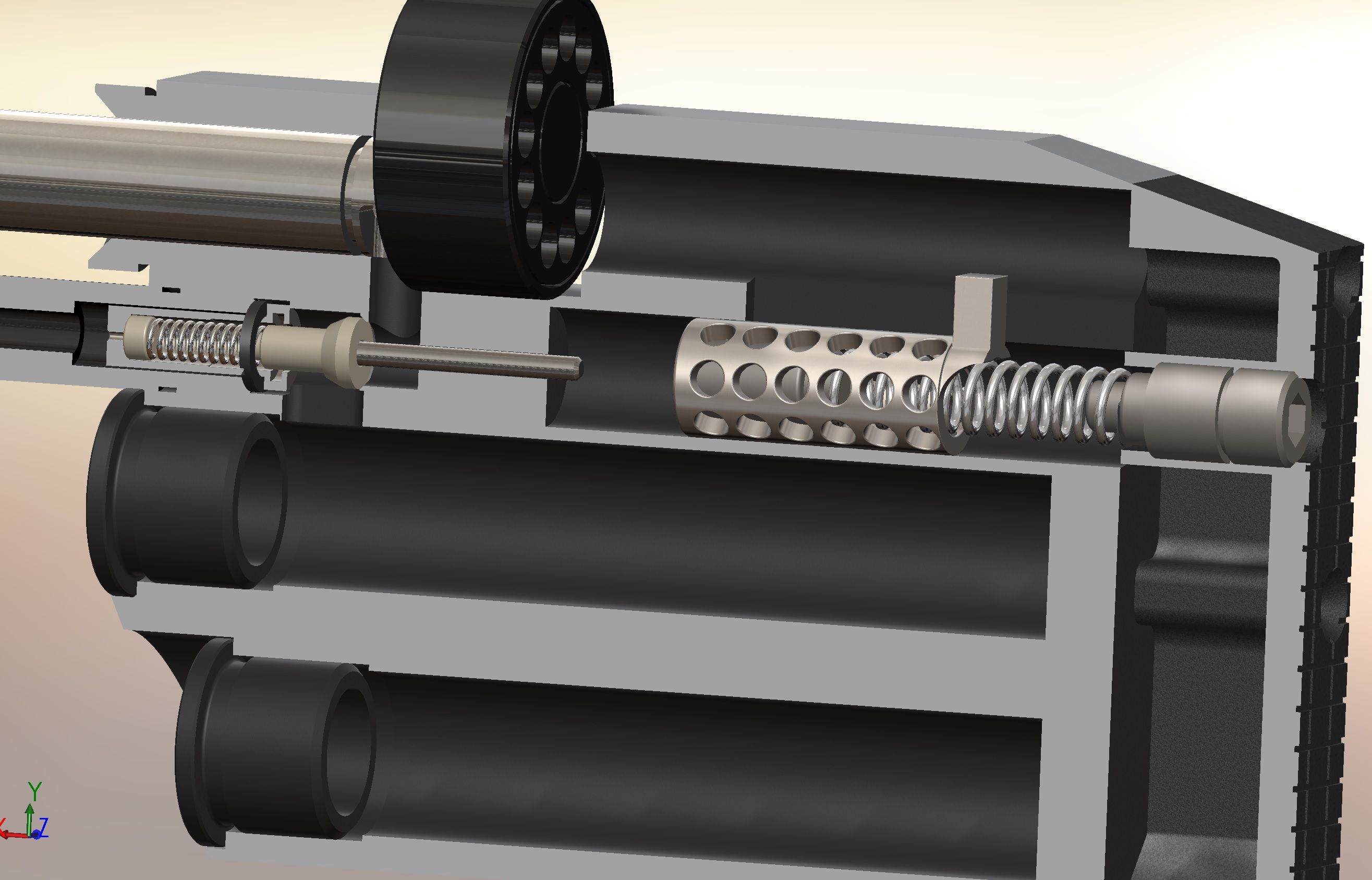

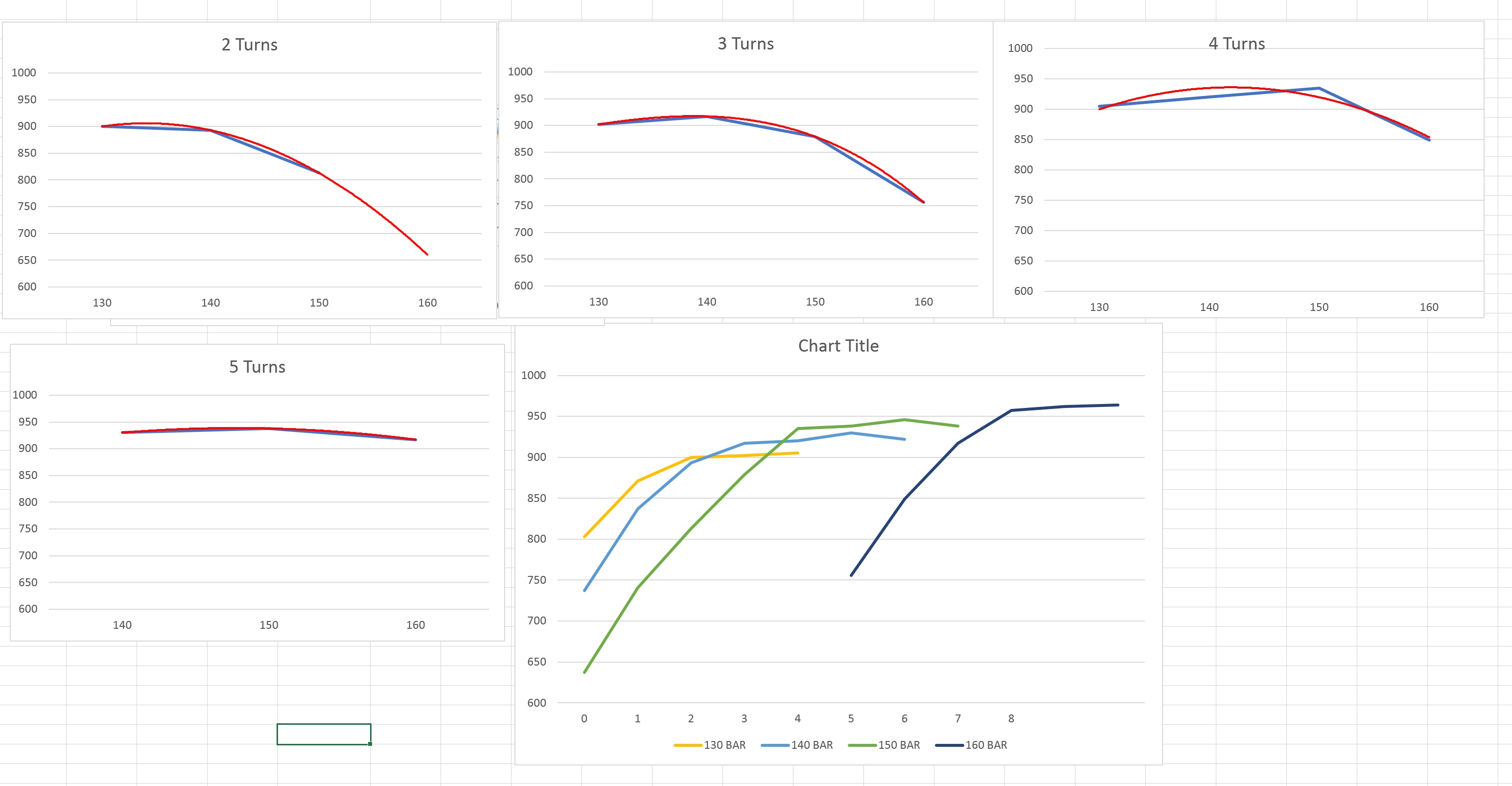

After a few months of struggling with the P2 with poor velocity spread and leaks I decided to have a go at fitting a standard type valve. The new valve is turned for PEEK with hardened 3mm steel rod. Other changes to make it work - Balance tube part drilled out to 6mm, O ring removed and 1mm hole at the back. New valve is shorter so spacer added behind spring. Hammer requires a lot more force so there is a weight/spacer inside the hammer to shorten spring. I still think the hammer needs more weight so have asked RTI for a P1 hammer. Have had 200 slugs through it so far mostly over the chrony for tuning. Its maxed out at about 56Ftlbs but I think a heavier hammer will sort that. Dosent seem to use more air than before. Cocking much harder of course and it was never like butter anyway. Graph using 27gn H&N slugs.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RTI Prophet II standard valve 'upgrade'.

- Thread starter Yorkie

- Start date

Very nice. Years back I dabbled in the valve game. It was the smart guys like Motorhead and others over on GTA that made be try. What I learned made me avoid the P2. For most guys, simple is better. Hope you get to enjoy that gun now.

Upvote 0

How's new valve hold up mate? And what's your efficiency like? with 27gr shooting how fast and the shot count from 220bar down?

Upvote 0

Somehow this is strange. The thing looks to be a professional job (i would call it downgrade sorry). Most of people are doing great with the assisted valve for me it wors also perfectly i was doing with that 0.6 MOA groups. So im just shocked how a such a good engineer was not able to fix the issue (let it be any kind) with the assisted valve but rather downgrade it to a normal unbalanced valve.

Upvote 0