Are taper lapped barrels a marketing ploy & just choked barrels with a normal hand lap .? Or are some of these truly tapered? Was thinking of picking up a 4G ratchet Shilen that are "Taper Lapped" . Ive seen this verbage used on different barrels over the tears on RF Central but never get the real story on it. Anschutz had so called tapper lapped too. If it's a real thing then how is it done.? The barrel makers are surely not going to tell ya.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Taper lapped .? real or not......

- Thread starter Jaxjax

- Start date

Taper lapping is real. It takes a "hard" lead lap (or series of laps) on a rotating cleaning rod to do it and a lot of skill. The degree of taper is less than 0.001" down from breech to muzzle on a rifle length barrel. The idea is to ensure that the projectile never goes loose as it travels down the barrel. That way it cannot yaw in the barrel.

The process is a lot more expensive than choking the muzzle with machine, so you are unlikely to see it on cheap mass produced airguns. It is used on custom made and improved airguns, and high end PB rifle barrels.

The process is a lot more expensive than choking the muzzle with machine, so you are unlikely to see it on cheap mass produced airguns. It is used on custom made and improved airguns, and high end PB rifle barrels.

Is There Something I'm Missing? - Airguns & Guns Forum

Is There Something I'm Missing?, Air guns, Airgun Forum

www.gatewaytoairguns.org

choking a barrel for improved accuracy - Airguns & Guns Forum

choking a barrel for improved accuracy, Air guns, Airgun Forum

www.gatewaytoairguns.org

Barrel Slugging an Air Venturi Avenger - Airguns & Guns Forum

Barrel Slugging an Air Venturi Avenger , Air guns, Airgun Forum

www.gatewaytoairguns.org

Upvote 0

The Truth About Cleaning Air Gun Barrels - Airguns & Guns Forum

The Truth About Cleaning Air Gun Barrels, Air guns, Airgun Forum

www.gatewaytoairguns.org

Robert Sterne said:

"

I use the VFG cleaning pellets of the appropriate caliber, on a mandrel that screws into a standard 8-32 cleaning rod, and lap from the breech.... There are two mandrels, the larger for .30 cal. and up.... and they are long enough to use two pellets at once, which is what I do.... On a new barrel, I use the method suggested by Sean Pero, which is 100 strokes full length, being careful not to run the pellets right out the muzzle on every stroke (it happens occasionally. which is OK).... I replace the Bore Paste every 20 strokes.... I then reduce the stroke about 1" for every 4 strokes, so for a 25" barrel the breech gets a total of 200 strokes, but the muzzle only the initial 100, with more strokes the closer you get to the breech.... Sean says this produces a very slight taper to the bore.... I then clean out all the grit, swab it with a couple of patches of solvent, then dry it, and switch over to the Bore Bright for the final 20 strokes, which leaves it gleaming smooth....

I now prep all my new barrels this way, regardless of brand, caliber, or projectile.... I think it not only makes them more accurate, but it takes longer for them to foul.... When I see leading (which usually shows up near the muzzle first) I swab out the barrel with Hoppe's #9, dry it, and then give it 20 strokes or so with Bore Bright, which puts that shine back on it.... Sean says that lead builds up in micro scratches in the bore, and eventually it goes longer, sometimes much longer, between cleans.... Whether the lead fills the scratches or you just eventually polish them all out with the Bore Bright I don't know, but the cleaning intervals do seem to increase over time.... I shoot almost all my guns in the mid 900s, so haven't noticed any difference in how they lead relative to velocity, but it makes sense that the faster you shoot, the quicker they will foul up....

"

Upvote 0

That sounds like a very good way to taper.

I have an outa spec Lilja w/ Bore @ .1695 & groove @ .1766. I am making a lapping plan to try & save this barrel. It's unchoked so I might try to taper it then chop 1" off & recrown. It's a 28" barrel. I'll be speaking with Shilen today on a match & select match. Last time I called them it was a year out for select match, match was much less time. I suspect there .22 rf button is "tight spec so they can do there taper., similar to Lilja .22rf " "tight" .220 x .215 button but no taper lap in Lilja. In my mind it just seems like the taper lap would be the smart play for pellets in subsonic land. I'm always suspect of factory chokes as there done in mass production barrels.

I have an outa spec Lilja w/ Bore @ .1695 & groove @ .1766. I am making a lapping plan to try & save this barrel. It's unchoked so I might try to taper it then chop 1" off & recrown. It's a 28" barrel. I'll be speaking with Shilen today on a match & select match. Last time I called them it was a year out for select match, match was much less time. I suspect there .22 rf button is "tight spec so they can do there taper., similar to Lilja .22rf " "tight" .220 x .215 button but no taper lap in Lilja. In my mind it just seems like the taper lap would be the smart play for pellets in subsonic land. I'm always suspect of factory chokes as there done in mass production barrels.

Upvote 0

I'll just say if you have the means the motivation to try it, I highly recommend it.

I’ve only been prepping barrels in this manner for a couple of years and still consider myself to be a newbie but I’ll share a few comments and observations. This process involves coarser abrasives than I had used in the past so I started with 3 poorly performing barrels I had set aside, with the mindset I can’t ruin what is already ruined. All 3 being barrels I had previously attempted to whip into shape with leade work, recrowning, and smoothing the bore...to no avail.

Well, suffice it to say these test runs were revealing. With two barrels the average groups shrank by a factor of 2x, and one by a factor of 3x. Granted these were complete basket cases so I’m skeptical the average barrel stands to benefit to such a large degree but it nevertheless opened my eyes to the potential.

After doing a few more, I started doing some for others and have heard some glowing feedback so I’m pretty well sold on it.

I’ve only been prepping barrels in this manner for a couple of years and still consider myself to be a newbie but I’ll share a few comments and observations. This process involves coarser abrasives than I had used in the past so I started with 3 poorly performing barrels I had set aside, with the mindset I can’t ruin what is already ruined. All 3 being barrels I had previously attempted to whip into shape with leade work, recrowning, and smoothing the bore...to no avail.

Well, suffice it to say these test runs were revealing. With two barrels the average groups shrank by a factor of 2x, and one by a factor of 3x. Granted these were complete basket cases so I’m skeptical the average barrel stands to benefit to such a large degree but it nevertheless opened my eyes to the potential.

After doing a few more, I started doing some for others and have heard some glowing feedback so I’m pretty well sold on it.

Upvote 0

Definitely gotta be something to it for the positive.

I just got off phone with Shilen & what I can get is interesting.

The match grade .22 4R ratchet barrels are 6-8 months out.

There select match grade is 18 month to 2 years out....... I instantly commented that they must be winning ALOT of RF benchrest comps. She said pretty much. Only the select grade get taper lapped , so match grade your on your own. I asked for bore & groove spec & that is a no go territory for Shilen. I told her I suspect there tight bore spec buttons if there doing the taper lapping. & nothing but quiet on that ...so I suspect there doing something neat .220 x .215 ish & then doing proprietary taper lap for select. you can get the 4R rachets in 12 or 16 twist & best of all is you can do the #11 contour & spec it from end to end down to .650 min. I always do .71 or .75. Not many will go below .75. I think I will order up a match grade as there are good for .0003 TIR, there select is .0001 TIR. & then try my hand at taper lapping it my self for kicks. They come at 28" & need 1" cut off on each end for 26" she also said. At $311. for the turned blank at least I get the .0003 TIR guarantee. Or maybe I'll beg you to do it nervoustrig

.

I just got off phone with Shilen & what I can get is interesting.

The match grade .22 4R ratchet barrels are 6-8 months out.

There select match grade is 18 month to 2 years out....... I instantly commented that they must be winning ALOT of RF benchrest comps. She said pretty much. Only the select grade get taper lapped , so match grade your on your own. I asked for bore & groove spec & that is a no go territory for Shilen. I told her I suspect there tight bore spec buttons if there doing the taper lapping. & nothing but quiet on that ...so I suspect there doing something neat .220 x .215 ish & then doing proprietary taper lap for select. you can get the 4R rachets in 12 or 16 twist & best of all is you can do the #11 contour & spec it from end to end down to .650 min. I always do .71 or .75. Not many will go below .75. I think I will order up a match grade as there are good for .0003 TIR, there select is .0001 TIR. & then try my hand at taper lapping it my self for kicks. They come at 28" & need 1" cut off on each end for 26" she also said. At $311. for the turned blank at least I get the .0003 TIR guarantee. Or maybe I'll beg you to do it nervoustrig

.

Upvote 0

I think that if you need to open a barrel by more than a few 0.0001", then a lead lap should be used. A felt lap will probably take off more from the lands than the grooves, while a lead lap will do that only in the leade, where you want a taper into the lands anyway.

Upvote 0

I did order the above barrel this morning in normal match version, so it won't come taper lapped..Ill have to do it my self. Ill practice on that outa spec Lilja disaster...lol

Upvote 0

Shilen just called & barrel is on way to me. Can't wait to take a a few measurements then its off to Martin's. I rolled the dice on it so fingers crossed.

Upvote 0

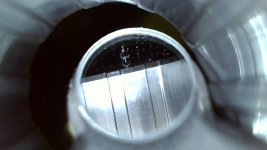

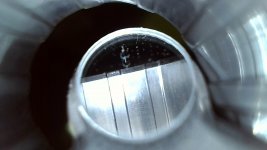

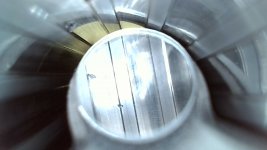

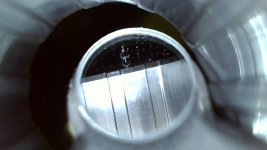

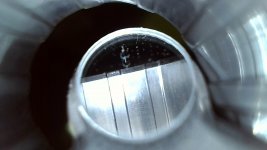

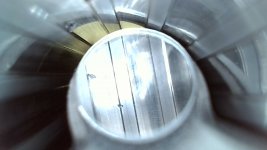

I tried to clean up the interior spec of a SS .25 LW non choked unit for last 2 days off & on. I have precision pin gauges in .247+-.2475-.278 etc.. I started by pushing a .250 + slug thru & without letting is out muzzle pushed it back to breech & did this a few times, revealing some not so nice tight spots in bore. I then went for the Loctite fine clover & piled up a few new slugs & using a wooden oak dowel I went for the tight spots by pushing & staying 6" away from muzzel & returning to breech etc.. I would pop out slug & check its was fallowing lands & it was. did this abit changing slugs every so often. The cleaned bore with 3-stacked 1/4 folded 2" patches & 91% Iso alcohol. Hard to get clean but 4 sets of 3 did it. Then stareted again with JB blue,, same gig. Then cleaned, Day 2 I gort out pin gauges out again. , .2475 does not fir bore but .247+ does, so I then slow pushed the pin gauge from breech & found to slight tight spots but pin gauge passed all the way thru. I took jb blue & coated pin gauge & slow worked it back & for down bore & letting pin come out muzzle but only half way. I did this about 100 times. the remaining titie spot mellowed out & reapplied jb blue a few times over during process. Did the iso alcolhol gig & the thriple stacked a few dry passes. What I did find out is just because the patch is clean it means nothing.........I look down bore showed sh.. even when Patches cames clean early in cleanout process. I have scope this sbarrel before & have pictures so easy reference. The bore had 2- factory bad spots with 1 on edge of a land. I dooght its a problem now but never know. I was happy with waht the scope shows & definitely happy with pushing a 34 grain pellet down it. Hope she shoots ok. Well see & will report good or bad. Also the pin gauges are harder then the barrel so ya gotta be careful & have a few sizes on hand . I'm looking for bore consistency for 34rg pellets & its gotta be better then before. LW spec are not correct as no way a .248 pin gauge is going down that bore. They spec .248 x .254. I'm also chopping 1" off all barrels from muzzle on blanks from now on. I should do that to breech to but so much going on there I think ok to leave that. It's amazing how not uniform these damn things are from factory.

1st pics are crown area.

sorry for the bright settong on scope, I like it bright & look on edges of that, all a compromise with this scope but it does help.

You can see the land & groove damaged in forward view & 90 mirror view in same pic in these last 3,

1st pics are crown area.

sorry for the bright settong on scope, I like it bright & look on edges of that, all a compromise with this scope but it does help.

You can see the land & groove damaged in forward view & 90 mirror view in same pic in these last 3,

Last edited:

Upvote 0

That nasty looking jagged pit probably won't affect how the barrel shoots. Time to try it out.

Upvote 0

Yep, not going to touch it any further before testing this weekend barring a big storm. Im going to focus on 50 yards this time of year to get a handle on what it is or not capable of.That nasty looking jagged pit probably won't affect how the barrel shoots. Time to try it out.

Upvote 0

Looks and sounds good in there now. It should be a shooter. I've had good success with tapering. It's a llooongggg choke.

Upvote 0