I have been working since April of this year with three or four other members of the forum who have been kind enough to test my work. It's been very frustrating at times because progress hasn't been as fast as I had hoped it might be. In order to establish a standard reference moderator I tested a number of commercial moderators, two Donnie's and a "no name" commercial, in addition to sending a couple of dozen moderators to different testers. I built baffles of various types and researched valves. I looked at a whole lot of pictures of silencer guts. I built some of those and modified them and tested them. I have written so much OpenScad code that I am dreaming in code again.

In the end I chose the stock Stormrider moderator as my reference moderator because it was so surprisingly good. A microphone placed at 3 o'clock, 15 ft away and 4 ft off the ground routinely read 67.5 decibels for that moderator. I tweaked it with a chain saw file (notched the conical baffles) and got it down to 66 decibels and have been using it as my reference moderator since then. My goal has been to build one that beats that.

This section of the forum is littered with threads discussing different types of baffles I have tried, arguing with and getting advice from other members. Special thanks to @MikeVV for motivating me to research microphones and test equipment and @qball, @woogie_man, and everyone else who opined in particular that more baffles wasn't "more better." The feedback from the guys testing has been very important and I'd thank them publicly but I'd rather they step up and take a bow if they feel like that. That way I don't "out" them if they would rather remain quiet.

Just before EBR, while one of my testers was preparing for it, a moderator that I shipped him for a 22 caliber Daystate failed spectacularly due to a bad glue up and a weak design.

I was frustrated and upset and just about ready to quit. Mind you I had been getting good reports but I was discovering that it's very hard to build a competitive moderator at a low price point.

I am happy to report that this moderator exceeds the performance of the stock Stormrider moderator by two decibels and it is easier on the eye!

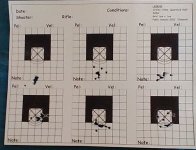

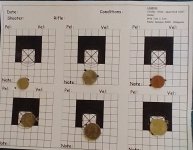

I tested accuracy this morning.

The moderator is so tight that it required about 70 shots to settle down and shoot groups as good as it does with the stock moderator and the H&N FTTs I am shooting. Generally those are 9 shot groups about the size of a dime at 25 yards, a nickle at 30 yards, and a quarter at 40 yards. The moderator settled in and I adjusted zero. It is going to wear this moderator for the rest of it's life, I expect. Now I am not trying to say these are good groups. I am saying that this is as good as this rifle groups with these pellets. These were shot at 30 yards in a very light breeze.

Now here is the good news:

I am going to build these and sell them, probably on EBay. The one in the image on my Stormrider is a .177. It is very, very, quiet. This morning with my standard test setup. It tested at 64 dB average over 9 shots with a standard deviation of about 1 dB. That is a full 2 dB better than the stock moderator performs. Each will be available in .177, .22, and .25. They can be had with 1/2 UNF printed threads, 1/2 UNF helicoil threads, and the M10x1.0 Stormrider printed threads. The helicoil threads will cost more. I have not calculated that cost yet. Other threads can be made available, contact me via PM if you want me to make a certain thread.

I intend to keep them on EBay to begin with and sell them as I build them, rather than try to keep up with orders. I have sold other items in the past and really prefer to have the unit in hand before I take someone's money. So EBAY ...

I will post information here as to what you should search on when I have the first one up there.

Link to my EBay account.

Last edited: