You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

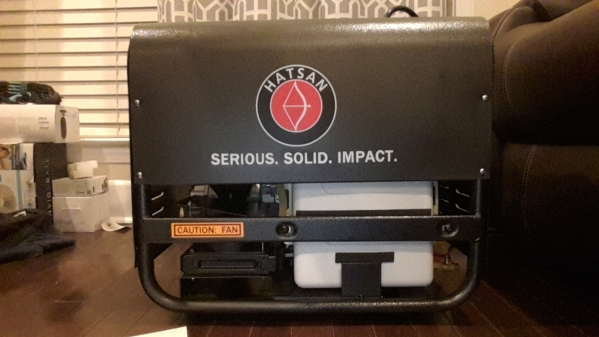

The Day's of manual labor are gone thanks to Hatsan

- Thread starter itaylor00769

- Start date

I found a super deal it was $993.00 with free shipping, as for the sound it reminds me of my Harbor Freight pancake compressor not to loud

Upvote 0

Filled gun from 100 bar to 220 bar in less than two minutes

ITaylor, couple of tips, as I owned that compressor back in July of 2018, almost two months before it was released to the public as an in stock item at Hatsan.

that cooling coil in the second pic, there’s a steel plate bolted down on top of it. Loosen the hold down nuts on top of that plate and raise that plate about 3/4” up and lock the nuts back down. By doing that you’ll free up the air flow for better cooling.

right next to that plate, towards the coolant tank, follow the coolant hoses down. You’ll see one if not both hoses right against that plate. In time with the vibration, you’ll chafe it. I wrapped electrical wire loom around the hoses in that area. Also, visually check that the hoses aren’t near any hot spots, like the high pressure air lines to and from the cylinders. Zip tie the hoses away and wire loom them.

couple of things on the instructions- before setting the pressure you want the compressor to shut down at, make sure you DO NOT turn on the coolant pump and fan button. Right after you first plug it in, then set your auto shut off pressure. Then turn on the cooling fan button. If you don’t follow this sequence, it will shut off at the last setting you programmed the last time you used it. Be aware, that the coolant fan switch plays a bigger role than just turning on the coolant fan and coolant pump. It pretty much sets the stage for othe things like calibration set up, etc.

hopefully you did not run a 50/50mix on the coolant, but rather 60% distilled water and 40% coolant, the G05 type like Zerex.

Double check the calibration set by the factory. Me, and others, have noticed ours was off by almost 150 psi. You will need a known good gage, plugged into the fill whip, and go thru the calibration process as outlined in the manual.

Lastly, get a stick on vibration hour meter, to keep tabs on the uses per hour. This will help in your maintenance schedule for oil and coolant change outs. Good luck, and enjoy it. I love mine a lot. Only fault so far, was the fill whip developed a leak and the minus button on the digital gage kept sticking in the pressed position, which made it hard for initial set ups. No worries, as Hatsan replaced both the whip and the gage assembly right away.

Upvote 0

Upvote 0

Bigragu A big +1 for you for posting those tips it will help out more than one person on the forum, well deserved. Thankyou for the advice just another reason why I like the forum so much. I personally don't have a compressor as of yet but it's on the bucket list.

Upvote 0

Saw this a while ago, just be aware that some have not had a pleasant experience with Field Supply when they had problems with the Lightning they bought from them......

https://www.airgunnation.com/topic/hatsan-tactair-lightning-pcp-compressor-sale/#post-406116

https://www.airgunnation.com/topic/hatsan-tactair-lightning-pcp-compressor-sale/#post-406116

Upvote 0

I used PAYPAL as a method of payment because I've never heard of Field Supply, but so far so good compressor is working great

Upvote 0

I used PAYPAL as a method of payment because I've never heard of Field Supply, but so far so good compressor is working great

Upvote 0

ITaylor, here are notes I made to myself in a binder I put together solely for the maintenance part of this compressor. I’ve shared it with others, so here you go. It deals mainly with the importance of that coolant switch upon start up and shut down, along with calibration.

Im actually on the look out for a lifetime air filter for the breather intake, like a K&N or something equal for this compressor, and if I should ever source one, I’ll let you know.

i also found the perfect cover for it, to keep it sparkling clean and new looking. I’ll send you a pic from amazons web site next

Upvote 0

Here is the 24” x 22” x 20” tall cover I got for it that fit perfect, along with the hour meter to easily track your oil and coolant service changes.

of course, I thought sticking that hour meter on the top would be the perfect spot for it, but even at its most sensitive adjustment, there wasn’t enough vibration transferring up to the top of the compressor to make it work. So, I stuck it on that plastic bell housing cover, and all works as should.

Upvote 0

when ready for use, I rigged up a 90 degree fitting with a female QD at one end, and a male QD on the other. All three are stainless fittings, 1/8” NPT from eBay.

The end that used to connect to the block I put on a male QD. So now with everything hooked up I have a clean 90 right off of the compressor, that also swivels. Makes things easy for storage, and the chance of bumping into the fill hose at the block and snapping off the connection is gone. I got the idea from Mark Nagel, who did a full review on this compressor, and made a point that the fill whip should have been at the side of the block, to protect it from a bump and snap.

it actually works best for me, to 90 off of the compressor with the whip, cause the way my compressor is oriented to my four wheel cart, I fill and shoot perpendicular to the carts layout.

Upvote 0

Decided it it was time for a top off. I did the yearly chronograph test on three pcp’s today and noted their status. When it came last to the Hercules Bully, I could tell the Airhog airtanks gage was starting to slow down while trying to get to 3,000 psi. After I was all done I noted the pressure in the tank, and it was at 3,400 psi. Time for a top off. All set up, and I cracked the tanks valve open once the Hatsan compressors gage showed 2,000 psi.

Upvote 0

Took pics of the vibration hour meter, along with gage readings on the compressor and the Airhog tank, to my sure my calibration was still in sync. I started my fill at exactly 2:12pm, CA time. For some reason at around 4,000 psi, the two gages in comparison are off like 150 psi, but once in the 4,200 psi range both gages match up. That’s ok, cause I foresaw this, and before starting the compressor up I set the digital gage to auto stop past 4500 psi by a hair.

Upvote 0