With the damage to the receiver.. Tearing out the indexing Pin....

a single Grub-screw wouldn't stop the barrel movement with that pounding.

But maybe with a little modifications....

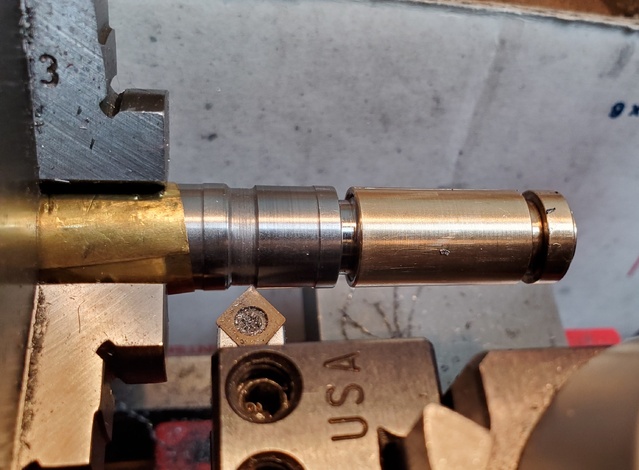

I went the route of Ernest Rowe... using 2 Grub-screws to secure the barrel for Tensioning....

But I also cut a groove for the grub-screw to sit in.

Also I can crank the Screws down without the fear of boogering the barrel extension up.

But even with these mods..... I am not sure it would hold up to a 5 lb sledge hammer!!

Stuart