This forum has been a great place to find lots of information about the operation and repair of YH compressors. Here's a bit more information that people may find useful at some point...

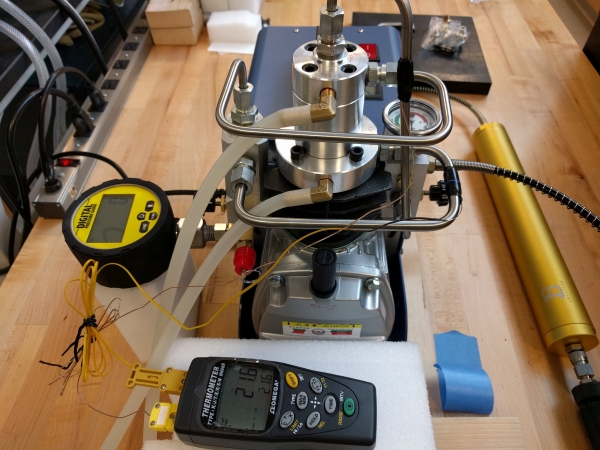

Today I finally got around to connecting a tee to the output of the 1st stage so I could monitor the output pressure of the 1st stage. I've included a picture of the setup below. Bascially, I just filled a gold filter to 4800 psi so it wouldn't take so long.To do this,I stuck a brass M10x1.0 tee where the red check valve was located and replaced the check valve after the tee. The digital pressure gauge is calibrated and accurate to 0.25% FS, which is, unfortunately, 6000psi, so the readings are +/-15psi. It turns out that the 1st stage is basically a 10:1 compressor as the output from it never went beyond 158psi. It was basically level at 155-158psi once the output gauge reached about 3000 psi. I monitored the 1st stage pressure from start until the output pressure was 4800psi.

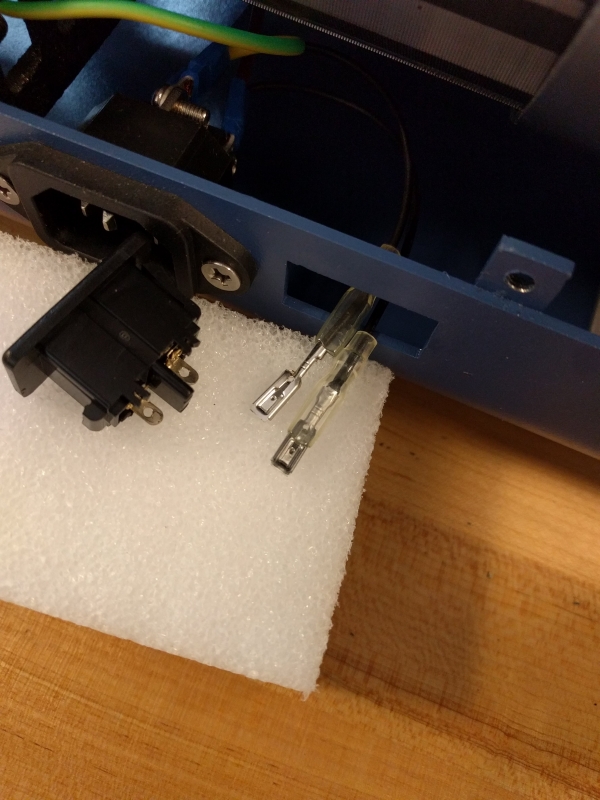

Also, during the test the receptacle for the water pump power vibrated loose - one of the plastic retaining clips on the side had busted.and this allowed the receptacle to vibrate loose and the spade wire connectors shook loose. That's kind of scary since those wires bring 220 to the receptacle for the supplied water pump (which I don't use). I was lucky the bare space connectors didn't contact one another and short.out. They do have an insulated housing but it slides easily back onto the wire to expose the bare metal spade lugs. So if you aren't using that receptacle for power, you might want to just disconnect the spade lugs and wrap them in electrical tape - that's what I did.

And one last thing - while I had the cover of the motor off, I noticed that the wiring for the reset button runs between the capacitor and the motor body. In mine, it was snug between those two. I'm not sure whether it's better to leave those wires there to prevent the capacitor from rubbing against the motor armature or move them and just leaving <1mm space between the capacitor and armature. With the heavy vibration of the unit while running, I'm a bit afraid that the capacitor might hit the armature repeatedly if it weren't "buffered" by the wire - so I left the wires jammed between the two and will just check on it every once in awhile.If it comes to it, I'll just snip the wires so they aren't connected to the power supply and use them as padding. I've attached a picture of what I am talking about below.

Anyway, this might be useful to someone if they experience a failure and it isn't one of the more obvious things to check (like has been covered in other threads).

Today I finally got around to connecting a tee to the output of the 1st stage so I could monitor the output pressure of the 1st stage. I've included a picture of the setup below. Bascially, I just filled a gold filter to 4800 psi so it wouldn't take so long.To do this,I stuck a brass M10x1.0 tee where the red check valve was located and replaced the check valve after the tee. The digital pressure gauge is calibrated and accurate to 0.25% FS, which is, unfortunately, 6000psi, so the readings are +/-15psi. It turns out that the 1st stage is basically a 10:1 compressor as the output from it never went beyond 158psi. It was basically level at 155-158psi once the output gauge reached about 3000 psi. I monitored the 1st stage pressure from start until the output pressure was 4800psi.

Also, during the test the receptacle for the water pump power vibrated loose - one of the plastic retaining clips on the side had busted.and this allowed the receptacle to vibrate loose and the spade wire connectors shook loose. That's kind of scary since those wires bring 220 to the receptacle for the supplied water pump (which I don't use). I was lucky the bare space connectors didn't contact one another and short.out. They do have an insulated housing but it slides easily back onto the wire to expose the bare metal spade lugs. So if you aren't using that receptacle for power, you might want to just disconnect the spade lugs and wrap them in electrical tape - that's what I did.

And one last thing - while I had the cover of the motor off, I noticed that the wiring for the reset button runs between the capacitor and the motor body. In mine, it was snug between those two. I'm not sure whether it's better to leave those wires there to prevent the capacitor from rubbing against the motor armature or move them and just leaving <1mm space between the capacitor and armature. With the heavy vibration of the unit while running, I'm a bit afraid that the capacitor might hit the armature repeatedly if it weren't "buffered" by the wire - so I left the wires jammed between the two and will just check on it every once in awhile.If it comes to it, I'll just snip the wires so they aren't connected to the power supply and use them as padding. I've attached a picture of what I am talking about below.

Anyway, this might be useful to someone if they experience a failure and it isn't one of the more obvious things to check (like has been covered in other threads).