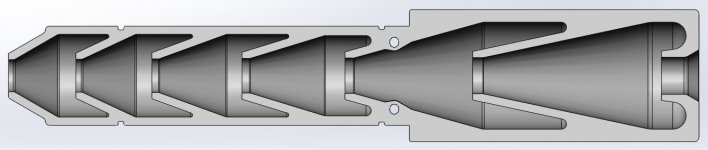

I don't do Facebook, but can I go there to see pictures or do you have to sign up? I'm curious about the 3d printed parts.. is there a place that does it for you or do a lot of people have 3d printers? are they expensive or hard to work? I can print out a email on the printer but I assume that it's a lot different printing out a 3d part.. I have my own machine shop and I have done machine work and mechanics and welding my whole life.. wish I had more time to play with the welder and machine tools now that I am retired but I don't seem to have as much time as I had when working.. but all my machine tools are old fashioned.. nothing digital other than the calipers.. my lathe is actually a craftsman probably my age if not older..Yes i don't use the factory shroud as I made my own. For the .177 I used 3D printed cones for the Umarex origin and for the .22 I use five cones from the Marauder rifle. For scope, I use an dovetail to picatinny adapter on the front side. The back I cut a piece of blank picatinny rail. All of this is on the Umarex Owners group on facebook under George Barber as I don't have an account on facebook. I just finished a drop block series for those that want to make it with just hand tools. My .22 now has 15" barrel and the .177" is 16" long.

you really have me interested in what you are doing.. let me know how to see the pictures and information you have posted..

thank you so much for sharing what you are doing

Mark

Upvote 0