Well…I finally got around to finishing my RTI P1 Compact Working Shroud project. RTI-P1C-WS

The standard shroud IMO is just a barrel centering device. Depending on the barrel length and shroud configuration, there is between 1”-4” of empty space in the shroud. There are no stock baffles. The stock RTI barrel centering part has holes to allow air to move back into the shroud, but they are much to small to be effective.

So I figured..why not make a shroud that actually allows air to be re-directed. Like use a muzzle brake style design within the shroud with nothing impeding airflow.

I thought about shortening the stock shroud, but decided against that route for a couple of reasons..one, while the shrouds aren’t exactly expensive, I didn’t want to hack the shroud if I didn’t have to..they do provide a very stiff barrel centering system..two, the barrel is only held in place by a single set screw in the receiver.

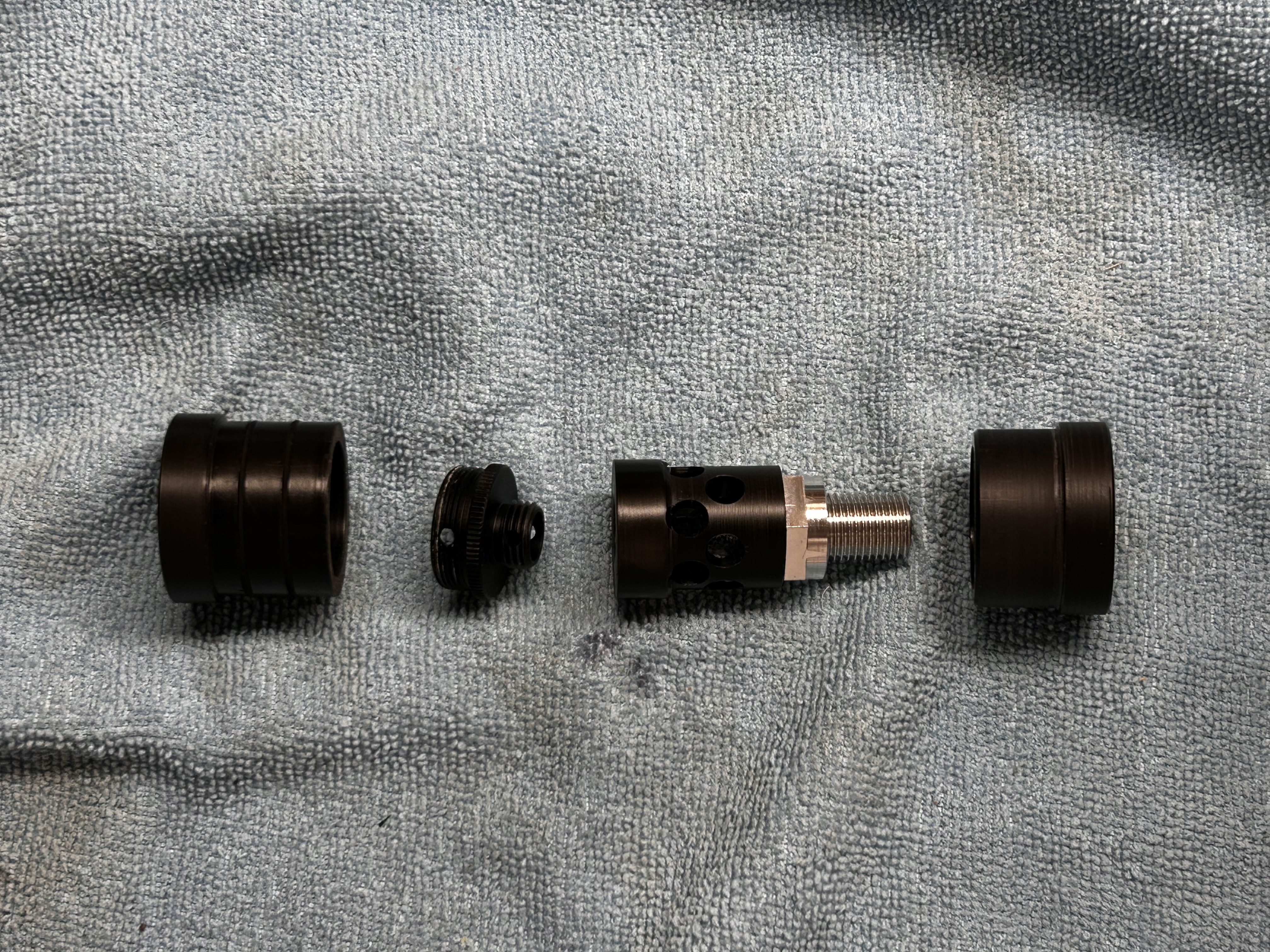

So, leave the standard shroud in place and add a larger shroud around it. Prototype with Delrin because it's easy and quick to machine. This would have been much easier with a 3D printer, BTW..but I don’t own one..yet. I needed a back cap that would slide over the standard shroud and capture the larger carbon fiber tube, an internal muzzle brake that would screw onto the standard shroud end cap, and a front cap that would hold everything in place.

Here are the prototype parts..

