Now comes the the fitting for Stock.

I think I missed posting the M1A1 Stock from King Arms, what can I say it's Tax time.

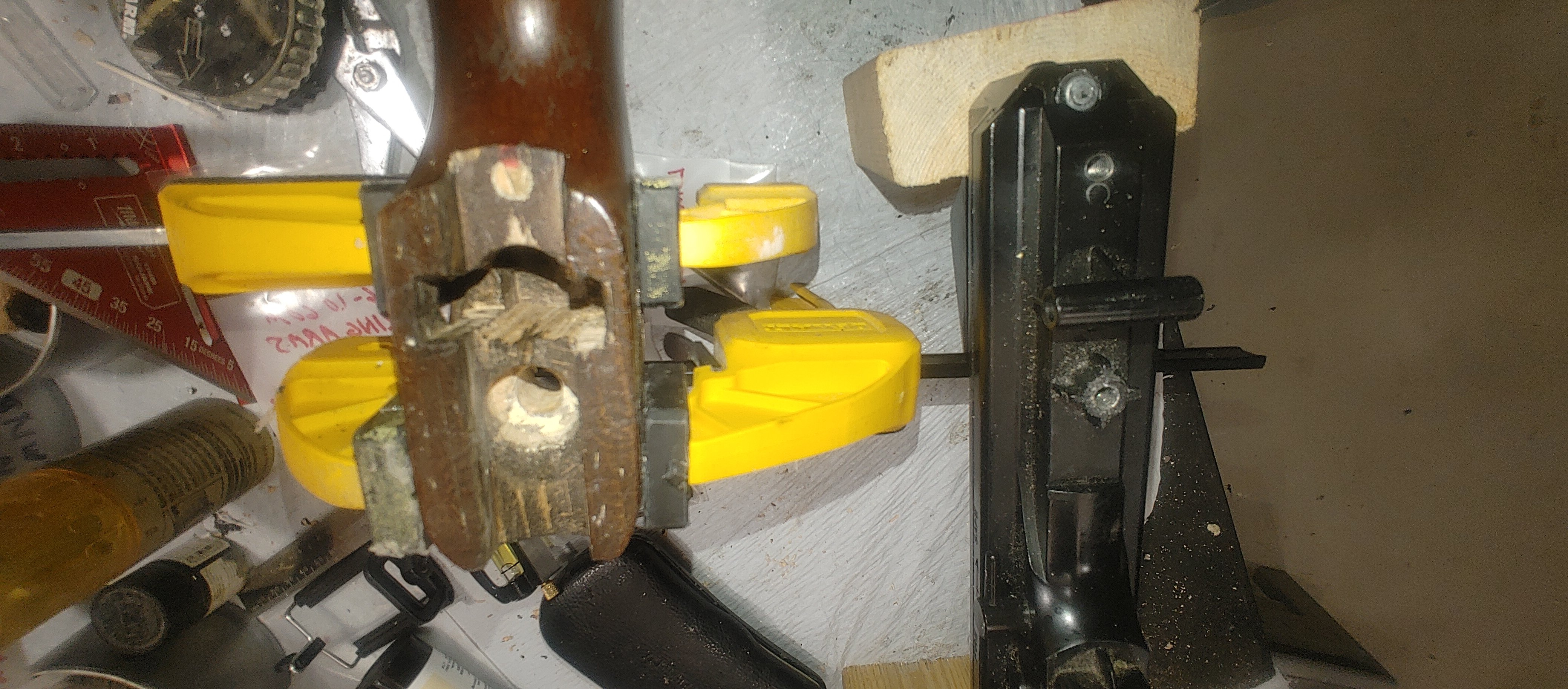

Anyway this was the most fun I had on the project of fitting the wood King Arms stock to the Umarex gun. I had to cut a channel down into the head of the (the part that is closest to the gun) stock so that the Umarex extended lateral bolt hole would accommodate the Umarex gun. Along with a center point that the trunnion bolt would be centered and fit. I also had to enlarge the round trunnion bolt ends as apparently the Airsoft ones are a bit smaller.

Little did I know at that time that I would not use the trunnion bolt at all. Why: because I didn't need it. That two long metric machine bolts would hold the stock with more that enough strength. So after I made a new trunnion bolt along with the two new side pieces I decide NOT to use it. I had made two silicone rubber molds and since I had cast more that two sets I just used the two side disks and glued them in the holes provided. You cannot tell the difference between the poly plastic pieces from the metal ones.

I used a very small saw (Japanese actually), then with a 1/4 inch chisel cut the excess out of the channel I needed. The markings are the channels with a centerline where the trunnion bolt goes. Then I needed to plug the old holes where the King Arms bolts would have gone and drill new holes for the M6-1.0x40 and M6-1.0 60 go in the Umarex gun.

I also needed (well I did not have to) fill the hole running down the center of the stock with a 1 3/4 inch long round wood dowel maybe an inch in diameter, where the battery wires would go thru the King Arms stock to connect to the Airsoft gun, the King Arms stock had an empty space there. I also filled the rather large hole towards the front of the gun and the rear bolt was not solid wood (bad) for structure of the stock. I did this so the wood was solid (no week points) where the bolts would go thru the stock and not have any air space inside of the stock that could cause a weak space in the stock.

