I don't like moderator designs that let a lot of air pass the projectile or strip air from the projectile on a bias that has the same effect as a crooked crown. In my testing the most effective design by far strips the maximum amount of air away from the projectile and takes it on a longer path than the projectile allowing the pressure reduction to be most linear with projectile travel. With a really efficient moderator you still hear the air leaving for a fraction of a second after the shot.

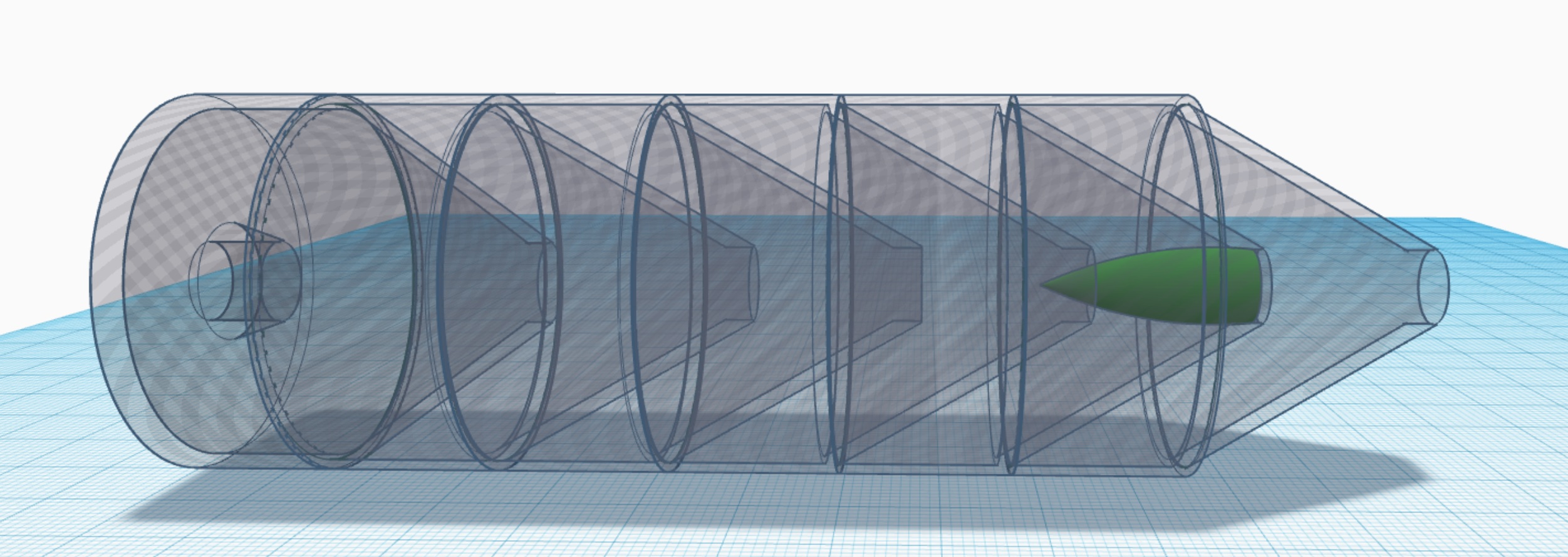

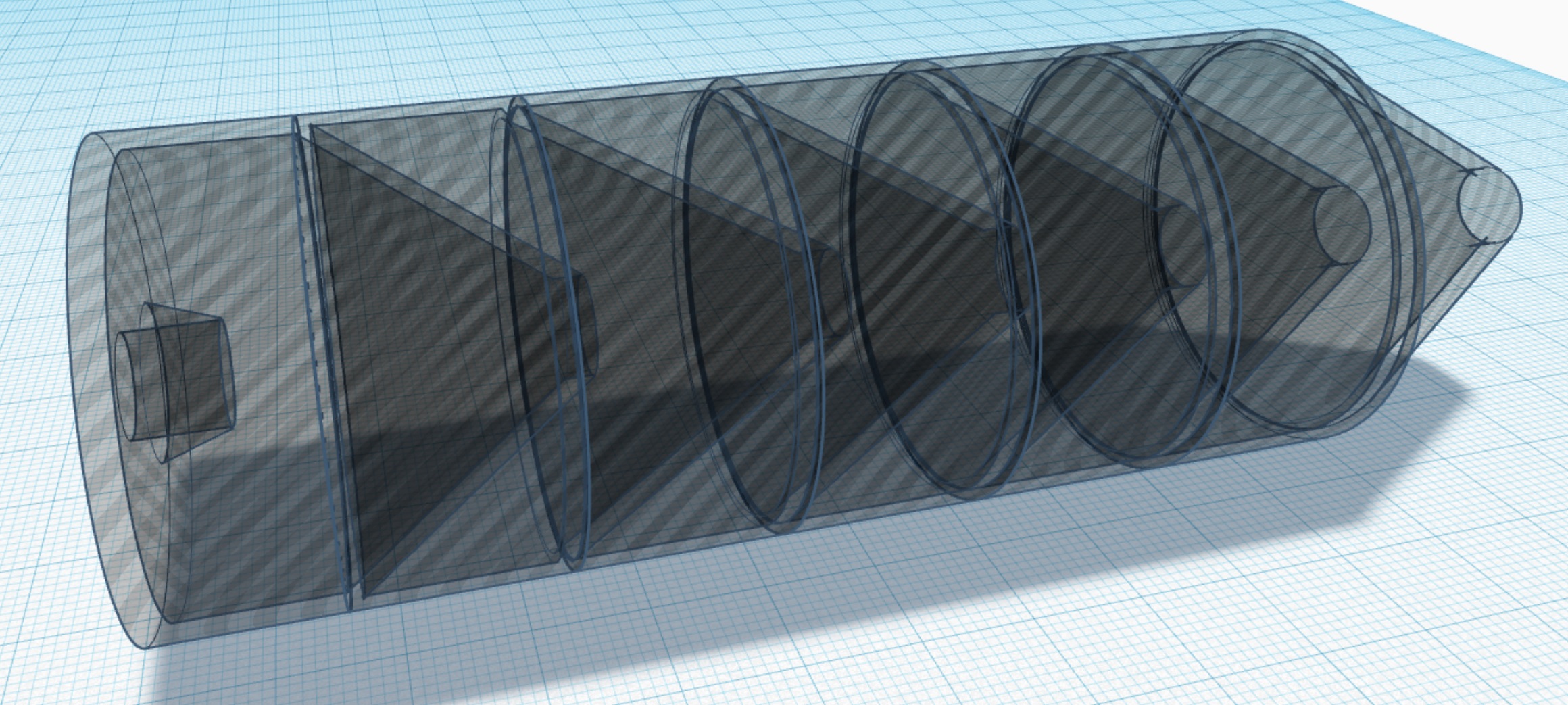

You can see that the projectile almost seals the air stripper baffles with a .6mm/.024" clearance in .30 caliber stripping the air away and giving it time to expand without passing the projectile. If you don't delay the high pressure air it will pass the projectile causing turbulence and more sound to escape.

Ideally you want the projectile to leave the moderator before any of the air that propels it thus allowing the air pressure to drop to a level that creates an acceptable report.

The straight wall height of the baffles can be tailored to suit projectile length so that the next chamber is sealed before high pressure air can pass the projectile if you'd like but I don't find it necessary.

