When i first heard about a new company called "SubMoa" making rifle barrels, it definitely caught my attention. I saw the pictures of fancy machinery, computers and stacks of materials. I thought how cool this is. Looking deeper into the subject, i found the price. It is a premium price. However, as you read on, i found that this premium price lacked any benefit to my shooting. I will go through my initial observation, internal inspection, and finally shooting targets at 50 and 100 yards. I am not a professional, i just like to shoot, and this is what i found.

INITIAL OBSERVATIONS

When I got the barrel, the 1st thing you notice is how much it weighs. It is HEAVY! I do not have a scale, but have seen the weight at around 9lbs, which doubles the weight of my Epoch. In fact, it was too heavy for my front rest's joystick control and made it sink.

2nd was the fact that the barrel was made from carbon steel...not stainless or chrome-moly..plain,rusting carbon steel. Skout has applied a coating to the outside of the barrels to prevent corrosion. At the price, these should be stainless 416 steel or better

3rd observation was how loud this barrel shoots! It sounds like there isn't a suppressor on the barrel when firing, and VERY loud if the supressor is removed. While the OEM supressor does a decent job, it is not that effective to quiet the bark in this case.

4th was on how thick the barrel is. Skout includes an additional locking collar to accomodate the extra thickness of this barrel. It is a one screw replacement of the collar..not at all dificult.

5th was the very strange ribbing i see down the barrel. Like the barrel was locked to tight in a vice and made an indentation. these are in increments down the length. I cannot say if this effect the overall performance of the barrel, but it seems like lack of finishing.

WHAT"S IN THE BORE

I wanted to know what was going on inside this barrel, so i pushed some pellets through the barrel using a rotating bore rod. The barrel was cleaned. When i looked at the pellets, i saw inconsistencies. One side of the pellet engraved wel, but on the flip side, it was different

After about 50 shots, I ran another pellet down the barrel…no cleaning

notice the bottom of the skirt..how ragged in texture

Why was it so torn up?

I went out and purchased a bore scope to take a look

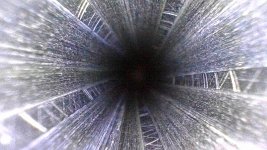

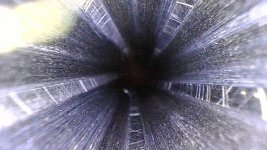

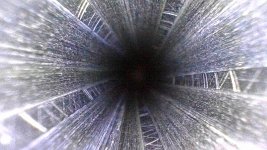

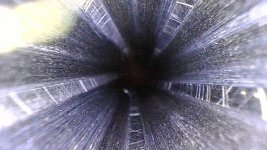

The breech seemed normal

as i went in further into the barrel, i found these marks on the lands

Not only do i see tooling marks on the lands, the grooves look to have a tree bark texture..not at all smooth

LETS GET TO SHOOTING

All the test shots were done at an indoor range. I am using a AR 250 front rest with Edgewood rear bags for these test. The rifle was cleaned when a new pellet was used.

I did testing with the 3 most popular pellets being used; JSB MRD deep-AEA 25.39g-JTS 22.07g

I did 10 consecutive 5 shot groups on a N50 target

JSB MRD DEEP AT 50 YARDS

these were taken straight from the tin, which i now realize was a mistake made by me. I was unable to tell if the shot was bad from the barrel or the pellet. The MRD's were shot at 935-940 fps i was running a S.D of 2.8

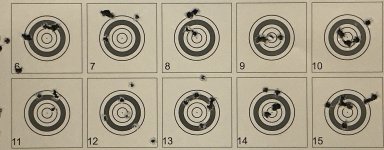

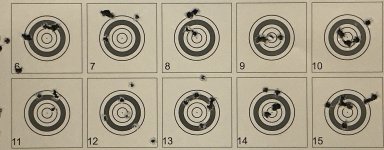

AEA 25.39g AT 50 YARDS

The pellets were shot straight from the tin. The consistency of weight leads to a better result with these pellets. Was able to barely get under MOA. The groups were tight, but the poi did wander a bit. I was zero'd on the bullseye. The AEA were shot at 935-940 fps and had a S.D of 2.8 the size of the groups varied from .30 to .52 These worked the best

JTS 22.07g AT 50 YARDS

. These did well in grouping, but the POI did wander. the size of the groups varied from.34 to .64. Not what i expected from these pellets, i thought they would perform better.

Shots are zero'd on the bullseye.

100 YARD SHOTS

Here is where it all falls apart

I cleaned the barrel for each pellet, followed up with a lead in of 5 shots

I took 10 consecutive shots at the target and then to another 10 on the next target. I did not center the shots to group at the bullseye .. just shot for groups

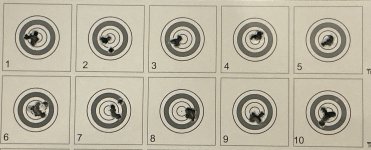

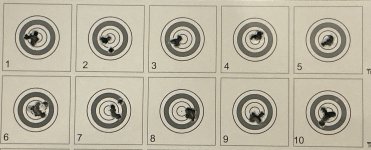

JSB MRD DEEP AT 100 YARDS

learning from my mistake of not weighing the JSB's, i sorted a batch of pellets to use at 100yards. Let's be honest, who doesn't sort for a 100 yard competition shoot?

The pellets went flying at 935-940 fps with a S.D of 2.9.

1st tsrget ctc = 2.21 inches 2nd target ctc 2.4 inches

AEA AT 100 YARDS

These showed less percission than the JSB, but if you take a close look at the top of the target sheet, you will see several shots off the paper. These were part of the group. While there was a tight group forming, it did not hold.

ctc on target 1=4.45 ctc on target 2 = 3.44

JTS AT 100 YARDS

Currently, these pellets are my favorite to shoot. The Submoa seemed to like them the best out of the 3. The JTS's were shot at 965-970 fps with a S.D of 2.5. Pellets were taken straight from the tin. The percission of the groups are much tighter, but still lack achieving submoa or moa

ctc of target 1=1.46 ctc of target 2= 1.81

CONCLUSION

50 yards and under, this is a "good" barrel. Not that special in comparrison to the other barrels i have owned like the RTI LR barrel and far below the standard of the Lothar Walther bull barrel.

I find the tooling marks to be very disturbing in a very expensive barrel .."V" and "X" marks on the lands is not what you want to see on an expensive barrel!

Does it shoot well at 100 yards= NO

Would i recommend this barrel to others based on my findings with this barrel=NO

SHould Skout find another vendor=YES

Most important...Was this barrel fun to shoot=NO

I am not an expert, but i would think that all these problems would lessen if there was ANY attention to finishing, which this barrel severely lacks. And not just this barrel! I have reached out to others who own these barrels including a prominent Smith who shared their results with me. It seems to be a common problem. Why would you pay a premium price for a barrel only to have to spend hours lapping the crap out of it to get (maybe) good(better) results?

Is this barrel worth it...in my opinion, you would be better off getting the Lothar Walther bullbarrel than the Submoa

Hope this helps someone make their decission on what after market barrel to purchase

Mike

INITIAL OBSERVATIONS

When I got the barrel, the 1st thing you notice is how much it weighs. It is HEAVY! I do not have a scale, but have seen the weight at around 9lbs, which doubles the weight of my Epoch. In fact, it was too heavy for my front rest's joystick control and made it sink.

2nd was the fact that the barrel was made from carbon steel...not stainless or chrome-moly..plain,rusting carbon steel. Skout has applied a coating to the outside of the barrels to prevent corrosion. At the price, these should be stainless 416 steel or better

3rd observation was how loud this barrel shoots! It sounds like there isn't a suppressor on the barrel when firing, and VERY loud if the supressor is removed. While the OEM supressor does a decent job, it is not that effective to quiet the bark in this case.

4th was on how thick the barrel is. Skout includes an additional locking collar to accomodate the extra thickness of this barrel. It is a one screw replacement of the collar..not at all dificult.

5th was the very strange ribbing i see down the barrel. Like the barrel was locked to tight in a vice and made an indentation. these are in increments down the length. I cannot say if this effect the overall performance of the barrel, but it seems like lack of finishing.

