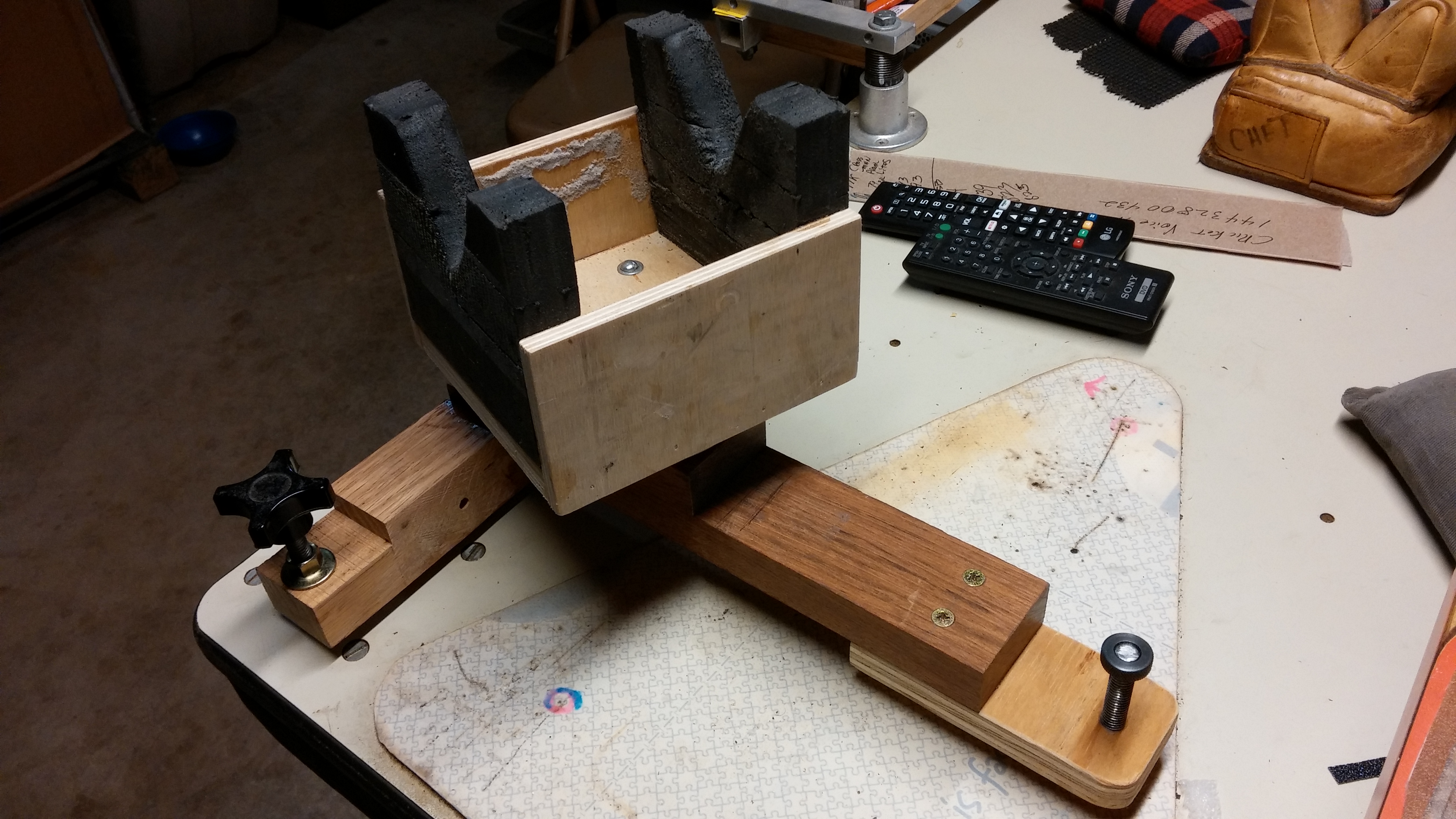

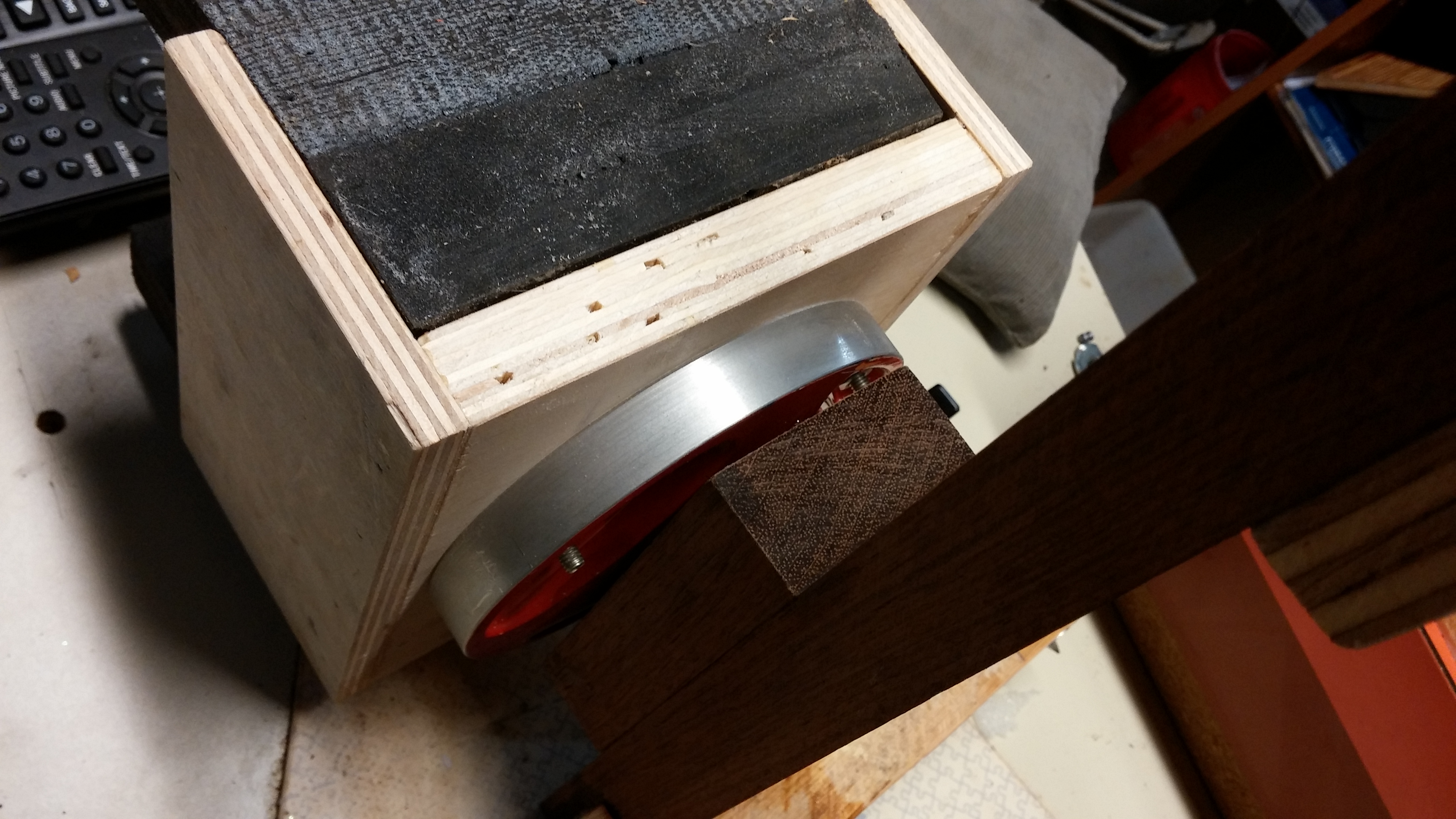

been shooting several springers off a solid bench for the last yew years at paper targets, i probably built 20 different front rest, could fill 3 or 4 buckets of them that did not prove much i disposed of or took apart and kept making different ones over the years, i have been hearing the most about the roller type i made some of them using the paint roller to a machined roller with a v in it ect wrapped in different densities of foam. the last one i made seems to work the best, been trying for a few weeks and with all the other rest shooting at 25yds 3/8 to 1/2" groups were here and there. nothing consistent, with this new front rest i can see consistency is there, once i figure how to post pics i will get them up, i will explain a bit how it is made, first off it swivels, just the top area mounted on a bearing the, top pc is 6" long 5" wide pc of 3/4 plywood then put a pc of 3/8" plywood 3" x 6" on each side of the 6" side of the plywood, flush with the bottom, you now have a channel pc, i found some 1" thick foam at a local foam store, it is rather stiff, i cut 2 pcs 5 1/8" wide x 5 1/8" sq, but a v in the foam about 2 in deep x 3" wide at the top. you now have to pcs the same, reason for 5 1/8" dimension is put some super glue on the side of each pc of foam and put them in the channel it will fit tight on each end, i put he top pc on a old front rest i have around, when you set the gun in the V if the foam is too soft the gun will sag in the foam, my hw97k barley sags, the idea is when the gun goes off the foam pcs move freely fore and aft during the shot, reason the bearing to swivel is when aiming from target to target moving side to side, you are not forcing the foam to flex after the shot the swiveling will keep side tension the same all the time, in the last few weeks i have shot some of the better and more consistent groups with this set up so far, hope i can figure how to post pics if not, i can send a pic by email

Chet

Chet