You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show me your DIY moderators!!!

- Thread starter IMADMAN

- Start date

- Status

- Not open for further replies.

Yes, these printers are great for prototyping but not so great for production unless you have a printer farm. If you print all the parts at an "acceptable" quality a good printer could probably produce about 3 moderators in 24 hours. Depending upon the size of the moderator and the desired quality. Once you have the STL files you can go to production any number of ways. I think injection molding would be the smart route in the AG world, not so much in the PB worldNever thought about it much. Raw material cost would be around $15 or less. I can make a threaded end cap on a manual lathe in about 15 min. So lets say 45 min labor or an hour to make it even. The baffles take longer to print but you are not standing there working the printer like a manual lathe. The baffles cost 15 cents in material. Depending on the rate at which a person would charge for the machining it could be as little as $75. I also would not go into production using manual equipment. I would run it on a cnc lathe with dual spindles. What the production cost would be using that equipment I dont know. It would boil down to how many tubes and caps could be pumped out. I will ask the guys in the machine shop how many baffles and tubes they can crank out on that piece of equipment.

Qball looked at some of my drawings and pointed out that I was putting the baffles too close together, so I tested that. Yup, he was right. I've spent the last month chasing a more dense baffle design thinking more baffles would work better. Nope. Testing yesterday showed that very clearly. The baffles need room to work. That kind of frustrates the effort to get the most baffles you can in the smallest space.

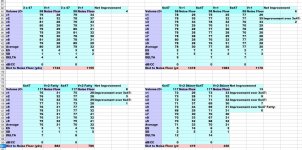

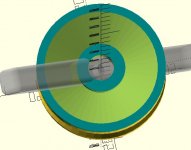

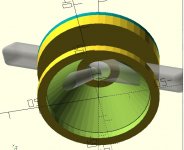

Here is the test you are talking about doing. I printed out three moderators. Each had six "Tesla Diodes" (for lack of a better name) arranged in the same pattern. Each diode had a 47 degree pitch and was identical to all the others in all the moderators. I varied length to double volume and I varied diameter to double volume.

You will see some references to "Improvement over xxxx". There was a previous experiment where I put three baffles in a 29x83 to test what happened when I doubled the number of baffles in the same tube. I picked up 2 dB that way.

After that I tested the improvement due to increasing volume. In that one the aseline was 29x83, "Skinny" was 29x166, "Fatty" was 42x83 (or whatever diameter is was that doubled the volume. Here is the spread sheet with the data.

NOTE: Edited to include more amplifying data.

Last edited:

Upvote 0

Thats exactly what I have found with stacked designs. Get them to short and close and it ruins it. I am going to start drawing up a 60 degree k style or modified k style baffle.

Upvote 0

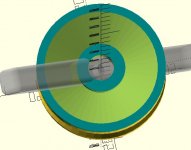

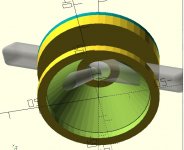

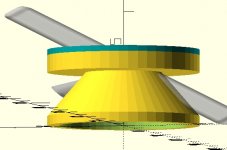

I have not had time to test this one much. I think it probably likes high power more than one without the "mouse hole" in it, but not sure that is just a guess at best. Seemed like that. I kept thinking this would work better if I was pushing it harder on a more powerful gun. Worth a try I suppose. Those gray shapes are the cuts to make the ramp and mouse hole and how they should line up with the jet from the muzzle.

Upvote 0

D

Deleted 45061

Guest

Hi Alphabet orgI know air gunners are pretty creative. Let's see what you come up with. I have limited mechanical skills, so no mills, lathes or cnc machines. I'd like to see you from the cheapest of the cheap to the ones that cost more than the a.g. itself. I'll post mine up when it is completed.

Upvote 0

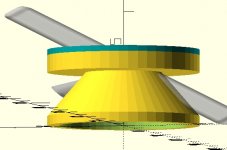

That little notch makes a big difference. I took a chain saw file too the cones in my Storm Rider and picked up about one and a half dBs.I just drew up a 60 degree cone. This is a design I will print tomorrow.View attachment 292407

Upvote 0

- Status

- Not open for further replies.