I had been planning on an oil change having just reached 15 hours on the clock. Last one was at 10 hours. However one last fill before I do it. Hmm was that a fart or belch I just heard as it started up. Well it ran fine but I knew it needed something.

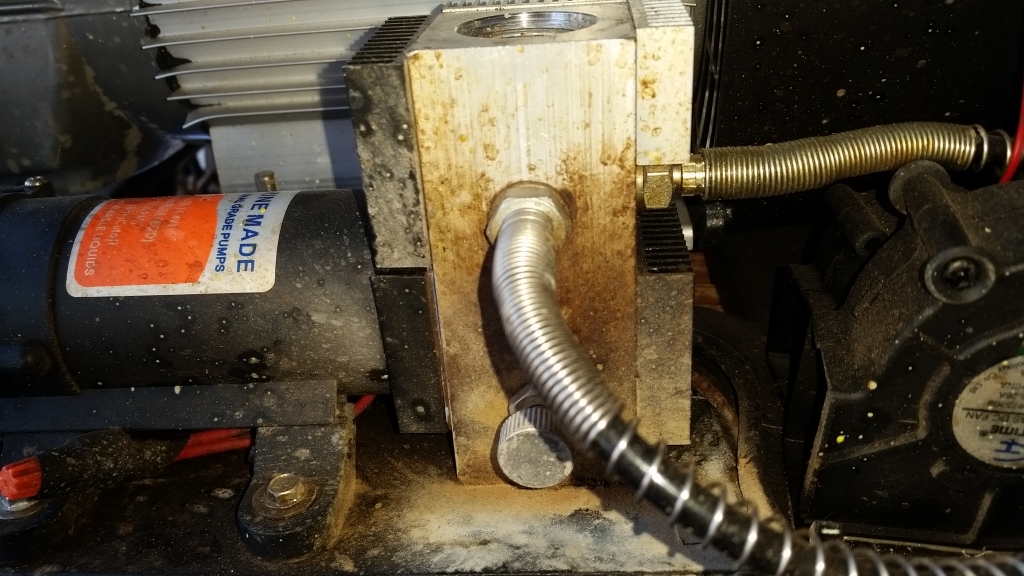

I had inspected the external filter a few days ago and it was perfect except for a tiny (like a tobacco) stain on the first filter. Changed that and reassembled but saw the crap that had accumulated on the pressure release block. That was from opening and closing the valve to release the moisture every five or ten minutes of running. (See attached photo)

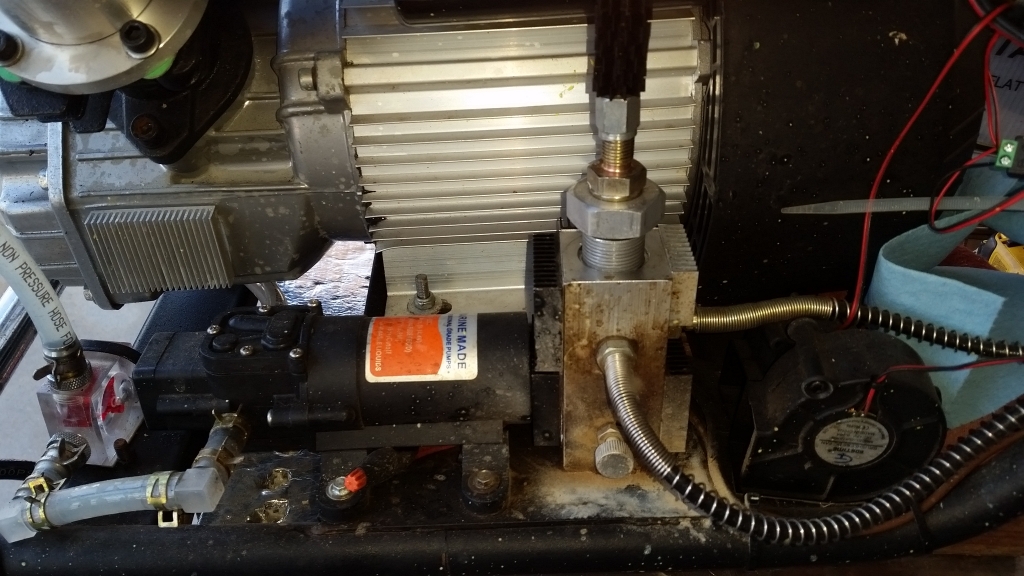

I started by changing the oil and it was very dark but no odor. Then moved on to the final check valve and pressure release block. There are three connectors here. The top is the high pressure into the check valve, then one high-pressure line going to the automatic shut off gauge and the third that runs through the final filter onto the tank being filled.

This block contains the check valve attached to a hollow first stage filter with a bronze screen at the bottom. The first stage is filled with desiccant. The air then proceeds into the final filter to the tank.

Photos show the first stage filter with check valve attached partially removed. Another photo shows the filter turned upside down resting on top. Another photo shows the filter, desiccant, check valve and bronze filter screen, all removed and filthy. We are seeing a lot of oil on the inside and mostly moisture on the outside. It was certainly packed into the base of the bronze screen.

These parts all cleaned up and repaired or replaced as needed. New O-rings installed and tiny bit of anti seize added to threads for future cleaning.

I was very surprised at the amount of crude accumulated in just 5 hours. I will pay attention to the oil and check the rings next time but do not suspect what I see is abnormal for these machines. It runs fine, fills fast and with all Centercut’s additions stays very cool.

I had inspected the external filter a few days ago and it was perfect except for a tiny (like a tobacco) stain on the first filter. Changed that and reassembled but saw the crap that had accumulated on the pressure release block. That was from opening and closing the valve to release the moisture every five or ten minutes of running. (See attached photo)

I started by changing the oil and it was very dark but no odor. Then moved on to the final check valve and pressure release block. There are three connectors here. The top is the high pressure into the check valve, then one high-pressure line going to the automatic shut off gauge and the third that runs through the final filter onto the tank being filled.

This block contains the check valve attached to a hollow first stage filter with a bronze screen at the bottom. The first stage is filled with desiccant. The air then proceeds into the final filter to the tank.

Photos show the first stage filter with check valve attached partially removed. Another photo shows the filter turned upside down resting on top. Another photo shows the filter, desiccant, check valve and bronze filter screen, all removed and filthy. We are seeing a lot of oil on the inside and mostly moisture on the outside. It was certainly packed into the base of the bronze screen.

These parts all cleaned up and repaired or replaced as needed. New O-rings installed and tiny bit of anti seize added to threads for future cleaning.

I was very surprised at the amount of crude accumulated in just 5 hours. I will pay attention to the oil and check the rings next time but do not suspect what I see is abnormal for these machines. It runs fine, fills fast and with all Centercut’s additions stays very cool.