Tried to fire it up on my phone but wouldn't connect without removing my case.. said screw that & went & got laptop. plugged it in got it running pretty quick. for the $60-80 I paid I won't complain abit. The LW SS .25 10g pics made me happy for bore condition except at lead in & will address that. The .30 barrel is a 6G that I always thought was a POLY barrel but the lands & grooves look conventional to me & have no clue what it is. It's an older RAW .30 barrel. What I would like to know is how to address the lead in.. I have clover & JB Blue on hand. I just want to get rid of the rough are at lead in ..after port seems ok.

The .30 lead in isn't as bad but still needs done IMO. I'm seriously thinking of a drill with a swabit & clover/JB blue in rotation & no further then back side of port. Not sure how to approach it really, to me the lead in looks like crap & needs smoothed out. 1st series of pics are the .25 10g 2nd is the 6g .30

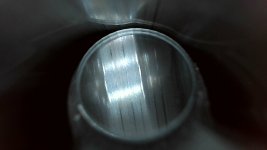

.30 6g & 1st pic is crown edge with the factory stripper still attached. Is it a Poly ?

The .30 lead in isn't as bad but still needs done IMO. I'm seriously thinking of a drill with a swabit & clover/JB blue in rotation & no further then back side of port. Not sure how to approach it really, to me the lead in looks like crap & needs smoothed out. 1st series of pics are the .25 10g 2nd is the 6g .30

.30 6g & 1st pic is crown edge with the factory stripper still attached. Is it a Poly ?