WHAT"S IN THE BORE

I wanted to know what was going on inside this barrel, so i pushed some pellets through the barrel using a rotating bore rod. The barrel was cleaned. When i looked at the pellets, i saw inconsistencies. One side of the pellet engraved wel, but on the flip side, it was different

After about 50 shots, I ran another pellet down the barrel…no cleaning

notice the bottom of the skirt..how ragged in texture

Why was it so torn up?

I went out and purchased a bore scope to take a look

The breech seemed normal

as i went in further into the barrel, i found these marks on the lands

Not only do i see tooling marks on the lands, the grooves look to have a tree bark texture..not at all smooth

LETS GET TO SHOOTING

All the test shots were done at an indoor range. I am using a AR 250 front rest with Edgewood rear bags for these test. The rifle was cleaned when a new pellet was used.

I did testing with the 3 most popular pellets being used; JSB MRD deep-AEA 25.39g-JTS 22.07g

I did 10 consecutive 5 shot groups on a N50 target

JSB MRD DEEP AT 50 YARDS

these were taken straight from the tin, which i now realize was a mistake made by me. I was unable to tell if the shot was bad from the barrel or the pellet. The MRD's were shot at 935-940 fps i was running a S.D of 2.8

AEA 25.39g AT 50 YARDS

The pellets were shot straight from the tin. The consistency of weight leads to a better result with these pellets. Was able to barely get under MOA. The groups were tight, but the poi did wander a bit. I was zero'd on the bullseye. The AEA were shot at 935-940 fps and had a S.D of 2.8 the size of the groups varied from .30 to .52 These worked the best

JTS 22.07g AT 50 YARDS

. These did well in grouping, but the POI did wander. the size of the groups varied from.34 to .64. Not what i expected from these pellets, i thought they would perform better.

Shots are zero'd on the bullseye.

100 YARD SHOTS

Here is where it all falls apart

I cleaned the barrel for each pellet, followed up with a lead in of 5 shots

I took 10 consecutive shots at the target and then to another 10 on the next target. I did not center the shots to group at the bullseye .. just shot for groups

JSB MRD DEEP AT 100 YARDS

learning from my mistake of not weighing the JSB's, i sorted a batch of pellets to use at 100yards. Let's be honest, who doesn't sort for a 100 yard competition shoot?

The pellets went flying at 935-940 fps with a S.D of 2.9.

1st tsrget ctc = 2.21 inches 2nd target ctc 2.4 inches

AEA AT 100 YARDS

These showed less percission than the JSB, but if you take a close look at the top of the target sheet, you will see several shots off the paper. These were part of the group. While there was a tight group forming, it did not hold.

ctc on target 1=4.45 ctc on target 2 = 3.44

JTS AT 100 YARDS

Currently, these pellets are my favorite to shoot. The Submoa seemed to like them the best out of the 3. The JTS's were shot at 965-970 fps with a S.D of 2.5. Pellets were taken straight from the tin. The percission of the groups are much tighter, but still lack achieving submoa or moa

ctc of target 1=1.46 ctc of target 2= 1.81

CONCLUSION

50 yards and under, this is a "good" barrel. Not that special in comparrison to the other barrels i have owned like the RTI LR barrel and far below the standard of the Lothar Walther bull barrel.

I find the tooling marks to be very disturbing in a very expensive barrel .."V" and "X" marks on the lands is not what you want to see on an expensive barrel!

Does it shoot well at 100 yards= NO

Would i recommend this barrel to others based on my findings with this barrel=NO

SHould Skout find another vendor=YES

Most important...Was this barrel fun to shoot=NO

I am not an expert, but i would think that all these problems would lessen if there was ANY attention to finishing, which this barrel severely lacks. And not just this barrel! I have reached out to others who own these barrels including a prominent Smith who shared their results with me. It seems to be a common problem. Why would you pay a premium price for a barrel only to have to spend hours lapping the crap out of it to get (maybe) good(better) results?

Is this barrel worth it...in my opinion, you would be better off getting the Lothar Walther bullbarrel than the Submoa

Hope this helps someone make their decission on what after market barrel to purchase

Mike

Last edited: