Okay guys I wanted to compile the O ring dimensions used on the Notos since I couldn't find a schematic. If there is one available please post it here.

In installing the plenum I was told by the plenum seller to check barrel o rings cause my FPS was lower than it should be. I found one article listing what size for OUTER o rings to get and I ordered them.

They arrived and look like this

The two vertical are OEM and others are O Ring Store. You can see the OEM are bigger ID. Yes OEM might be stretched but they definitely were chewed up from the factory hence FPS loss.

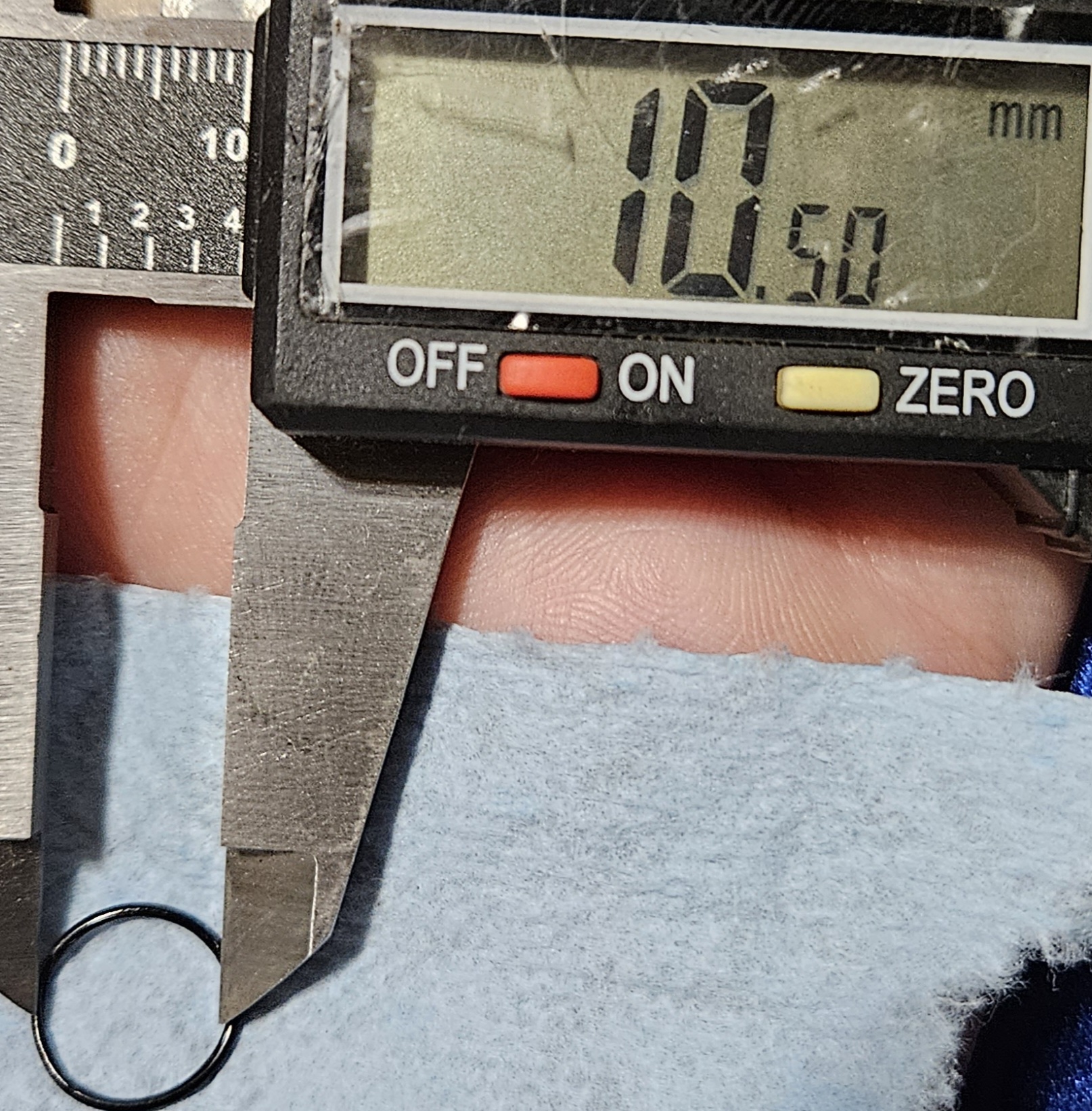

I measured the OUTER 2 barrel o rings here:

ID

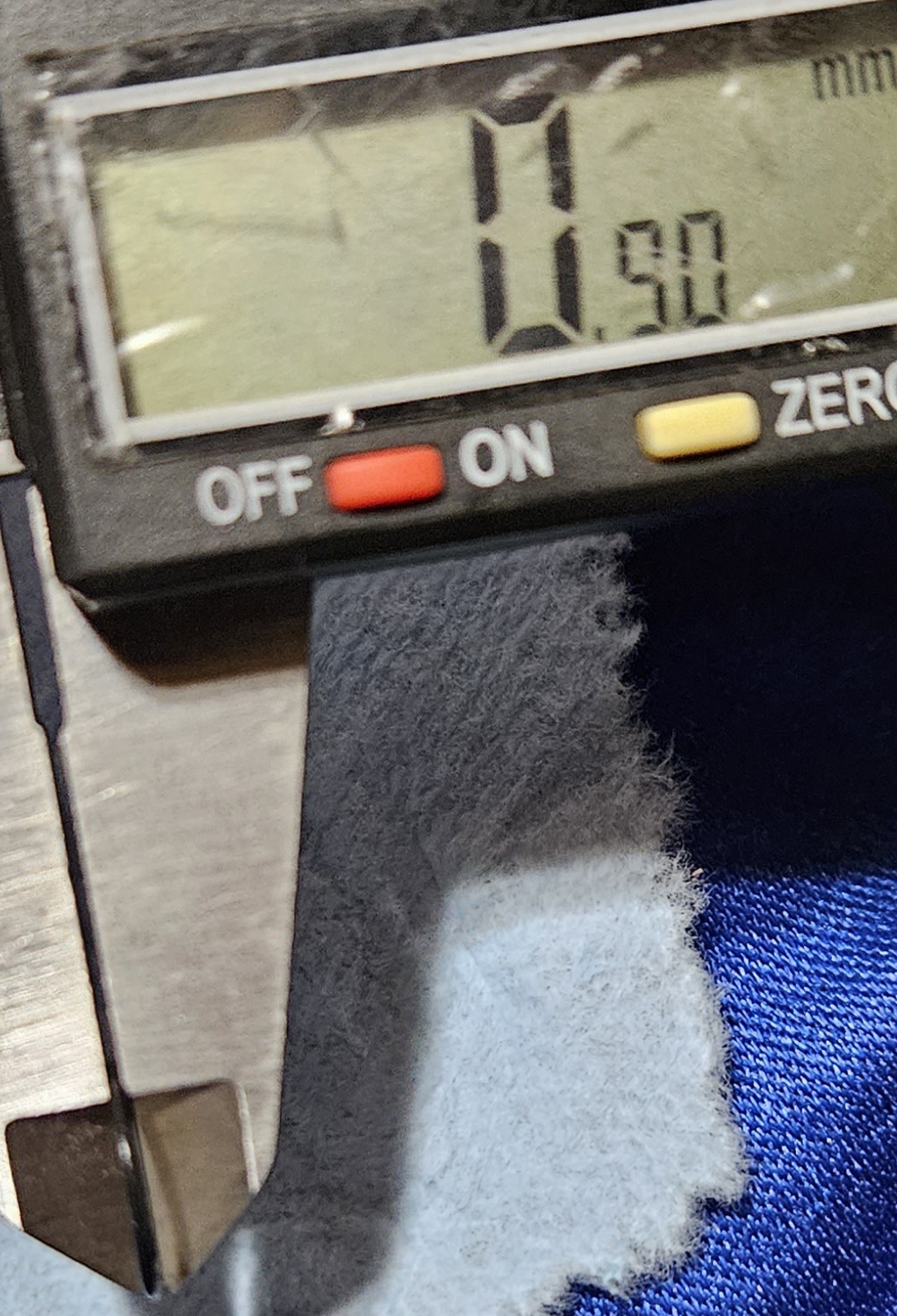

Thickness: 0.90mm

And OD

Okay then I took out the INNER 1 barrel o ring and measured that

ID

Thickness

OD

If someone got different results let me know I'm not a machinist just a casual caliper owner lol

Please post the rest of the O ring sizes for whomever to use so we can keep these awesome Notos's shooting strong!

In installing the plenum I was told by the plenum seller to check barrel o rings cause my FPS was lower than it should be. I found one article listing what size for OUTER o rings to get and I ordered them.

Notos barrel o-rings - Airguns & Guns Forum

Notos barrel o-rings , Air guns, Airgun Forum

www.gatewaytoairguns.org

They arrived and look like this

The two vertical are OEM and others are O Ring Store. You can see the OEM are bigger ID. Yes OEM might be stretched but they definitely were chewed up from the factory hence FPS loss.

I measured the OUTER 2 barrel o rings here:

ID

Thickness: 0.90mm

And OD

Okay then I took out the INNER 1 barrel o ring and measured that

ID

Thickness

OD

If someone got different results let me know I'm not a machinist just a casual caliper owner lol

Please post the rest of the O ring sizes for whomever to use so we can keep these awesome Notos's shooting strong!