This post is more of a initial start and short telling of my first experience at long range with slugs in SURELY, as well as a little content about swaging. For now I don't have many photos to show of "official" targets per say, or of the steel I shot at. Part of the reason is the longer range steel past 100Y is up a very steep cinder hill that is a hard climb so these don't get painted very often. When I get a low wind day in the next few months I'll go ahead and make the climb anyway and paint those steel spinners white to see exactly where I'm hitting on the steel. For now all I know is when I hit them because of the sound and movement vs dirt and dust being kicked up when I miss.

SURELY with the pellet barrel on, it looks the same with the slug barrel on but lacking the muzzle brake. Those 100Y targets are with pellets not slugs.

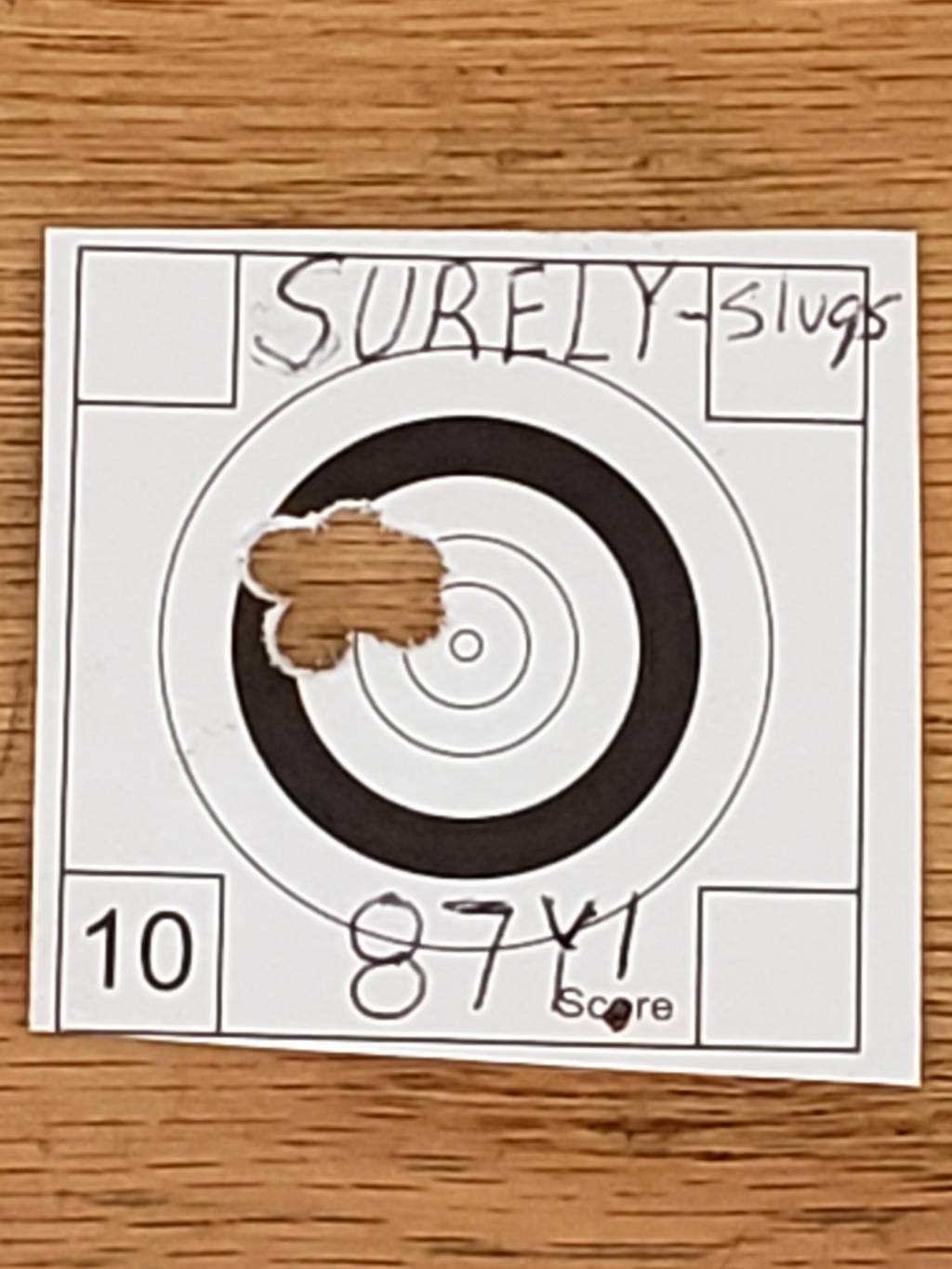

Backing up - In October I went to visit my BIL and SIL in Montrose CO, and also to visit with Mike Niksch, owner of ThomasAir, and hang out a bit, as well as to pick up my slug barrel, swage die, and sizer insert, from