor on safety factor is a great thing, but what happens in the real world?

You should correct that sentence to All metal alloys loose strenght with heat. Very basic thing of material design, you should know that.

A question about that cylinder MJP cut in half. If you use that kind of cylinder as intended, only filling to 300bar, when will it break? Safety factor on safety factor is a great thing, but what happens in the real world?

Upvote 0

Read up on fatigue life of Steel versus aluminum. even at 300 bar cycle aluminum enough times it will fail. Whereas a design of Steel with smaller safety margin is considered safe because steel below a certain threshold is considered to have an infinite fatigue life. The reason for industry standard larger safety margins with aluminum is because you are trying to compensate for aluminums poor fatigue life. So in real world use the cycle limit will never be hit."Most aluminum alloys loose strength with heat."

You should correct that sentence to All metal alloys loose strenght with heat. Very basic thing of material design, you should know that.

A question about that cylinder MJP cut in half. If you use that kind of cylinder as intended, only filling to 300bar, when will it break? Safety factor on safety factor is a great thing, but what happens in the real world?

By the way that diagram that it can provided looks indicative of a simple operation with a drill bit. It does show larger dimensions than what was discovered in the tube that was measured and tested on this thread.

Last edited:

Upvote 0

I am not sure if that can be predicted numerically. I think there must be fatigue tests involved.If you use that kind of cylinder as intended, only filling to 300bar, when will it break?

Upvote 0

Anyway, what concerns me the most is the slow degradation of quality when it comes to EDgun. Just take a look at these two plugs. The first one comes from Matador R3M and the second one from Matador R5M.

In the first picture you can see a nice round corner. In the second picture you can see a sharp corner.

In the first picture you can see a nice round corner. In the second picture you can see a sharp corner.

Upvote 0

In deed it does, at worst you could be talking roughly a minute given how fast your machine is and how fast turret from tool to tool. But tens of seconds any case.

And then we get to the original design with 118deg drill bottom.

It looks better if the material is correct.

But if not then it's again anyone's guess.

Simulation on the dimensions I have, not necessarily concerning all products as there seems to be more than one variants.

Marko

And then we get to the original design with 118deg drill bottom.

It looks better if the material is correct.

But if not then it's again anyone's guess.

Simulation on the dimensions I have, not necessarily concerning all products as there seems to be more than one variants.

Marko

Upvote 0

Perhaps Ed can start fabrication tomorrow using Titanium and wham o, send the replacements out next week!

Case closed.

Case closed.

Upvote 0

Wow, it seems the maximum stress is reduced by close to 50% if the drill with a classical angle is used. Have we just found a potential root cause of the explosion?In deed it does, at worst you could be talking roughly a minute given how fast your machine is and how fast turret from tool to tool. But tens of seconds any case.

And then we get to the original design with 118deg drill bottom.

It looks better if the material is correct.

But if not then it's again anyone's guess.

Simulation on the dimensions I have, not necessarily concerning all products as there seems to be more than one variants.

Marko

Upvote 0

Wow, it seems the maximum stress is reduced by close to 50% if the drill with a classical angle is used. Have we just found a potential root cause of the explosion?

The maximum stress location changes into the threads with a 118 degree drill angle if I understand correctly, the threads are not under pressure and would evacuate air if the seal failed (I hope).

Upvote 0

If so then this is insane how a small change in the geometry can lead to disastrous consequences. It could be committed by an unaware worker. But anyway, it should've been detected during QA.The maximum stress location changes into the threads with a 118 degree drill angle if I understand correctly, the threads are not under pressure and would evacuate air if the seal failed (I hope).

Upvote 0

If so then this is insane how a small change in the geometry can lead to disastrous consequences. It could be committed by an unaware worker. But anyway, it should've been detected during QA.

Its true and one of the key points Marko has pointed out, its a big no no that *MAY* have results in the failure of the tube in question. Anyone with a keen eye can examine the original photo well enough and say it appears to have failed in that region of the tube.

Upvote 0

7075-t6 is what I use for my projects that see pressure.

6061 in non critical/pressure parts.

One aluminum that lies between these two (depending on temper) is 2024 alloy.

I will be curious to see what the tube you have there, Marko, truly is.

I will probably just make myself a new tube from 7075-t6 and roll with that. I always go a lot thicker than my calcs tell me and I can radius my corners how I see fit.

Dave

6061 in non critical/pressure parts.

One aluminum that lies between these two (depending on temper) is 2024 alloy.

I will be curious to see what the tube you have there, Marko, truly is.

I will probably just make myself a new tube from 7075-t6 and roll with that. I always go a lot thicker than my calcs tell me and I can radius my corners how I see fit.

Dave

Upvote 0

So anyone willing to open theirs to take pictures from the cylinders if there is a sharp corner or not would be great.

I've just examined 3 buttstock extensions AKA upper reservoir tubes from my Leshiys.

1 long extension, came from a complete gun from Edgun West from one of the first runs: conical bottom of the tube, some machining marks on the bottom, but smooth transition from walls. Hard to tell but there could be a small radius there.

1 shorter extension, came from Edgun Spain as a part of complete EAR rear assembly around 1 year ago: conical bottom, also a smooth transition.

1 shorter extension, came recently from Edgun West as a separate part: flat bottom, sharp corner. Also no anodizing on the bottom of the tube.

So yes, there are clearly at least 2 variations of the shorter buttstock extension out there.

poopty pictures from my phone, but you get the idea.

Upvote 0

Although I do not own a edgun. Im reading (skimming) through pages... Your comment definitely caught my attention... I've been a machinist for over 30 years and have made a lot of things over the years... Yes small changes do and will make a huge difference in a given part... These Minor changes definitely affect things.. I've seen machinist that have the ignorant mind setIf so then this is insane how a small change in the geometry can lead to disastrous consequences. It could be committed by an unaware worker. But anyway, it should've been detected during QA.

"It doesn't matter" as long as it gets done mindset... You very well could have found the root cause... It is very possible the machinist cut a few corners and now is a potential safety issue...

Last edited:

Upvote 0