Figured I'd share this for anyone who doesn't do Instagram. I came into some much needed free time recently and I got a new vertical mill for parts prototyping. There's only so much that one can do on a lathe!

My first priority was making some upgrades to the Taipan Veteran (and Mutant) cocking system. The factory lever does the job, but it's always felt a little "min bar", so I had to raise it up some.

First, the biathlon style levers - I machined a completely new lever from aluminum. I wanted to get a feel for extending the lever forward, and adding a charging handle on the end. It took some time to cut and drill the new lever, and I turned a quick and dirty knurled handle and threaded the top half:

It feels pretty frigging awesome!!! Cocking effort is much easier and very smooth. I will probably make more of these from 7075 aluminum soon with some more refined charging handles in different diameters.

Next up, I wanted to test some theories that I had for adding a slip-on handle for the factory levers. I'm not going to reveal how I went about it just yet, but low and behold the idea appears to be rock solid!!!

The handle is affixed to the lever with excellent strength, without any damage or marring to the anodized finish on the lever. There are also substantially less chances for accidentally opening the lever in the field (I always seem to get my lever caught on stuff hunting, which gets pretty aggravating):

This was another quick and dirty knurled handle to test the attachment concept. My next idea is to make some stackable threaded pieces, so the height can be adjusted on each side

Last but not least for charging mods, I'm fine tuning an all new side cocking action that moves the cocking effort forward at the trigger housing. I knew that I wanted to attach the mount to the barrel right, but that real estate is precious for mounting magazines! I didn't want to compromise the magazine mounting features, so I decided to mill the mount in a way that allows for mounting 1/2 of the factory accessory magazine mount as a backing to the charging system mount.

I've had a bunch of different ideas marinating for the cocking action:

As I began milling the lever components, I decided that I wanted to go all at first with my second idea - the speed-cocking action. The parameters for this system - heavy-duty and overbuilt. I want to be able to abuse it without concerns, yet keeping the weight down at a reasonable level.

It's taken some time to work everything out, but what I have come up with is a universal mounting block that will allow for interchangeable cocking actions. I milled a few new replacements for the factory lever (mainly for the linkage requirements), but I will have a bolt-on linkage adapter that will mount straight up to the factory lever.

