Previously I have copied the Airforce baffle stack in TPU and run a quick test this morning. This is proving to be more difficult than I expected. I am going to detail that momentarily, however, I want to address something which may or may not prove out in the accuracy testing down the road. At this point it is s SUSPICION and purely undocumented except for my subjective observations.

Yesterday when testing with the stock baffle stack accuracy was bang on and then the next group would fall apart. Then I'd buckle down and shoot another good group. As I tested it over and over I finally concluded that wind seemed to be opening my groups up. Now I am not saying causing drift, I am saying pellet stability seemed to be an issue when there was a breeze blowing. Normally that rifle is a 3/8" rifle at 25 yards but I had never tested it in moderate (5 to 15mph) winds. I did not observe the same problem with the PETG or TPU design but they were both about a dB louder.

You can see that data from the post above. That said, those observations are not measured they are therefore little more than suspicion at this point.

ONWARD!

Yesterday printing went well and I managed to complete the TPU stack and do some shooting in the evening. Things sounded good and I was hopeful that the gun was now quieter than with the stock baffle set. I went to bed eager to get up and run the test this morning. When I woke it was quite windy. I walked the dogs and made a "wind break" for the camera and got down to testing.

The method was otherwise identical to my normal method and I got results which looked pretty good. I compiled audio of three shot samples for the bare rifle, the stock baffle stack, and the TPU baffle stack.

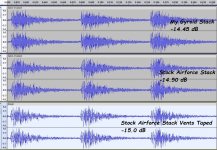

Here is that information in a graphic.

How about that?! Still no joy! The stock baffle stack still wins by 0.6 dB. Yesterday the difference between the stock baffles and my TPU design was 24% (about 1.2 decibels) today is is 13%. Now that doesn't seem like much of an improvement but (and this is where dBs are going to bake your noodle) that difference is 3 decibels. Yup. You have to remember the rule if you double the power you have changed it by 3 decibels. It doesn't matter what power you started with only that you doubled it (or in this case halved the difference).

Never the less I still have no joy. Those kids at Airforce did their homework and they have shown me that their choice of material is more absorptive than I thought. Perhaps I could improve upon my material by using a different density? More on that later.

Well if you listen really closely you may be able hear the difference in this audio sample. I can not hear the difference but my ears aren't so good anymore. Three shots each from the bare rifle, the stock baffles, and the TPU baffles. Each shot sampled for a duration of 250ms.

I want to talk a little about the difference between these two moderators so that we can get an idea of the magnitude of difference we are discussing. There is a number I like to calculate when I am comparing moderators.

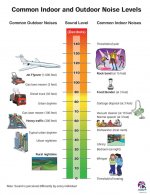

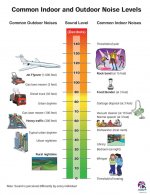

In the past I have called it the "distance to noise floor" and explained that here. I think a better name for that calculation would be the "detectable range". Simplifying the formula by declaring a standard noise floor would be helpful. Here is a chart. You can use when you are making these sorts of measurements with your phone. Your phone uses this scale.

When I test I actually measure the noise floor. I don't usually report it because I am not reporting detectable range. Lets look at that number for both moderator stacks I tested today. The noise floor was measured at -44 dB. The bare rifle tested at -11.42 dB. That is a difference of 32. 46 decibels and works out to a "detectable range" of 213 yards if the sensor was at 5 yards. The stock baffle stack was measured at -18.54 dB. That is a difference of 25.46 dB and works out to a detectable range of 95 yards.

I told you it was a good moderator

. Ninety five yards! That is not bad! On a windy morning in the country you are not going to be able to hear this thing at 100 yards! So how good did the TPU do? Well it measured at -17.94 dB (0.6 dB more) and that works out to 101 yards! So there's not a whole lot of wiggle room there. There could be enough measurement error here to invalidate these findings BUT I don't THINK there is. The stock baffle set has consistently been testing better than the TPU. Let's go with that.

Fear not though for I have not given up the effort! Today I will print a couple more baffle stacks in different densities. PERHAPS one of them will improve the performance of the TPU baffle stack. I will link that study here when I have it complete.

I am sticking by my opinion though. I should have copied their design but in a new material...

I am sticking by my opinion though. I should have copied their design but in a new material...