OldSpook,

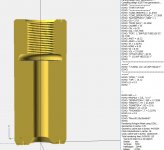

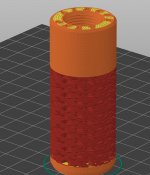

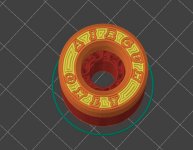

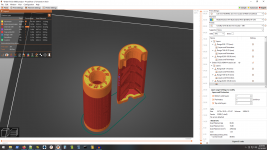

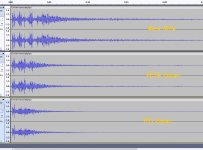

I'm using BambuStudio (which is related to a few other slicers). I experimented with 15%-30%. How the infill is generated is not really consistent from one percentage to the next. At lower infill percentages it combines strands together to make fewer but thicker inner walls. You keep getting more walls until about 20% when the infill strands start getting smaller but more numerous. It gets more mesh like. I didn't notice a significant difference in sound between the percentages, so I went with what I needed structurally. I tried it "side vented" into lambswool about 2mm thick wrapped around the insert and stuffed in a metal shroud. I also tried it taped and without the wool. I think it was better taped and it was certainly less of a pain in the ass to repack.

I was printing on a Bambu X1C and I was printing fast.

I needed a brim to keep it from detaching from the build plate. (Especially if you turn off top/bottom shells)

I printed with PLA and PETG... I think PETG is structurally the better choice.

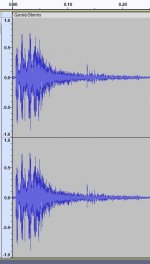

But better than PETG in the actual business of suppressing sound was TPU.

TPU had by far the largest impact on sound of any "refinement" on basic design I've tried.

I thought it would be a pain to print, but I slowed it down just a bit and it printed like a dream. Prints nicer than PLA, I just can't use the automatic filament changer.

I'm using BambuStudio (which is related to a few other slicers). I experimented with 15%-30%. How the infill is generated is not really consistent from one percentage to the next. At lower infill percentages it combines strands together to make fewer but thicker inner walls. You keep getting more walls until about 20% when the infill strands start getting smaller but more numerous. It gets more mesh like. I didn't notice a significant difference in sound between the percentages, so I went with what I needed structurally. I tried it "side vented" into lambswool about 2mm thick wrapped around the insert and stuffed in a metal shroud. I also tried it taped and without the wool. I think it was better taped and it was certainly less of a pain in the ass to repack.

I was printing on a Bambu X1C and I was printing fast.

I needed a brim to keep it from detaching from the build plate. (Especially if you turn off top/bottom shells)

I printed with PLA and PETG... I think PETG is structurally the better choice.

But better than PETG in the actual business of suppressing sound was TPU.

TPU had by far the largest impact on sound of any "refinement" on basic design I've tried.

I thought it would be a pain to print, but I slowed it down just a bit and it printed like a dream. Prints nicer than PLA, I just can't use the automatic filament changer.

Upvote 0