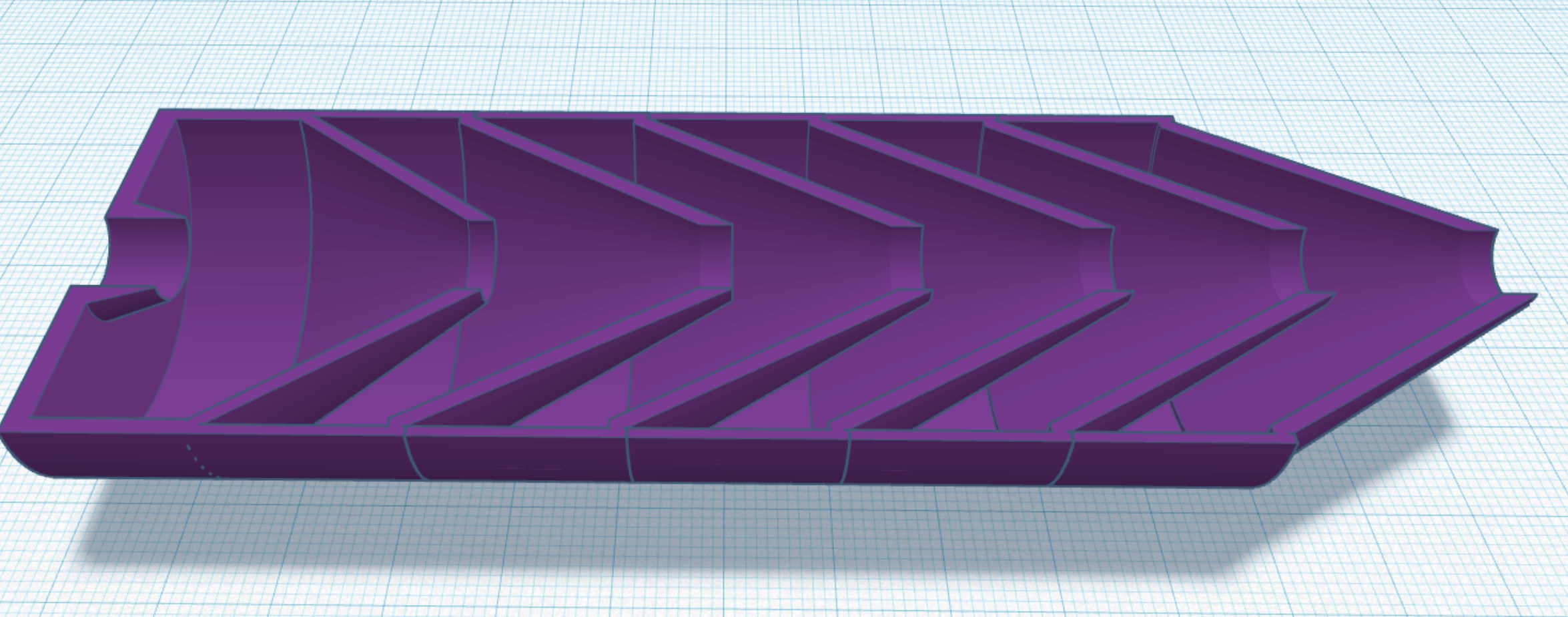

These are the modular 3d printed baffles I used in my latest build. When they're in the can there's another chamber before the projectile enters the first baffle.

You can click the pics twice for the largest version.

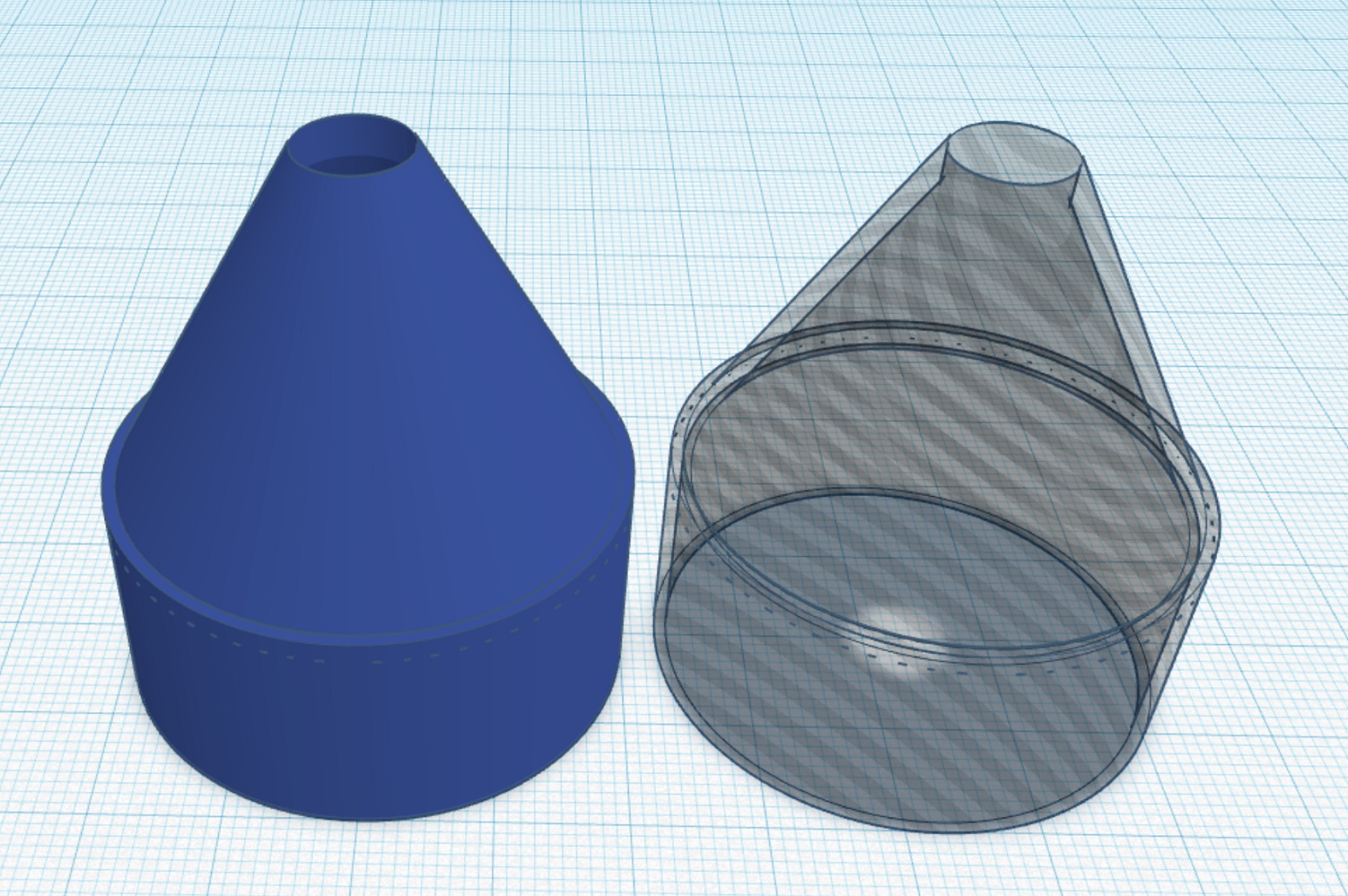

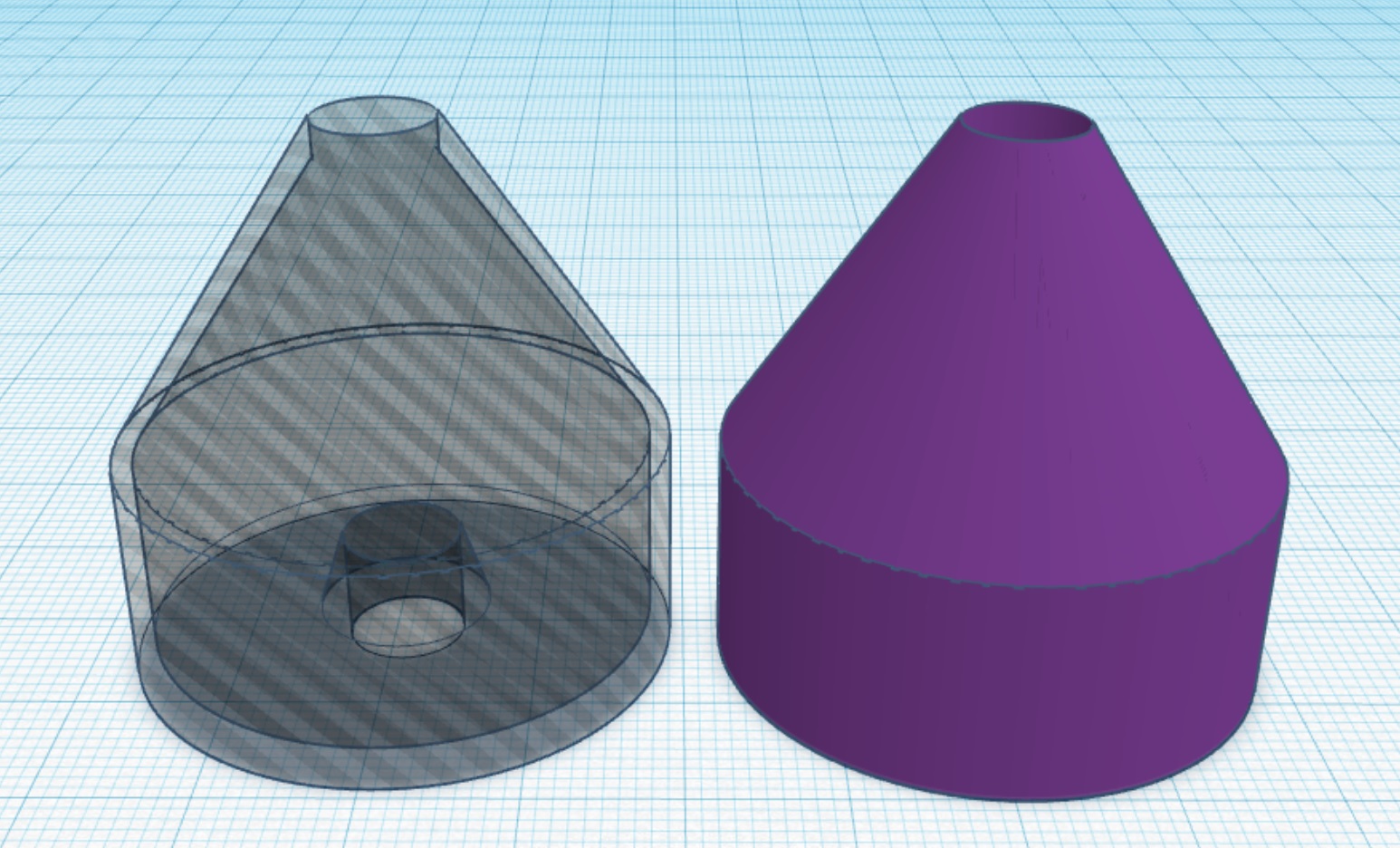

Next pic is the main baffles.

Below is the exit baffle. The aluminum end cap hole is large so if I ever had clipping it would only damage the plastic baffle and not the aluminum cap.

This moderator is 194mm long and 40mm id. Cost me less than $20 total to make and a couple hours of my time. Crazy priced mono core suppressors do not come close in sound reduction. I can't believe what people pay for horribly inefficient chinese manufactured monocore suppressors from the big names in this business.

Please post your thoughts on this subject.

You can see that the projectile almost seals the air stripper baffles with a .6mm/.024" clearance in .30 caliber stripping the air away and giving it time to expand without passing the projectile. If you don't delay the high pressure air it will pass the projectile causing turbulence and more sound to escape.

Ideally you want the projectile to leave the moderator before any of the air that propels it thus allowing the air pressure to drop to a level that creates an acceptable report.

The straight wall height of the baffles can be tailored to suit projectile length so that the next chamber is sealed before high pressure air can pass the projectile if you'd like but I don't find it necessary.

These are the modular 3d printed baffles I used in my latest build. When they're in the can there's another chamber before the projectile enters the first baffle.

You can click the pics twice for the largest version.

Next pic is the main baffles.

Below is the exit baffle. The aluminum end cap hole is large so if I ever had clipping it would only damage the plastic baffle and not the aluminum cap.

This moderator is 194mm long and 40mm id. Cost me less than $20 total to make and a couple hours of my time. Crazy priced mono core suppressors do not come close in sound reduction. I can't believe what people pay for horribly inefficient chinese manufactured monocore suppressors from the big names in this business.

Please post your thoughts on this subject.