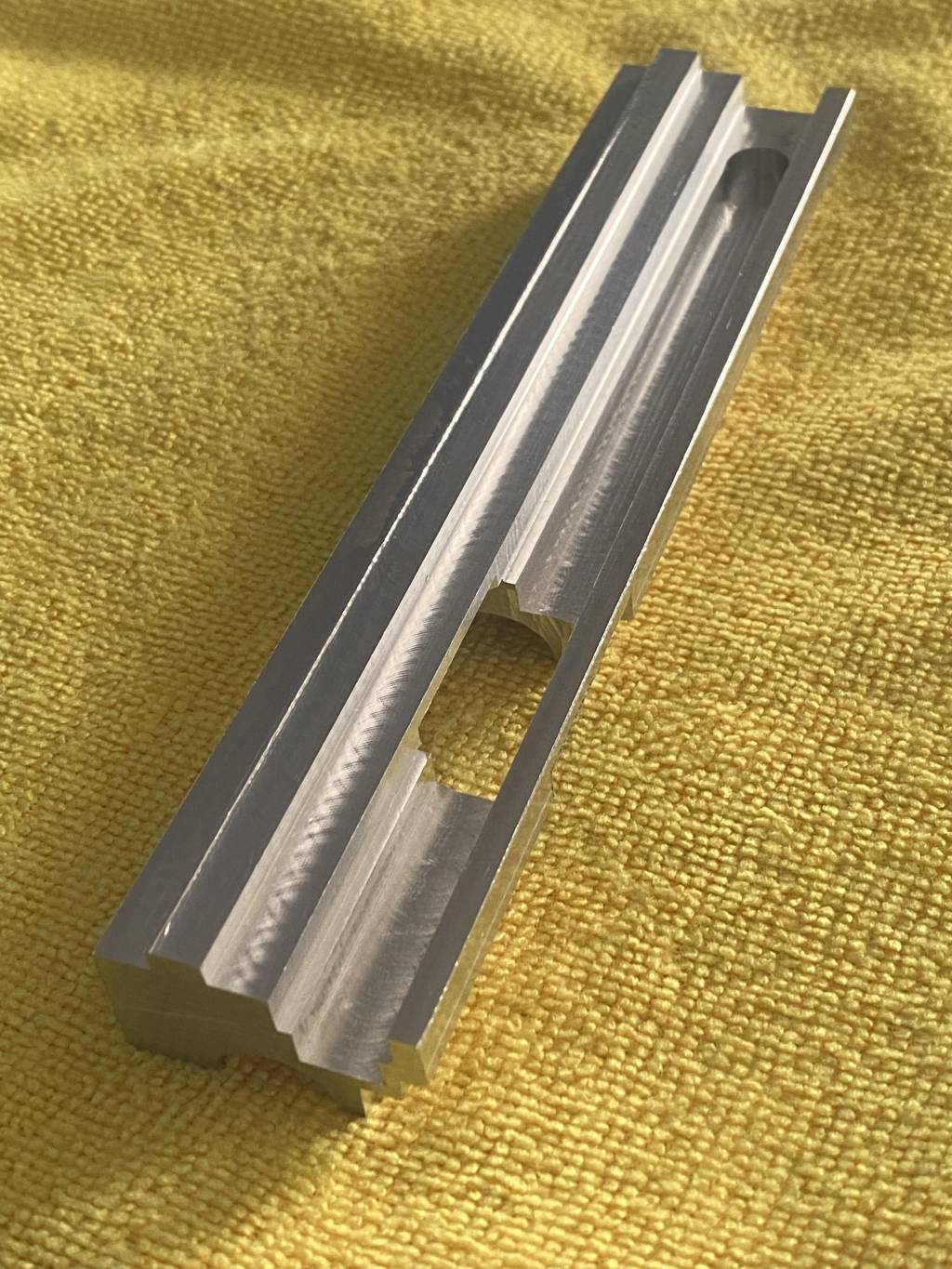

Here's a preview of what some that will look like (in raw 6061 T651 aluminum format):

My ideas have been getting in the way of finishing the first basic prototype. I'm too much of a perfectionist, but suffice to say that I came up with a few additional ideas that will take a little time to whip up on my manual / vertical mill - but they are non-negotiable features in my opinion! As soon as I get them all built out, I should have a pretty bad ass working prototype that I'll demonstrate afterwards.

Once I can fine tune anything that requires adjustments, I'll finish drafting everything in Fusion and then figure out how much it will cost to produce them (CNC fab, blasting & anodizing/Cerakote). They'll look a lot more spiffier than the raw milled prototypes that I'm testing

My first priority was making some upgrades to the Taipan Veteran (and Mutant) cocking system. The factory lever does the job, but it's always felt a little "min bar", so I had to raise it up some.

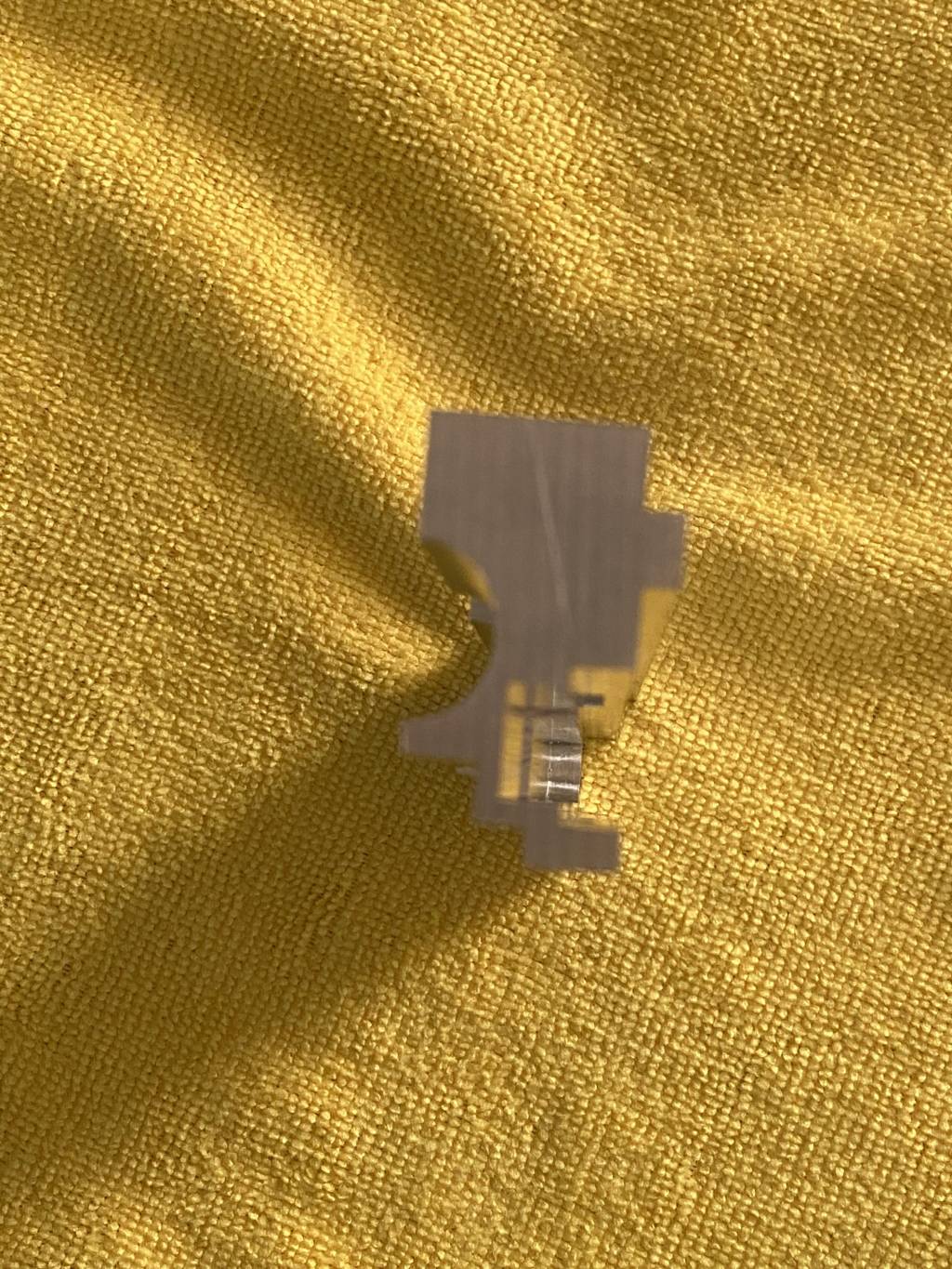

First, the biathlon style levers - I machined a completely new lever from aluminum. I wanted to get a feel for extending the lever forward, and adding a charging handle on the end. It took some time to cut and drill the new lever, and I turned a quick and dirty knurled handle and threaded the top half:

It feels pretty frigging awesome!!! Cocking effort is much easier and very smooth. I will probably make more of these from 7075 aluminum soon with some more refined charging handles in different diameters.

Next up, I wanted to test some theories that I had for adding a slip-on handle for the factory levers. I'm not going to reveal how I went about it just yet, but low and behold the idea appears to be rock solid!!!

The handle is affixed to the lever with excellent strength, without any damage or marring to the anodized finish on the lever. There are also substantially less chances for accidentally opening the lever in the field (I always seem to get my lever caught on stuff hunting, which gets pretty aggravating):

This was another quick and dirty knurled handle to test the attachment concept. My next idea is to make some stackable threaded pieces, so the height can be adjusted on each side

Last but not least for charging mods, I'm fine tuning an all new side cocking action that moves the cocking effort forward at the trigger housing. I knew that I wanted to attach the mount to the barrel right, but that real estate is precious for mounting magazines! I didn't want to compromise the magazine mounting features, so I decided to mill the mount in a way that allows for mounting 1/2 of the factory accessory magazine mount as a backing to the charging system mount.

I've had a bunch of different ideas marinating for the cocking action:

- Standard lever action

- Shorter throw speed-cocking mechanism

- Pump action

As I began milling the lever components, I decided that I wanted to go all at first with my second idea - the speed-cocking action. The parameters for this system - heavy-duty and overbuilt. I want to be able to abuse it without concerns, yet keeping the weight down at a reasonable level.

It's taken some time to work everything out, but what I have come up with is a universal mounting block that will allow for interchangeable cocking actions. I milled a few new replacements for the factory lever (mainly for the linkage requirements), but I will have a bolt-on linkage adapter that will mount straight up to the factory lever.

Here's a preview of what some that will look like (in raw 6061 T651 aluminum format):

My ideas have been getting in the way of finishing the first basic prototype. I'm too much of a perfectionist, but suffice to say that I came up with a few additional ideas that will take a little time to whip up on my manual / vertical mill - but they are non-negotiable features in my opinion! As soon as I get them all built out, I should have a pretty bad ass working prototype that I'll demonstrate afterwards.

Once I can fine tune anything that requires adjustments, I'll finish drafting everything in Fusion and then figure out how much it will cost to produce them (CNC fab, blasting & anodizing/Cerakote). They'll look a lot more spiffier than the raw milled prototypes that I'm testing