You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Let’s see some custom moderators

- Thread starter Jimtx200

- Start date

I've found that cone baffles are pretty simple, and tend to create a ton of turbulence. Which equates to slower gas exit, and longer pressure release. The smaller the bore size, the better, so long as accuracy does not suffer. Both of these guns have air strippers that vent backwards into the shroud which also has a vent in the rear. The Rifle moderator just has two cone baffles, the first one has pinhole vents in the tube at it's base. 28fpe, short barrel .22, very quiet in this config. The pistol is also .22, bore size is 6mm. Very effective.

Upvote 0

Here is my Custom Titanium Franken-Rapid.

Custom fabricated Carbon fiber shroud, with the endcap that has upward pointed vents..

The barrel has a Custom Air-Stripper, this help redirect the muzzle blast back down the length of the shroud..

Adding to the the Reflect(volumetric) moderating.

Also to keep the carbon fiber tube in place and the barrel concentric....

There are 2 Delrin supports secured by setscrews equally spaced down the barrel.

The final touch is the series of Custom K-Baffles the finish the job of keeping it Quiet as Possible!

I experiment with various combinations of length of K-baffles... I settle on 2 long and 3 short!

Custom fabricated Carbon fiber shroud, with the endcap that has upward pointed vents..

The barrel has a Custom Air-Stripper, this help redirect the muzzle blast back down the length of the shroud..

Adding to the the Reflect(volumetric) moderating.

Also to keep the carbon fiber tube in place and the barrel concentric....

There are 2 Delrin supports secured by setscrews equally spaced down the barrel.

The final touch is the series of Custom K-Baffles the finish the job of keeping it Quiet as Possible!

I experiment with various combinations of length of K-baffles... I settle on 2 long and 3 short!

Last edited:

Upvote 0

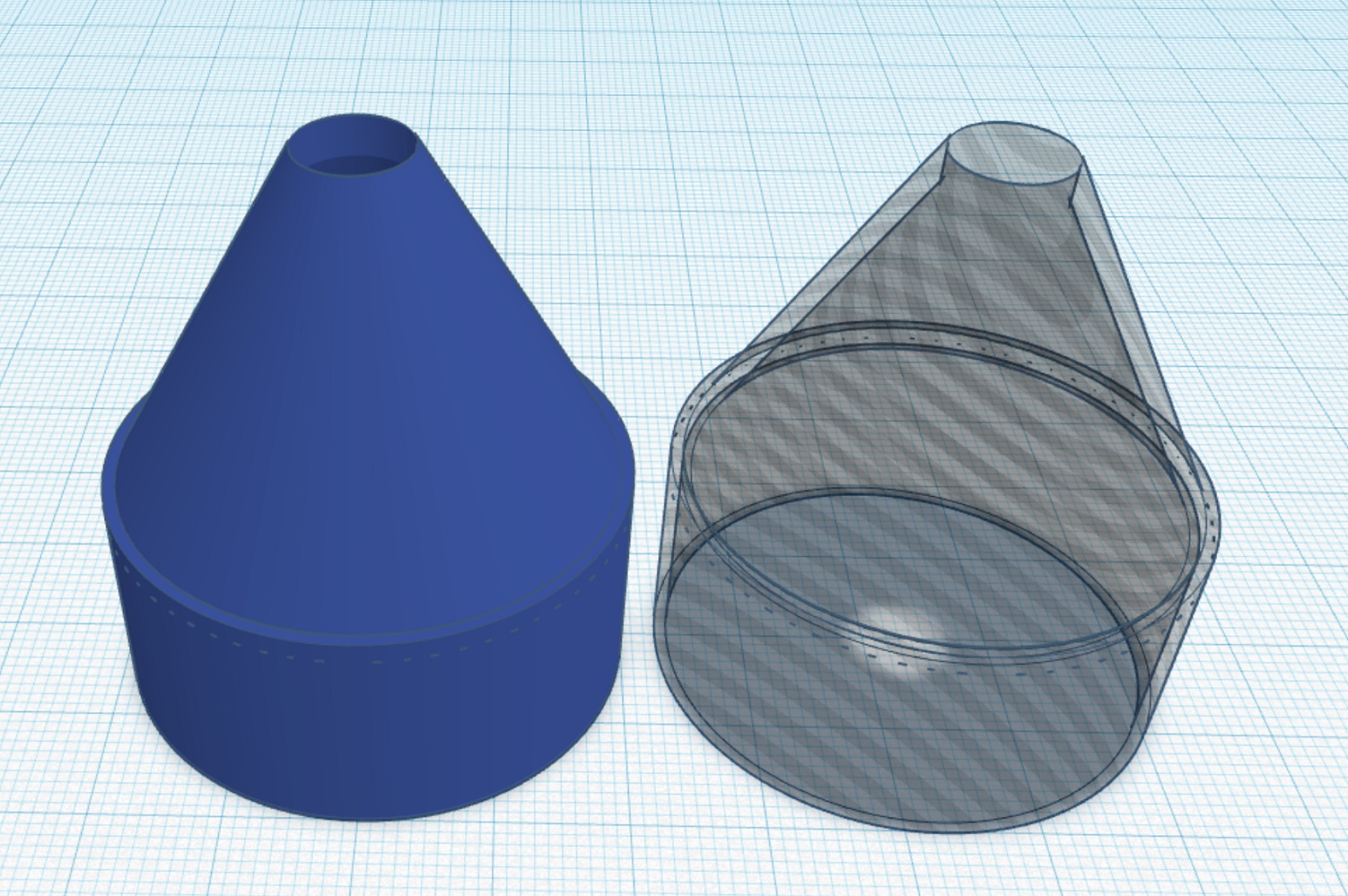

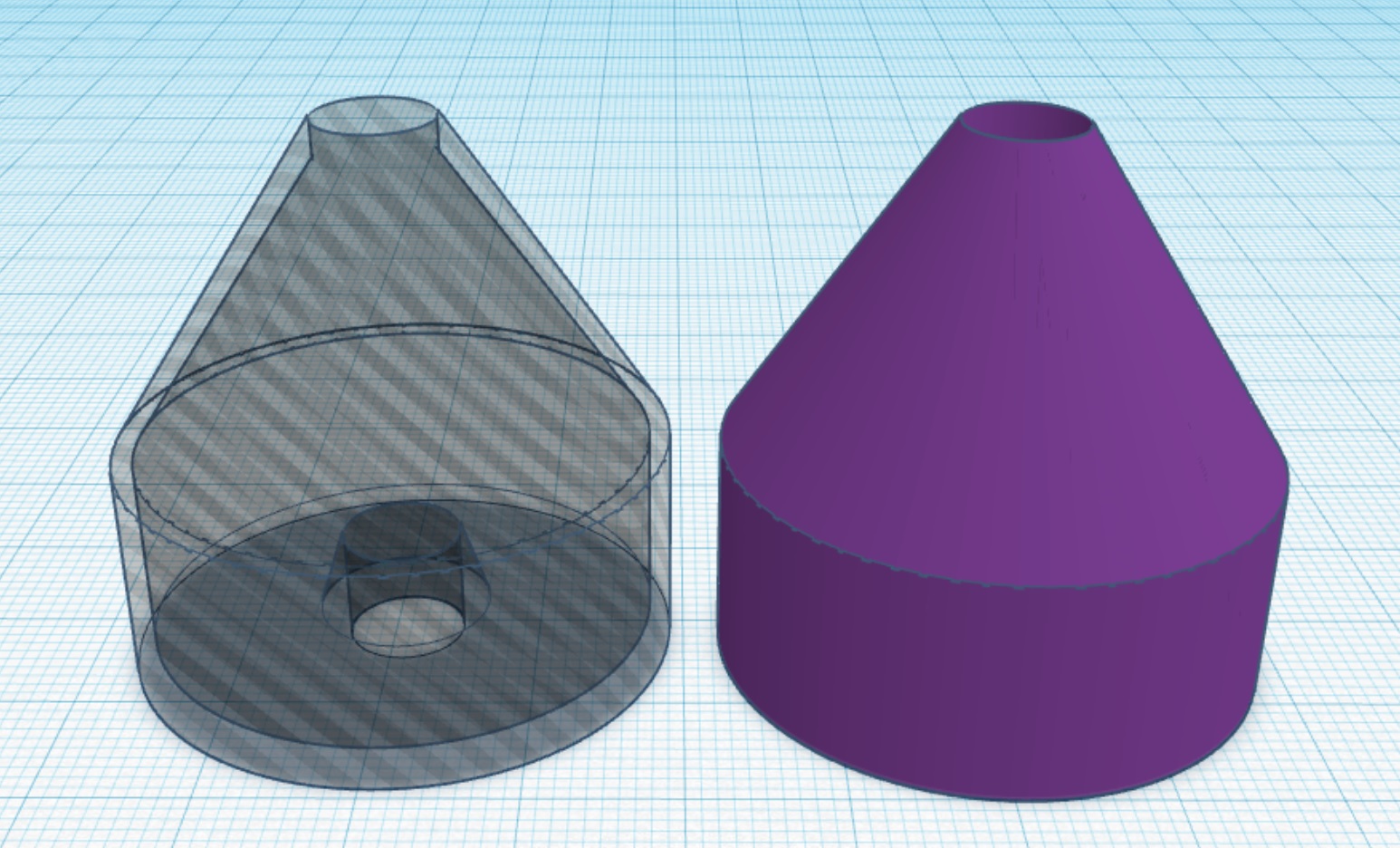

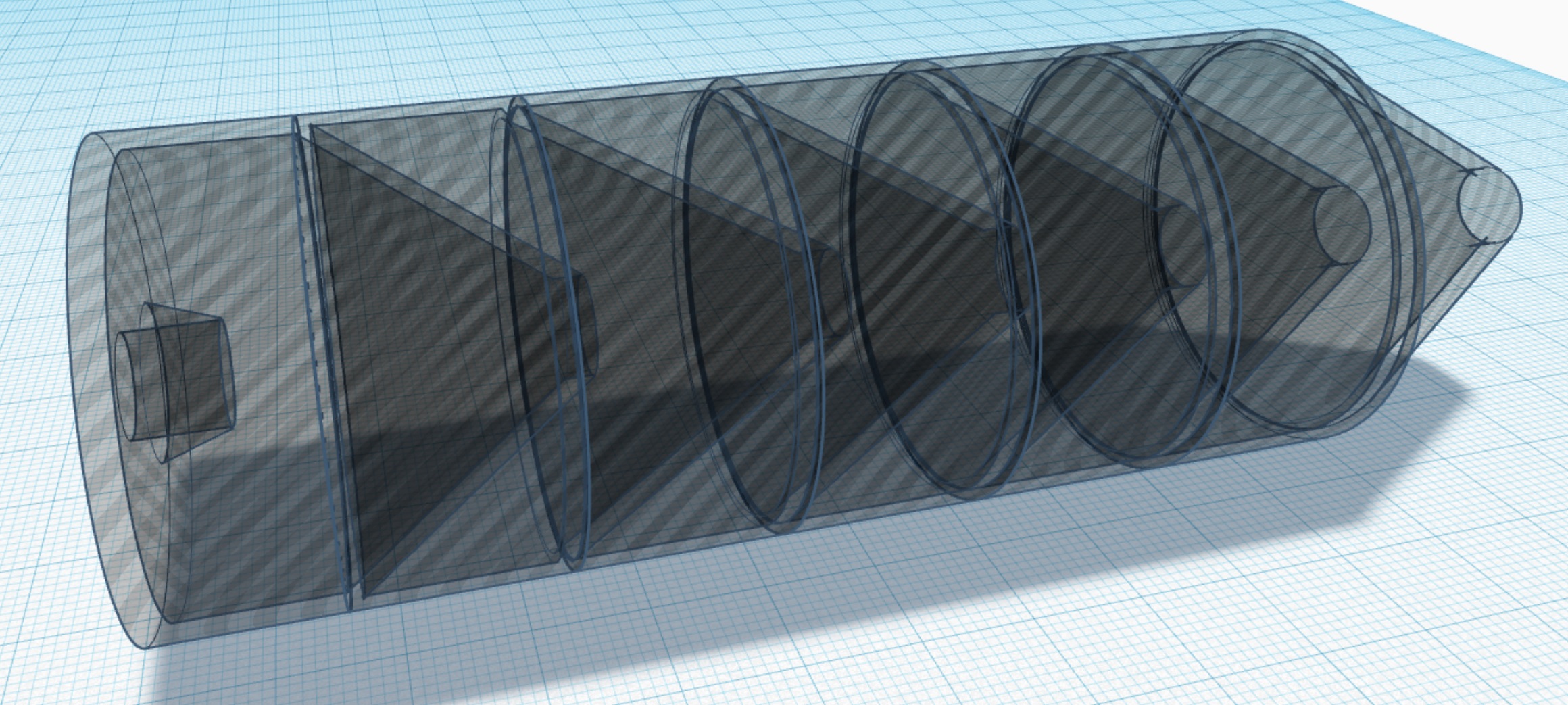

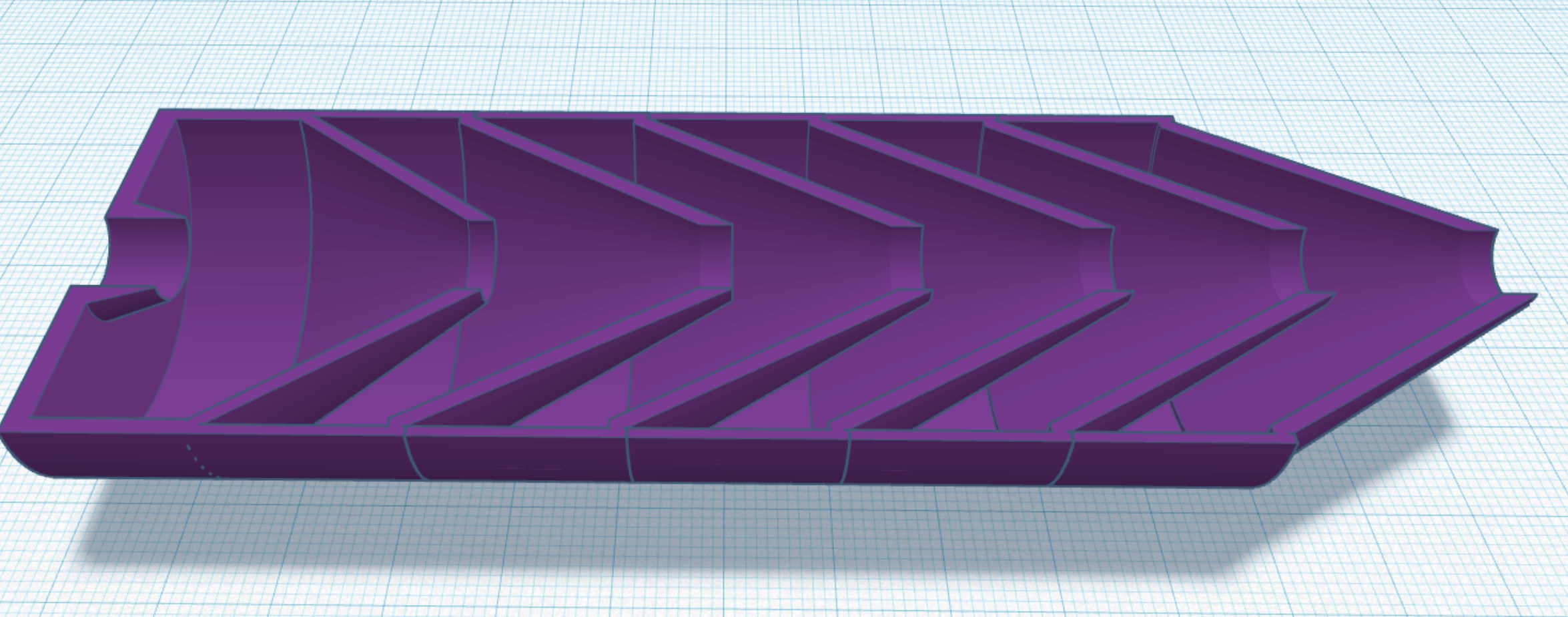

I just made this one for my son's .30 challenger. It's 194mm long 40mm id using six 3d printed baffles. Shooting a 100gn slug at 980fps the hammer striking the valve is most of the sound you'd hear. The moderator costs me about $20 in materials and a couple hours of my time.

Six air stripper baffles are used, 3d printed in PETG material for toughness. The baffles in the main body are designed with a ledge around the base of the cone for the next baffle to register on and match the housing id exactly for perfect alignment. The nose/exit baffle is designed with a floor and final air stripper. I do this so that the exit hole in the aluminum can be oversized so if anything ever clipped it would only break plastic instead of destroying the end cap. Clear and solid pics of each type are shown. The center hole is Edit: .6mm/.0236" over projectile size for .30 cal. I'll anodize the can soon.

You can click the pics twice for the largest version. Edit: Added see through stack and cutaway stack to see how they sit in the can.

Six air stripper baffles are used, 3d printed in PETG material for toughness. The baffles in the main body are designed with a ledge around the base of the cone for the next baffle to register on and match the housing id exactly for perfect alignment. The nose/exit baffle is designed with a floor and final air stripper. I do this so that the exit hole in the aluminum can be oversized so if anything ever clipped it would only break plastic instead of destroying the end cap. Clear and solid pics of each type are shown. The center hole is Edit: .6mm/.0236" over projectile size for .30 cal. I'll anodize the can soon.

You can click the pics twice for the largest version. Edit: Added see through stack and cutaway stack to see how they sit in the can.

Last edited:

Upvote 0

0.3mm (0.012") over bore? That's pretty tight! No issues with clipping?I just made this one for my son's .30 challenger. It's 194mm long 40mm id using six 3d printed baffles. Shooting a 100gn slug at 980fps the hammer striking the valve is most of the sound you'd hear. The moderator costs me about $20 in materials and a couple hours of my time.

Six air stripper baffles are used, 3d printed in PETG material for toughness. The baffles in the main body are designed with a ledge around the base of the cone for the next baffle to register on and match the housing id exactly for perfect alignment. The nose/exit baffle is designed with a floor and final air stripper. I do this so that the exit hole in the aluminum can be oversized so if anything ever clipped it would only break plastic instead of destroying the end cap. Clear and solid pics of each type are shown. The center hole is .3mm over projectile size for .30 cal. I'll anodize the can soon.

You can click the pics twice for the largest version. Edit: Added see through stack and cutaway stack to see how they sit in the can.

View attachment 416333View attachment 416335View attachment 416354View attachment 416355

View attachment 416329

Upvote 0

Nope. I made the first set of baffles 8.5mm for testing. They looked perfect so I tightened it up and all is well so far. Haven't shot targets yet I'm waiting for my son to be off work. My youngest son has a Bamboo Lab X-1 Carbon 3d printer that makes really nice clean prints in PETG so the baffles are printed on his machine. I also did a trigger job on the challenger that took it from very heavy to less than a pound. I'm hoping we can punch some paper Wednesday.0.3mm (0.012") over bore? That's pretty tight! No issues with clipping?

Upvote 0

This aluminum airstripper will be my next winter project. Anywhere available to buy online or was that your DIY?...The barrel has a Custom Air-Stripper, this help redirect the muzzle blast back down the length of the shroud..

Adding to the the Reflect(volumetric) moderating.

Upvote 0

DIY Project... Mill and Lathe......This aluminum airstripper will be my next winter project. Anywhere available to buy online or was that your DIY?

Upvote 0

This aluminum airstripper will be my next winter project. Anywhere available to buy online or was that your DIY?

Upvote 0

I didn't know you could have sound suppression in Canada.I have a bunch of external airstrippers, I wanna build one internal backwards directing.

Upvote 0

I said air stripper. Inside shroud, like my Impacts haveI didn't know you could have sound suppression in Canada.

Upvote 0

It's ignorance on my part. For some reason I thought the Canadian airguns didn't even have a functioning shroud because they suppress part of the sound.I said air stripper. Inside shroud, like my Impacts have

If you have access to a 3d printer you can make your part with ease.

Upvote 0

It's ignorance on my part. For some reason I thought the Canadian airguns didn't even have a functioning shroud because they suppress part of the sound.

No problem around that, I am shooting in gun club only, with earmuffs. I am a big fan of (external) airstrippers and I have a documented evidence that these help with accuracy, I am just exploring ideas how to make the setup shortest possible .

Upvote 0

I was shooting some lighter cast slugs this evening and one clipped my end baffle so I'm going back to 8.5mm, .8 over bore to be sure.0.3mm (0.012") over bore? That's pretty tight! No issues with clipping?

Plastic is cheap so no harm experimenting.

Upvote 0

The eaglevision air strippers I have the .22 cone is drilled to 5.9 mm and works flawless. You cannot imagine how much dust it collects.

I just checked an other day they started fabricating moderators as well.

I just checked an other day they started fabricating moderators as well.

Upvote 0

The sound wasn't much quieter going from 8.5mm to 8mm. My son will just be deer hunting with it so I doubt he'd get more than one shot anyway.The eaglevision air strippers I have the .22 cone is drilled to 5.9 mm and works flawless. You cannot imagine how much dust it collects.

I just checked an other day they started fabricating moderators as well.

Upvote 0

I had earlier a couple more but kept only what is worth considering. My high hope is the eaglevision for 80+ fpe but works well with 35fpe as well.

What I like with eaglevision that the inserts are caliber specific, not connecting two calibers like donyFL 117-22 or 22-25 or 25-30

What I like with eaglevision that the inserts are caliber specific, not connecting two calibers like donyFL 117-22 or 22-25 or 25-30

Last edited:

Upvote 0