Upvote 0

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shoebox compressor parts

- Thread starter shaunmiller78

- Start date

I've got quite a few spare parts for my F10, mostly rebuild oring kits etc. One thing I'll need next time will be the spacers for the top cylinder. I think I could fabricate them from Delrin on the lathe so I'm not panicking yet. It looks like OCO Labs sells the bottom cylinder spacers but I didn't see the top cylinder ones. You can also get the replacement bushings for the crank arm online, which looks like you might need for the next rebuild or repair.

Upvote 0

I bought a ton of spare parts when Tom Kaye stopped production...I don't even remember what all I bought now.  But I haven't got to do much airgunning the last year or so, so my F10 only has about 20 hours of lifetime hours on it. (I keep a written log). With all the newer compressors coming out like the GX-CS4 and the Bauer Jr. I've wondered if it would be worth selling my shoebox while it still has such low hours and buy one of hot new models. Still undecided....

But I haven't got to do much airgunning the last year or so, so my F10 only has about 20 hours of lifetime hours on it. (I keep a written log). With all the newer compressors coming out like the GX-CS4 and the Bauer Jr. I've wondered if it would be worth selling my shoebox while it still has such low hours and buy one of hot new models. Still undecided....

Upvote 0

"It looks like OCO Labs sells the bottom cylinder spacers but I didn't see the top cylinder ones."

Yep, the OCO Labs machine only has the small piston/cylinders, thus no large are available, nor the spacers.

As a matter of fact, anything to do with the large piston/cylinder cannot be had from OCO, even the high-pressure air connector.

Those small pistons and cylinders are also much shorter than the Shoebox uses, so no dice using them either.

I do have a spreadsheet of parts (not all unfortunately) that was made by someone else here (thank you!), that has many of the parts available from Grainger or McMaster Carr.

Really, the only items that I cannot locate are the cylinders and spacers, everything else is pretty-much available per that spreadsheet.

mike

Yep, the OCO Labs machine only has the small piston/cylinders, thus no large are available, nor the spacers.

As a matter of fact, anything to do with the large piston/cylinder cannot be had from OCO, even the high-pressure air connector.

Those small pistons and cylinders are also much shorter than the Shoebox uses, so no dice using them either.

I do have a spreadsheet of parts (not all unfortunately) that was made by someone else here (thank you!), that has many of the parts available from Grainger or McMaster Carr.

Really, the only items that I cannot locate are the cylinders and spacers, everything else is pretty-much available per that spreadsheet.

mike

Upvote 0

If you wouldn't mind, could you repost or message me the spreadsheet. I'd love to have it on hand."It looks like OCO Labs sells the bottom cylinder spacers but I didn't see the top cylinder ones."

Yep, the OCO Labs machine only has the small piston/cylinders, thus no large are available, nor the spacers.

As a matter of fact, anything to do with the large piston/cylinder cannot be had from OCO, even the high-pressure air connector.

Those small pistons and cylinders are also much shorter than the Shoebox uses, so no dice using them either.

I do have a spreadsheet of parts (not all unfortunately) that was made by someone else here (thank you!), that has many of the parts available from Grainger or McMaster Carr.

Really, the only items that I cannot locate are the cylinders and spacers, everything else is pretty-much available per that spreadsheet.

mike

Thanks

Upvote 0

jking --- = ---

Some of the parts listed are either now not available, or the vendor is no longer around. There are a few holes, but the sheet is very extensive, listing (it appears) parts for all iterations of the Shoeboxes as they were updated. I've been meaning to redo/go over it, but haven't found the time to do so just yet.

Thanks to whom ever created the spreadsheet, it's really a decent reference and a lot of work was put into it.

Mike

View attachment Shoebox Parts List w-Some Links.xlsx

Some of the parts listed are either now not available, or the vendor is no longer around. There are a few holes, but the sheet is very extensive, listing (it appears) parts for all iterations of the Shoeboxes as they were updated. I've been meaning to redo/go over it, but haven't found the time to do so just yet.

Thanks to whom ever created the spreadsheet, it's really a decent reference and a lot of work was put into it.

Mike

View attachment Shoebox Parts List w-Some Links.xlsx

Upvote 0

I'd say that if you have everything and it is working well for you then just stick with it. The resale value is not all that high due to the lack of parts support and the full DIY approach to any issues - I bought a barely used F10 (under 10 hours!) earlier this year for $350 shipped with extra hoses and filters and rebuild kits from somebody getting out of PCPs to have as a backup to my ~10 year old Max,I bought a ton of spare parts when Tom Kaye stopped production...I don't even remember what all I bought now.But I haven't got to do much airgunning the last year or so, so my F10 only has about 20 hours of lifetime hours on it. (I keep a written log). With all the newer compressors coming out like the GX-CS4 and the Bauer Jr. I've wondered if it would be worth selling my shoebox while it still has such low hours and buy one of hot new models. Still undecided....

Personally, I love the Shoebox approach - it is so great to have access to the shop air to completely dry it with desiccant before the Shoebox, and the slow speed / low heat approach works perfect for filling tanks. Earlier this year I was contemplating what to do to insure I had plenty of parts and a path to air on hand when the opportunity to buy the F10 came along, so as a Shoebox fan I jumped on it. With two boxes and probably less spare parts on hand than you have, I should still be good for a long time.

My Max has almost 300 hours on it, has only had one cylinder o-ring rebuild done to it, and still works as new (I log everything to watch for performance drops). The F10 is for when the Max dies (I'll use it twice a year in the meantime to keep it fresh), but one thing I know I will do if that happens is swap the drive pulley out of the Max and into the F10 to slow it down some for reduced bearing loads and added life - that F10 is running scary fast. Here is a thread where I tested the different pulleys and the results I got:

Slowing down a Shoebox F10 for increased longevity

I have been a Shoebox user for almost ten years, and I absolutely love how great it is as a “set it and forget it” compressor to fill tanks. My Shoebox Max is in its tenth year, having about 270 hours of run time on it (with only one “rebuild” along the way) and I figure it has compressed over...

Given that most of my shooting lately is with a Huben and Sidewinder, I have been living on the higher end of pressure, so the pump is seeing a typical tank fill of about 3800-4500 psi, so I really like the Shoebox over the other compressors out there - although the GX-CS4 does look promising so far . . . time will tell.

Upvote 0

I too have experimented with the speeds and agree that it does remain cooler using slower speed. I have zero issues with the timing of my fills, the Box works great in doing so.

I recently (yesterday) have added a small radiator to the inflow side of the fan and am running ice water through the radiator to give it more cooling. I am in the very early stages of testing at this point and do not have an outcome or data yet but will post likely in a week or two with that information. The radiator was only about $25 by the way and looks very promising as it is putting out <50° air to the cylinders. The ambient temperature yesterday was around 76°. Since I live in a hot clime (most of the time), it's important to me that the air is as cool as possible to aid in mitigating the possible heat issues.

My humidity meter shows <30% normally (unless overcast) and I usually top-off my tanks between 15% and 25% humidity, even having a pre and post moisture filters, thus the normally hot temperatures.

Mike

I recently (yesterday) have added a small radiator to the inflow side of the fan and am running ice water through the radiator to give it more cooling. I am in the very early stages of testing at this point and do not have an outcome or data yet but will post likely in a week or two with that information. The radiator was only about $25 by the way and looks very promising as it is putting out <50° air to the cylinders. The ambient temperature yesterday was around 76°. Since I live in a hot clime (most of the time), it's important to me that the air is as cool as possible to aid in mitigating the possible heat issues.

My humidity meter shows <30% normally (unless overcast) and I usually top-off my tanks between 15% and 25% humidity, even having a pre and post moisture filters, thus the normally hot temperatures.

Mike

Upvote 0

Mike,I too have experimented with the speeds and agree that it does remain cooler using slower speed. I have zero issues with the timing of my fills, the Box works great in doing so.

I recently (yesterday) have added a small radiator to the inflow side of the fan and am running ice water through the radiator to give it more cooling. I am in the very early stages of testing at this point and do not have an outcome or data yet but will post likely in a week or two with that information. The radiator was only about $25 by the way and looks very promising as it is putting out <50° air to the cylinders. The ambient temperature yesterday was around 76°. Since I live in a hot clime (most of the time), it's important to me that the air is as cool as possible to aid in mitigating the possible heat issues.

My humidity meter shows <30% normally (unless overcast) and I usually top-off my tanks between 15% and 25% humidity, even having a pre and post moisture filters, thus the normally hot temperatures.

Mike

Can you put a link to where you purchased the radiator and maybe so pictures of your modifications.

Mark

Upvote 0

Alan - I think your advice is wise, thanks. But you did remind me to order some new dessicant...

Upvote 0

Yep, I love my F10. I hook it up,turn it on and just let it run. I do have to check it about once an hour because living off grid when my shop compressor starts up the F10 stops so I have to turn off the tank and bleed the hose then start it back up.

Upvote 0

Tackleberry --=--

I bought the radiator through Walmart, took a couple of weeks to get. Not a deal breaker as I already had the Box fan, but this rediator comes with a fan, however the specs on the Walmart page neglects to state that it's 204-220v, not 120v as needed. I'm not certain that it wouldn't work as I didn't try though. I picked this one because it has copper coils instead of plastic, I think that copper would transfer temperature better. (Unfortunately, made in China....I hate that)

As stated, I'm in process of running it through testing, but looks very promising so far. I currently am using a small bucket for the aquarium water pump but need something larger for a better heat sink.

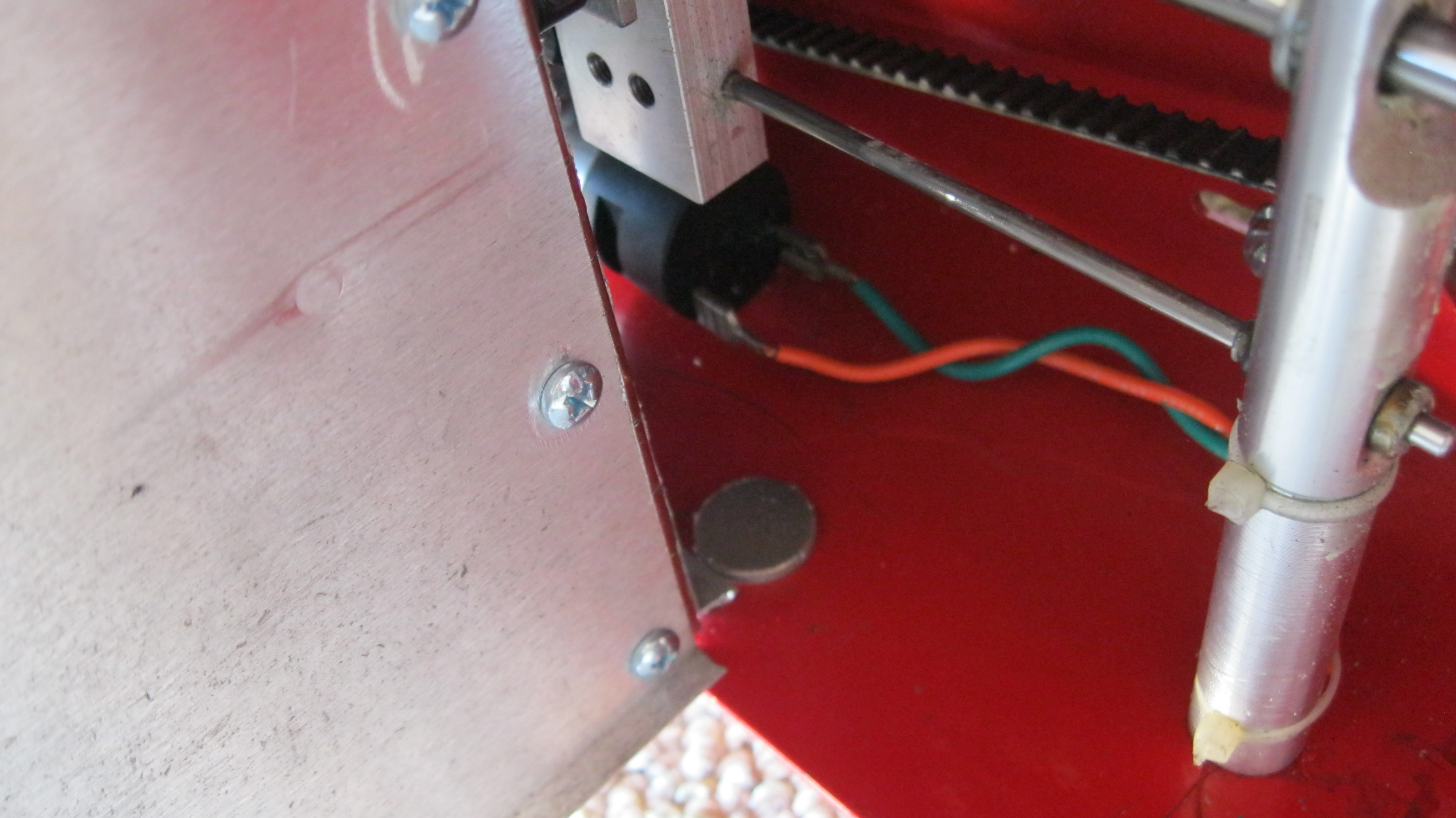

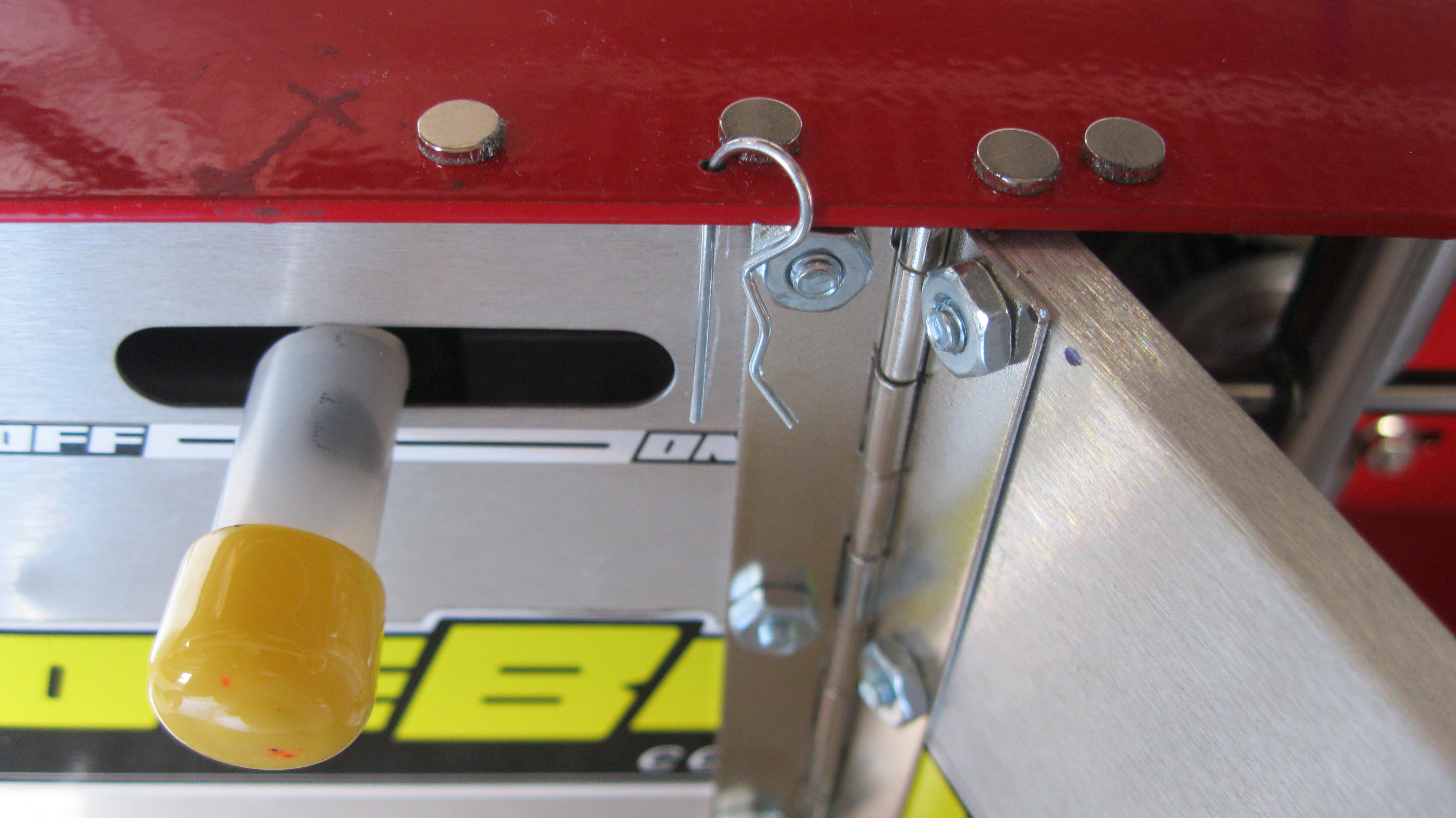

I initially planned to install the radiator along with the fan on the removable front panel, I drilled holes in the panel to allow the air flow. I ended up just using the stock Box fan, blowing through the holes instead. I also added a piano hinge to the right side of the front panel to allow lubrication of the pistons without removing the front panel.

Pictures to follow later today.

Here is the Walmart radiator....

I bought the radiator through Walmart, took a couple of weeks to get. Not a deal breaker as I already had the Box fan, but this rediator comes with a fan, however the specs on the Walmart page neglects to state that it's 204-220v, not 120v as needed. I'm not certain that it wouldn't work as I didn't try though. I picked this one because it has copper coils instead of plastic, I think that copper would transfer temperature better. (Unfortunately, made in China....I hate that)

As stated, I'm in process of running it through testing, but looks very promising so far. I currently am using a small bucket for the aquarium water pump but need something larger for a better heat sink.

I initially planned to install the radiator along with the fan on the removable front panel, I drilled holes in the panel to allow the air flow. I ended up just using the stock Box fan, blowing through the holes instead. I also added a piano hinge to the right side of the front panel to allow lubrication of the pistons without removing the front panel.

Pictures to follow later today.

Here is the Walmart radiator....

Last edited:

Upvote 0

Okay, attached are pics of the entire Box set up from low pressure Milton pre-filters, to the Box and water pump, radiator on back and close up of hinged front panel for lube access. Also included is the box that the small water pump came in for the part number information.

Any questions, just ask, not a problem. As stated however, it is very early in testing and I will provide more detailed information when it becomes available.

Mike

Any questions, just ask, not a problem. As stated however, it is very early in testing and I will provide more detailed information when it becomes available.

Mike

Upvote 0

I really like the way you made it your own with the customization. Got a couple of questions. Do you think it runs cooler with the cover off, completely off? I take my off while running it, assuming it would get a lot more ventilation. How often do you lube your pistons and with what grease, lithium?

Have you been lubing your crank arm bushings? I do mine but I thought the bushings were supposedly self-lubricating.

Any other tips, please do share.

jk

Have you been lubing your crank arm bushings? I do mine but I thought the bushings were supposedly self-lubricating.

Any other tips, please do share.

jk

Upvote 0

jking --=--

I ran it with the cover off for a long time, also added an external fan (table model) off to the right side, blowing in line with the pistons to try and keep it cooler. Not sure that worked as it is in essence blowing hot ambient air over an already hot piston/cylinder....but that's all I had at that time.

The holes were actually drilled to mount the new radiator in the front with the new fan, but that fell through due to the fan being 204/220 V as stated, so I thought that having holes (I could put a new plate over them) would actually be a good idea to keep cold air in there slightly longer for more cooling yet allow air to escape enough to create flow. I'm not a scientist, but it makes sense to me.

I do lube with white lithium grease, a very light coating on the pistons. I also have the felt pads that are lubed every third/fourth run, otherwise it gets pushed into the cylinders and becomes a gunky mess, causing the Box to not pump to the needed 4,300PSI.

I normally pump to 4,300PSI so as not to make the Box work harder than needed. I only need that much for a lot of shooting in one day. I typically top-off from around 3,800PSI to 4,300 PSI after every trip (once a week) to keep the Box running as short of a time as I can. Typical run time for that fill is between 45-60 minutes.

That is if it's not too humid. If it's too humid, (even with the pre and post moisture separators) I will use the large tank until it needs a larger top-off and go to a dive shop for that purpose.

I only lube the crank arm bushing when disassembling for reseal. Never had any issues doing it on that interval.

The water pump is now housed in a larger container with a lid to keep mosquitos out, and I will use three, maybe four, Pelican, 1-pound blue ice blocks to cool the water.

Problem at the moment is that weather-wise it's raining making it difficult for me to top-off a tank with high humidity (a rarity in my clime).

One tip that worked extremely well was when the burst disc popped, I found it on the back of the main air block. This meant that a complete disassembly was needed to replace it. I took careful measurements on its location and drilled a 1" hole through the back of the Box to access without removing anything but the burst disc for replacement. I used a deep socket to remove and replace. WAY less work! Amazon sells like 6 discs for not much money, and I believe that they are 7,500PSI.

Mike

I ran it with the cover off for a long time, also added an external fan (table model) off to the right side, blowing in line with the pistons to try and keep it cooler. Not sure that worked as it is in essence blowing hot ambient air over an already hot piston/cylinder....but that's all I had at that time.

The holes were actually drilled to mount the new radiator in the front with the new fan, but that fell through due to the fan being 204/220 V as stated, so I thought that having holes (I could put a new plate over them) would actually be a good idea to keep cold air in there slightly longer for more cooling yet allow air to escape enough to create flow. I'm not a scientist, but it makes sense to me.

I do lube with white lithium grease, a very light coating on the pistons. I also have the felt pads that are lubed every third/fourth run, otherwise it gets pushed into the cylinders and becomes a gunky mess, causing the Box to not pump to the needed 4,300PSI.

I normally pump to 4,300PSI so as not to make the Box work harder than needed. I only need that much for a lot of shooting in one day. I typically top-off from around 3,800PSI to 4,300 PSI after every trip (once a week) to keep the Box running as short of a time as I can. Typical run time for that fill is between 45-60 minutes.

That is if it's not too humid. If it's too humid, (even with the pre and post moisture separators) I will use the large tank until it needs a larger top-off and go to a dive shop for that purpose.

I only lube the crank arm bushing when disassembling for reseal. Never had any issues doing it on that interval.

The water pump is now housed in a larger container with a lid to keep mosquitos out, and I will use three, maybe four, Pelican, 1-pound blue ice blocks to cool the water.

Problem at the moment is that weather-wise it's raining making it difficult for me to top-off a tank with high humidity (a rarity in my clime).

One tip that worked extremely well was when the burst disc popped, I found it on the back of the main air block. This meant that a complete disassembly was needed to replace it. I took careful measurements on its location and drilled a 1" hole through the back of the Box to access without removing anything but the burst disc for replacement. I used a deep socket to remove and replace. WAY less work! Amazon sells like 6 discs for not much money, and I believe that they are 7,500PSI.

Mike

Upvote 0

You really don't need to concern your self with the humidity level when running a Shoebox, if you do it right - meaning allowing the air charge from the shop compressor to cool back to ambient before feeding the Shoebox.jking --=--

I ran it with the cover off for a long time, also added an external fan (table model) off to the right side, blowing in line with the pistons to try and keep it cooler. Not sure that worked as it is in essence blowing hot ambient air over an already hot piston/cylinder....but that's all I had at that time.

The holes were actually drilled to mount the new radiator in the front with the new fan, but that fell through due to the fan being 204/220 V as stated, so I thought that having holes (I could put a new plate over them) would actually be a good idea to keep cold air in there slightly longer for more cooling yet allow air to escape enough to create flow. I'm not a scientist, but it makes sense to me.

I do lube with white lithium grease, a very light coating on the pistons. I also have the felt pads that are lubed every third/fourth run, otherwise it gets pushed into the cylinders and becomes a gunky mess, causing the Box to not pump to the needed 4,300PSI.

I normally pump to 4,300PSI so as not to make the Box work harder than needed. I only need that much for a lot of shooting in one day. I typically top-off from around 3,800PSI to 4,300 PSI after every trip (once a week) to keep the Box running as short of a time as I can. Typical run time for that fill is between 45-60 minutes.

That is if it's not too humid. If it's too humid, (even with the pre and post moisture separators) I will use the large tank until it needs a larger top-off and go to a dive shop for that purpose.

I only lube the crank arm bushing when disassembling for reseal. Never had any issues doing it on that interval.

The water pump is now housed in a larger container with a lid to keep mosquitos out, and I will use three, maybe four, Pelican, 1-pound blue ice blocks to cool the water.

Problem at the moment is that weather-wise it's raining making it difficult for me to top-off a tank with high humidity (a rarity in my clime).

One tip that worked extremely well was when the burst disc popped, I found it on the back of the main air block. This meant that a complete disassembly was needed to replace it. I took careful measurements on its location and drilled a 1" hole through the back of the Box to access without removing anything but the burst disc for replacement. I used a deep socket to remove and replace. WAY less work! Amazon sells like 6 discs for not much money, and I believe that they are 7,500PSI.

Mike

Ambient humidity really only impacts the condensation that will occur in your shop compressor, not the Shoebox. This is because once the air is pressurized to even just a few bar, the dewpoint rises to way above ambient temperature, and thus the water vapor will condense out of the air in the shop compressor, if given time to cool back down to ambient. Basically, unless the air entering the shop compressor is very dry (with a dew point approaching 0 F), the air coming out of the compressor to feed the Shoebox is going to be at 100% relative humidity anyways - this is normal and is OK.

This is why we like to use a desiccant drier feeding the Shoebox, as most of the water vapor has already been condensed out by the shop compressor (approaching 90% of it) so it can be reasonably dried at this point if the filter is good enough. And once the air in the compressor system is sufficiently "dried out" there won't be condensation later - this is why I do not use a desiccant filter after my Shoebox, as I already have the air dry enough (saves time by not compressing wasted air there). I'd rather use more desiccant and run the compressor less than use less desiccant and run the compressor more.

I have attached a table that shows different values of absolute humidity under different conditions with resulting dewpoints. It is part of what I used to plan out what I would do. And I've attached a picture of my simple but extremely effective set up - which I have verified to work with direct inspection of fill tanks after close to 1000 cubic feet of air compressed through it, and careful measurement of the amount of water trapped (by weight) in my desiccant media. Not shown is the fact that the shop compressor is in the garage, and the Shoebox is in my basement workshop and is fed via a manifold with liquid traps and over 70 feet of line, allowing for a fully cooled down air charge (never above about 60-70F in my case).

View attachment Dewpoint and absolute humity values.pdf

Last edited:

Upvote 0

AlanMcD --=--

I thank you for the chart and have it downloaded and ready to print now.

Unfortunately, my shop compressor is within 4 feet of the Box, connected with a coiled plastic line that perhaps has a length of +- 20 feet. Likely not enough to allow the cooling time required per your used length.

It is strange however that I have yet to see/realize any moisture in the low-pressure moisture separator. I have an initial one on the shop compressor's manifold, then a particulate filter, then the sieve moisture filter that has the blue to pink silicate beads within (in pic).

So, I'm not certain that I truly have a moisture issue but have in the distant past before installing the Milton filter bank, seen evidence of moisture when resealing the Box. Although that evidence could possibly have been from over lubing the felts for the pistons, creating liquid gunk at the check valves.

While the silicate has just now turned a slightly in between blue/pink color, I have changed it out, yet still see zero moisture in the filter (I added a small blow-off valve at the bottom to check) and it was completely dry when the media was changed.

Might you have any ideas on that please?

Thank you!

Mike

I thank you for the chart and have it downloaded and ready to print now.

Unfortunately, my shop compressor is within 4 feet of the Box, connected with a coiled plastic line that perhaps has a length of +- 20 feet. Likely not enough to allow the cooling time required per your used length.

It is strange however that I have yet to see/realize any moisture in the low-pressure moisture separator. I have an initial one on the shop compressor's manifold, then a particulate filter, then the sieve moisture filter that has the blue to pink silicate beads within (in pic).

So, I'm not certain that I truly have a moisture issue but have in the distant past before installing the Milton filter bank, seen evidence of moisture when resealing the Box. Although that evidence could possibly have been from over lubing the felts for the pistons, creating liquid gunk at the check valves.

While the silicate has just now turned a slightly in between blue/pink color, I have changed it out, yet still see zero moisture in the filter (I added a small blow-off valve at the bottom to check) and it was completely dry when the media was changed.

Might you have any ideas on that please?

Thank you!

Mike

Upvote 0

I'm loving all the booster discussion.

Boosters have been my source of air since 2018, Shoebox F10 for most of that time, Altaros for the last about 8-10months.

@Revoman, seems like you and I maybe talked about this at one time.....I agree on the humidity level. More humidity in the air = more water in blowouts = more water in the system. And yeah that water is typically focused in the low pressure side (blowouts and silica dryers) but it's still in the system.

Where I live the humidity is typically in the teens (%), and when it's a rainy day, logically much higher. Rainy days = more moisture in the shop compressor blowouts and pre booster dryers. I've always used at least a 100foot low pressure line between the compressor and the booster, and have always placed the booster above the shop compressor, with hopes the water will condense out on the inside of all that surface area the low pressure lines represent, and run back downhill.

Boosters have been my source of air since 2018, Shoebox F10 for most of that time, Altaros for the last about 8-10months.

@Revoman, seems like you and I maybe talked about this at one time.....I agree on the humidity level. More humidity in the air = more water in blowouts = more water in the system. And yeah that water is typically focused in the low pressure side (blowouts and silica dryers) but it's still in the system.

Where I live the humidity is typically in the teens (%), and when it's a rainy day, logically much higher. Rainy days = more moisture in the shop compressor blowouts and pre booster dryers. I've always used at least a 100foot low pressure line between the compressor and the booster, and have always placed the booster above the shop compressor, with hopes the water will condense out on the inside of all that surface area the low pressure lines represent, and run back downhill.

Upvote 0

Franklink --=--

I'm not sure about talking with you about moisture but thank you for the valued input now (by the way, that is the F-10 depicted that you sold to me).

I too live in a dry clime, but as you stated, rainy weather is no time to use the compressor/Box, at least in my view.

Putting your input and AlanMcD's together, perhaps I should simply coil up a 100' hose around the base of my shop compressor then use the three Milton filters to further consolidate the non-moisture issue by allowing cooling to occur.

My Box is higher than the shop compressor, however the Milton filters are higher than the Box. The high-pressure separator is also lower that the Box. I can at times hear what sounds like a slight gurgle when decompressing the high-pressure moisture separator post filling, but it's minor and I cannot feel any moisture on my hand/fingers, nor see any sign on the cloth that I use to mitigate the high-pressureair flow.

I agree this thread has many good ideas and advice for using the Box and shop compressor for filling.

Mike

I'm not sure about talking with you about moisture but thank you for the valued input now (by the way, that is the F-10 depicted that you sold to me).

I too live in a dry clime, but as you stated, rainy weather is no time to use the compressor/Box, at least in my view.

Putting your input and AlanMcD's together, perhaps I should simply coil up a 100' hose around the base of my shop compressor then use the three Milton filters to further consolidate the non-moisture issue by allowing cooling to occur.

My Box is higher than the shop compressor, however the Milton filters are higher than the Box. The high-pressure separator is also lower that the Box. I can at times hear what sounds like a slight gurgle when decompressing the high-pressure moisture separator post filling, but it's minor and I cannot feel any moisture on my hand/fingers, nor see any sign on the cloth that I use to mitigate the high-pressureair flow.

I agree this thread has many good ideas and advice for using the Box and shop compressor for filling.

Mike

Upvote 0