I don't recommend nothing of his business, I send him the gun directly from the seller we talked n texted espesific about what I wanted n what could be done .. as soon he got the gun started pushing about the money.. that he needed it because he doesn't work on guns without deposit .n how fast that build was going to be .. that makes all the sense, but I didn't ask him to start.. that week I had purchased a machine for my business n had pay the card complete but the transaction has not cleared yet. We are talking about 5 or 7 days after he got the gun .. transaction cleared I send him the complete amount as agreed, buid was going to take 28days .. 7 months later he send me another invoice because the way we had agreed to build the can't be done.. it was a lie because he had not made the bullet lead in yet according to the reasons he had not sent me the gun yet he had not received the tooling for the lead in so he can't been shooting the gun without finishing the barrel that is why he asked for more money because he said it was shooting bad.. and needed another $375 in machining.. I was not going to argue I just wanted finished.. and to finish the business started.. how it ended.. the gun was received 9 MONTHS LATER a gun with crapy machining.. parts finish with sharpie..safety was ordered to be changed to aluminum.. NOT DONE .. the cut picatinny rail was ordered to be refinished NO DONE .. barrel ordered to be able to shoot bullets from 110gr to 120 gr ..NOT DONE that bullet size dance on the lead in even when the bolt is closed.. bullets that work are from 125gr n up to 138gr wish I didn't have molds at the moment.. I still have not received the 2 magazine shipped with the gun 10 months + later , why because the bullets that fit the magazine will tumble in the bullet lead in so they don't work.. well you have being warned  if you get burned, you can't say no body told you..IS more important for me that you know the truth. Than my ability to sell the gun later .....

if you get burned, you can't say no body told you..IS more important for me that you know the truth. Than my ability to sell the gun later .....

