I've had this idea floating around in my head for a while, but I have zero experience with ballistic fabrics. The primary goal is to make a silent backstop that will stop a pellet generating up to about 80 FPE.

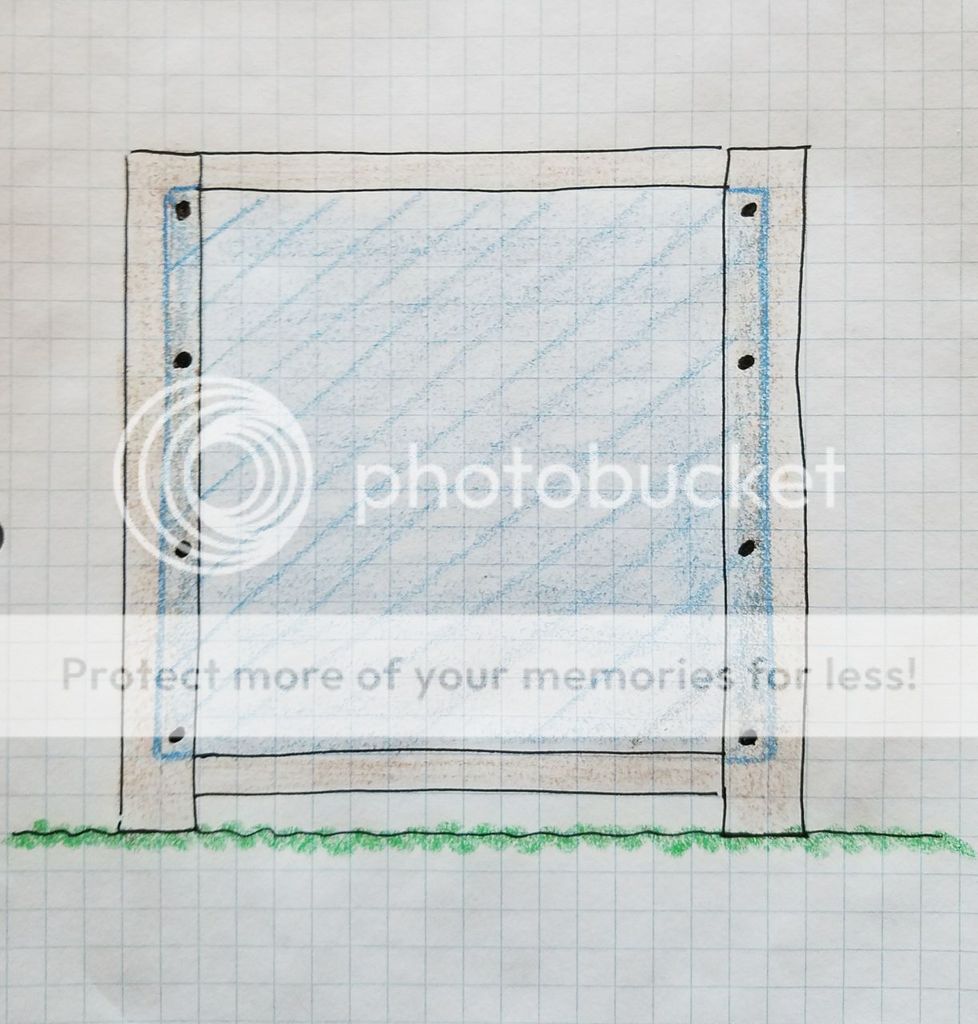

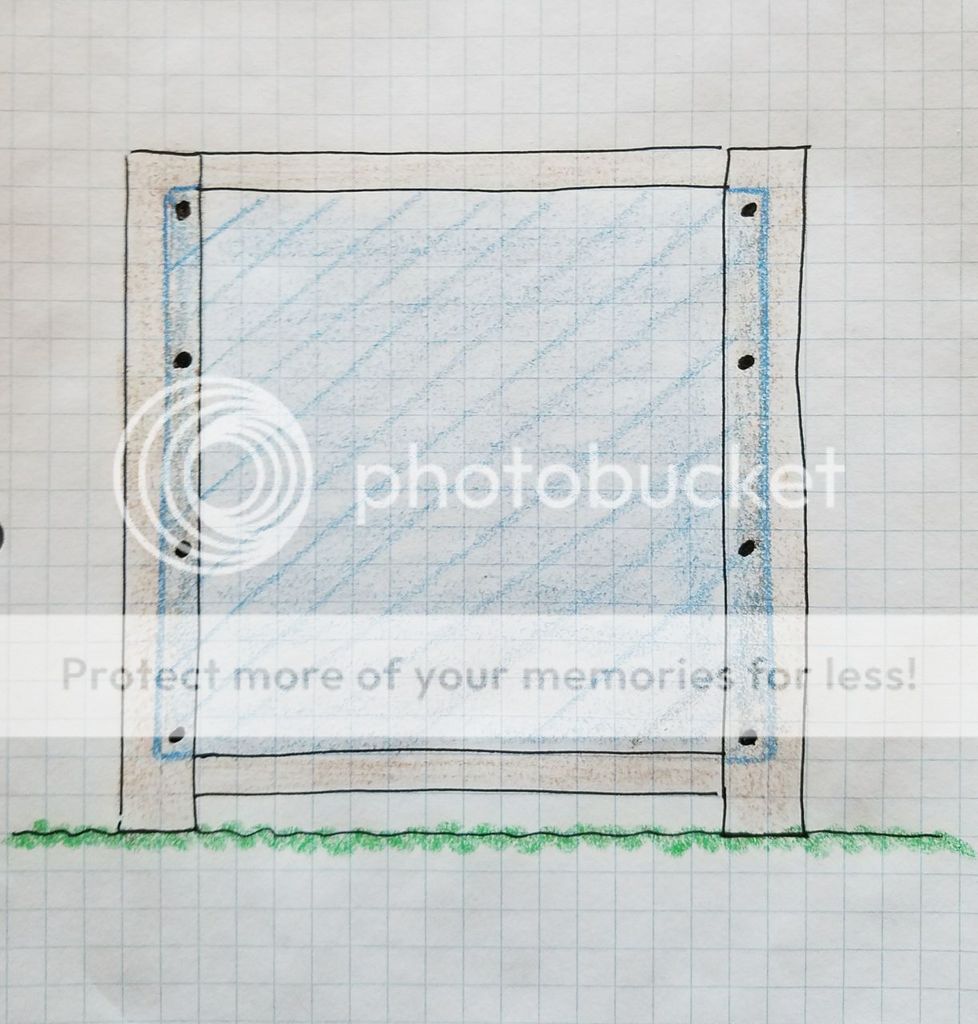

This crude drawing depicts what I have in mind. A 4x4 wooden frame with a sheet of Kevlar/Dyneema loosely bolted to it. I say loosely because I'm using the concept of catching an egg in a piece of fabric. Cradling the pellet as it impacts the fabric.

So here are a few questions about these materials:

This crude drawing depicts what I have in mind. A 4x4 wooden frame with a sheet of Kevlar/Dyneema loosely bolted to it. I say loosely because I'm using the concept of catching an egg in a piece of fabric. Cradling the pellet as it impacts the fabric.

So here are a few questions about these materials:

- Will a single sheet of Kevlar/Dyneema stop a pellet? If not how do I "bond" multiple sheets together (as done for personal body armor)?

- Am I on the right path thinking the material can be loose? Or does it need to be taught?

- If I make the material taught will the pellet bounce back?

- Will it require some type of backing? If so what type of material would keep it silent?

- Can I drill thru Kevlar/Dyneema? If not how do I make a hole in it?

- Which is stronger 3000 denier, 1500 denier, or 1000 denier?

- Would a resin coated Kevlar work better than strictly Kevlar?

- Does anyone have experience with Dyneema HB26? Which apparently is 40% stronger than Kevlar?

[/LIST=1]

Any and all experience with either of these materials would be helpful.

Let's make a stronger, lighter, quieter backstop.

Thanks