I decided to send my new HW95N to Mike Ellingsworth for a tune, along with my friends R9 that had a broken spring.

Mike jumped on them and I got them back quickly.

Both rifles were flawless for the first 50 shots or so.

Unfortunately both rifles began to bind and there was metal to metal galling starting to happen.

I was dismayed to have to call Mike about it but he was totally supportive immediately about it.

I sent him the rifles and at his own expense he went through both and fixed everything!

They now cock silently and as smooth as butter!

He made up a report on what he did and here it is, complete with pictures.

Thanks again Mike for going the extra miles on these rifles.

Below is Mike’s report.

Two guns came into the shop for a full tune

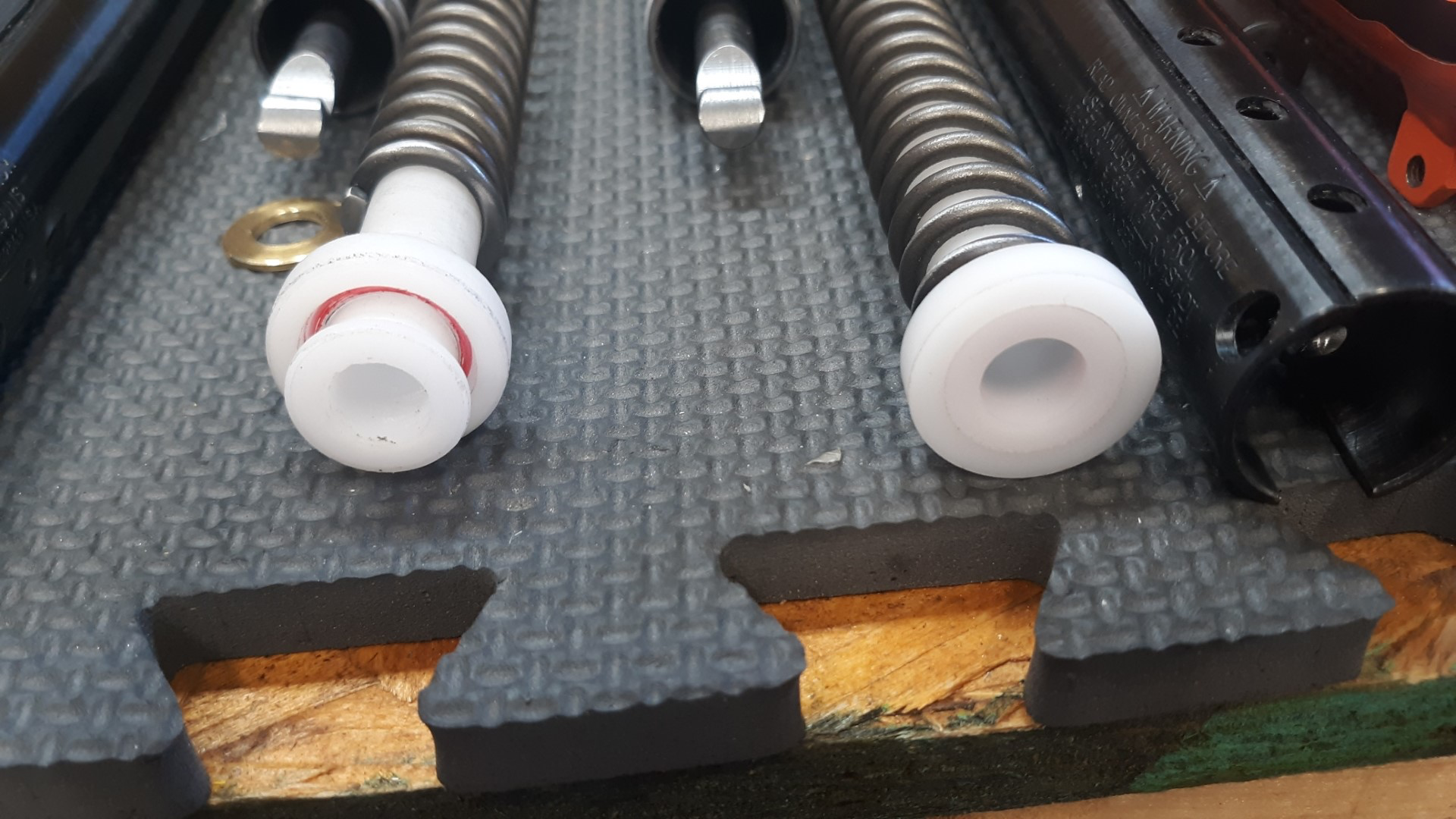

Typical tune consist of a new spring and custom machined delrin spring guide and top hat.

fresh piston seal, new breech seal install and adjustment along with trigger cleaned lubed and adjusted , Barrel adjusted

with a zeroed out Hawke scope @ 18 yrds with the point of impact hitting the bulls eye.

After years of using the 0.128 spring wire with no issues both guns pistons started to gall the receiver tube, Looking into the matter It was obvious that the Outside diameter

of the spring was not filling the pistons liner enough and when in use the spring was canting with so much pressure it cause the piston to start galling the tube

The available space between bottom of piston to trigger block is checked with spring coil count and wire diameter math to work properly with the guide and top hat to work within the available space.

Switching to a wider spring that fills the piston will prevent the spring from being able to cant causing the issue, how ever after the new spring install I noticed a slight noise when cocking the barrel back fast which really bothered me, so now extra lube must be used inside the piston entrance to make that go away, and that's irritating also .

At least the new vac seal design stops piston slap or wood knock in the HW 95 models when fired and with the bigger diameter spring filling the piston we are back on track!

The only thing left was a custom Delrin piston bearing ring install and that is exactly what we did.

Two smooth HW 95 models not maxed out for maximum power is a dream and Dave totally agrees !

Here is some pictures for your interest

Thanks Dave it was a pleasure working with you !

Mike Ellingsworth

Mike jumped on them and I got them back quickly.

Both rifles were flawless for the first 50 shots or so.

Unfortunately both rifles began to bind and there was metal to metal galling starting to happen.

I was dismayed to have to call Mike about it but he was totally supportive immediately about it.

I sent him the rifles and at his own expense he went through both and fixed everything!

They now cock silently and as smooth as butter!

He made up a report on what he did and here it is, complete with pictures.

Thanks again Mike for going the extra miles on these rifles.

Below is Mike’s report.

Two guns came into the shop for a full tune

Typical tune consist of a new spring and custom machined delrin spring guide and top hat.

fresh piston seal, new breech seal install and adjustment along with trigger cleaned lubed and adjusted , Barrel adjusted

with a zeroed out Hawke scope @ 18 yrds with the point of impact hitting the bulls eye.

After years of using the 0.128 spring wire with no issues both guns pistons started to gall the receiver tube, Looking into the matter It was obvious that the Outside diameter

of the spring was not filling the pistons liner enough and when in use the spring was canting with so much pressure it cause the piston to start galling the tube

The available space between bottom of piston to trigger block is checked with spring coil count and wire diameter math to work properly with the guide and top hat to work within the available space.

Switching to a wider spring that fills the piston will prevent the spring from being able to cant causing the issue, how ever after the new spring install I noticed a slight noise when cocking the barrel back fast which really bothered me, so now extra lube must be used inside the piston entrance to make that go away, and that's irritating also .

At least the new vac seal design stops piston slap or wood knock in the HW 95 models when fired and with the bigger diameter spring filling the piston we are back on track!

The only thing left was a custom Delrin piston bearing ring install and that is exactly what we did.

Two smooth HW 95 models not maxed out for maximum power is a dream and Dave totally agrees !

Here is some pictures for your interest

Thanks Dave it was a pleasure working with you !

Mike Ellingsworth