My last winter (re)build/project involves my L2, which was a simple 177/250mm REPR that was used for pesting/plinking in the yard and backpacked for hiking and skiing. It was made redundant by my Huben GK1 and I wanted to repurpose it as a dedicated ratter. The goal is to shoot small Zan 177 slugs out to 100y accurately and quietly - two things that the L2 isn’t particularly good at, at least relative to other, bolt-action 177 slug guns.

I first tried upgrading to an Alfa 450mm barrel to juice up the shooting to 20-25fpe. Accuracy was pretty good with Zan 10 and 13 grain slugs, aside from the odd flyer. In terms of sound, it was a bit louder than I’d favor, using a variety of mods. Overall, it didn’t meet my goals but I did learn that a favorable combination of traits was to (1) retain the dog bone and collar for a very tight ES, and (2) running a high reg pressure with large jets produces a quiet, efficient and snappy shot cycle (producing good slug accuracy).

I then decided to try the Flex approach using a Huma adapter and FX liner/barrel sleeve and shroud. I used a 177 500mm heavy liner that came from Europe that I already knew to have stellar performance with the little Zan pills in my M3.

Initial testing was made with 150bar reg and 2.2mm total jetting shooting the 10g slugs at 970fps. No doubt, the platform is capable of much more but that’s not my goal here. If I can shoot beyond 80y accurately then I’ll take the quieter, more efficient 10g slugs over their larger siblings.

The first evaluation of this approach , using a standard barrel setup with the liner secured with 2 orings and the FX shroud in place was pretty good. Accuracy was on a par with the Alfa barrel but the fliers were gone. I’d say 1.5-2moa at 80y. However, a big improvement was observed in terms of sound. The FX shroud and an IA1200 mod completely silenced the front end, leaving only the action noise which is pretty mute with the high reg pressure/large jets producing a very snappy cycle. Unquestionably backyard friendly and no louder than popping open a can of soda.