Then all I had to do was to drill new bolt holes that aligned with the Umarex gun. That's it and done, except for the striping, staining and polyurethane coating.

Man, three (3) coats of Dark Walnut stain, 24 hours for each coat to dry, then two coats of poly, again 24 hours to harden. All of this too only about 15-20 minutes, the rest was doing other things.

You can see I just marked the wood I had to remove, being careful not to cut outside the lines marked (you do not want to remove any more than what is necessary).

I used a very fine Japanese saw to cut the edge's of the wood I wanted to remove so all I had to do was to use a 1/4" chisel to remove the wood for the Umarex Thompson the fit. That way I could make a perfect fit.

I had to make the trunnion hole to fit (just a tad bigger) the Umarex metal trunnion I chose a wood hole cutter that worked just fine.

The wooden dowel just fills the miss-fitting original hole, making a new hole secure. That is the wooden peg you see sticking up. .

The red mark at the back of the stock is the new hole that must be drilled. Since I did not have drill press to drill the hole I drilled two guide holes on the top and bottom of the stock to then guide the drill since the stock was solid wood now. Being VERY careful that the angle was correct both lengthwise and sideways. It worked just fine.

The wooden stick is extending out of the stock was not used. Because of the original use of the stock had a larger hole drilled through the neck of the stock for wires for the battery wires from the battery in the stock. I selected a larger wooden dowel cut to length and just glued it in inside the stock for extra support. Before i drilled the shorter bolt I did fill all the other holes (empty spaces) with wood to give the forward part of the stock more structural strength.

Then I just measured the angle of the second bolt through the wood stock carefully; very careful to get it correct and drilled the final bolt hole to fit the Umarex M1A1. So you now see the fitting of the Umarex trunnion bolt cutout in the stock.

I think I missed posting the M1A1 Stock from King Arms, what can I say it's Tax time.

Anyway this was the most fun I had on the project of fitting the wood King Arms stock to the Umarex gun. I had to cut a channel down into the head of the (the part that is closest to the gun) stock so that the Umarex extended lateral bolt hole would accommodate the Umarex gun. Along with a center point that the trunnion bolt would be centered and fit. I also had to enlarge the round trunnion bolt ends as apparently the Airsoft ones are a bit smaller.

Little did I know at that time that I would not use the trunnion bolt at all. Why: because I didn't need it. That two long metric machine bolts would hold the stock with more that enough strength. So after I made a new trunnion bolt along with the two new side pieces I decide NOT to use it. I had made two silicone rubber molds and since I had cast more that two sets I just used the two side disks and glued them in the holes provided. You cannot tell the difference between the poly plastic pieces from the metal ones.

I used a very small saw (Japanese actually), then with a 1/4 inch chisel cut the excess out of the channel I needed. The markings are the channels with a centerline where the trunnion bolt goes. Then I needed to plug the old holes where the King Arms bolts would have gone and drill new holes for the M6-1.0x40 and M6-1.0 60 go in the Umarex gun.

I also needed (well I did not have to) fill the hole running down the center of the stock with a 1 3/4 inch long round wood dowel maybe an inch in diameter, where the battery wires would go thru the King Arms stock to connect to the Airsoft gun, the King Arms stock had an empty space there. I also filled the rather large hole towards the front of the gun and the rear bolt was not solid wood (bad) for structure of the stock. I did this so the wood was solid (no week points) where the bolts would go thru the stock and not have any air space inside of the stock that could cause a weak space in the stock.

Then all I had to do was to drill new bolt holes that aligned with the Umarex gun. That's it and done, except for the striping, staining and polyurethane coating.

Man, three (3) coats of Dark Walnut stain, 24 hours for each coat to dry, then two coats of poly, again 24 hours to harden. All of this too only about 15-20 minutes, the rest was doing other things.

You can see I just marked the wood I had to remove, being careful not to cut outside the lines marked (you do not want to remove any more than what is necessary).

I used a very fine Japanese saw to cut the edge's of the wood I wanted to remove so all I had to do was to use a 1/4" chisel to remove the wood for the Umarex Thompson the fit. That way I could make a perfect fit.

I had to make the trunnion hole to fit (just a tad bigger) the Umarex metal trunnion I chose a wood hole cutter that worked just fine.

The wooden dowel just fills the miss-fitting original hole, making a new hole secure. That is the wooden peg you see sticking up. .

The red mark at the back of the stock is the new hole that must be drilled. Since I did not have drill press to drill the hole I drilled two guide holes on the top and bottom of the stock to then guide the drill since the stock was solid wood now. Being VERY careful that the angle was correct both lengthwise and sideways. It worked just fine.

The wooden stick is extending out of the stock was not used. Because of the original use of the stock had a larger hole drilled through the neck of the stock for wires for the battery wires from the battery in the stock. I selected a larger wooden dowel cut to length and just glued it in inside the stock for extra support. Before i drilled the shorter bolt I did fill all the other holes (empty spaces) with wood to give the forward part of the stock more structural strength.

Then I just measured the angle of the second bolt through the wood stock carefully; very careful to get it correct and drilled the final bolt hole to fit the Umarex M1A1. So you now see the fitting of the Umarex trunnion bolt cutout in the stock.

Last edited:

Upvote 0