Recently I got to thinking about shooting to ranges of 100 yards and the problems with pellet spiralling at the longer ranges, so I thought I would try to have a look at it for a couple of pellet designs.

The two pellet designs are JSB pellets, not because they have particularly bad problems, but because I happen to have most modelling data on those two. I started with the .177 10.3 grain Heavy pellet with its more cylindrical shape, which in previous studies had shown a tendency to increased yaw angles at longer ranges and higher speeds. I then scaled up the design to .22 to see what happened. The .22 pellet came out at 19.7 grains. I used a muzzle velocity of 950 ft/sec, simply because it seemed a reasonable starting point, and a barrel twist rate of one turn in 16 inches.

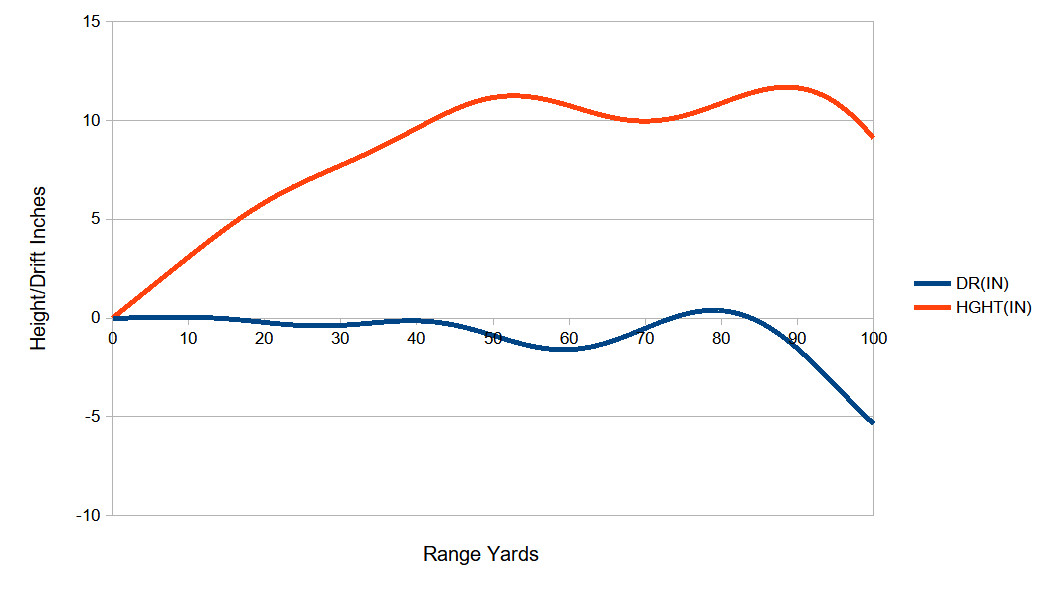

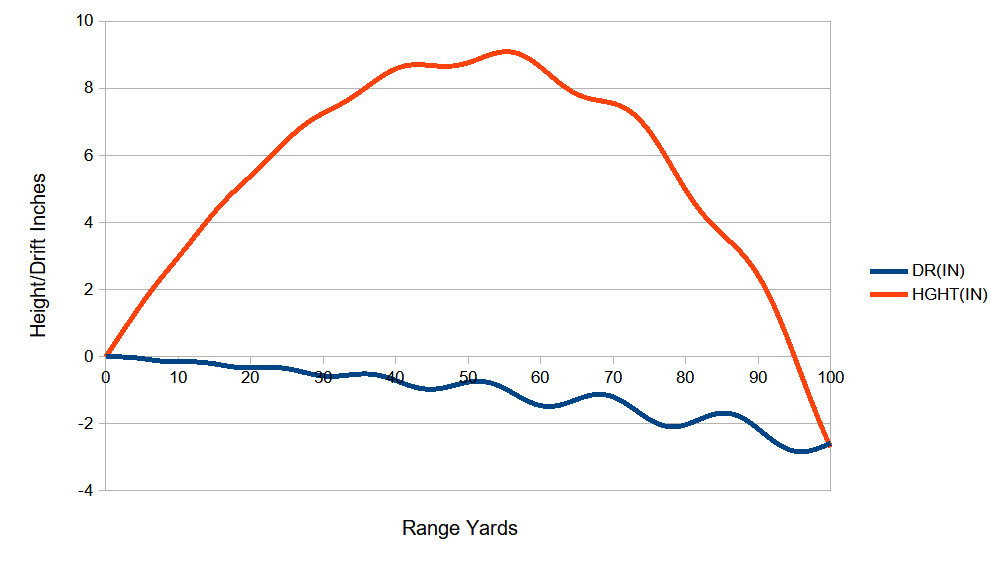

The predicted trajectory for the .22 calibre scaled up pellet is shown below.

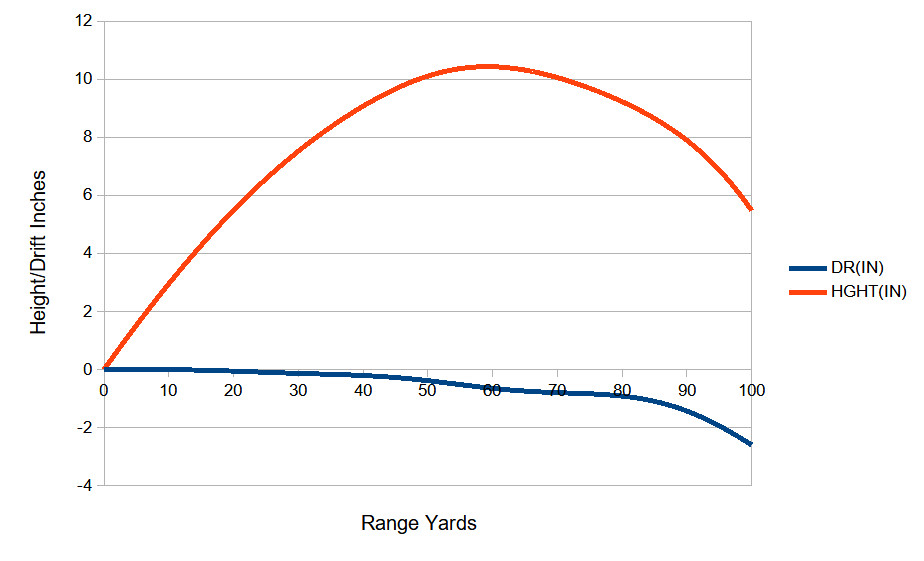

You can see there is definitely a problem showing up here. A perfect pellet of the same configuration and calibre fired perfectly from a gun will give the flight profile below.

Much better but still with apparent problems at long range.

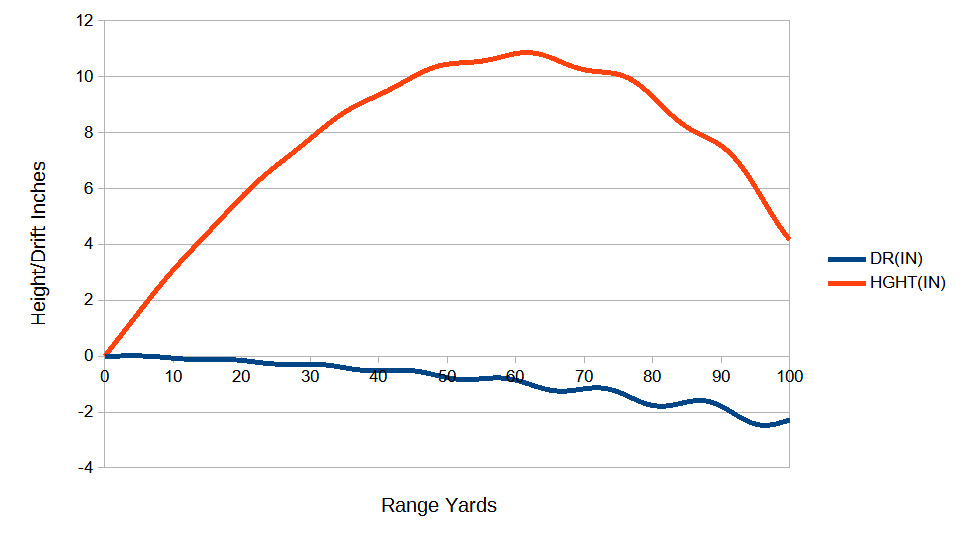

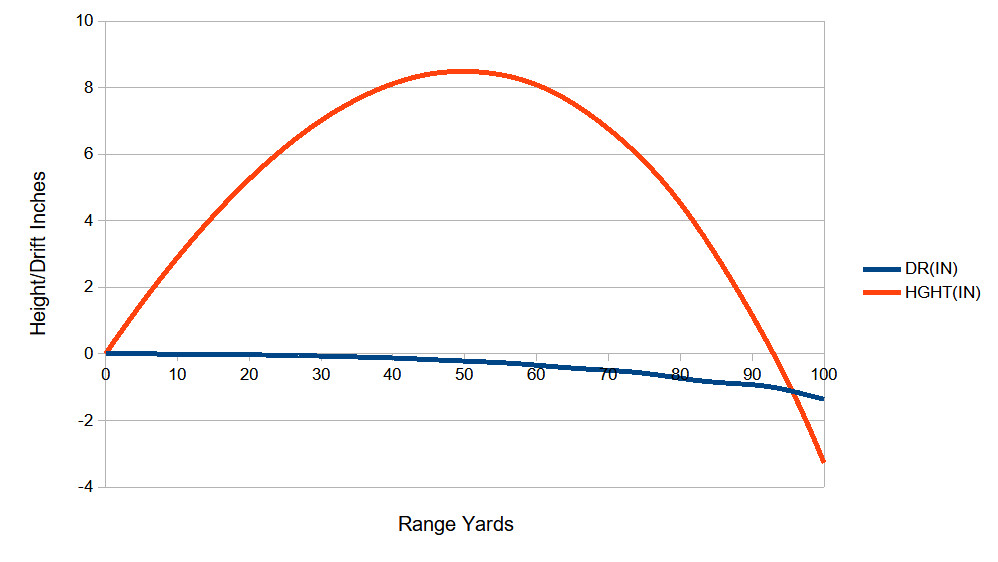

The next stage is to look if another pellet design acts the same. Data is available for the JSB 15.9 grain .22 pellet, so this one was modelled. The result is shown below with the same initial yaw rate.

The result is predicting much better behaviour, but there is still a tendency towards spiral type problems.

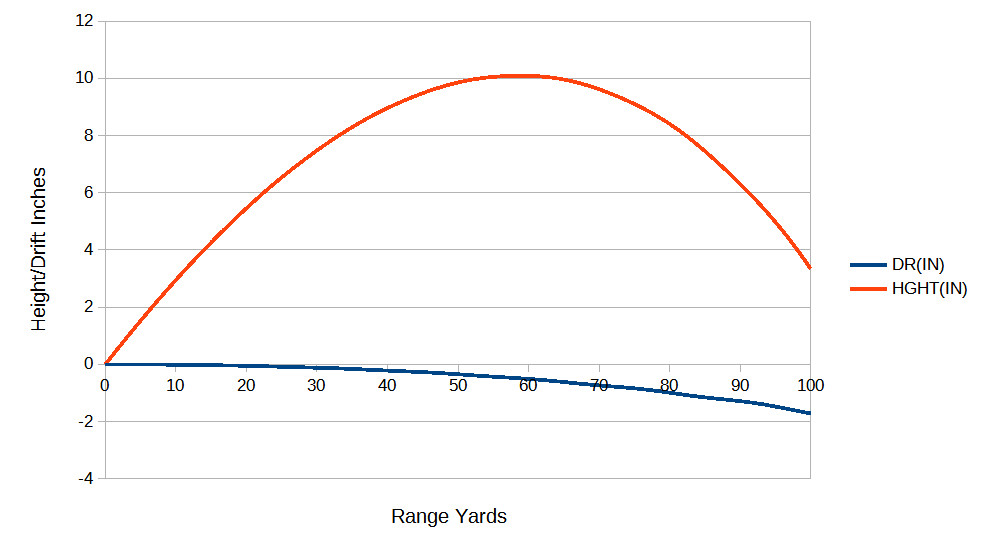

The result for a perfect pellet fired perfectly is shown below.

This round is showing acceptable behaviour.

The accepted way for reducing pellet spiralling at long ranges is to use lower twist rates and a reduced velocity. The improvements can be seen below where the .177 JSB Heavy has been fired at a muzzle velocity of 850 ft/sec from a barrel with a one turn in 32 inches twist rate. Previous trajectories had been modelled with a simple initial yaw rate for simplicity. As a problem had been suggested in the modelling using a simple yaw rate, a more complex system of pellet flaws was used from now on. The first diagram shows the predicted behaviour of a pellet with a CG offset from the pellet centreline and with a flat spot on the front facing part of the nose giving an asymmetry, i.e. a pellet with flaws.

The effects compared to the trajectory of the .22 calibre version at 950 ft/sec, with a 16 inch twist rate barrel and a simpler pellet flaw are much reduced but still present.

Using a perfect pellet with no flaws and a perfect barrel, the trajectory looks like this.

This is probably a usable trajectory, but there still seems to be possible problems as the range increases, and again hoping for a perfect pellet is not a good idea.

The problem with using guns with low twist barrels which are a perfect fit to your choice of pellets, and have lower muzzle velocities, is that changes to the gun are being used to try to solve what is basically a pellet problem. In addition, not everyone can afford a new gun or even a new barrel with the fitting costs, if they do not have the necessary skills or knowledge to do it themselves.

The cause of the problems with the pellets is two fold. One is the lack of dynamic stability, which enables pellet yaw angles to increase as the pellet flies down range. Secondly, as the ratio between the forward velocity and the pellet spin rate changes, it gives increases in gyroscopic stability which causes increased yaw wave lengths, i.e. it takes a longer distance for the pellet to go through a complete wobble which leads to the pellet moving away from its normal trajectory, leading to increased size spirals.

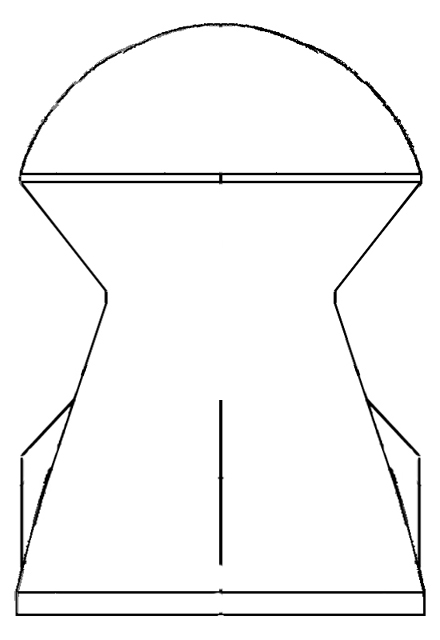

If increases in the pellet spin rate compared to the pellet forward velocity are what seems to be the major cause of problems, the logical answer is to make the spin rate slow down at a faster rate. This can be done in a number of ways, one of which is to add very small strakes to the sides of the pellet flare. A possible design would be like this one shown below, using in this case a JSB 15.9 grain .22 pellet as the basis.

There are four strakes on the pellet shown positioned evenly around the pellet flare. It is possible to estimate the approximate spin damping given by these strakes. No other effects of the strakes were taken into account.

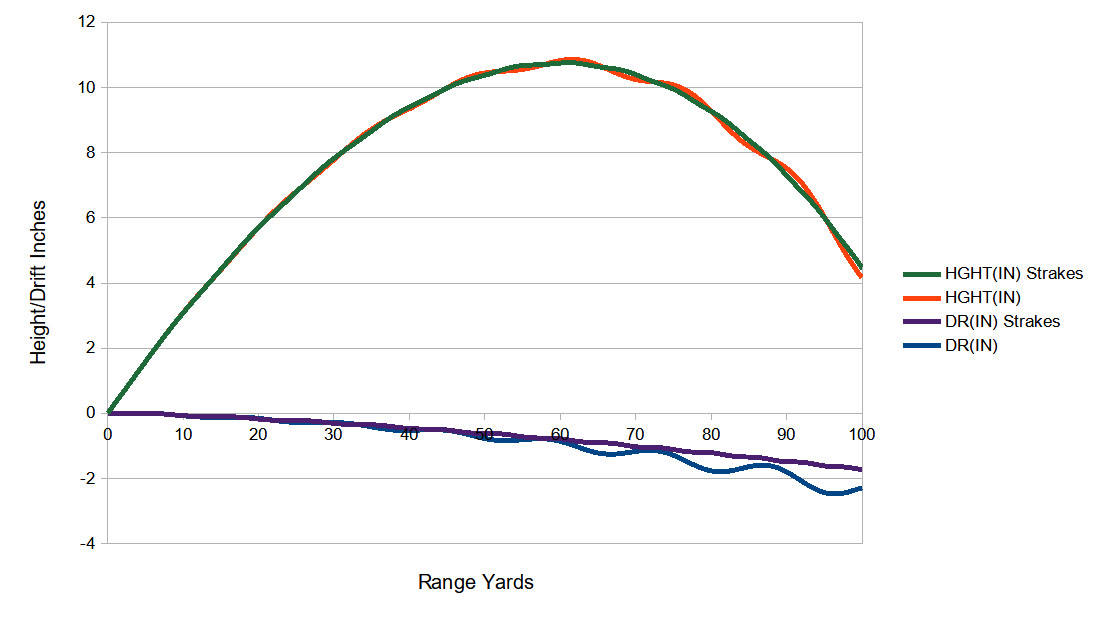

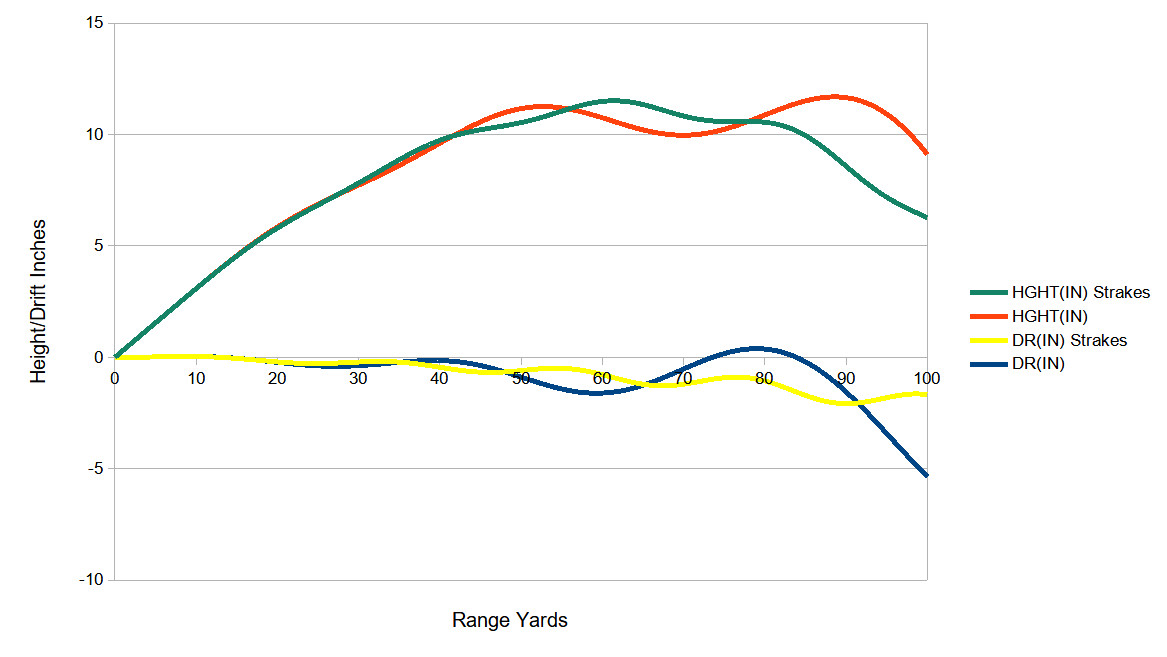

The resulting trajectory for the JSB 15.9 grain .22 pellet with the strakes and with the pellet flaws used in the modelling before are compared to the previous figure for this pellet fired without strakes. There is a large improvement with the almost complete elimination of spiral type behaviour.

