I'd like to lighten up the trigger on my Parrus. Not worried about any warranty issues. It is already very smooth. Is there a tutorial on how to lighten these up?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuning Walther Parrus, modifying trigger

- Thread starter BeeGee11

- Start date

I found this, which is helpful, but since I'm new to all of this it's still not as pictorial as I'd hope for.

https://www.gatewaytoairguns.org/GTA/index.php?topic=161749.0

https://www.gatewaytoairguns.org/GTA/index.php?topic=161749.0

Upvote 0

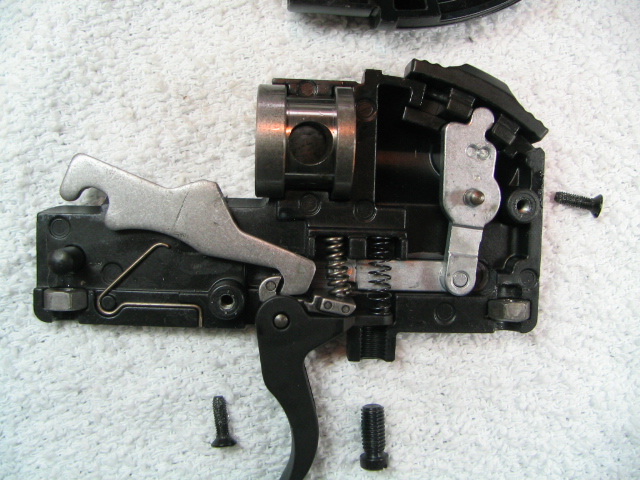

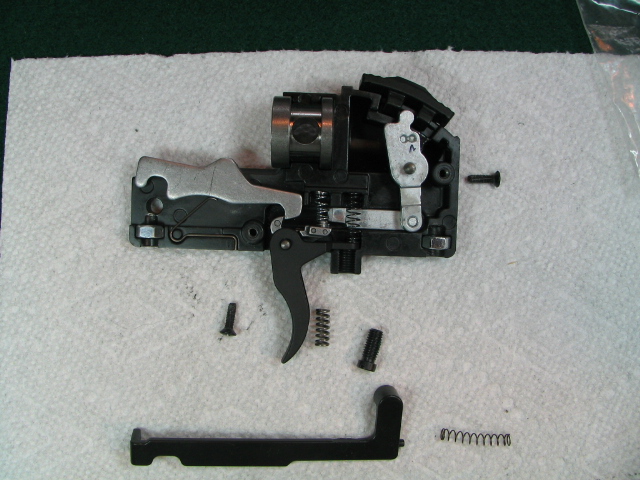

Ok, so I'm an impatient, hands on, touch it with my own eyes kind of guy. So here goes, all finished up. I'm very pleased with the end result, the trigger is actually a little bit smoother and requires much less force to fire. IMO a must have for this springer!

Hopefully this will help someone else in the future. Also interesting to note, the trigger guard and almost everything else is glass reinforced nylon. The only metal (non silver colored) piece in the trigger assembly is the safety rocker.

Hopefully this will help someone else in the future. Also interesting to note, the trigger guard and almost everything else is glass reinforced nylon. The only metal (non silver colored) piece in the trigger assembly is the safety rocker.

Upvote 0

For the first stage spring, I cut out about 30% of it and stretched evenly to fit. For the second stage (the one that releases the spring to fire) spring, I played around with cutting and goofing around with it but eventually used another spring altogether. This one is very similar to the first stage spring with a little bit more.force required to compress.

Upvote 0

One of the best things you can do to a trigger is polish contact points. There is a lot of talk about not polishing the sear engagement areas due to changing the angle of contact. If you set it up in a jig that holds the angles and go real slow, you can make the area shine without disrupting the angles at all. I have often used different grades of wet and dry sand paper glued to a flat metal piece.

After the sear, the other points are important also. It is a great rainy day job.

By a spring kit with as many assorted springs as possible and do some experimenting there also.

When you are done, be sure to load the gun and give it a few sharp raps in a safe direction of course to see if the sear holds. If not, readjust any screws or go back in as make necessary changes to finally end up with a safe gun.

After the sear, the other points are important also. It is a great rainy day job.

By a spring kit with as many assorted springs as possible and do some experimenting there also.