Mike at his residence in Olathe which is only 25 minutes away from my relatives which is quite convenient. Long story short Mike showed me how to swage pure lead cores and the basics of the process of completing a slug ready to be shot. He also tuned my gun on paper while I watched. He used his super solid bench, and his amazing one piece benchrest, and of course his refined wind reading and gun handling skills, for both pellets and slugs. He literally had SURELY using the pellet barrel and pellets, which had gone out of tune due to me messing with it, to cutting the vertical in half at 50Y within a few minutes. Then he put the slug barrel on and tuned that as well while I watched. The end result and last group of the day was a 5 shot group at 87Y that was a nice round 1/4"-ish cluster which I had shot. Sure was cool when the 5th went into the rest! Oh boy, that got me excited for the future using slugs out of SURELY!!!

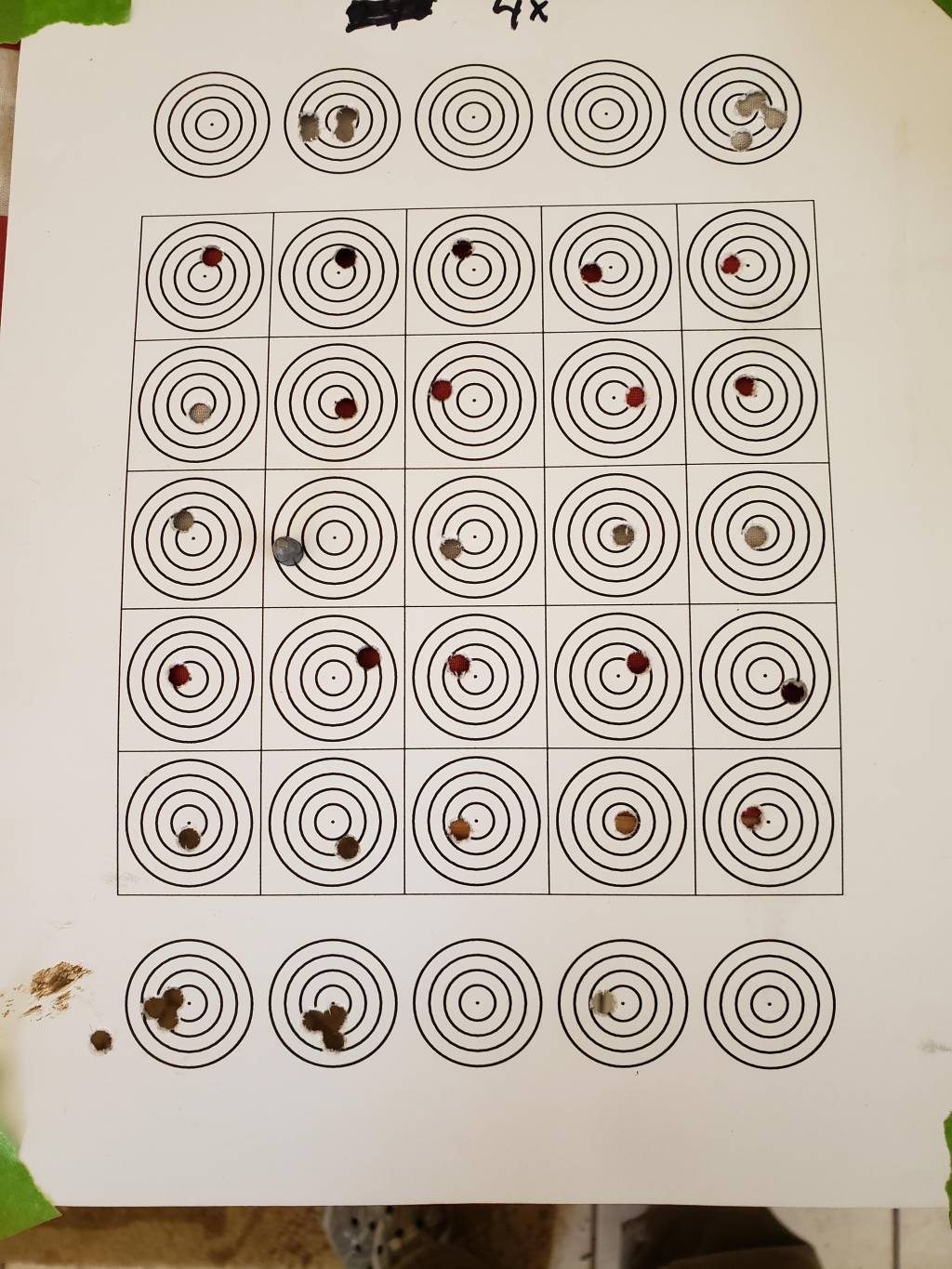

N50 target at 50Y from a couple days ago using slugs out of SURELY. 3rd row, 2nd from left, is a slug I used to plug the target.

I drug my feet sourcing a Arbor press because of various reasons, one being my bad shoulder and not being sure which type/strength to order, but I finally made a decision to go for a 2 ton press which arrived a month ago. The Arbor press is needed to apply enough pressure down on the lead core "in the swage die" that forms the slug. In the same time frame I also bought a 25lb spool of lead wire from Roto Metals, and a lead wire core cutter from Corbin, as well as a bottle of swage lube.

In this photo if you enlarge it is the swage die, the top to it, and the slug ejection tool with a slug on top of it.

Making lead cores - I mounted the core cutter on my bench near the wood stove, inserted the lead wire into it, and adjusted it by trial and error to give the correct length of core. Its a simple endeavor and the goal is to let about a 1/2" of lead be ejected out of the bleed hole in the swage die. But it is time consuming and monotonous so when I'm already bored and looking for something to do this is when I head out to the shop to cut cores for 30 minutes or so.

Swaging is simple too. Lube the cores. Insert the lead core into the swage die, make sure the swage die top is perfectly aligned and partially inside the bottom swage die, move over to the press, push down gently to make sure the top and bottom are indeed correctly fitted together, then apply pressure until the two pieces touch together. Then take the die off the press, take the top off and insert the swage die into a specially made slug ejector tool that the swag die fits in, and out pops the perfectly formed 42gr solid point rebated boat tail slug. I took 3 slugs out of the pile I had made and weighed them on my fancy powder scale, all 3 were less than a tenth of a grain from each other, more like a 20th of a grain, awesome!!!!

Next thing to do is size the slug by pushing it through the appropriately sized insert located in the size die which is screwed into my Lee press that is mounted upside down to take advantage of gravity. Out pops the sized slug into my hand and there you go, you're done with one slug.

All this takes TIME, lol, but in the end each slug is basically exactly like the next which means "PRECISION", so I'm okay with this because I'm retired and like the idea of swaging for myself and its benefits.

Yesterday I went out to my bud Johns place which is his shooting range on 20 acres of land. Sighted SURELY in at 50Y on a weathered cardboard box, last 3 shots into 1/8th", then hit the 1" spinner until I got bored. Wind was from our backs and mostly from 4 to 6 oclock at 2-6 mph. I put a .14 G1 BC into my SHOOTER ballictic app at 800 fps and got going. I shot at steel spinners at 50Y, 65Y, 70Y, 75Y, 80Y, 90Y, 100Y, 112Y, 136Y, 161Y, and 190Y, these range from 1 moa to 2.4 moa in size. It was ASTOUNDING because I hardly missed and I usually hit them at each distance on the first try! The most fun I had was tagging the 5" plate at 190Y 12 times in a row until I went off reg. I was using a .8 mil wind holdoff. But the very last thing I did was to shoot a group at 100Y on a bigger piece of steel that still had a patch of white paint left on it. I shot 6 shots which made a .4" tall by .75" wide splat. Immediately after that my friend put 3 into one splat which was 1/2" or so just left of my group.

My 6 shots in the upper left, and my friends 3 shots - lower pic at 100Y.

As a long time lover of shooting and owning some super precise firearms, as well as some of the better airguns, SURELY really impressed me using these unique swaged slugs!

Some perspective - To date, even with my Anschutz 22rf using $17 a 50 box retail match ammo I've never hit the 190Y steel that many times in a row! I never imagined I'd have a pcp air rifle that would hold its own with my rimfire at long range before yesterday, let alone exceeding it!

Thanks a bunch Mike N for creating such a great shooting rifle and slug system, to say that I'm pleased is a major understatement!

SURELY with the pellet barrel on, it looks the same with the slug barrel on but lacking the muzzle brake. Those 100Y targets are with pellets not slugs.

Backing up - In October I went to visit my BIL and SIL in Montrose CO, and also to visit with Mike Niksch, owner of ThomasAir, and hang out a bit, as well as to pick up my slug barrel, swage die, and sizer insert, from Mike at his residence in Olathe which is only 25 minutes away from my relatives which is quite convenient. Long story short Mike showed me how to swage pure lead cores and the basics of the process of completing a slug ready to be shot. He also tuned my gun on paper while I watched. He used his super solid bench, and his amazing one piece benchrest, and of course his refined wind reading and gun handling skills, for both pellets and slugs. He literally had SURELY using the pellet barrel and pellets, which had gone out of tune due to me messing with it, to cutting the vertical in half at 50Y within a few minutes. Then he put the slug barrel on and tuned that as well while I watched. The end result and last group of the day was a 5 shot group at 87Y that was a nice round 1/4"-ish cluster which I had shot. Sure was cool when the 5th went into the rest! Oh boy, that got me excited for the future using slugs out of SURELY!!!

N50 target at 50Y from a couple days ago using slugs out of SURELY. 3rd row, 2nd from left, is a slug I used to plug the target.

I drug my feet sourcing a Arbor press because of various reasons, one being my bad shoulder and not being sure which type/strength to order, but I finally made a decision to go for a 2 ton press which arrived a month ago. The Arbor press is needed to apply enough pressure down on the lead core "in the swage die" that forms the slug. In the same time frame I also bought a 25lb spool of lead wire from Roto Metals, and a lead wire core cutter from Corbin, as well as a bottle of swage lube.

In this photo if you enlarge it is the swage die, the top to it, and the slug ejection tool with a slug on top of it.

Making lead cores - I mounted the core cutter on my bench near the wood stove, inserted the lead wire into it, and adjusted it by trial and error to give the correct length of core. Its a simple endeavor and the goal is to let about a 1/2" of lead be ejected out of the bleed hole in the swage die. But it is time consuming and monotonous so when I'm already bored and looking for something to do this is when I head out to the shop to cut cores for 30 minutes or so.

Swaging is simple too. Lube the cores. Insert the lead core into the swage die, make sure the swage die top is perfectly aligned and partially inside the bottom swage die, move over to the press, push down gently to make sure the top and bottom are indeed correctly fitted together, then apply pressure until the two pieces touch together. Then take the die off the press, take the top off and insert the swage die into a specially made slug ejector tool that the swag die fits in, and out pops the perfectly formed 42gr solid point rebated boat tail slug. I took 3 slugs out of the pile I had made and weighed them on my fancy powder scale, all 3 were less than a tenth of a grain from each other, more like a 20th of a grain, awesome!!!!

Next thing to do is size the slug by pushing it through the appropriately sized insert located in the size die which is screwed into my Lee press that is mounted upside down to take advantage of gravity. Out pops the sized slug into my hand and there you go, you're done with one slug.

All this takes TIME, lol, but in the end each slug is basically exactly like the next which means "PRECISION", so I'm okay with this because I'm retired and like the idea of swaging for myself and its benefits.

Yesterday I went out to my bud Johns place which is his shooting range on 20 acres of land. Sighted SURELY in at 50Y on a weathered cardboard box, last 3 shots into 1/8th", then hit the 1" spinner until I got bored. Wind was from our backs and mostly from 4 to 6 oclock at 2-6 mph. I put a .14 G1 BC into my SHOOTER ballictic app at 800 fps and got going. I shot at steel spinners at 50Y, 65Y, 70Y, 75Y, 80Y, 90Y, 100Y, 112Y, 136Y, 161Y, and 190Y, these range from 1 moa to 2.4 moa in size. It was ASTOUNDING because I hardly missed and I usually hit them at each distance on the first try! The most fun I had was tagging the 5" plate at 190Y 12 times in a row until I went off reg. I was using a .8 mil wind holdoff. But the very last thing I did was to shoot a group at 100Y on a bigger piece of steel that still had a patch of white paint left on it. I shot 6 shots which made a .4" tall by .75" wide splat. Immediately after that my friend put 3 into one splat which was 1/2" or so just left of my group.

My 6 shots in the upper left, and my friends 3 shots - lower pic at 100Y.

As a long time lover of shooting and owning some super precise firearms, as well as some of the better airguns, SURELY really impressed me using these unique swaged slugs!

Some perspective - To date, even with my Anschutz 22rf using $17 a 50 box retail match ammo I've never hit the 190Y steel that many times in a row! I never imagined I'd have a pcp air rifle that would hold its own with my rimfire at long range before yesterday, let alone exceeding it!

Thanks a bunch Mike N for creating such a great shooting rifle and slug system, to say that I'm pleased is a major understatement!