My advice would be to first try and find a manual like this, or similar, like Southbend how to run a lathe, but there are many books out there. This one here is a really in depth look at manual lathe machining processes and practices, a great reference manual.

Also safety is a big factor with machine tools, eye protection a must. Also great youtube channels, Tubalcain is one, Stefan Gotteswinter, Keith Fenner are a few of my favorites.

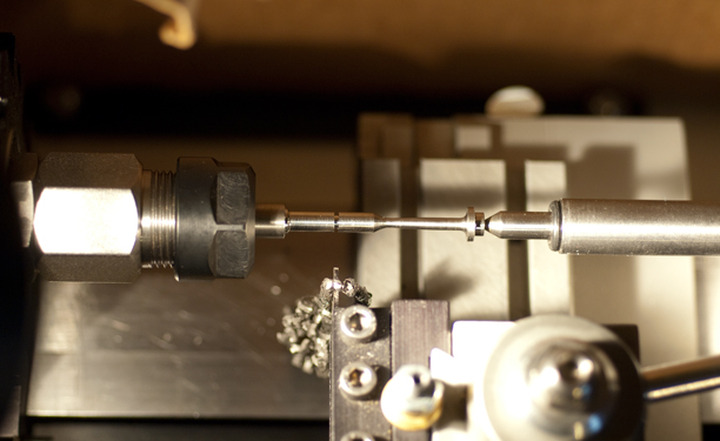

Here are a few tools I have at the ready at my lathe, all set and on center, just swap'em and go.

GROOVING.....left to right

HSS cut off, two inserted cut off tools, two OD groove tools, last one is .034 wide.

TURNING tools... left to right, CCMT .008NR sharp positive rake, aluminum, plastics. CCMT .008NR for hard steels. Left and right 35deg tools with .008NR for steels.

MICRO BORING...solid carbide boring bars for small holes down to under .100" diameter.

Couple more boring bars..micro bars and 1/4" carbide inserted bar far right, that can go fairly deep, bar is 6" long.

45 deg cemented carbide tip tools for breaking edges quickly, and top, a deep cut OD groove inserted, can also part off with this tool, or cut deep grooves on back side of part.

LIVE center and keyless drill chuck for the tail stock. On top a deep ID grooving tool.

These are what I keep ready at my lathe. You will find out tooling is where your money goes when starting out. A 5C collet chuck is one of my most used chucks for fast set ups. 3 jaw and 4 jaw also

needed for certain jobs.