[parts pics]

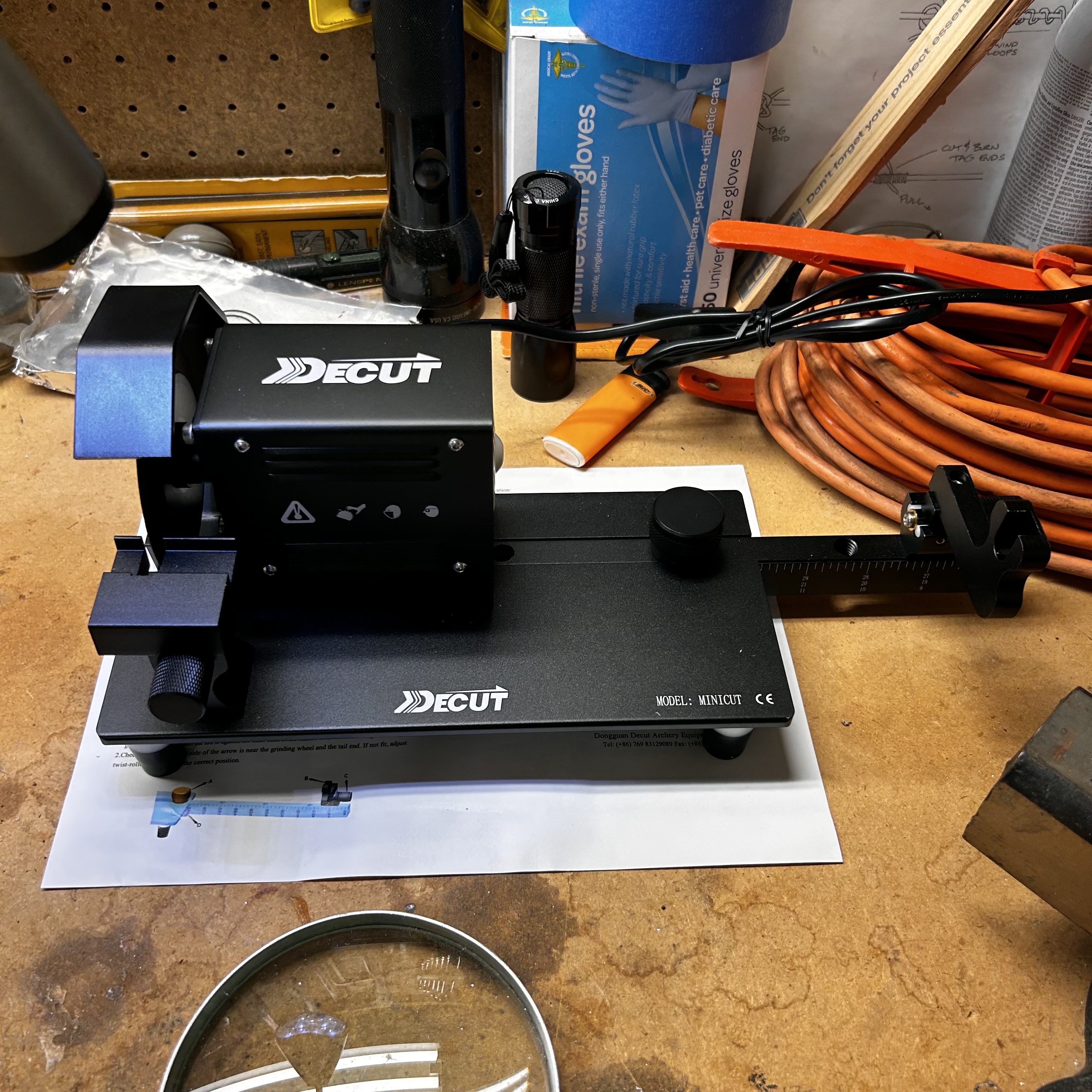

CF tubing that is 34mm OD and 32mm ID was the largest I could squeeze between the CF bottle and the 20MOA Picatinny rail. Cutting square ends was easy..I used my arrow cut-off saw

[saw pics]

Put it all together, and whada ya got?

[before pics]

[after pics]

The standard shroud IMO is just a barrel centering device. Depending on the barrel length and shroud configuration, there is between 1”-4” of empty space in the shroud. There are no stock baffles. The stock RTI barrel centering part has holes to allow air to move back into the shroud, but they are much to small to be effective.

So I figured..why not make a shroud that actually allows air to be re-directed. Like use a muzzle brake style design within the shroud with nothing impeding airflow.

I thought about shortening the stock shroud, but decided against that route for a couple of reasons..one, while the shrouds aren’t exactly expensive, I didn’t want to hack the shroud if I didn’t have to..they do provide a very stiff barrel centering system..two, the barrel is only held in place by a single set screw in the receiver.

So, leave the standard shroud in place and add a larger shroud around it. Prototype with Delrin because it's easy and quick to machine. This would have been much easier with a 3D printer, BTW..but I don’t own one..yet. I needed a back cap that would slide over the standard shroud and capture the larger carbon fiber tube, an internal muzzle brake that would screw onto the standard shroud end cap, and a front cap that would hold everything in place.

Here are the prototype parts..

[parts pics]

CF tubing that is 34mm OD and 32mm ID was the largest I could squeeze between the CF bottle and the 20MOA Picatinny rail. Cutting square ends was easy..I used my arrow cut-off saw

[saw pics]

Put it all together, and whada ya got?

[before pics]

[after pics]

Last edited: