I know air gunners are pretty creative. Let's see what you come up with. I have limited mechanical skills, so no mills, lathes or cnc machines. I'd like to see you from the cheapest of the cheap to the ones that cost more than the a.g. itself. I'll post mine up when it is completed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show me your DIY moderators!!!

- Thread starter IMADMAN

- Start date

- Status

- Not open for further replies.

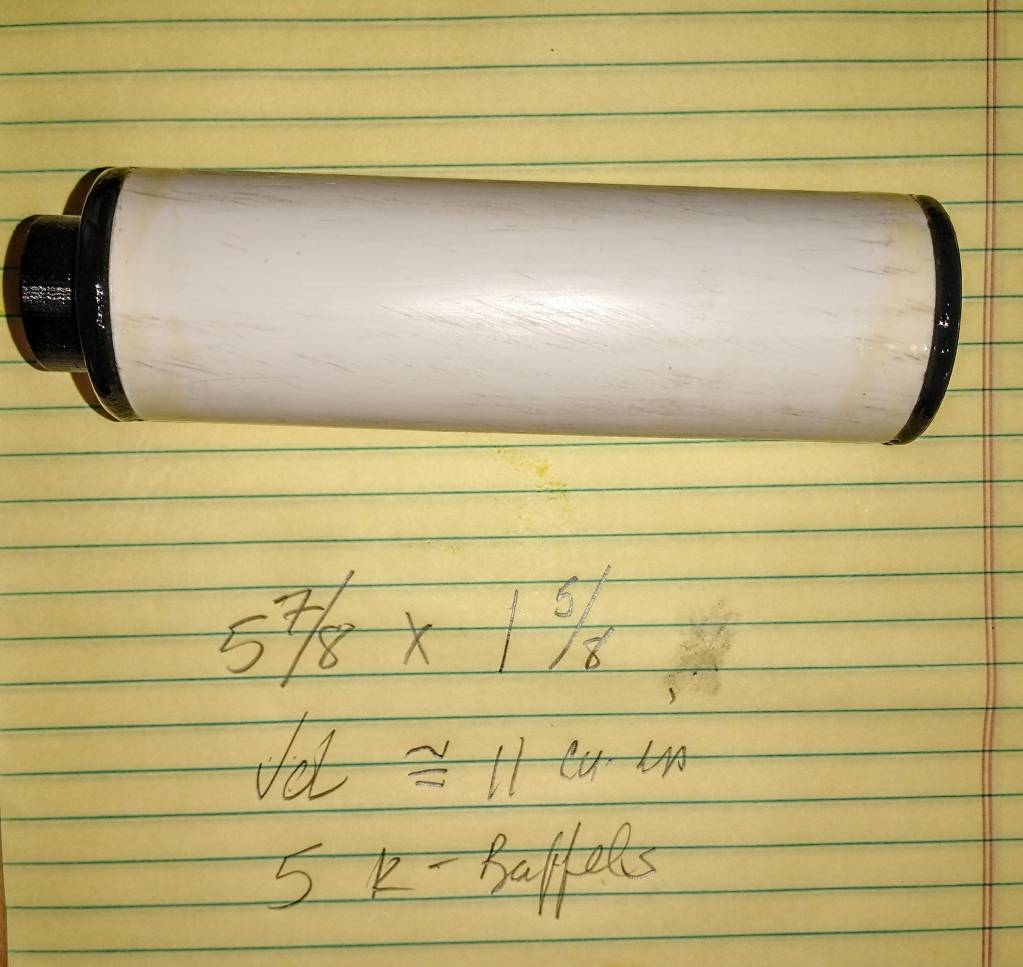

Well OK, I'll bite.

I have not finished the work. It has not even been shot once. Perhaps tomorrow, weather permitting.

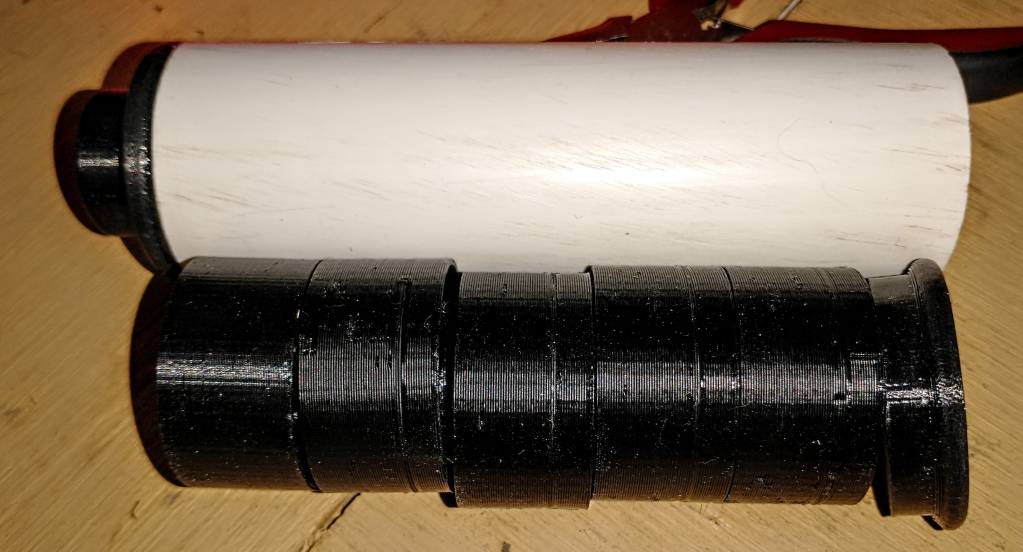

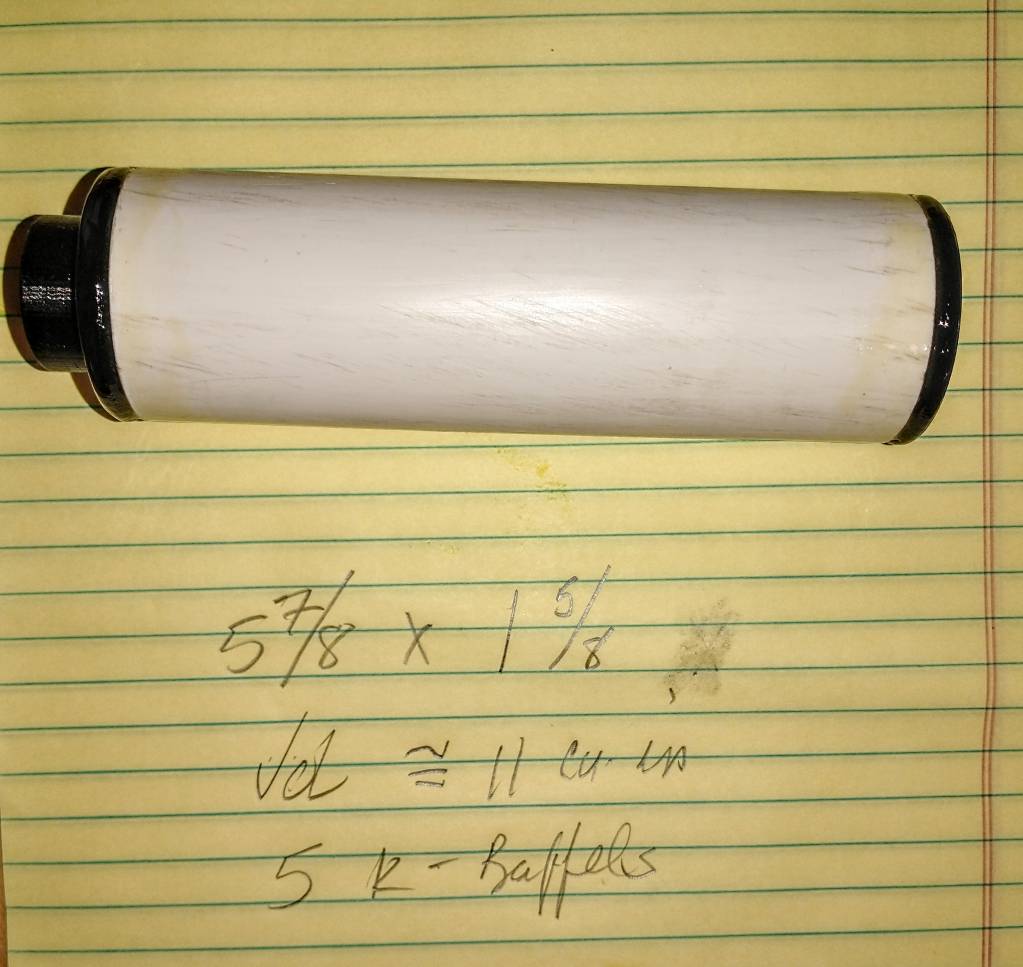

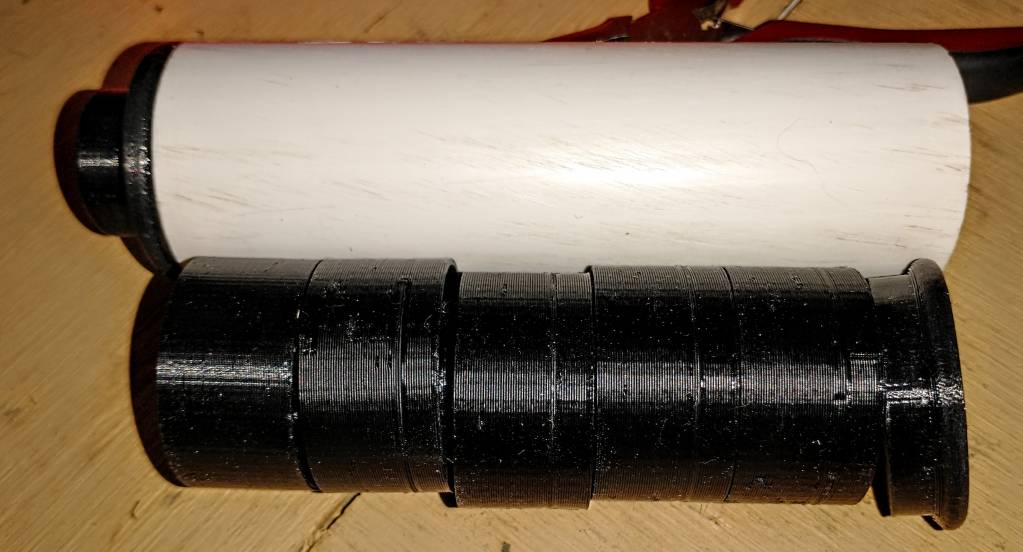

The finished unit will have a side wall of carbon fiber (if I decide the weight savings are worth it). At this time it is PVC water pressure pipe. Strength is not the issue, weight is the issue. This thing weighs about five or maybe six ounces, which can be trimmed some by changing the baffle design.

ID is 38mm

OD is 42.5mm

Functional length inside is 120mm

OAL is 150mm

Internal volume empty is about 12 cu. in.

There are 5 baffles, each 20mm tall inside.

There is an expansion chamber at the barrel end which is about 1.5 cu in.

The baffles are stacked against the muzzle end end cap.

