Re .22 cal QB 79

Heard these shot well. Got one a while back and the barrel was no good. Gave up wasting pellets on day one and took a Lothar Walther conventional barrel out of its bag, drew up a way to mount it securely and modified the internals to improve the function as well. This version cocks on opening;

(internet photo of the rest I used in above description);

Only had a few pic's of the machining phase. Will try to take some pictures of it outfitted with iron sights if anyone is interested.

Heard these shot well. Got one a while back and the barrel was no good. Gave up wasting pellets on day one and took a Lothar Walther conventional barrel out of its bag, drew up a way to mount it securely and modified the internals to improve the function as well. This version cocks on opening;

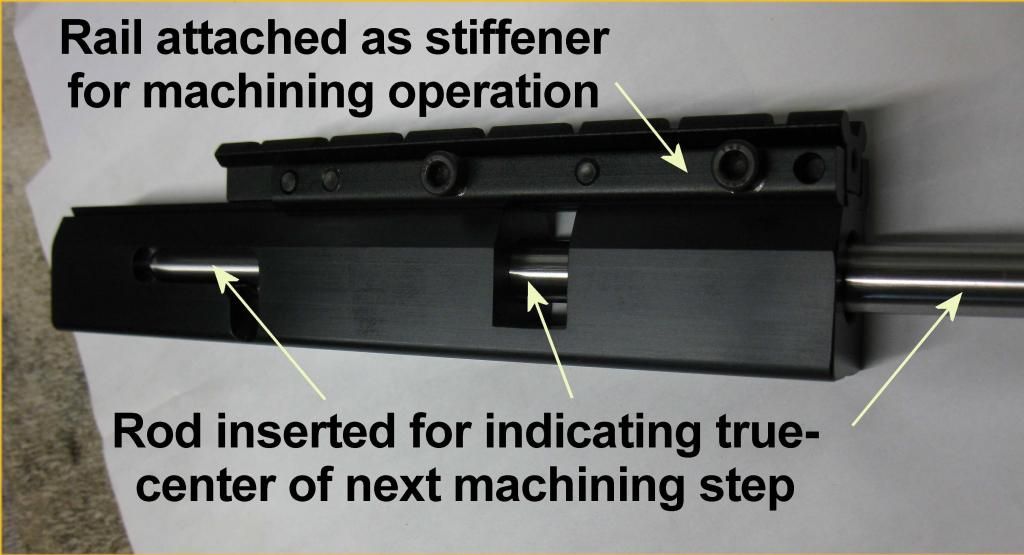

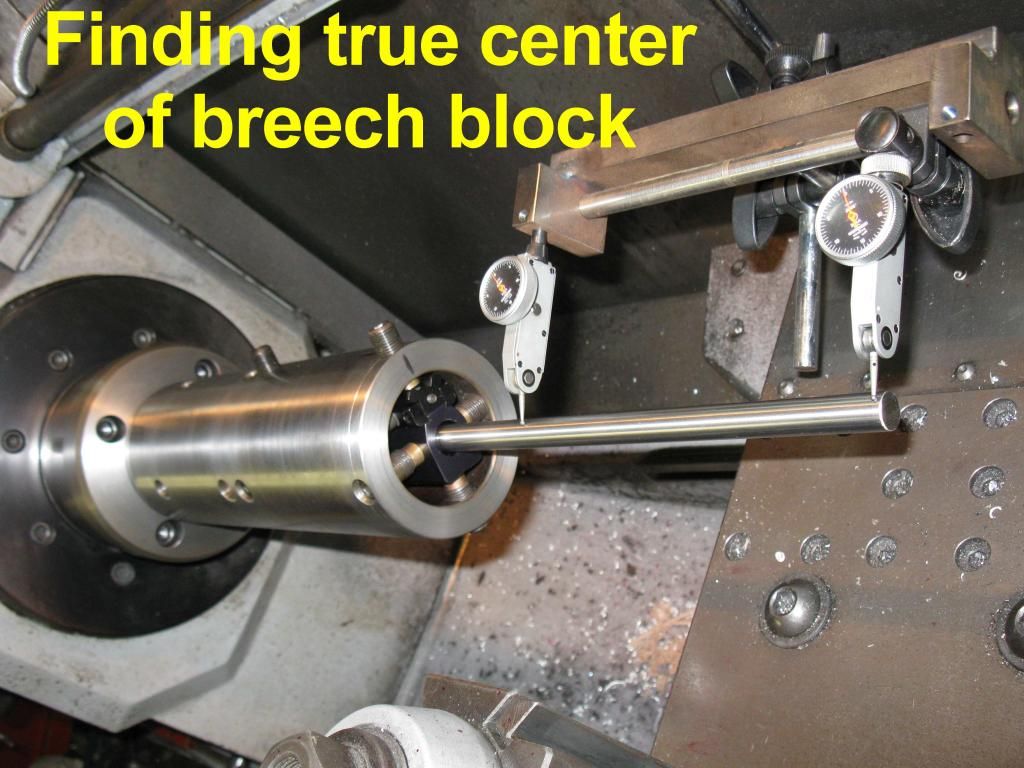

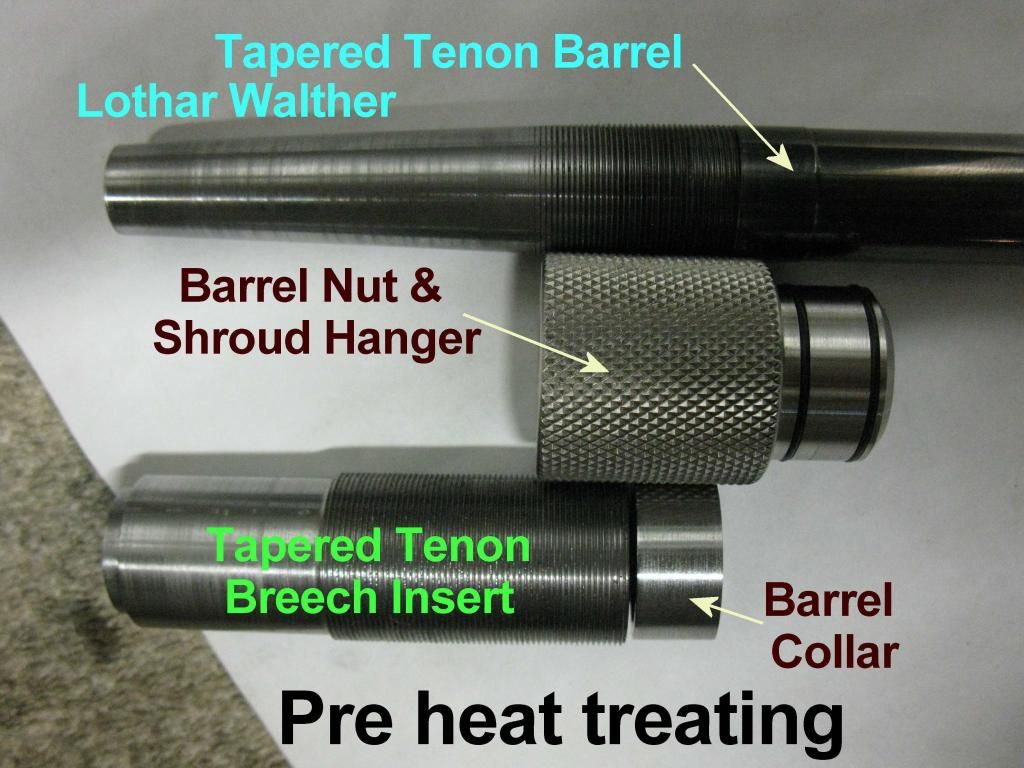

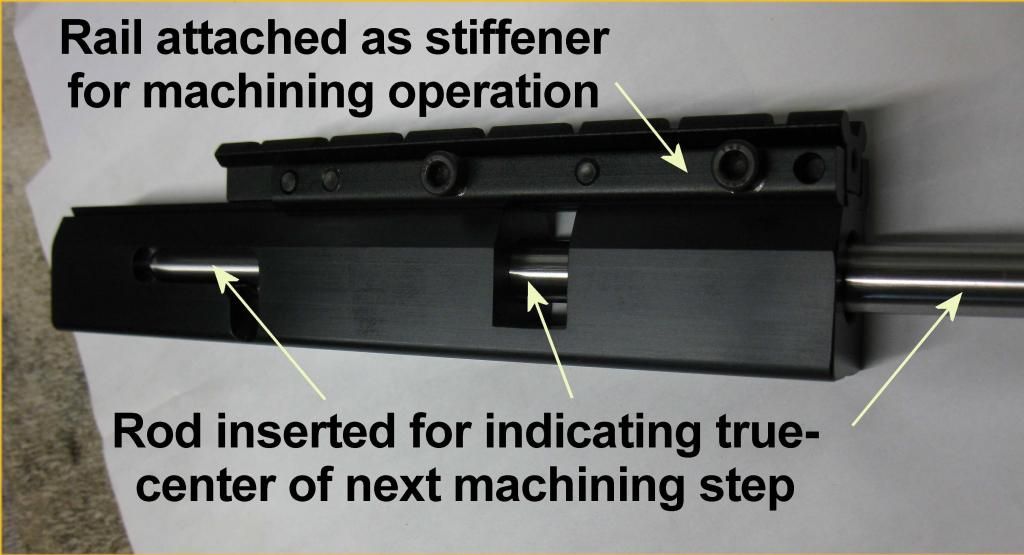

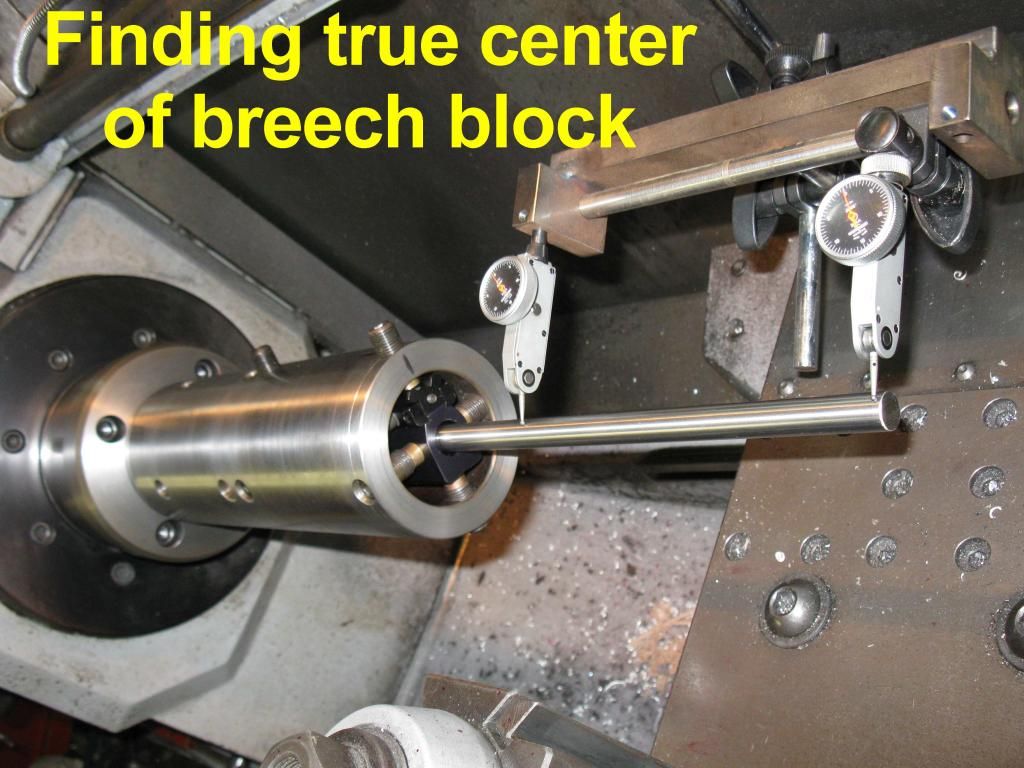

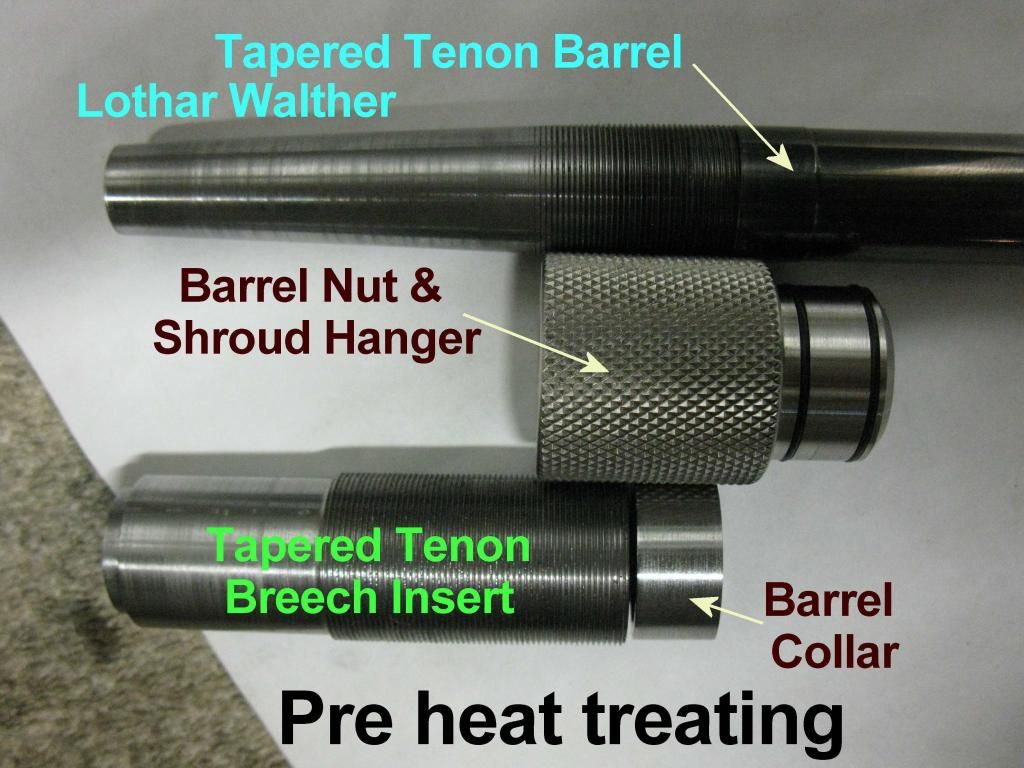

- Machined receiver to accept a heat treated A2 tapered barrel tenon, doing away with the marginal set screw arrangement and sloppy barrel fit. This also eliminated the need for multiple barrel mounted o-rings where sealing is concerned.

- Fashioned a knurled nut from 304 stainless, which pulls the barrel's matching taper into the now permanently mount receiver insert. The knurled nut "pulls" on a collar that is permanently mounted to the barrel.