When you are done, be sure to load the gun and give it a few sharp raps in a safe direction of course to see if the sear holds. If not, readjust any screws or go back in as make necessary changes to finally end up with a safe gun.

I got a Terrus a couple years ago and had the same problem. It was said to have a 3 lb trigger. A guy said he sold his because it had a two fingered trigger. I got my 1st trigger gauge just to see and it was breaking at 5 lbs. After reading about replacing the trigger spring that's what I did and now it breaks at 1 lb.

I got a precision compression spring at Mcmaster-Carr, .5" long - .18 OD - .144 ID - .018 wire (306 or 316 stainless)

Diagram - 1st photo shows the original spring, the second has the new spring in with the original below (behind trigger)

David

I got a precision compression spring at Mcmaster-Carr, .5" long - .18 OD - .144 ID - .018 wire (306 or 316 stainless)

Diagram - 1st photo shows the original spring, the second has the new spring in with the original below (behind trigger)

David

Upvote 0

The lighter trigger makes the gun so much more enjoyable. Aainds, did you polish up the sear and matching surfaces?

Upvote 0

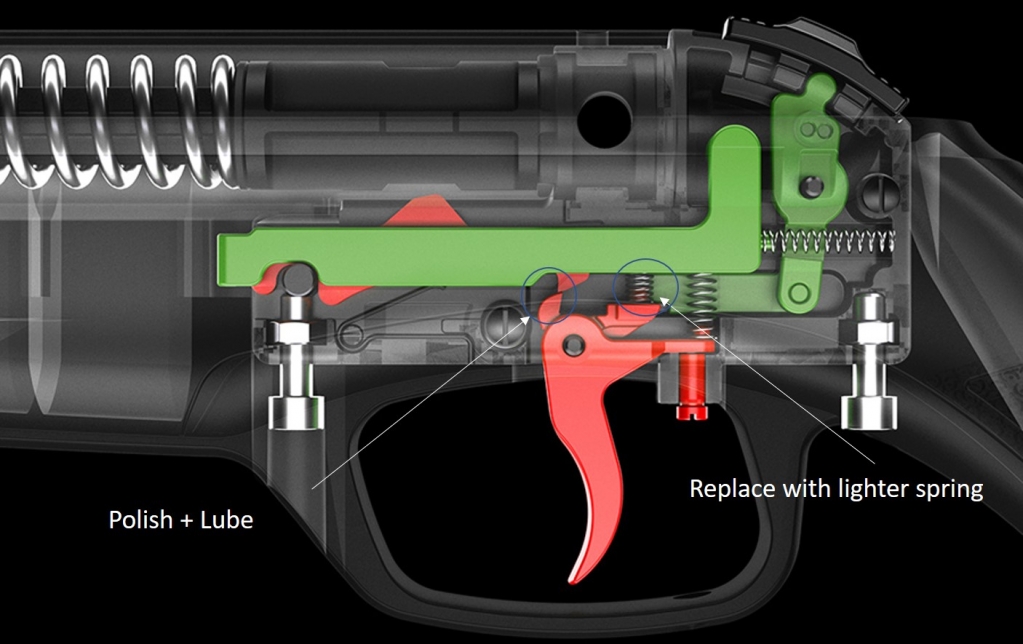

You can also "turn off" the automatic safety in the Parrus/Terrus. Easiest to explain with the colored diagram above.

You see the green colored rounded knob that sticks up and fits between the 2 tabs on the bottom of the safety switch. See how the distance from one tab to the end of the switch is longer toward the top end than the other tab to the bottom end, turn it around so the longer distance is toward the bottom and you have no auto safety. I learned this by accident but liked it. I wish I knew an easy way to disable it on my HW 97/98 & TX200.

Hunters might like safety's but I have no use for it. The very first thing I get in the habit of doing after cocking and loading is hit the safety button.

You see the green colored rounded knob that sticks up and fits between the 2 tabs on the bottom of the safety switch. See how the distance from one tab to the end of the switch is longer toward the top end than the other tab to the bottom end, turn it around so the longer distance is toward the bottom and you have no auto safety. I learned this by accident but liked it. I wish I knew an easy way to disable it on my HW 97/98 & TX200.

Hunters might like safety's but I have no use for it. The very first thing I get in the habit of doing after cocking and loading is hit the safety button.

Upvote 0