An interesting turn of events today! I decided to spend some time re-evaluating these two new 700mm CZs that I've had stashed away for a few months. I knew they had tight bores, super-conservative chamber throats (chamber "leade in"), and unintentional chokes in them (likely from aggressive machining / threading operations at the factory.

My prior experience shooting a 700mm CZ was in a friend's rifle was anything but spectacular (3-6" at 100y no matter what ammo I tried). I figured if worse came to worse, I would chop one down 100mm and see what happens

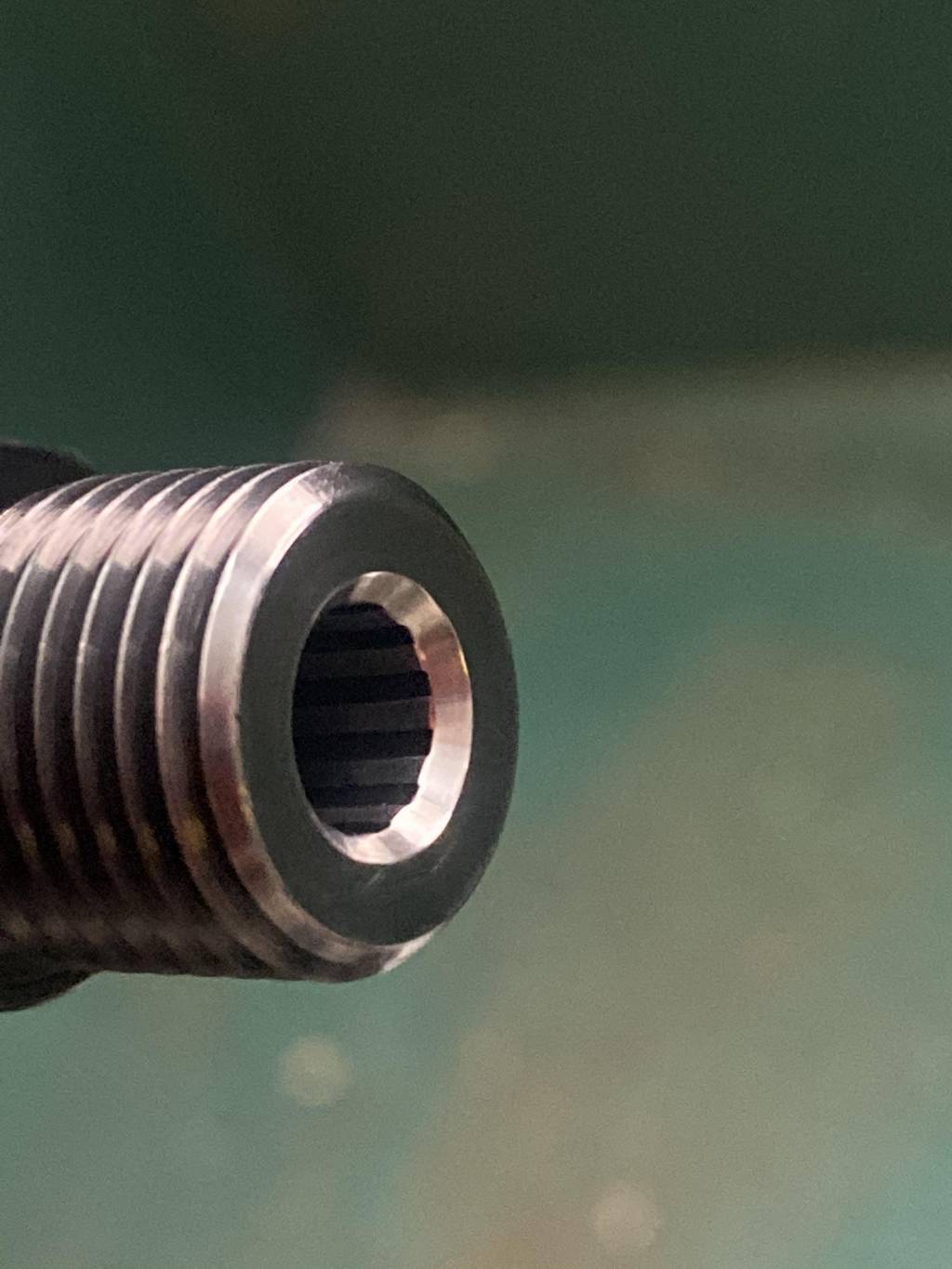

Longer story short, I realized today that there were common problems with these barrels (and likely others out in the wild) - the primary issue - they both had some burrs at the muzzle crown! These burrs are like a big fat speed bump for the projectile exiting the barrel. I pushed an 18gr JSB through the bore, which started off a little rough, then smoothed out until it hit a slight choke (3/4" from the muzzle), where it then came to a DEAD stop right at the crown!

Made an attempt to lap it away with my brass lapping tool, but that failed because it was too recessed. I could see that it was going to take some effort after I saw it through my 90 degree borescope attachment.

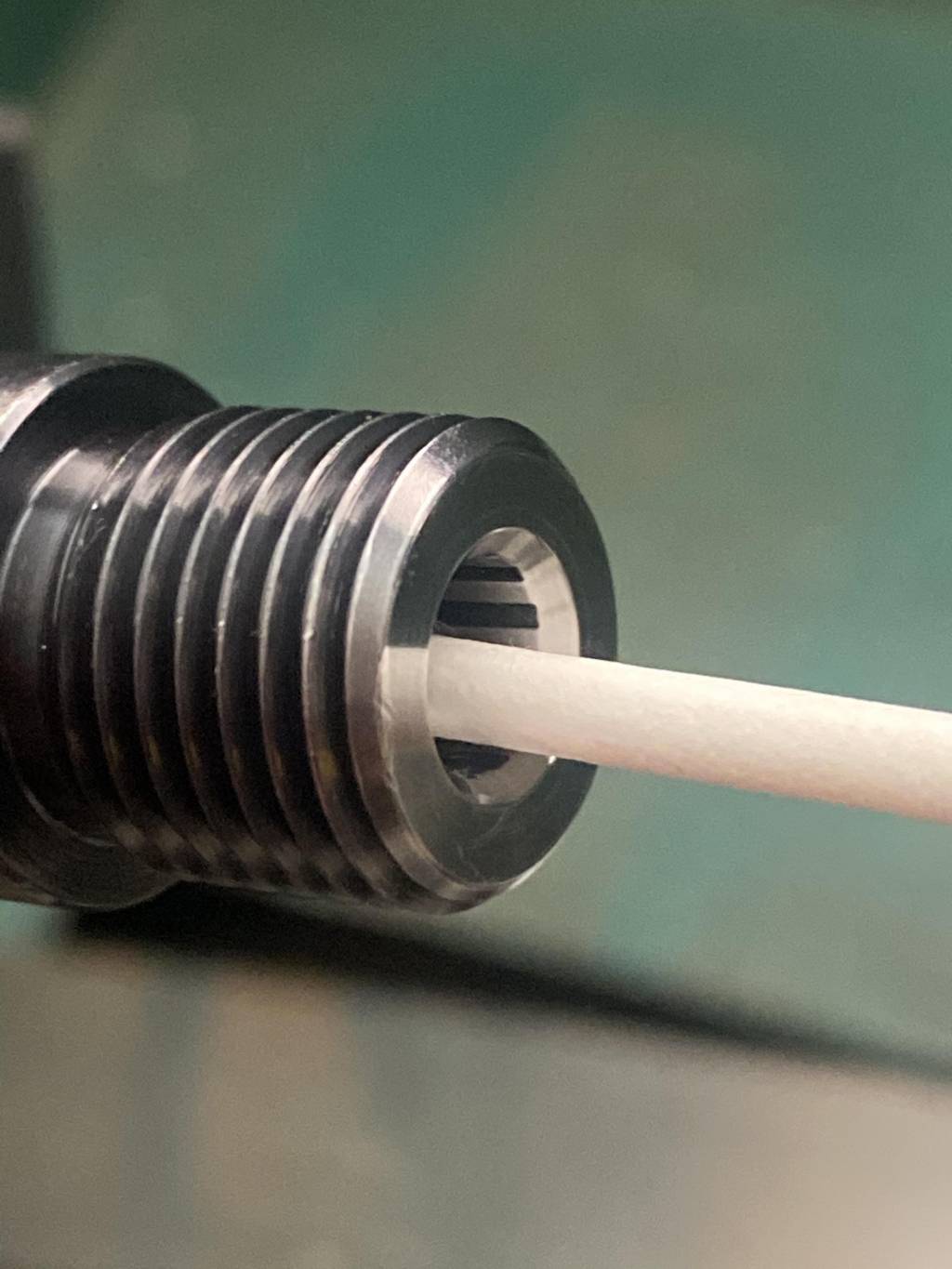

Being late in the day and a little burned out on barrel machining and unmotivated to set my lathe back up for barrel turning (I had already machined two other custom barrels this week and stowed away my 4-jaw), I decided to use my .22cal hand crowning tool, I just needed to make a new brass pilot for it matching the diameter of the crown burr, and I would then cut away the burr while making a new 45 degree crown. I had already made a CZ .22 brass bore pilot anyway, so this plan made the most sense.

After two passes with the hand tool - bingo! My CZ bore pilot fit and I finished up the new crown. Probably the largest 45 degree crown that I have made to date, but hey it worked

I could probably face it a little and shrink it, but who cares

So how does it shoot? MUCH better than the first 700mm that I shot! Although, I was ill prepared today making the last minute decision to test it. I was rushed to install the barrel, scope the rifle, and race out to my shooting spot (it's illegal to shoot here after 5pm now!). I turned up the reg from 100bar to 150, but forgot to put in a heavier spring. It was also very windy as usual, and I didn't grab all the ammo that I intended to test - but I only had about an hour before I had to pack up and leave.

Even with the suboptimal velocities, it was still printing 1.5" in the wind with 24.8gr NSAs, 24gr (2S nose) Varmint Knockers, and 32.80gr XLHPs. The few Monster RDs that I had were in two tuns that have been at the bottom of my range bag since late 2018 .. but they show STRONG signs of doing well with these barrels!

.. but they show STRONG signs of doing well with these barrels!

If anyone needs guidance for getting your barrel to shoot right, let me know. ALSO, very important - I also discovered a while ago with my 550mm CZ that reinstalling these barrels can be TRICKY!!!! There's a tendency for them to bottom out in a way that they're incorrectly oriented! If you were to torque the barrel down real tight with the barrel skewed non-concentric, and if you were to torque down the caps on the trigger housing, your barrel would be ruined (bent)! There's a process that I've developed that I can share at some point, but feel free to ping me if you need help

My prior experience shooting a 700mm CZ was in a friend's rifle was anything but spectacular (3-6" at 100y no matter what ammo I tried). I figured if worse came to worse, I would chop one down 100mm and see what happens

Longer story short, I realized today that there were common problems with these barrels (and likely others out in the wild) - the primary issue - they both had some burrs at the muzzle crown! These burrs are like a big fat speed bump for the projectile exiting the barrel. I pushed an 18gr JSB through the bore, which started off a little rough, then smoothed out until it hit a slight choke (3/4" from the muzzle), where it then came to a DEAD stop right at the crown!

Made an attempt to lap it away with my brass lapping tool, but that failed because it was too recessed. I could see that it was going to take some effort after I saw it through my 90 degree borescope attachment.

Being late in the day and a little burned out on barrel machining and unmotivated to set my lathe back up for barrel turning (I had already machined two other custom barrels this week and stowed away my 4-jaw), I decided to use my .22cal hand crowning tool, I just needed to make a new brass pilot for it matching the diameter of the crown burr, and I would then cut away the burr while making a new 45 degree crown. I had already made a CZ .22 brass bore pilot anyway, so this plan made the most sense.

After two passes with the hand tool - bingo! My CZ bore pilot fit and I finished up the new crown. Probably the largest 45 degree crown that I have made to date, but hey it worked

I could probably face it a little and shrink it, but who cares

So how does it shoot? MUCH better than the first 700mm that I shot! Although, I was ill prepared today making the last minute decision to test it. I was rushed to install the barrel, scope the rifle, and race out to my shooting spot (it's illegal to shoot here after 5pm now!). I turned up the reg from 100bar to 150, but forgot to put in a heavier spring. It was also very windy as usual, and I didn't grab all the ammo that I intended to test - but I only had about an hour before I had to pack up and leave.

Even with the suboptimal velocities, it was still printing 1.5" in the wind with 24.8gr NSAs, 24gr (2S nose) Varmint Knockers, and 32.80gr XLHPs. The few Monster RDs that I had were in two tuns that have been at the bottom of my range bag since late 2018

If anyone needs guidance for getting your barrel to shoot right, let me know. ALSO, very important - I also discovered a while ago with my 550mm CZ that reinstalling these barrels can be TRICKY!!!! There's a tendency for them to bottom out in a way that they're incorrectly oriented! If you were to torque the barrel down real tight with the barrel skewed non-concentric, and if you were to torque down the caps on the trigger housing, your barrel would be ruined (bent)! There's a process that I've developed that I can share at some point, but feel free to ping me if you need help