G

Guest

Guest

PART ONE

PART TWO

PART THREE

PART FOUR

PART FIVE

PLEASE NOTE: If there is anyone here who can show me that it is possible for two pellets having any difference in their external dimensions can roll on the same curve. I would greatly appreciate the information. I've been working on that for three days and I just keep proving it can't happen. There has to be something I am missing.

Summary to date:

If you want to bypass the reading there is a video here showing the machine

https://www.youtube.com/watch?v=M0LYlFFcAHQ

and a video here explaining the write up below.

https://www.youtube.com/watch?v=KLUvpbSzS1g

In part one I set up a test bed and a "rolling machine", selected the pellet to test, collected some data at 25 meters on my outdoor range, and proved the accuracy of the rifle used in the test was sufficient to measure any statistically significant improvement in group size. At the end of that series of targets I concluded that indoor testing would remove the "noise" of wind drift and scheduled a session at the "basement", which is a 25 yard indoor range to which I have access.

In part two I shot test groups and collected data which led to results which clearly indicated I was not measuring any statistically significant improvement in the test groups relative to the control group and again PROVED the accuracy of the rifle used in the test is sufficient to measure any statistically significant change in group size. The data showed no statistically significant improvement in the test groups. I established the "rolling machine" did indeed sort pellets by some criteria and there was discussion of what that might be but no conclusive proof of what characteristic of the pellet was indeed being sorted by the machine. The question was asked, "What exactly are we measuring?" The quality of the test machine was questioned and I resolved to rebuild the machine to improve selectivity.

In this part I answer the question, "What does the machine discriminate upon?". I have studied the machine. After all if we don't know what we are measuring, the result always will be meaningless. To that end I collected the following data:

Test One ~~ Does the new machine work?

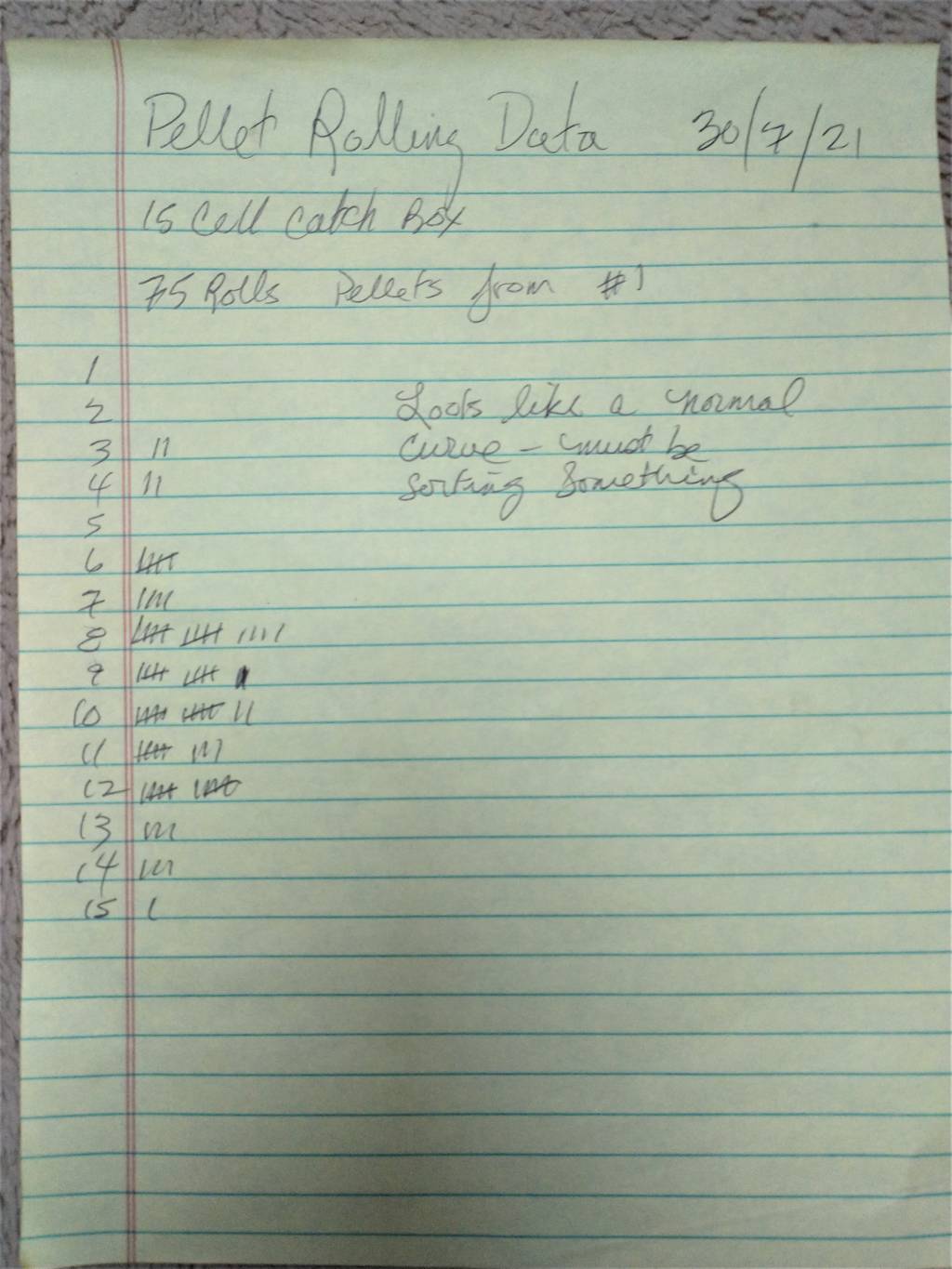

I rebuilt the test machine and increased the number of "cells" in the catch box of the machine to 15 with the hope of improving its selectivity. I chose pellets which were already sorted on the first machine and fell into group #1 (the most central group). I rolled 75 of those pellets on the new machine. I observed a normal curve. This proves the test machine is sorting something. The question though is "why do pellets which have already been sorted once, fall into a normal curve on the new machine?" Part of the answer to that question is obvious. There are more cells in the new catch box and they are narrower, naturally they will be separated more. That was the objective, higher selectivity. But the distance across which they spread was significantly larger than the original cell into which they were sorted. Here is a page of notes I took at that time:

Test Two ~~ How accurate is the machine?

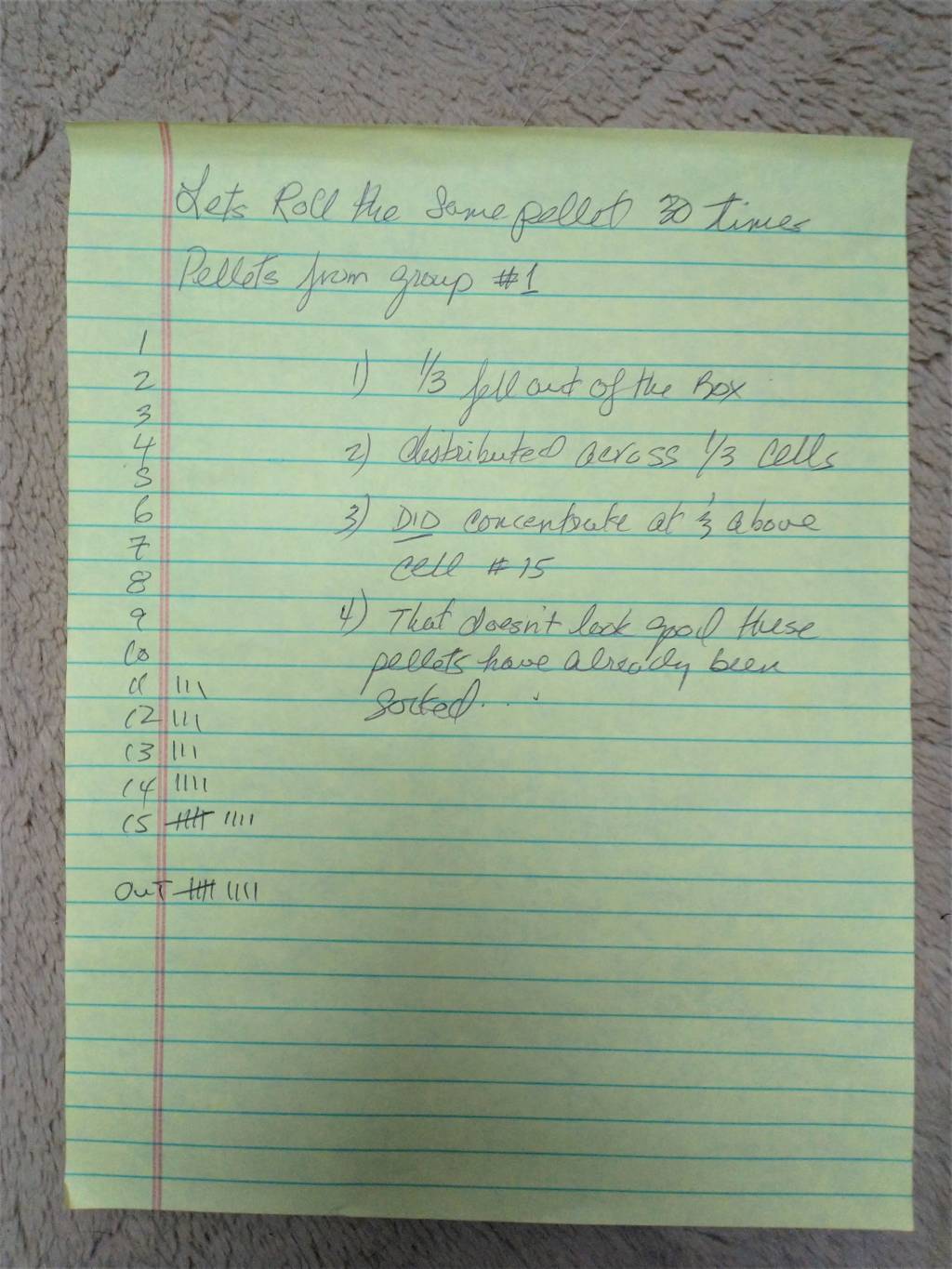

Clearly something was amiss and a theory emerged. I decided to roll the same pellet 30 times to discover how the rolling machine was performing. I selected one at random from the original test sort #1. It rolled "long" about a third of the time but again we see in my note page that a normal curve was forming. That single pellet did not consistently land in the same cell? Here are the notes I took on that test.

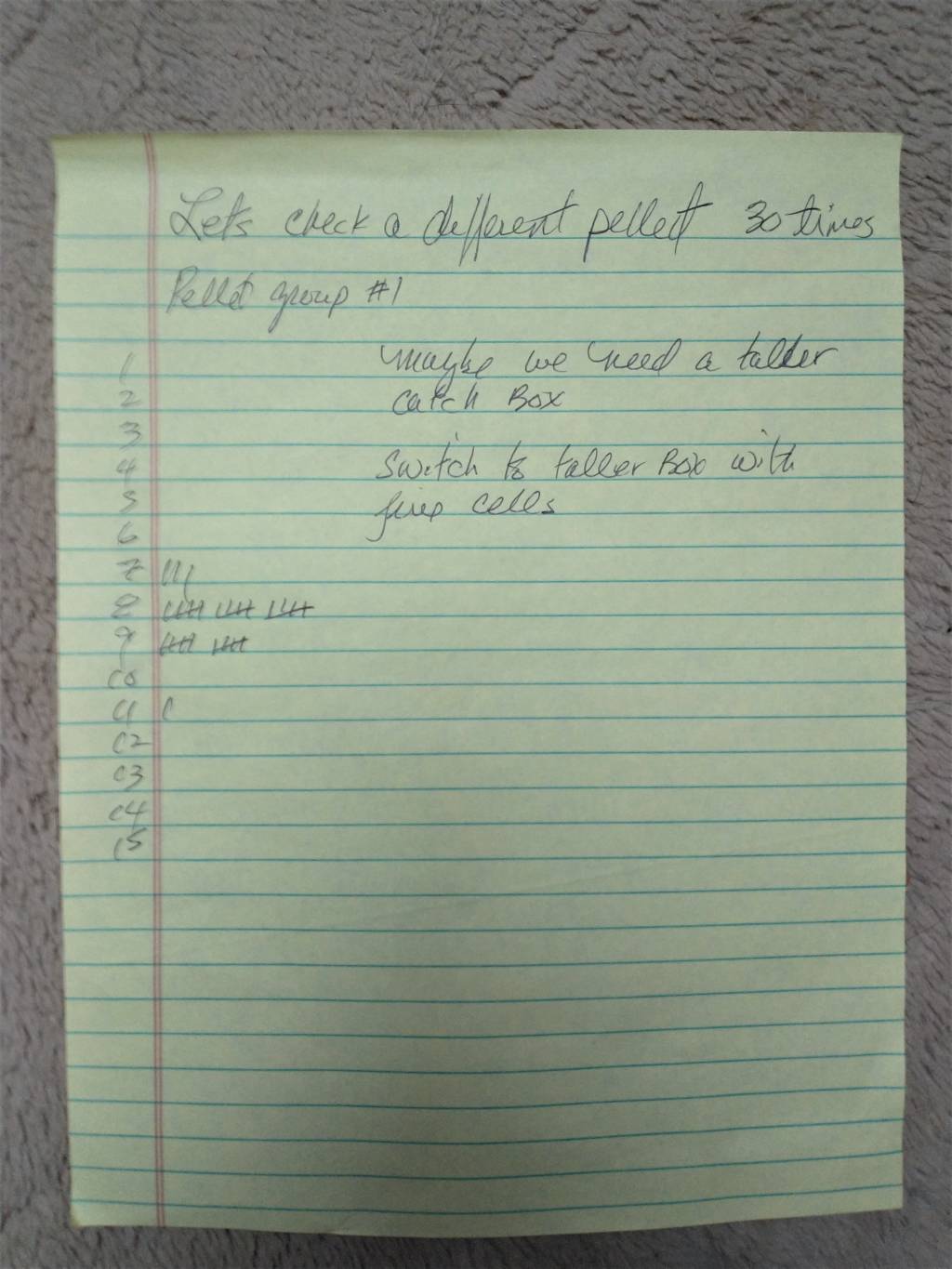

I was not happy with the fact that the pellet under test above fell past the catch box so many times and so ran that test again with a different pellet from test group #1. I selected the new pellet in order to ensure it fell towards the middle of the catch box. I then rolled that pellet 30 times. This I did because I wanted to confirm the above result. The pellet fell into four different cells in this test in what appears to be a normal curve. Here is that page of notes:

Test Three ~~ Is there a problem with the catch box?

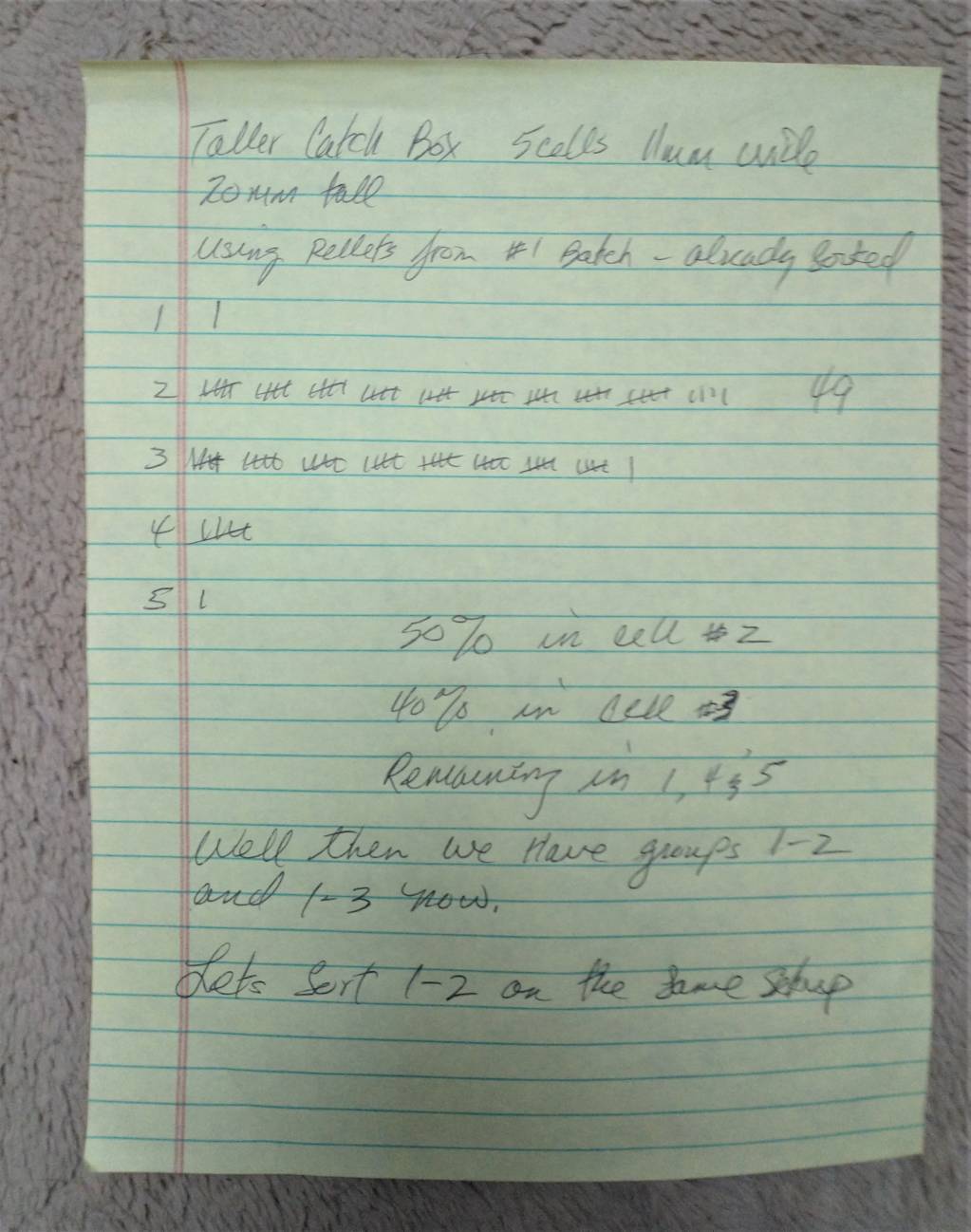

These results prompted me to replace the 15 cell catch box which was 10mm high with a 5 cell catch box which was 20 mm high. I did this to reduce the fall distance from the edge of the rolling table to the top of the catch box. I surmised the scattering I observed might be due to that drop. At this point I needed to establish a new control because I had again changed the machine. Using all the pellets from test group #1 (the original sorted group) I rolled 97 pellets into the new catch box. NOTE: These pellets were already sorted once on the first iteration of the machine. They should be similar. I kept notes and here is that page of notes. You will observe that ~50% of those pellets fell into cell number #2 and ~40% of those fell into cell #3. This gives us two new sorted groups, one of 49 pellets named 1-2 and one of 41 pellets 1-3.

Test Four ~~ Lets sort pellets we have already sorted (BECAUSE SCIENCE, RIGHT?)

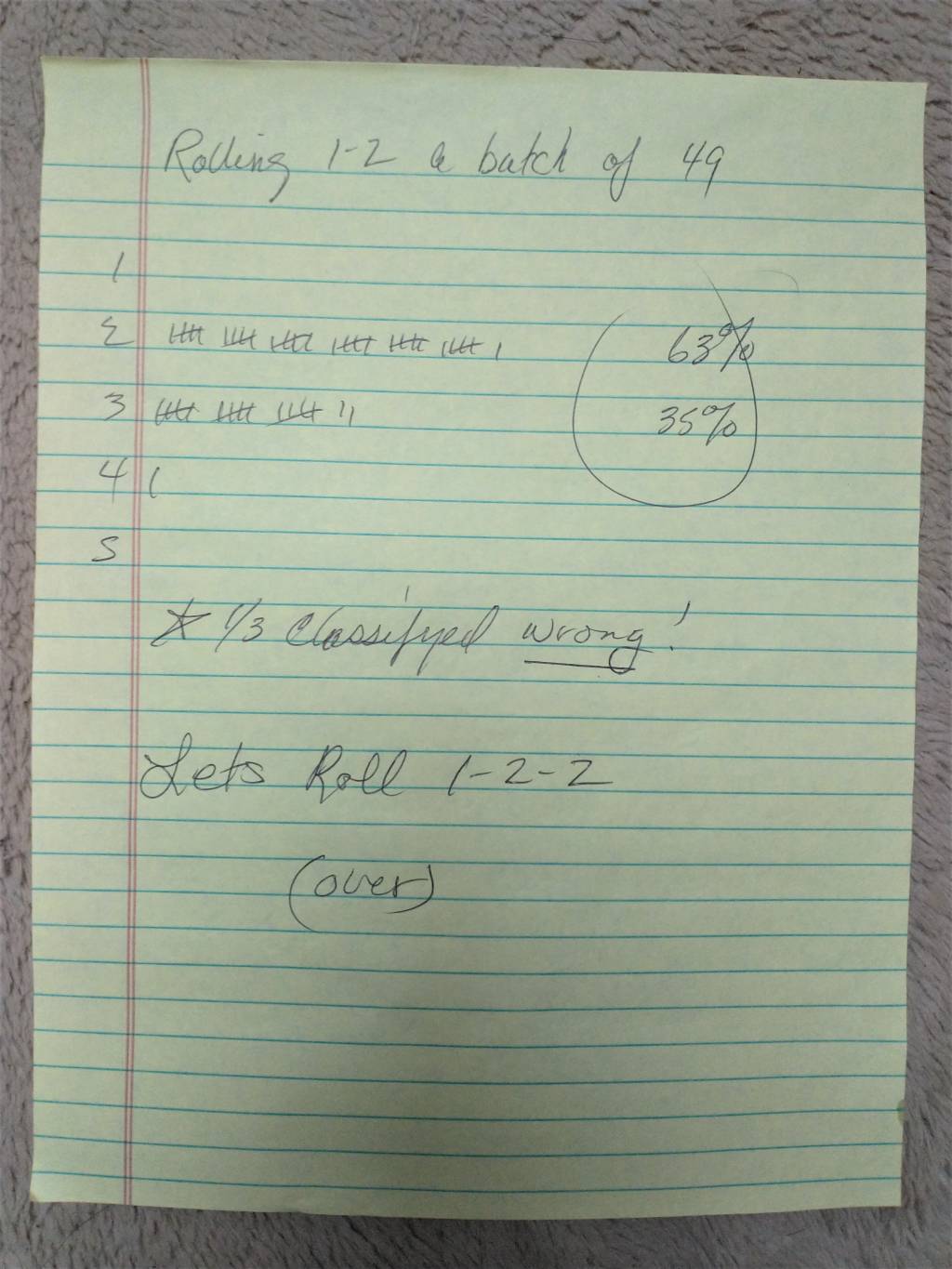

So I selected the pellets from group 1-2 which have now been sorted twice. Once on the original machine and once on this exact setup. We want to know if the machine really is sorting pellets. They should all fall into the same cell they fell into above. This will give us an idea how well we are actually sorting pellets. Here is the result of that test.

What do you know? Pellets which, by all which is reasonable, should have fallen into cell number 2 instead fell into TWO cells. How can this be?

Test Five ~~ Lets do that again, we like punishment, master

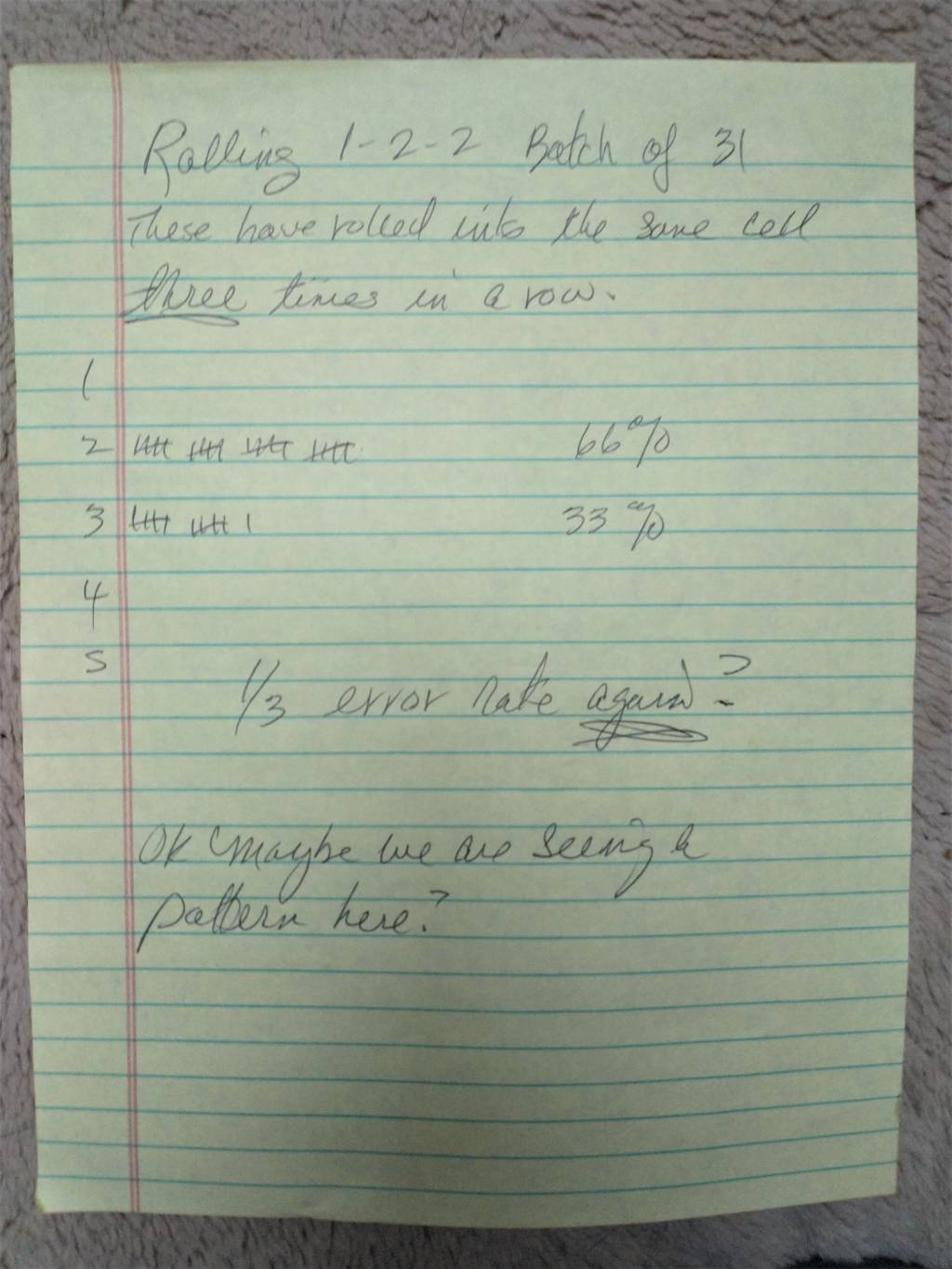

So I collected the pellets and called that group 1-2-2. That means the pellets I am about to roll have been sorted three times and three times all of these pellets have landed in the same group:

My, my, isn't that interesting?

Test six ~~ Hit me beat me, make me feel cheap

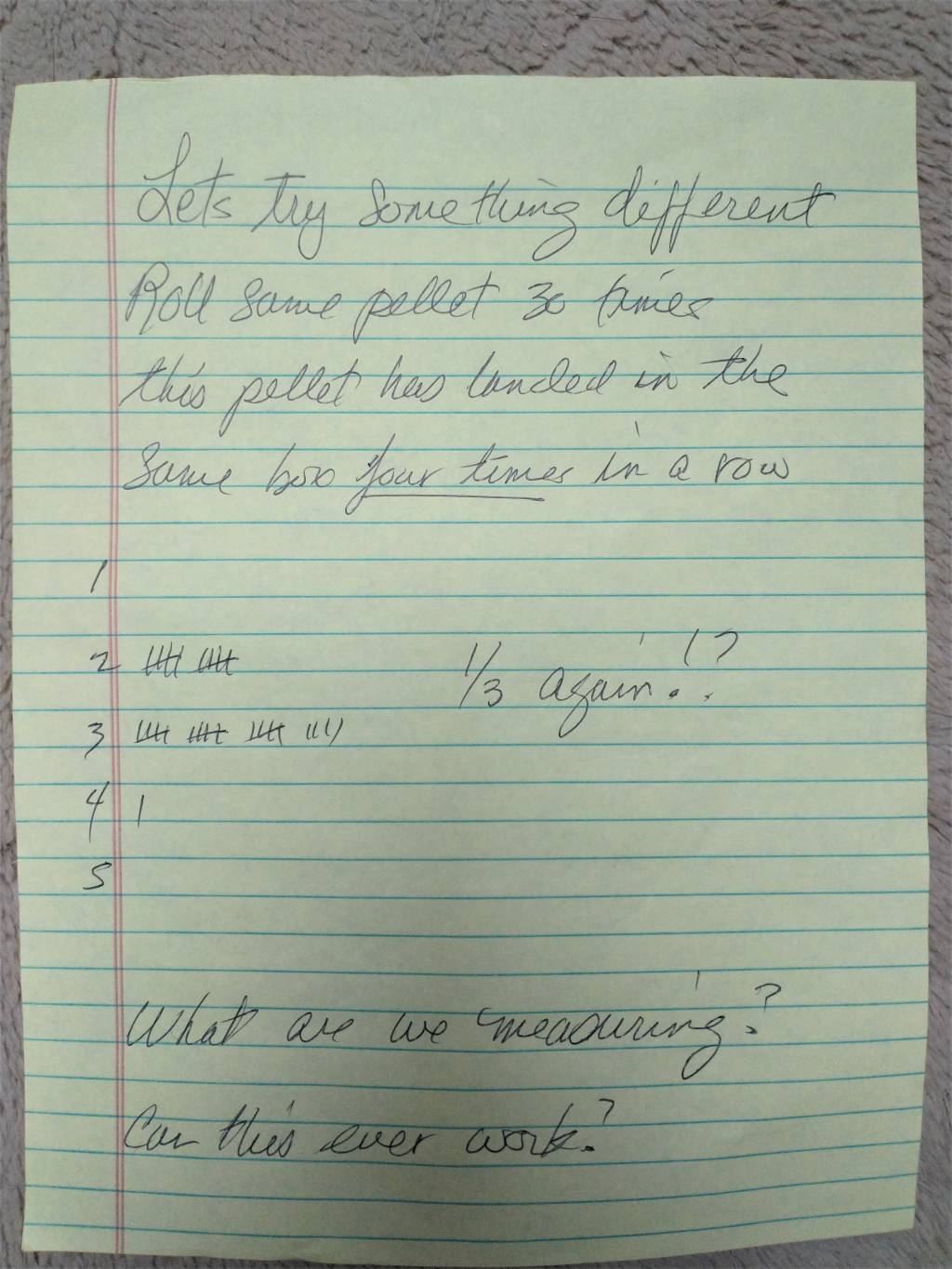

Let's roll a single pellet which has fallen into the same cell four (4), that's FOUR, times in a row. Let's to that 30 times just to make sure we have a REASONABLE statistical sample.

Does it fall into the same cell every time?

Nope, master, I am a pathetic worm. I have failed.

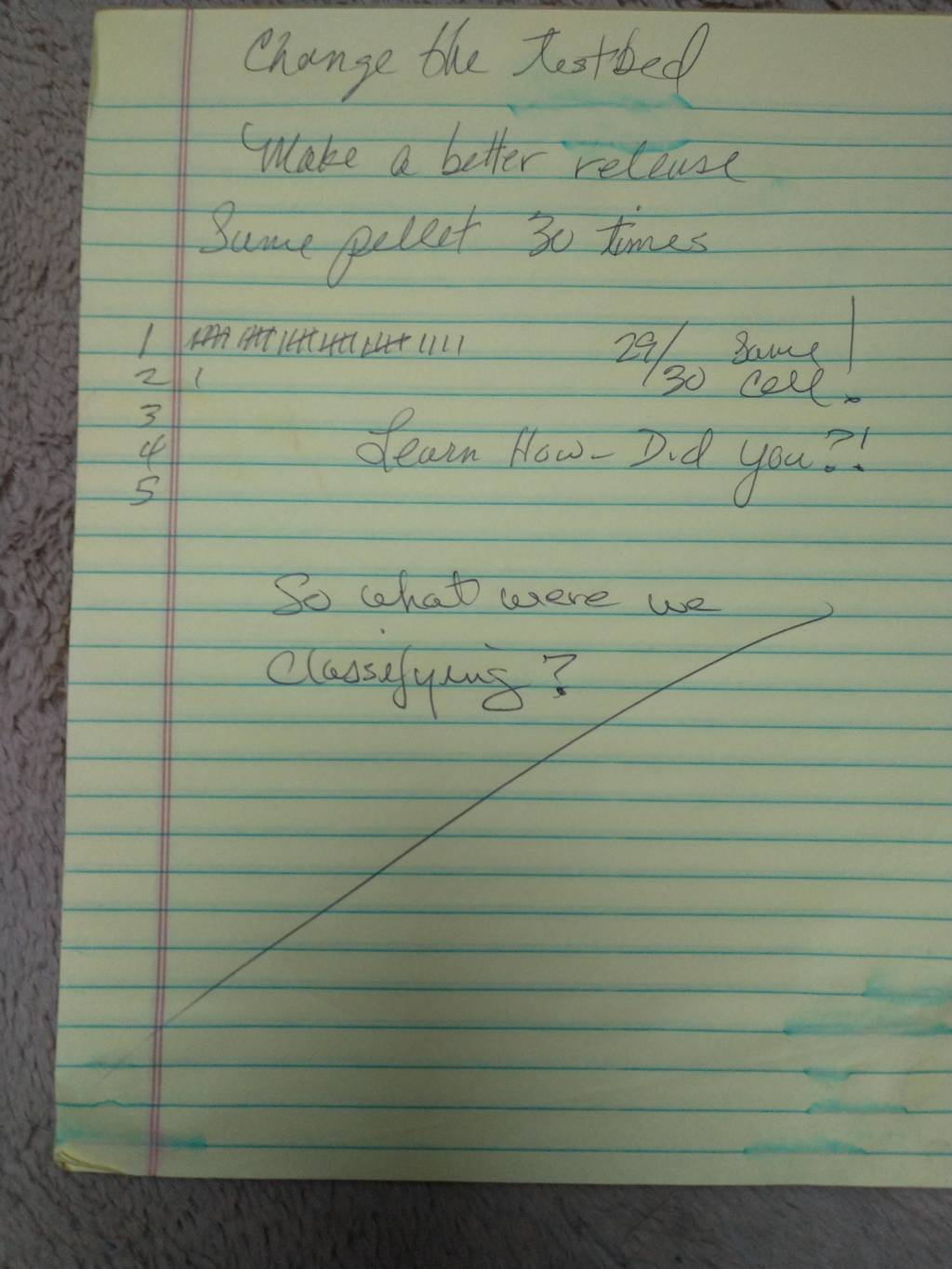

Test seven ~~ Did you learn how to roll the pellet before you decided to use the machine?

It turns out that is a fair question. If you didn't, you were measuring how consistently you could roll a pellet... That's what this test measures as configured and commonly done. If you didn't take the time to LEARN how to put the same pellet in the same hole almost every time you were simply classifying pellets based upon how well you could roll them. To get valid data with this test machine a MECHANICAL release mechanism is almost mandatory.

Here is your sign (for those of you who have made up your minds already... and I don't mean YOU)

More will follow and be linked here when it does.

Have a truly beautiful day.

PART TWO

PART THREE

PART FOUR

PART FIVE

PLEASE NOTE: If there is anyone here who can show me that it is possible for two pellets having any difference in their external dimensions can roll on the same curve. I would greatly appreciate the information. I've been working on that for three days and I just keep proving it can't happen. There has to be something I am missing.

Summary to date:

If you want to bypass the reading there is a video here showing the machine

https://www.youtube.com/watch?v=M0LYlFFcAHQ

and a video here explaining the write up below.

https://www.youtube.com/watch?v=KLUvpbSzS1g

In part one I set up a test bed and a "rolling machine", selected the pellet to test, collected some data at 25 meters on my outdoor range, and proved the accuracy of the rifle used in the test was sufficient to measure any statistically significant improvement in group size. At the end of that series of targets I concluded that indoor testing would remove the "noise" of wind drift and scheduled a session at the "basement", which is a 25 yard indoor range to which I have access.

In part two I shot test groups and collected data which led to results which clearly indicated I was not measuring any statistically significant improvement in the test groups relative to the control group and again PROVED the accuracy of the rifle used in the test is sufficient to measure any statistically significant change in group size. The data showed no statistically significant improvement in the test groups. I established the "rolling machine" did indeed sort pellets by some criteria and there was discussion of what that might be but no conclusive proof of what characteristic of the pellet was indeed being sorted by the machine. The question was asked, "What exactly are we measuring?" The quality of the test machine was questioned and I resolved to rebuild the machine to improve selectivity.

In this part I answer the question, "What does the machine discriminate upon?". I have studied the machine. After all if we don't know what we are measuring, the result always will be meaningless. To that end I collected the following data:

Test One ~~ Does the new machine work?

I rebuilt the test machine and increased the number of "cells" in the catch box of the machine to 15 with the hope of improving its selectivity. I chose pellets which were already sorted on the first machine and fell into group #1 (the most central group). I rolled 75 of those pellets on the new machine. I observed a normal curve. This proves the test machine is sorting something. The question though is "why do pellets which have already been sorted once, fall into a normal curve on the new machine?" Part of the answer to that question is obvious. There are more cells in the new catch box and they are narrower, naturally they will be separated more. That was the objective, higher selectivity. But the distance across which they spread was significantly larger than the original cell into which they were sorted. Here is a page of notes I took at that time:

Test Two ~~ How accurate is the machine?

Clearly something was amiss and a theory emerged. I decided to roll the same pellet 30 times to discover how the rolling machine was performing. I selected one at random from the original test sort #1. It rolled "long" about a third of the time but again we see in my note page that a normal curve was forming. That single pellet did not consistently land in the same cell? Here are the notes I took on that test.

I was not happy with the fact that the pellet under test above fell past the catch box so many times and so ran that test again with a different pellet from test group #1. I selected the new pellet in order to ensure it fell towards the middle of the catch box. I then rolled that pellet 30 times. This I did because I wanted to confirm the above result. The pellet fell into four different cells in this test in what appears to be a normal curve. Here is that page of notes:

Test Three ~~ Is there a problem with the catch box?

These results prompted me to replace the 15 cell catch box which was 10mm high with a 5 cell catch box which was 20 mm high. I did this to reduce the fall distance from the edge of the rolling table to the top of the catch box. I surmised the scattering I observed might be due to that drop. At this point I needed to establish a new control because I had again changed the machine. Using all the pellets from test group #1 (the original sorted group) I rolled 97 pellets into the new catch box. NOTE: These pellets were already sorted once on the first iteration of the machine. They should be similar. I kept notes and here is that page of notes. You will observe that ~50% of those pellets fell into cell number #2 and ~40% of those fell into cell #3. This gives us two new sorted groups, one of 49 pellets named 1-2 and one of 41 pellets 1-3.

Test Four ~~ Lets sort pellets we have already sorted (BECAUSE SCIENCE, RIGHT?)

So I selected the pellets from group 1-2 which have now been sorted twice. Once on the original machine and once on this exact setup. We want to know if the machine really is sorting pellets. They should all fall into the same cell they fell into above. This will give us an idea how well we are actually sorting pellets. Here is the result of that test.

What do you know? Pellets which, by all which is reasonable, should have fallen into cell number 2 instead fell into TWO cells. How can this be?

Test Five ~~ Lets do that again, we like punishment, master

So I collected the pellets and called that group 1-2-2. That means the pellets I am about to roll have been sorted three times and three times all of these pellets have landed in the same group:

My, my, isn't that interesting?

Test six ~~ Hit me beat me, make me feel cheap

Let's roll a single pellet which has fallen into the same cell four (4), that's FOUR, times in a row. Let's to that 30 times just to make sure we have a REASONABLE statistical sample.

Does it fall into the same cell every time?

Nope, master, I am a pathetic worm. I have failed.

Test seven ~~ Did you learn how to roll the pellet before you decided to use the machine?

It turns out that is a fair question. If you didn't, you were measuring how consistently you could roll a pellet... That's what this test measures as configured and commonly done. If you didn't take the time to LEARN how to put the same pellet in the same hole almost every time you were simply classifying pellets based upon how well you could roll them. To get valid data with this test machine a MECHANICAL release mechanism is almost mandatory.

Here is your sign (for those of you who have made up your minds already... and I don't mean YOU)

More will follow and be linked here when it does.

Have a truly beautiful day.