The total effect can perhaps best be seen if we look at the trajectories from the back rather than the side view. The diagram below shows the trajectory as seen from behind the shooter.

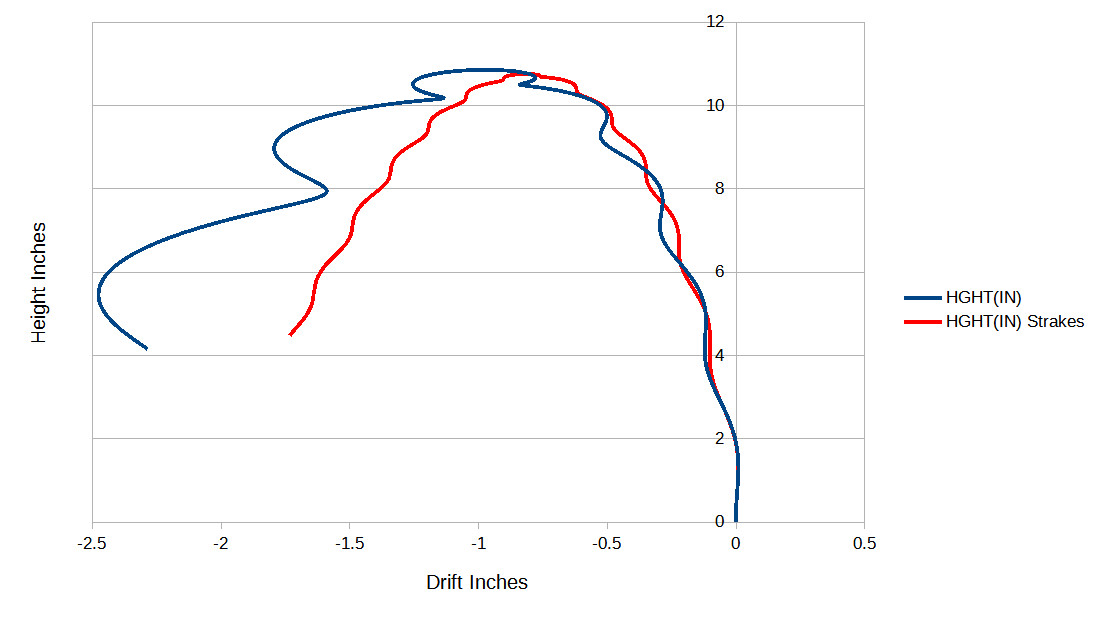

Since the strakes appeared to work on the 15.9 grain pellet, they were tried on the JSB Heavy pellet in .22 size. The resulting trajectory is shown below. There are still some spirals present, but they are much reduced compared to the same pellet without strakes.

Again, the effect can best be seen from behind the shooter.

These are the same sized strakes as used on the lighter pellet. Larger strakes could give additional spin damping and further reduced spirals.

The strakes modelled are just a first guess at the size needed and to see if it is possible to improve the pellet flight in this way. Much further modelling would be needed to optimize the strake size, position, angle to give fixed spin to forward velocity ratios and total effect. They will also increase the complication in making the pellets, but four strakes should be possible without too much difficulty. Strakes may not be the only way of increasing the spin damping.

As a first look at the possibilities, the strakes seem to show some promise, and the theory of increasing the spin damping appears to give benefits.

The two pellet designs are JSB pellets, not because they have particularly bad problems, but because I happen to have most modelling data on those two. I started with the .177 10.3 grain Heavy pellet with its more cylindrical shape, which in previous studies had shown a tendency to increased yaw angles at longer ranges and higher speeds. I then scaled up the design to .22 to see what happened. The .22 pellet came out at 19.7 grains. I used a muzzle velocity of 950 ft/sec, simply because it seemed a reasonable starting point, and a barrel twist rate of one turn in 16 inches.

The predicted trajectory for the .22 calibre scaled up pellet is shown below.

You can see there is definitely a problem showing up here. A perfect pellet of the same configuration and calibre fired perfectly from a gun will give the flight profile below.

Much better but still with apparent problems at long range.

The next stage is to look if another pellet design acts the same. Data is available for the JSB 15.9 grain .22 pellet, so this one was modelled. The result is shown below with the same initial yaw rate.

The result is predicting much better behaviour, but there is still a tendency towards spiral type problems.

The result for a perfect pellet fired perfectly is shown below.

This round is showing acceptable behaviour.

The accepted way for reducing pellet spiralling at long ranges is to use lower twist rates and a reduced velocity. The improvements can be seen below where the .177 JSB Heavy has been fired at a muzzle velocity of 850 ft/sec from a barrel with a one turn in 32 inches twist rate. Previous trajectories had been modelled with a simple initial yaw rate for simplicity. As a problem had been suggested in the modelling using a simple yaw rate, a more complex system of pellet flaws was used from now on. The first diagram shows the predicted behaviour of a pellet with a CG offset from the pellet centreline and with a flat spot on the front facing part of the nose giving an asymmetry, i.e. a pellet with flaws.

The effects compared to the trajectory of the .22 calibre version at 950 ft/sec, with a 16 inch twist rate barrel and a simpler pellet flaw are much reduced but still present.

Using a perfect pellet with no flaws and a perfect barrel, the trajectory looks like this.

This is probably a usable trajectory, but there still seems to be possible problems as the range increases, and again hoping for a perfect pellet is not a good idea.

The problem with using guns with low twist barrels which are a perfect fit to your choice of pellets, and have lower muzzle velocities, is that changes to the gun are being used to try to solve what is basically a pellet problem. In addition, not everyone can afford a new gun or even a new barrel with the fitting costs, if they do not have the necessary skills or knowledge to do it themselves.

The cause of the problems with the pellets is two fold. One is the lack of dynamic stability, which enables pellet yaw angles to increase as the pellet flies down range. Secondly, as the ratio between the forward velocity and the pellet spin rate changes, it gives increases in gyroscopic stability which causes increased yaw wave lengths, i.e. it takes a longer distance for the pellet to go through a complete wobble which leads to the pellet moving away from its normal trajectory, leading to increased size spirals.

If increases in the pellet spin rate compared to the pellet forward velocity are what seems to be the major cause of problems, the logical answer is to make the spin rate slow down at a faster rate. This can be done in a number of ways, one of which is to add very small strakes to the sides of the pellet flare. A possible design would be like this one shown below, using in this case a JSB 15.9 grain .22 pellet as the basis.

There are four strakes on the pellet shown positioned evenly around the pellet flare. It is possible to estimate the approximate spin damping given by these strakes. No other effects of the strakes were taken into account.

The resulting trajectory for the JSB 15.9 grain .22 pellet with the strakes and with the pellet flaws used in the modelling before are compared to the previous figure for this pellet fired without strakes. There is a large improvement with the almost complete elimination of spiral type behaviour.

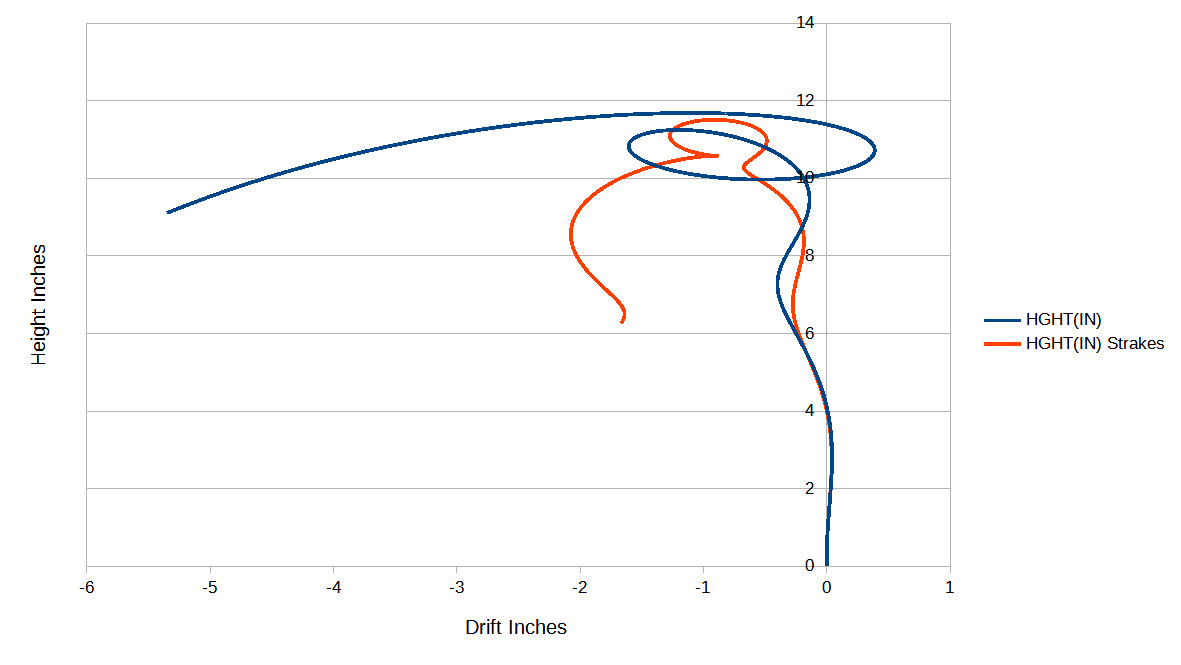

The total effect can perhaps best be seen if we look at the trajectories from the back rather than the side view. The diagram below shows the trajectory as seen from behind the shooter.

Since the strakes appeared to work on the 15.9 grain pellet, they were tried on the JSB Heavy pellet in .22 size. The resulting trajectory is shown below. There are still some spirals present, but they are much reduced compared to the same pellet without strakes.

Again, the effect can best be seen from behind the shooter.

These are the same sized strakes as used on the lighter pellet. Larger strakes could give additional spin damping and further reduced spirals.

The strakes modelled are just a first guess at the size needed and to see if it is possible to improve the pellet flight in this way. Much further modelling would be needed to optimize the strake size, position, angle to give fixed spin to forward velocity ratios and total effect. They will also increase the complication in making the pellets, but four strakes should be possible without too much difficulty. Strakes may not be the only way of increasing the spin damping.

As a first look at the possibilities, the strakes seem to show some promise, and the theory of increasing the spin damping appears to give benefits.