Greetings Airgunners!

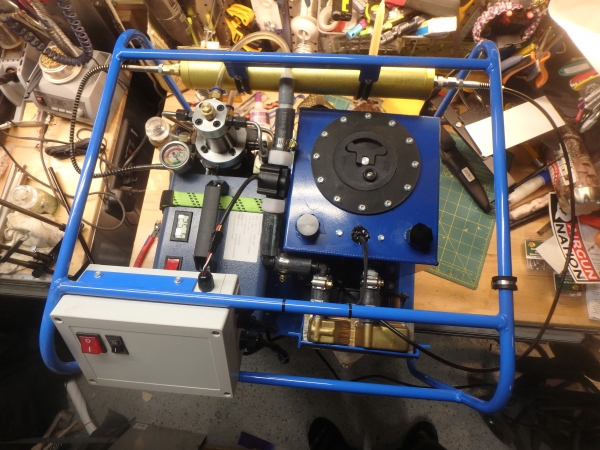

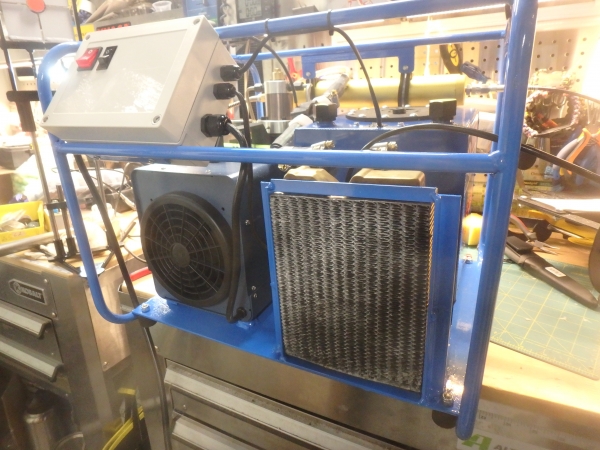

Like many of us, my air gun interests inevitably lead me down the PCP path, and that means a ready air source. I used my local dive shop here in Central Kalifornia but, as with most things here in the Golden State, the costs add up pretty quick. They where charging me $20 a fill and with regular shooting, filling guns for friends, etc. it started to add up. I watched the Yong Heng reviews with interest and eventually got myself one, just a simple 110VAC non shutoff model. I paid $200 including delivery and then when I complained about the collapsed vinyl cooling lines they gave me $20 bucks back, so all in, I spent $180 on the pump. I set it up initially with the 5 gallon bucket and the supplied pump and quickly found that filling my 97 cubic foot bottles took forever because I kept hitting the temp limit. I really didn't like the "open cooling system" either so I drew this guy up in CAD and fabbed up a frame to mount everything to. I used a 2.5 gallon aluminum dragster fuel tank for water storage and expansion (helps the thermal mass too!), a heater core from an Chevy Cavalier (I bought it years ago to build a TIG torch cooler but never used it), a high flow muffin fan, and a pump that flows 400 GPH (3 times the size of the one provided). So the water flows out of the tank, into the radiator (heater core), through a flow meter (eventually to be used as a layer of automated safety) and then through the cylinder head, and back into the tank. Currently I'm using plain water with water wetter as the coolant. I'm calling this level of build Phase 1, not sure if I'll ever do Phase 2 cause it works so darn well now. Temp on the cylinder head never exceeds 58 degrees C and it can run for hours (first fill was 2 97 Cubic foot cylinders from 1000 psi to 4500, it took a while). The fuel tank (filled with water) was only $80 bucks on Amazon, but they wouldn't ship it to Kalifornia because "God Forbid" you build a damn race car or otherwise cause an ecological disaster. Had it shipped to my Son, in Wisconsin (where they still have a modicum of sanity) and he shipped it to me. So yes, I'm a fuel tank smuggler now. Anyways I really like building stuff and this kept me out of the bars for a bit, and turned out pretty nice. Big thanks to the guys at Airguns of Arizona for the stickers! The frame is fabricated out of 1/2" steel tubing we had left over from a job and the plate that everything mounts to is 1/8" steel. The pump is trapped in place using bits of 3/4" angle and a heavy duty elastic strap. The compressor can be pulled out in seconds allowing for easy service or replacement. I would like to build a fill manifold for it to keep the filter/separator pressurized all the time while allowing the water to be purged at the pump and the fill line to be discharged. If you know where I can find some decent needle valves in 1/8 BSPP and rated for 5000 PSI I would really appreciate a heads up.

Like many of us, my air gun interests inevitably lead me down the PCP path, and that means a ready air source. I used my local dive shop here in Central Kalifornia but, as with most things here in the Golden State, the costs add up pretty quick. They where charging me $20 a fill and with regular shooting, filling guns for friends, etc. it started to add up. I watched the Yong Heng reviews with interest and eventually got myself one, just a simple 110VAC non shutoff model. I paid $200 including delivery and then when I complained about the collapsed vinyl cooling lines they gave me $20 bucks back, so all in, I spent $180 on the pump. I set it up initially with the 5 gallon bucket and the supplied pump and quickly found that filling my 97 cubic foot bottles took forever because I kept hitting the temp limit. I really didn't like the "open cooling system" either so I drew this guy up in CAD and fabbed up a frame to mount everything to. I used a 2.5 gallon aluminum dragster fuel tank for water storage and expansion (helps the thermal mass too!), a heater core from an Chevy Cavalier (I bought it years ago to build a TIG torch cooler but never used it), a high flow muffin fan, and a pump that flows 400 GPH (3 times the size of the one provided). So the water flows out of the tank, into the radiator (heater core), through a flow meter (eventually to be used as a layer of automated safety) and then through the cylinder head, and back into the tank. Currently I'm using plain water with water wetter as the coolant. I'm calling this level of build Phase 1, not sure if I'll ever do Phase 2 cause it works so darn well now. Temp on the cylinder head never exceeds 58 degrees C and it can run for hours (first fill was 2 97 Cubic foot cylinders from 1000 psi to 4500, it took a while). The fuel tank (filled with water) was only $80 bucks on Amazon, but they wouldn't ship it to Kalifornia because "God Forbid" you build a damn race car or otherwise cause an ecological disaster. Had it shipped to my Son, in Wisconsin (where they still have a modicum of sanity) and he shipped it to me. So yes, I'm a fuel tank smuggler now. Anyways I really like building stuff and this kept me out of the bars for a bit, and turned out pretty nice. Big thanks to the guys at Airguns of Arizona for the stickers! The frame is fabricated out of 1/2" steel tubing we had left over from a job and the plate that everything mounts to is 1/8" steel. The pump is trapped in place using bits of 3/4" angle and a heavy duty elastic strap. The compressor can be pulled out in seconds allowing for easy service or replacement. I would like to build a fill manifold for it to keep the filter/separator pressurized all the time while allowing the water to be purged at the pump and the fill line to be discharged. If you know where I can find some decent needle valves in 1/8 BSPP and rated for 5000 PSI I would really appreciate a heads up.