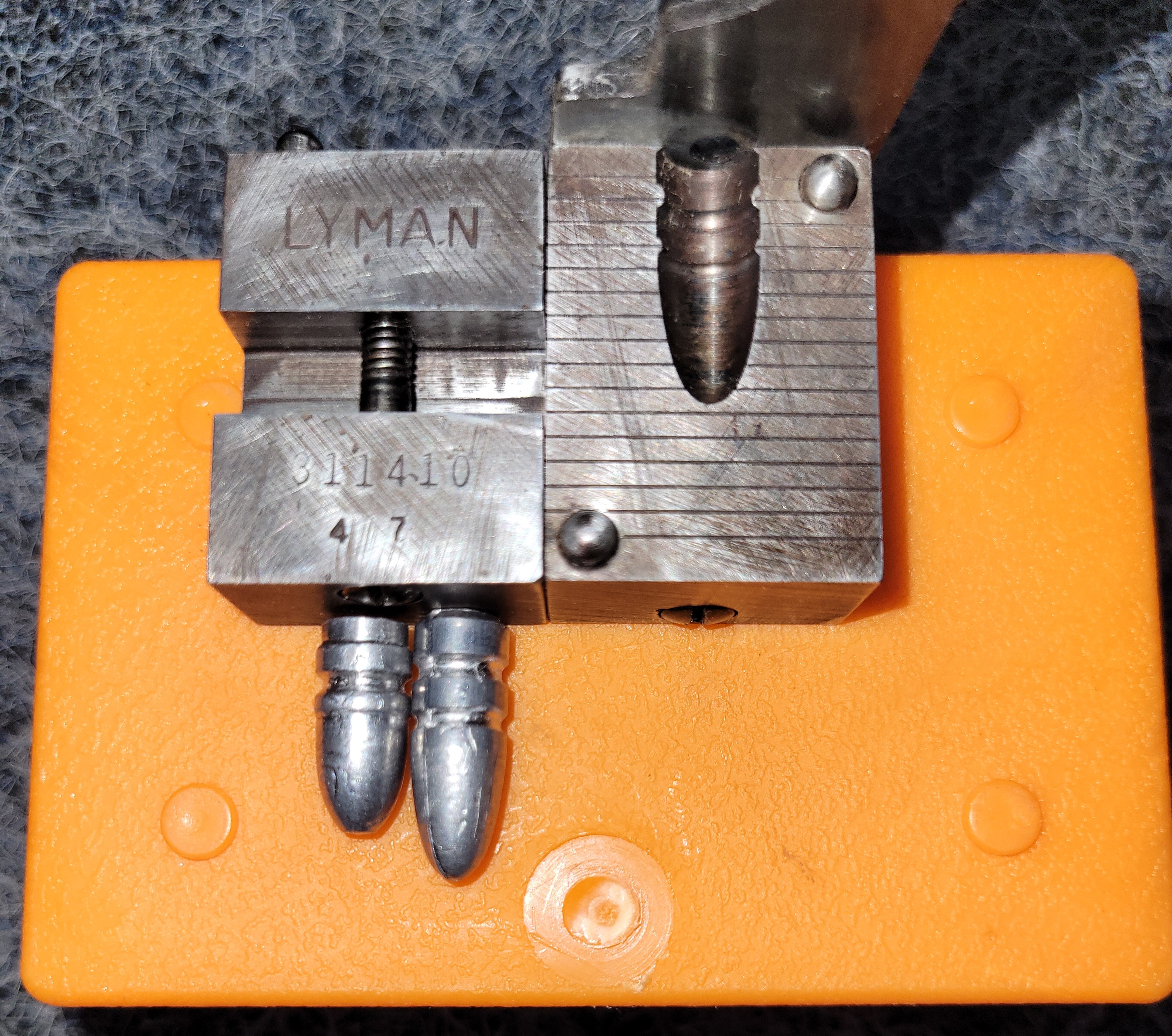

why I waited 2 months I was waiting for 2 barrels That I have no interest to be worked on to be sent back to me + I was waiting for the safety that he told me when I received the gun that it was on the mail.. and the 2 mags supposedly will be Goin in the mail in those days to .. safety didn't come we never discussed that aluminum wasn't going to work.. lie # 1 -- lie # 2 no mag were in the box because he knew they don't work with the lead in he has done.. he send me the pics of a 2d printed ones he was going to send..lies they didn't arrive either.. I'm going to prove he is a lies master caught .. in his own picture.. the picture that he posted that prove the lands are engaging the barrel..that is the one he send me.. that mold is not 110gr as he told me I knew it ... that is why I wanted to finish doing that business because I knew.. it was going to be for the worst an no satisfactory solution could be found with a lier ..that mold is a hollow point lyman 311-410 that cast with pure lead 138+gr no matter how deep the hollow point is it will never go to 110gr.. is a long bullet compared to 112gr that I will show in this pic .. where the lands engage the long bullet could barely touch the short one ..so he lied when he sent me the pic about 110g working in this barrel..do you think after i saw this i want to discuss anything..he doesn't know to do custom work..he is just learning at the cost of us.. when the time come to work on your gun he doesn't have the funds to work on your gun and even worse the skill to deliver a proper finish to his work.. if you decide to send him your gun n money is on you .. why i have not post it for sale..this doesn't worth the effort to be for sale when i know i will be selling a worth less work .. my loss .. he knows how to speak about machining -' but has no talent doing the work..unless the only guns you even had where old hatsan. Then maybe you could acept his work as good.

why I waited 2 months I was waiting for 2 barrels That I have no interest to be worked on to be sent back to me + I was waiting for the safety that he told me when I received the gun that it was on the mail.. and the 2 mags supposedly will be Goin in the mail in those days to .. safety didn't come we never discussed that aluminum wasn't going to work.. lie # 1 -- lie # 2 no mag were in the box because he knew they don't work with the lead in he has done.. he send me the pics of a 2d printed ones he was going to send..lies they didn't arrive either.. I'm going to prove he is a lies master caught .. in his own picture.. the picture that he posted that prove the lands are engaging the barrel..that is the one he send me.. that mold is not 110gr as he told me I knew it ... that is why I wanted to finish doing that business because I knew.. it was going to be for the worst an no satisfactory solution could be found with a lier ..that mold is a hollow point lyman 311-410 that cast with pure lead 138+gr no matter how deep the hollow point is it will never go to 110gr.. is a long bullet compared to 112gr that I will show in this pic .. where the lands engage the long bullet could barely touch the short one ..so he lied when he sent me the pic about 110g working in this barrel..do you think after i saw this i want to discuss anything..he doesn't know to do custom work..he is just learning at the cost of us.. when the time come to work on your gun he doesn't have the funds to work on your gun and even worse the skill to deliver a proper finish to his work.. if you decide to send him your gun n money is on you .. why i have not post it for sale..this doesn't worth the effort to be for sale when i know i will be selling a worth less work .. my loss .. he knows how to speak about machining -' but has no talent doing the work..unless the only guns you even had where old hatsan. Then maybe you could acept his work as good.

Last edited: