Preface - this is a WIP, I will upload more photos and images to this first post as time allows

This info could void your warranty and introduce safety issues, I take no responsibility for any damages of any kind!

I have spent a great deal of time experimenting with both of my FX Crowns to produce substantially more power, in order to shoot heavier ammo with it. There have been several threads with information (for better or worse) on achieving similar goals, so I thought that I would start this thread to consolidate the modifications that I have done and hopefully others can contribute new mods that benefit other Crown owners.

First, there's a thread that @edosan started on this forum that is identical in nature for the FX Impact. There are details within that thread that have some overlap with power tuning, but these are different rifles with some similar DNA and parts. The Impact has some advantages over the Crown for power, but if you're like me - the Crown is just a better fit ergonomically and there is no reason they can't be more than doubled in power from the factory!

Strategy

Since the Crown has less plenum volume than something like it's brother, the FX Impact - shooting heavy ammo at higher velocities requires running the Crown with higher pressure settings (over the factory recommended limits). FX designs the Crown to shoot at a wide range of reg pressures, capping out what the hammer system do for opening the valve (generally around 150bar, give or take).

Depending on the tuning goals and ammo weight, you may need anywhere from 145-180bar (190 in extreme top end circumstances, but I generally run no higher than 168-170 for the heaviest ammo that I shoot).

Airflow Restrictions

In order to optimize the power, the airflow has to be unrestricted as best as possible. There are three primary mods that need to be done to achieve this. I'll put these in order of feasibility for most Crown owners:

Wider Transfer Port (TP) Diameter

When you remove the barrel from the Crown's action and look inside, you will see the transfer port underneath the area where the barrel's brass piece sits. The factory brass TP inlet is smaller in diameter than the TP outlet, so the brass TP must be enlarged to be closer in size with the action. This on its own can yield upwards of +50fps velocity.

There is another way to achieve even greater optimization, which requires double porting the brass TP. I have not done this (yet), but I haven't had a need to go this far.

Pellet Probe

The pellet probe also introduces some airflow restrictions that hurt velocity. The probe can be modified in several different ways to unrestrict the flow. I have had gains upwards of 12-20fps using different designs, but I have settled on taking a smaller gain and using a double ported probe design.

Larger Valve Seat (VS)

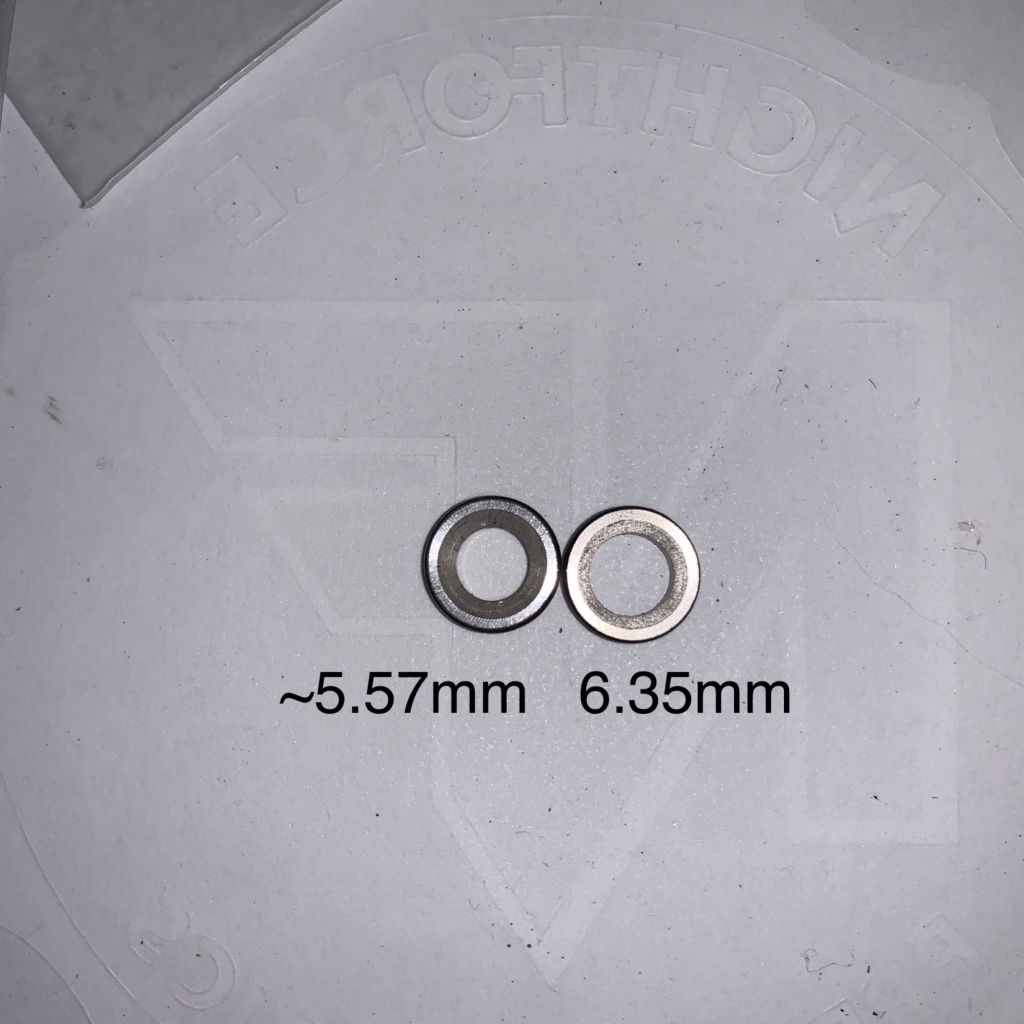

The factory VS has a relatively small inside diameter that restricts airflow, somewhere around 5.57mm. To improve airflow efficiency, a VS with a larger inside diameter is required. It has been said that the diameter larger than caliber being shot is doesn't matter, but I have seen much better performance with the larger seat!

You can carefully modify yours, machine / have one machined, or you can purchase one. FX sells a Titanium VS with an inside diameter of 6.35mm. Here are the two side by side:

Be advised, you need to make sure that your valve pin has a large enough Delrin seat that seals against the VS! The newer Crowns come with them already, otherwise you can order them from FX.

The FX part numbers are:

Regulator Pressure

Note, I have only had Crowns with the "gen 3" AMP regulators, so there may be some variations in the requirements for older generation Crowns.

Identify Your Use Case

The first thing you should determine before proceeding any further is what your end goals are for your Crown. A good starting point is identifying ammo weight and target velocities. You may not need to do much if you're only planning to shoot ammo weighing 24 grains or less, anything over 24 grains over 950fps is where the real experimentation begins.

I'll start with my use case. I wanted to be able to shoot anything up to 36 grains without pushing my rifle over 170bar or so. The real sweet spot for my rifle is 30 grains, where I can run my reg as low as 165 bar and push .217 Varmint Knockers out at 954-950fps, which have been deadly accurate even in 35mph wind gusts. If it's just breezy and not a gale, I can push 27-28gr slugs to 1040fps accurately for long distance. That said, I wanted the option on the table for shooting 33gr and 36gr slugs, so I worked towards the goal of being able to use as much as 190bar for piece of mind.

Spring Tension & Hammer Weight

With the airflow restrictions optimized with an otherwise stock Crown, you will quickly find that at higher reg pressures, your velocity decreases. The reason for this is simple - as mentioned before, the factory hammer system cannot open the valve at higher pressures, even with maximum factory hammer spring tension. Simply put - it just doesn't have enough force to overcome the pressures that push the valve pin against the valve seat. This is a problem, but there are different approaches that can be taken to solve for it - depending on your use case requirements.

For example - if you're shooting lighter ammo, 23-24gr slugs - you may only need another 5-10bar of usable regulated pressure to achieve your target velocity with that projectile. For a stock rifle, you may not even need a hammer weight. It is entirely possible that you can do one of two relatively low effort modifications to increase the hammer tension for gaining the extra usable pressure:

This info could void your warranty and introduce safety issues, I take no responsibility for any damages of any kind!

I have spent a great deal of time experimenting with both of my FX Crowns to produce substantially more power, in order to shoot heavier ammo with it. There have been several threads with information (for better or worse) on achieving similar goals, so I thought that I would start this thread to consolidate the modifications that I have done and hopefully others can contribute new mods that benefit other Crown owners.

First, there's a thread that @edosan started on this forum that is identical in nature for the FX Impact. There are details within that thread that have some overlap with power tuning, but these are different rifles with some similar DNA and parts. The Impact has some advantages over the Crown for power, but if you're like me - the Crown is just a better fit ergonomically and there is no reason they can't be more than doubled in power from the factory!

Strategy

Since the Crown has less plenum volume than something like it's brother, the FX Impact - shooting heavy ammo at higher velocities requires running the Crown with higher pressure settings (over the factory recommended limits). FX designs the Crown to shoot at a wide range of reg pressures, capping out what the hammer system do for opening the valve (generally around 150bar, give or take).

Depending on the tuning goals and ammo weight, you may need anywhere from 145-180bar (190 in extreme top end circumstances, but I generally run no higher than 168-170 for the heaviest ammo that I shoot).

Airflow Restrictions

In order to optimize the power, the airflow has to be unrestricted as best as possible. There are three primary mods that need to be done to achieve this. I'll put these in order of feasibility for most Crown owners:

Wider Transfer Port (TP) Diameter

When you remove the barrel from the Crown's action and look inside, you will see the transfer port underneath the area where the barrel's brass piece sits. The factory brass TP inlet is smaller in diameter than the TP outlet, so the brass TP must be enlarged to be closer in size with the action. This on its own can yield upwards of +50fps velocity.

There is another way to achieve even greater optimization, which requires double porting the brass TP. I have not done this (yet), but I haven't had a need to go this far.

Pellet Probe

The pellet probe also introduces some airflow restrictions that hurt velocity. The probe can be modified in several different ways to unrestrict the flow. I have had gains upwards of 12-20fps using different designs, but I have settled on taking a smaller gain and using a double ported probe design.

Larger Valve Seat (VS)

The factory VS has a relatively small inside diameter that restricts airflow, somewhere around 5.57mm. To improve airflow efficiency, a VS with a larger inside diameter is required. It has been said that the diameter larger than caliber being shot is doesn't matter, but I have seen much better performance with the larger seat!

You can carefully modify yours, machine / have one machined, or you can purchase one. FX sells a Titanium VS with an inside diameter of 6.35mm. Here are the two side by side:

Be advised, you need to make sure that your valve pin has a large enough Delrin seat that seals against the VS! The newer Crowns come with them already, otherwise you can order them from FX.

The FX part numbers are:

- Titanium VS: 29970

- Valve Pin: 19929

Regulator Pressure

Note, I have only had Crowns with the "gen 3" AMP regulators, so there may be some variations in the requirements for older generation Crowns.

Identify Your Use Case

The first thing you should determine before proceeding any further is what your end goals are for your Crown. A good starting point is identifying ammo weight and target velocities. You may not need to do much if you're only planning to shoot ammo weighing 24 grains or less, anything over 24 grains over 950fps is where the real experimentation begins.

I'll start with my use case. I wanted to be able to shoot anything up to 36 grains without pushing my rifle over 170bar or so. The real sweet spot for my rifle is 30 grains, where I can run my reg as low as 165 bar and push .217 Varmint Knockers out at 954-950fps, which have been deadly accurate even in 35mph wind gusts. If it's just breezy and not a gale, I can push 27-28gr slugs to 1040fps accurately for long distance. That said, I wanted the option on the table for shooting 33gr and 36gr slugs, so I worked towards the goal of being able to use as much as 190bar for piece of mind.

Spring Tension & Hammer Weight

With the airflow restrictions optimized with an otherwise stock Crown, you will quickly find that at higher reg pressures, your velocity decreases. The reason for this is simple - as mentioned before, the factory hammer system cannot open the valve at higher pressures, even with maximum factory hammer spring tension. Simply put - it just doesn't have enough force to overcome the pressures that push the valve pin against the valve seat. This is a problem, but there are different approaches that can be taken to solve for it - depending on your use case requirements.

For example - if you're shooting lighter ammo, 23-24gr slugs - you may only need another 5-10bar of usable regulated pressure to achieve your target velocity with that projectile. For a stock rifle, you may not even need a hammer weight. It is entirely possible that you can do one of two relatively low effort modifications to increase the hammer tension for gaining the extra usable pressure:

- Acquire a heavier hammer spring - the tough part of this for a layman is precision. If your spring is too strong, it will be difficult to cock the rifle, cause wear and tear, and eventually break critical components

- Adding spacers to the stock hammer system - the advice is to go small, and increase the spacer length in 1mm increments. You will eventually hit a point where you cannot cock the rifle anymore, and this is the turning point IMO for needing a hammer weight

[/LIST=1]

If you have hit this wall and you're determined to get past it, you need to prepare yourself for modifying the Crown's spring guide and producing a custom hammer weight. FX sells a hammer weight kit that contains a 7 gram hollowed brass hammer, a modified spring guide, and a new factory spring (it's the same spring as what is included with the factory rifles). This may be enough to hit your goals, I have found that the hammer weight in this kit only opens the valve up to 160bar (in both my Crowns).

This is where I began to get creative. My first approach was to determine the rate and specification of the factory spring and ordered a half dozen others that were very close in specs. I cut them down to the proper size, grinded the ends flat, and none of them provided adequate power to open my valve over ~165bar.

It was at this point that I began to make custom hammer weights.

The brass weight in the middle is the one Ernest designed, and the one at the top is the one that I'm using. Thus far, I have found higher grade brass to be the best material to use for this purpose. Stainless is too light, tungsten alloys are hard to machine and slightly brittle. Using the factory spring, modified spring guide, I tested several different variations of hammer weights using brass. The first was a test that I did filling the FX / Ernest Rowe hollowed hammer weight with lead, for a total weight of 9.9 grams. This still wouldn't allow me to surpass the 170 bar mark (~168 bar), but it showed promise. The first custom brass hammer weight that I machined weighed in at 11.9 grams. This was finally enough to surpass the 170 bar mark, but velocity dropped over 172! I then made another that weighed 12.6 grams with a ~9.4mm flange, and this was finally enough to open the valve up to 190 bar.

I have since tweaked and tuned the specs and my weight is right around 12.5 grams with a 8mm flange.

Note: the spring guide modification is needed so the spring can compress when the rifle is cocked, otherwise the weight would bottom out on the guide post that the spring rides on!

(To be continued)