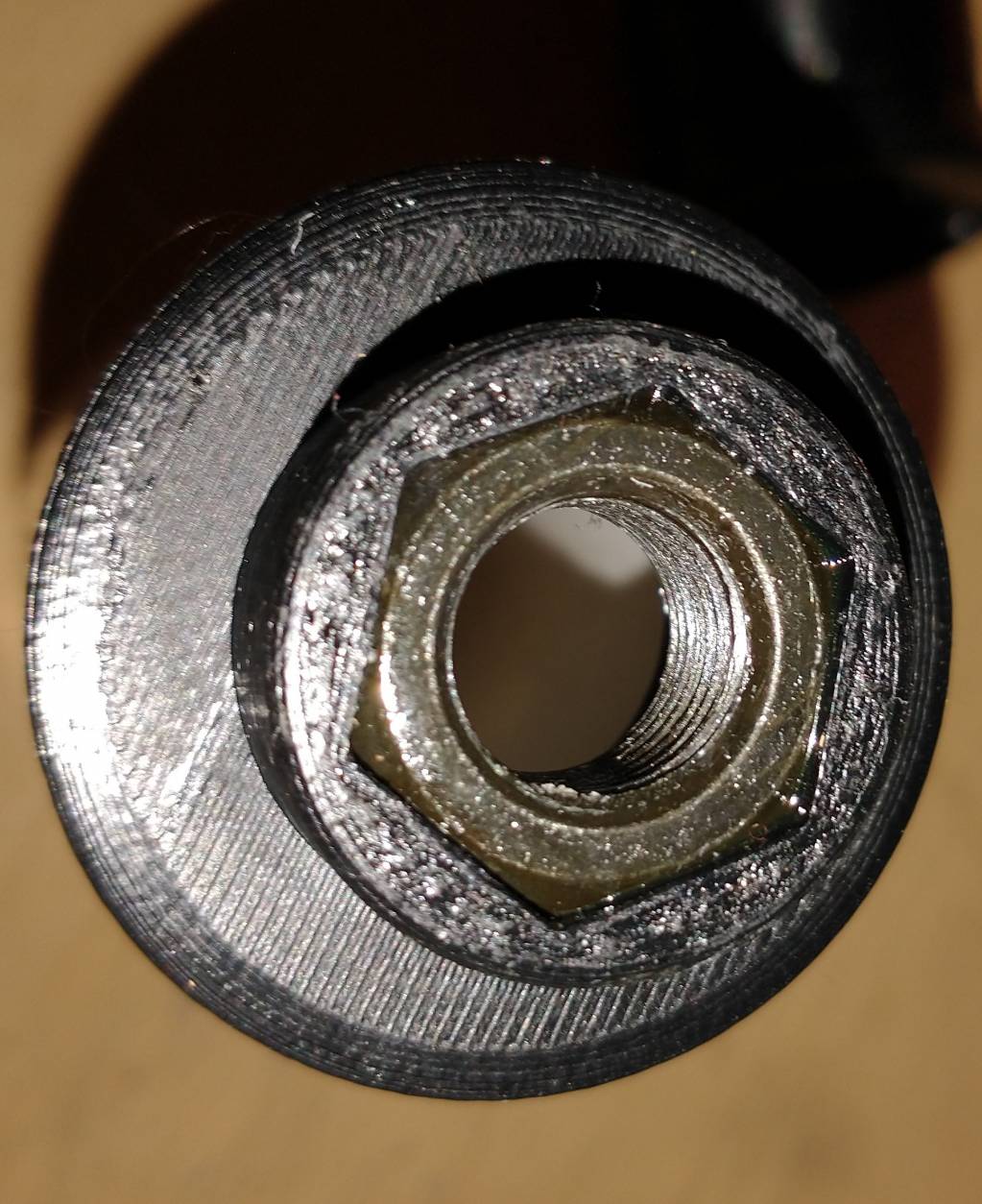

There is a 1/2 x 20 UNF nut embedded in the end cap to attach to a rifle. I can print that cap so that the nut is not exposed. This will do for prototyping.

A touch of flat black paint should improve the appearance of the device but I won't need to do that till I've tested it. Who knows how bad it might be clipping?

I have not finished the work. It has not even been shot once. Perhaps tomorrow, weather permitting.

The finished unit will have a side wall of carbon fiber (if I decide the weight savings are worth it). At this time it is PVC water pressure pipe. Strength is not the issue, weight is the issue. This thing weighs about five or maybe six ounces, which can be trimmed some by changing the baffle design.

ID is 38mm

OD is 42.5mm

Functional length inside is 120mm

OAL is 150mm

Internal volume empty is about 12 cu. in.

There are 5 baffles, each 20mm tall inside.

There is an expansion chamber at the barrel end which is about 1.5 cu in.

The baffles are stacked against the muzzle end end cap.

There is a 1/2 x 20 UNF nut embedded in the end cap to attach to a rifle. I can print that cap so that the nut is not exposed. This will do for prototyping.

A touch of flat black paint should improve the appearance of the device but I won't need to do that till I've tested it. Who knows how bad it might be clipping?

Upvote 0

Well OK, I'll bite.

I have not finished the work. It has not even been shot once. Perhaps tomorrow, weather permitting.

The finished unit will have a side wall of carbon fiber (if I decide the weight savings are worth it). At this time it is PVC water pressure pipe. Strength is not the issue, weight is the issue. This thing weighs about five or maybe six ounces, which can be trimmed some by changing the baffle design.

ID is 38mm

OD is 42.5mm

Functional length inside is 120mm

OAL is 150mm

Internal volume empty is about 12 cu. in.

There are 5 baffles, each 20mm tall inside.

There is an expansion chamber at the barrel end which is about 1.5 cu in.

The baffles are stacked against the muzzle end end cap.

There is a 1/2 x 20 UNF nut embedded in the end cap to attach to a rifle. I can print that cap so that the nut is not exposed. This will do for prototyping.

A touch of flat black paint should improve the appearance of the device but I won't need to do that till I've tested it. Who knows how bad it might be clipping?

That is way cool! Thanks for sharing!

Upvote 0

Have rules changed? I thought discussing the construction and design of moderators was prohibited, but I see several threads in here and at least one of them was moved by a mod/admin to this new section.

Upvote 0

Have rules changed? I thought discussing the construction and design of moderators was prohibited, but I see several threads in here and at least one of them was moved by a mod/admin to this new section.

I believe you are confusing this forum with another outdated forum which had all sorts of censorship policies and rules. I could be wrong, I suppose. You could flag the thread and run it past a moderator.

Upvote 0

They seem to know the posts are here, no need to flag anything. I'll just read and store info.

Upvote 0

30mm OD CFT with 28mm ID, 28mm delrin discs cut on my lathe, 30mm/28mm aluminum end pieces, 28mm delrin barrel spaces with 5/8" holes to fit tight on barrel. Drillled 1/8" holes in spacers so air could flow back from the muzzle, actual LDC about 5.25" ahead of crown. (6) 28mm delrin discs held between varying 28mm CFT spacers.

Upvote 0

nice, if it works good you might consider schedule 20 pvc (low pressure) for a weight savings on the tube.

Upvote 0

Made up this dinky little thing to take the crack out of my AP16. No baffles, just a single open chamber and a close tolerance exit hole (which acts as a baffle I guess). Anyway it's tiny and dumb but bombproof and did what I needed it to do.

Upvote 0

Could not find a moderator that would be mouse fart quiet for my low power back yard guns so I made my own.

Made some for my friend’s avengers and airarm.

Made some for my friend’s avengers and airarm.

Last edited:

Upvote 0

I have been wondering lately about using old politicians yard signs corrugated plastic ones and cutting baffles from that material / cut 1/4 inch id x 1 inch od washer shape and glue a few together then spaced apart . i suppose you could use regular cardboard as a test . but paper and humidity do not mix so only a test. I made one from cork sheet once but to fragile , it worked for a time .

If the sign material works you could say "BS to silence is golden" ?

If the sign material works you could say "BS to silence is golden" ?

Upvote 0

This one is going to it's new home this afternoon.

Click to enlarge.

This one turned out ok and it works pretty well.

Click to enlarge.

This one turned out ok and it works pretty well.

Last edited:

Upvote 0

Cheapest of the cheap? Limited skills?I know air gunners are pretty creative. Let's see what you come up with. I have limited mechanical skills, so no mills, lathes or cnc machines. I'd like to see you from the cheapest of the cheap to the ones that cost more than the a.g. itself. I'll post mine up when it is completed.

For barrels up to 0.55" (14mm), you can use 1/2" PVC pipe with alternating #10 finishing washers and split-ring lockwashers (bent flat):

Little ring of PVC glued into the end to capture the washer stack:

3 grub screws tapped right into the PVC for securing it to the barrel:

Or to improve internal volume and reduce weight, use springs as spacers between the finishing washers:

As crude as it is, it takes out a lot of the bark.

Upvote 0

That looks awesome! Going to doing more?This one is going to it's new home this afternoon.

Click to enlarge.

View attachment 269123

View attachment 269124

View attachment 269125

View attachment 269126

This one turned out ok and it works pretty well.

Upvote 0

Yes If I can find a market I would like to start selling them. There is still a bit of testing that needs doing and I think I can improve the appearance a bit as well... What gun do you want to put it on?That looks awesome! Going to doing more?

Upvote 0

My current gun is a Taipan Compact Vet in .25 with a plenum extension. I would need a 30 mm diameter unit. Drop me a PM with a ballpark price and your specs. Thanks.Yes If I can find a market I would like to start selling them. There is still a bit of testing that needs doing and I think I can improve the appearance a bit as well... What gun do you want to put it on?

Upvote 0

I'm sorry. Kind of you to suggest that idea but I'm not really ready to set price points and I haven't finished researching yet. I am about 2 weeks out from production. The shooters who are testing have not finished their work.My current gun is a Taipan Compact Vet in .25 with a plenum extension. I would need a 30 mm diameter unit. Drop me a PM with a ballpark price and your specs. Thanks.

Upvote 0

- Status

- Not open for further replies.