- Barrel taper is "non-releasing" similar to Morse or B&S type tooling, which requires a split ring attached to barrel for disassembly With the split ring temporarily attached to the barrel just ahead of the knurled retainer, the knurled barrel retainer can "push" against it (split ring) for barrel removal.

- Installed an alignment pin to time the barrel to the receiver tenon for repeatability of zero.

- Included o-ring mounts on the knurled barrel retainer to float the rear of the titanium LDC.

- Titanium LDC is fashioned to accept Airforce baffles and end cap

- Fashioned removable Anschutz patterned front sight base for iron sight use when titanium LDC is removed

- Installed Redfield type rear sight base (fits under scope) for Redfield Palma rear sight

- Devised new cocking geometry that eliminates need to hold bolt handle to the rear when performing magazine changes, slightly increasing hammer stroke.

- Converted hammer/striker to Torlon with heat treated A2 striker face to reduce mass induced hammer bounce, and decrease lock time

- Redesigned probe for better flow and side-by-side poly o-rings

- Fashioned adjustable hammer spring mechanism from 304 stainless

- Modified stock to alleviate having to remove safety when taking action out of stock

- Stippled grip portion of stock

(internet photo of the rest I used in above description);

Only had a few pic's of the machining phase. Will try to take some pictures of it outfitted with iron sights if anyone is interested.