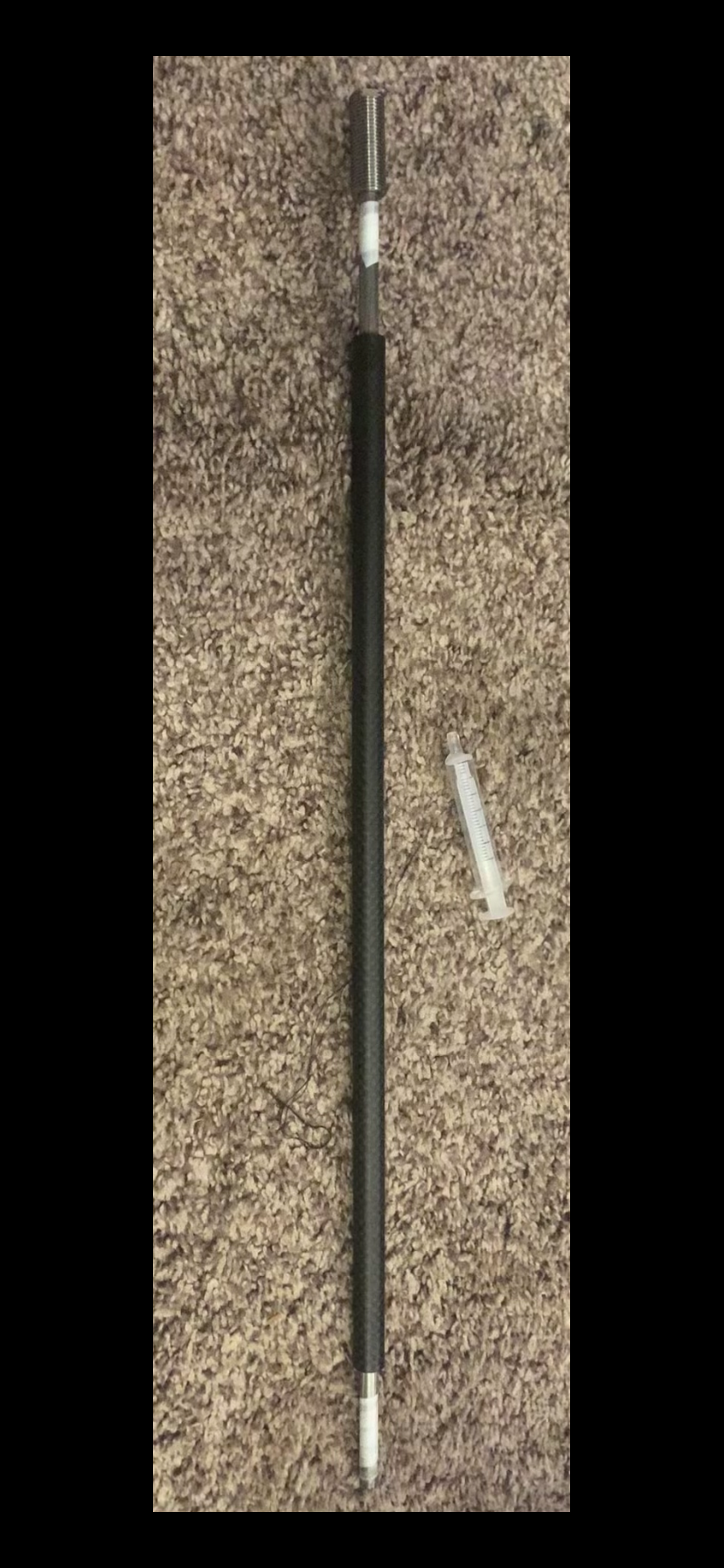

Still, I felt that the accuracy could improve so I set about making the liner and barrel more rigid. First, installed a carbon liner sleeve bonded with silicone and wrapped the ends of the liner with Teflon tape to ensure a snug fit into the FX jam nut and TP adapter:

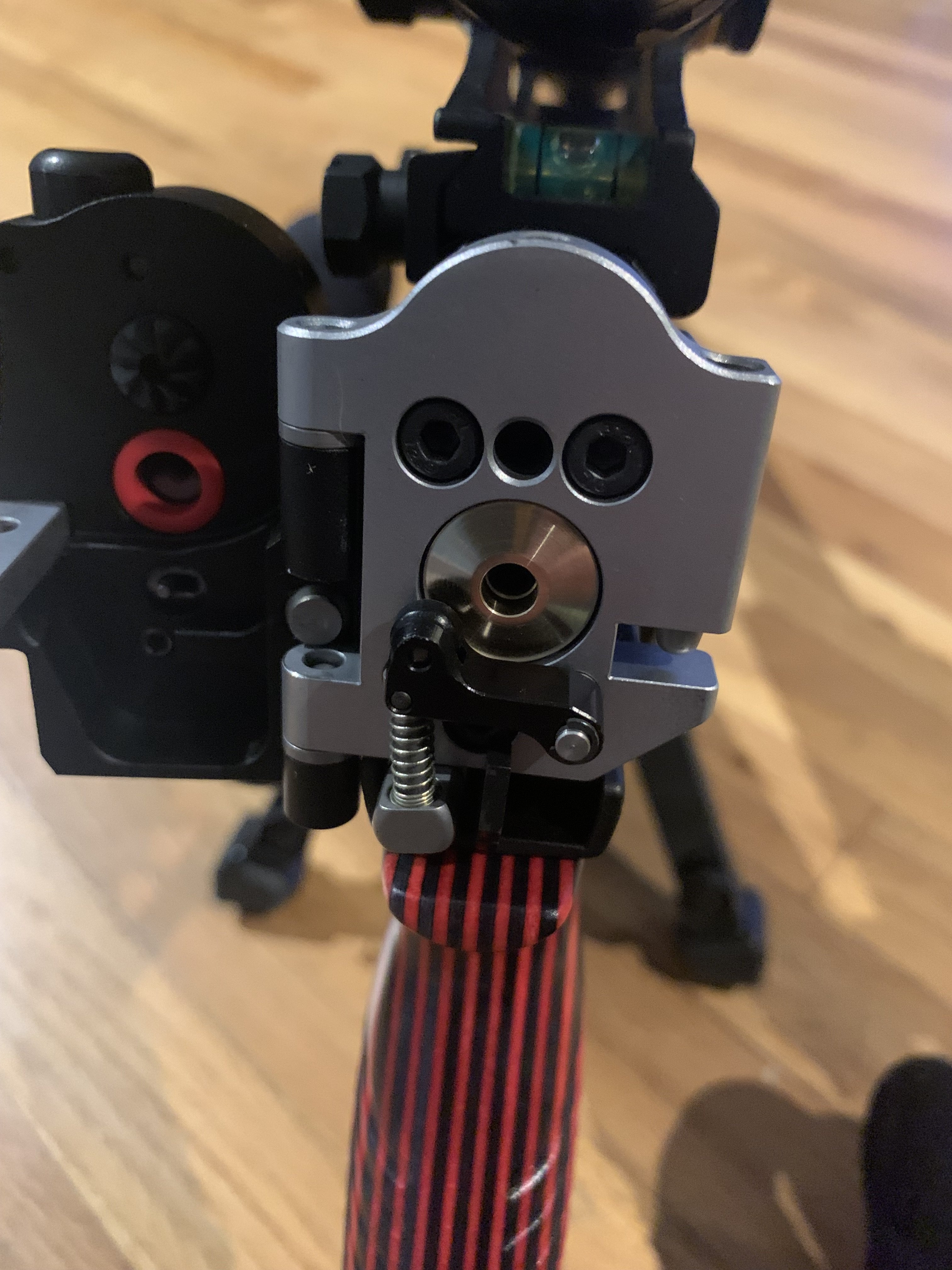

Then, over a few weeks I tried various methods of making the barrel more rigid. Sparing the details, I ended up using a printed piece to fill the gap between action and shroud. Because the shroud and printed “buffer” might not have perpendicular ends, they were put together using epoxy washers, with the shroud getting tightened down while the epoxy was soft, to create a natural fit. The shroud and action surface were first coated with silicone to prevent the epoxy from sticking, allowing the shroud and buffer tube to be removable. Shot with just the buffer tube on: (ignore orings - they were superseded by the epoxy attachment method)

Following mounting of the shroud, a CF tube with an ID matching the OD of the shroud was slipped over and glued in situ to the printed buffer. Note that this is not working as a tensioner, just a stiffener.

The whole arrangement is very rigid, consistent in POI and increased in accuracy.

8 shots at 80y:

The slugs extracted from the duct seal:

And 8 at 100y:

Pretty happy with this 21fpe performance and I don’t think I could do better with this trigger. Certainly minute of rat out to 100. Will be playing around with jets, speeds and trying out the 13g in the next week.

I first tried upgrading to an Alfa 450mm barrel to juice up the shooting to 20-25fpe. Accuracy was pretty good with Zan 10 and 13 grain slugs, aside from the odd flyer. In terms of sound, it was a bit louder than I’d favor, using a variety of mods. Overall, it didn’t meet my goals but I did learn that a favorable combination of traits was to (1) retain the dog bone and collar for a very tight ES, and (2) running a high reg pressure with large jets produces a quiet, efficient and snappy shot cycle (producing good slug accuracy).

I then decided to try the Flex approach using a Huma adapter and FX liner/barrel sleeve and shroud. I used a 177 500mm heavy liner that came from Europe that I already knew to have stellar performance with the little Zan pills in my M3.

Initial testing was made with 150bar reg and 2.2mm total jetting shooting the 10g slugs at 970fps. No doubt, the platform is capable of much more but that’s not my goal here. If I can shoot beyond 80y accurately then I’ll take the quieter, more efficient 10g slugs over their larger siblings.

The first evaluation of this approach , using a standard barrel setup with the liner secured with 2 orings and the FX shroud in place was pretty good. Accuracy was on a par with the Alfa barrel but the fliers were gone. I’d say 1.5-2moa at 80y. However, a big improvement was observed in terms of sound. The FX shroud and an IA1200 mod completely silenced the front end, leaving only the action noise which is pretty mute with the high reg pressure/large jets producing a very snappy cycle. Unquestionably backyard friendly and no louder than popping open a can of soda.

Still, I felt that the accuracy could improve so I set about making the liner and barrel more rigid. First, installed a carbon liner sleeve bonded with silicone and wrapped the ends of the liner with Teflon tape to ensure a snug fit into the FX jam nut and TP adapter:

Then, over a few weeks I tried various methods of making the barrel more rigid. Sparing the details, I ended up using a printed piece to fill the gap between action and shroud. Because the shroud and printed “buffer” might not have perpendicular ends, they were put together using epoxy washers, with the shroud getting tightened down while the epoxy was soft, to create a natural fit. The shroud and action surface were first coated with silicone to prevent the epoxy from sticking, allowing the shroud and buffer tube to be removable. Shot with just the buffer tube on: (ignore orings - they were superseded by the epoxy attachment method)

Following mounting of the shroud, a CF tube with an ID matching the OD of the shroud was slipped over and glued in situ to the printed buffer. Note that this is not working as a tensioner, just a stiffener.

The whole arrangement is very rigid, consistent in POI and increased in accuracy.

8 shots at 80y:

The slugs extracted from the duct seal:

And 8 at 100y:

Pretty happy with this 21fpe performance and I don’t think I could do better with this trigger. Certainly minute of rat out to 100. Will be playing around with jets, speeds and trying out the 13g in the next week.

Last edited: