I know Neil Clague used to but I haven’t heard much about him anymore.. anyone else in the shroud business??

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Who makes custom shrouds??

- Thread starter Rvaughn

- Start date

I don't make shrouds, but I design custom inserts that you or someone else would 3D print. Then the insert would be contained by means of threads, or glued into a custom shroud tube.

It would be useful if you provide details about what the shroud is for. Forum member weevil has printed a number of my insert designs recently and glued them into CF tubing to make his own shrouds. You might ask him if he is satisfied.

You could use aluminum tubing, or if the shrouds are short enough, print the entire thing with baffles inside. Details help....

It would be useful if you provide details about what the shroud is for. Forum member weevil has printed a number of my insert designs recently and glued them into CF tubing to make his own shrouds. You might ask him if he is satisfied.

You could use aluminum tubing, or if the shrouds are short enough, print the entire thing with baffles inside. Details help....

Upvote 0

weevil started a thread about the above custom shrouds:

www.airgunnation.com

www.airgunnation.com

Western Airguns - Hushing the Sidewinder Mini .30

This is long, even by my painful standards. Grab a drink… In this thread, the marvelous @subscriber and I will document our efforts to reduce the bark of the .30 cal Western Airguns Sidewinder Mini/Compact. This collaborative project has been going on for some time and has recently borne its...

Upvote 0

I don't make shrouds, but I design custom inserts that you or someone else would 3D print. Then the insert would be contained by means of threads, or glued into a custom shroud tube.

It would be useful if you provide details about what the shroud is for. Forum member weevil has printed a number of my insert designs recently and glued them into CF tubing to make his own shrouds. You might ask him if he is satisfied.

You could use aluminum tubing, or if the shrouds are short enough, print the entire thing with baffles inside. Details help....

Sounds like you’ve designed a very effective baffle, thanks for the info!

The shroud is for my JSAR Raptor mini that I recently re-barreled with a .35 cal barrel from a Kral bighorn.

Currently it’s around 100fpe due to the smallish plenum but even at that power level it’s planets loud and I prefer my air rifles to be stealthy..

Later I plan to run it unregulated in hopes of squeezing more fpe out of it so the shroud would need to be designed to handle a possible of 150ish fpe air blast without self destructing..

I know weevils is a .30 so I assume he’s at or near that power level therefore I would also assume 3d printing materials would be sufficient enough for that type of power application? Feel free to enlighten me if I’m wrong pls.

Upvote 0

Rvaugn,

As they say, the devil is in the details. If the moderator has a large volume (specifically the first expansion chamber), then the stress it sees is lower than if the moderator is small. So, the limit for printed inserts is not FPE related, but volume related. Also, the design of the baffles make a difference. The first baffle/s that the air slams into should be made thick, while those further forwards can be made thinner, as they do not work as hard.

I strongly advise you to use a aluminum or CF tube to house the internals, so that the stronger outer tube is the pressure vessel, rather than the printed insert. This is similar to a brass case being supported by a steel chamber in a PB.

If you provide basic dimensions I should be able to tell you if your goal is feasible. I need:

Shroud OD; and if it is stepped, both diameters.

Shroud length ahead of the barrel muzzle; and behind the muzzle. If this is one tube that makes things simpler.

I assume the barrel has a threaded stud. What is the thread diameter, pitch and length?

You can do a lot with a 1.5 to 2" OD tube. Depending on available materials, you may choose a 40 mm OD CF or aluminum tube. from a design perspective, I would ultimately need to know the tube ID as measured, rather than just nominal, as sold.

Considering you expectations, I think you will be disappointed with any length less than 8" ahead of the barrel muzzle.

What is the barrel length on your Raptor, as this affects muzzle pressure?

As they say, the devil is in the details. If the moderator has a large volume (specifically the first expansion chamber), then the stress it sees is lower than if the moderator is small. So, the limit for printed inserts is not FPE related, but volume related. Also, the design of the baffles make a difference. The first baffle/s that the air slams into should be made thick, while those further forwards can be made thinner, as they do not work as hard.

I strongly advise you to use a aluminum or CF tube to house the internals, so that the stronger outer tube is the pressure vessel, rather than the printed insert. This is similar to a brass case being supported by a steel chamber in a PB.

If you provide basic dimensions I should be able to tell you if your goal is feasible. I need:

Shroud OD; and if it is stepped, both diameters.

Shroud length ahead of the barrel muzzle; and behind the muzzle. If this is one tube that makes things simpler.

I assume the barrel has a threaded stud. What is the thread diameter, pitch and length?

You can do a lot with a 1.5 to 2" OD tube. Depending on available materials, you may choose a 40 mm OD CF or aluminum tube. from a design perspective, I would ultimately need to know the tube ID as measured, rather than just nominal, as sold.

Considering you expectations, I think you will be disappointed with any length less than 8" ahead of the barrel muzzle.

What is the barrel length on your Raptor, as this affects muzzle pressure?

Upvote 0

I would be cautious of making a shroud out of CF if it’s to be used on high power guns, carbon is brittle, the pressure inside the shroud is immense, any slight manufacturing defect or physical damage can cause the carbon to explode like a grenade.I don't make shrouds, but I design custom inserts that you or someone else would 3D print. Then the insert would be contained by means of threads, or glued into a custom shroud tube.

It would be useful if you provide details about what the shroud is for. Forum member weevil has printed a number of my insert designs recently and glued them into CF tubing to make his own shrouds. You might ask him if he is satisfied.

You could use aluminum tubing, or if the shrouds are short enough, print the entire thing with baffles inside. Details help....

Ask me howi know

Bb

Upvote 0

Bb,

If one does not use thick enough, quality CF tubing with an appropriate filament weave for radial pressure, then aluminum is more forgiving, for sure. The latter will bulge before it bursts. A factor to consider when opting for low weight.

If your PCP's valve sticks wide open and dumps the tank, that may also burst your moderator, if it is not designed for such events. This is like your car, that is not designed to be drivable after crashing into a 2 foot diameter tree at 40 MPH.

If one does not use thick enough, quality CF tubing with an appropriate filament weave for radial pressure, then aluminum is more forgiving, for sure. The latter will bulge before it bursts. A factor to consider when opting for low weight.

If your PCP's valve sticks wide open and dumps the tank, that may also burst your moderator, if it is not designed for such events. This is like your car, that is not designed to be drivable after crashing into a 2 foot diameter tree at 40 MPH.

Upvote 0

If I am making a shroud for my own use, to cope with even low power I prefer aluminum tubing, simply because I don't want to deal with carbon fiber dust.

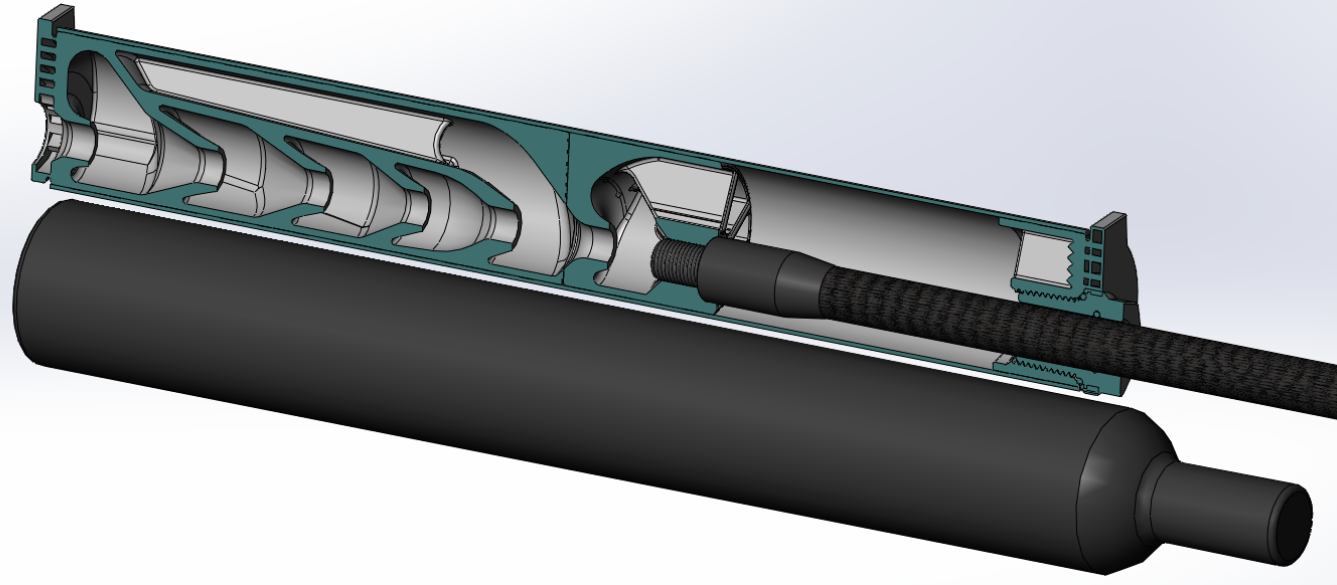

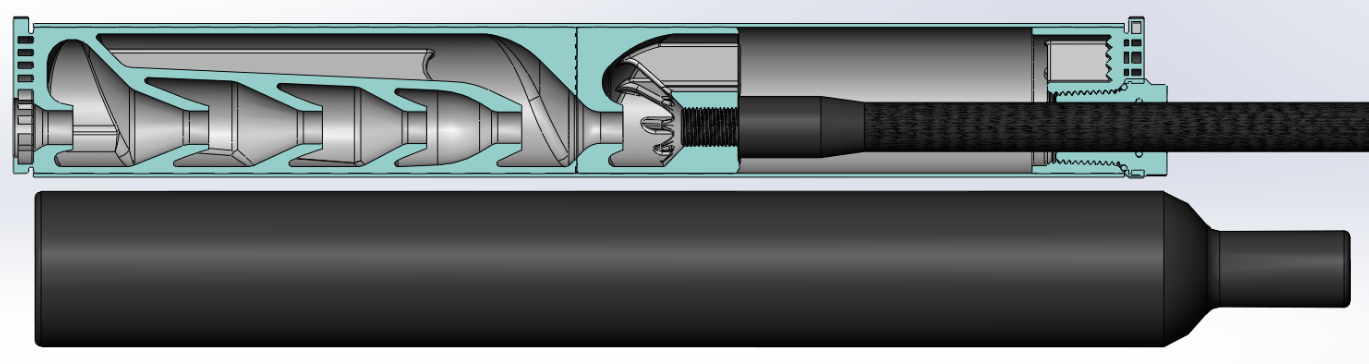

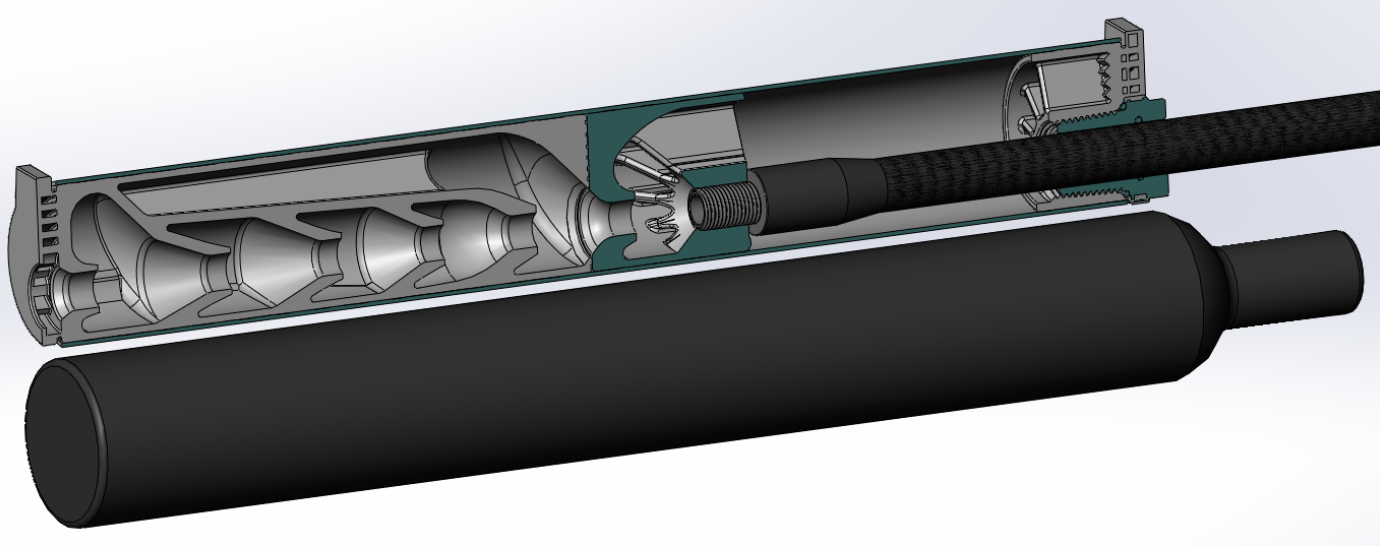

Here is a .357 offset reflex moderator I designed for mackeral5. The 3D printed bits were produced by TorqueMaster, while mackeral5 did the integration, using a 6061 Al tube. The airgun is mackeral5 mongrel with a 12" barrel, shooting at 100 FPE. More info here:

The perforated bits at the front and rear ends are clocking alignment features for assembly. They were used only while gluing the three main printed insert parts into the aluminum tube. The alignment features were cut off, and the front and rear faces of the moderator dressed flat, after the glue had set.

The barrel has a "knot" behind the muzzle, that required a tapered collet to center and secure the barrel at the rear of the shroud. Without that printed collet, the barrel cannot be screwed into the moderator, or removed.

All that said, I am not opposed to someone choosing carbon fiber tubing, if the moderator capacity is large enough for the power they intent to shoot at. Also, that they are willing and able to make and test the shroud themselves; and understand how to conduct at least a rudimentary proof test.

In the case of weevil's current exercise, he actually tested fully printed "inserts" to prove the first designs, before his CF tubing arrived. Yes, the printed outer wall thickness was increased to twice that of the CF tube. The printed moderators did not fail, and the CF tubing is a lot stronger than twice the printed PETG.

There is a difference between making a commodity moderator, and a custom one. With the custom moderator, the end user needs to be (willing to be) part of the development process, while one assumes name brand moderators have been fully developed by their manufacturer. If you expect a custom moderator to be produced solely by a "tuner" type individual, then that person will need the same air rifle you use, in the same state of tune, shooting the same projectiles. In the absence of that, the custom maker will need to over design their moderator to guarantee it will not fail. That will make it heavy, and possibly very large, so that it is not stressed very much for the volume and pressure of air dumped into it.

I have a large number of 3D printed moderator designs that act as their own outer shell. How do I know they are strong enough? By designing some test versions with the walls thinned out to half the intended thickness, or less, and trying them out. If the thinner versions survive, then the thicker ones should be OK.

Yes, this depends on who prints my designs, the material they use and their print settings. So, I offer no guarantee for my designs that are printed by unknown people, using unknown equipment and settings. I don't charge for my designs and they should be considered experimental. Yet they seem to work OK and don't fail, unless deliberately abused. Even then they are designed to fail safe; by throwing the larger chunks forwards, away from the person behind the airgun.

So, a little insight about the process I and my development partners follow.

Here is a .357 offset reflex moderator I designed for mackeral5. The 3D printed bits were produced by TorqueMaster, while mackeral5 did the integration, using a 6061 Al tube. The airgun is mackeral5 mongrel with a 12" barrel, shooting at 100 FPE. More info here:

Subscriber designed 3D printed offset reflex moderator - Airguns & Guns Forum

Subscriber designed 3D printed offset reflex moderator, Air guns, Airgun Forum

www.gatewaytoairguns.org

The perforated bits at the front and rear ends are clocking alignment features for assembly. They were used only while gluing the three main printed insert parts into the aluminum tube. The alignment features were cut off, and the front and rear faces of the moderator dressed flat, after the glue had set.

The barrel has a "knot" behind the muzzle, that required a tapered collet to center and secure the barrel at the rear of the shroud. Without that printed collet, the barrel cannot be screwed into the moderator, or removed.

All that said, I am not opposed to someone choosing carbon fiber tubing, if the moderator capacity is large enough for the power they intent to shoot at. Also, that they are willing and able to make and test the shroud themselves; and understand how to conduct at least a rudimentary proof test.

In the case of weevil's current exercise, he actually tested fully printed "inserts" to prove the first designs, before his CF tubing arrived. Yes, the printed outer wall thickness was increased to twice that of the CF tube. The printed moderators did not fail, and the CF tubing is a lot stronger than twice the printed PETG.

There is a difference between making a commodity moderator, and a custom one. With the custom moderator, the end user needs to be (willing to be) part of the development process, while one assumes name brand moderators have been fully developed by their manufacturer. If you expect a custom moderator to be produced solely by a "tuner" type individual, then that person will need the same air rifle you use, in the same state of tune, shooting the same projectiles. In the absence of that, the custom maker will need to over design their moderator to guarantee it will not fail. That will make it heavy, and possibly very large, so that it is not stressed very much for the volume and pressure of air dumped into it.

I have a large number of 3D printed moderator designs that act as their own outer shell. How do I know they are strong enough? By designing some test versions with the walls thinned out to half the intended thickness, or less, and trying them out. If the thinner versions survive, then the thicker ones should be OK.

Yes, this depends on who prints my designs, the material they use and their print settings. So, I offer no guarantee for my designs that are printed by unknown people, using unknown equipment and settings. I don't charge for my designs and they should be considered experimental. Yet they seem to work OK and don't fail, unless deliberately abused. Even then they are designed to fail safe; by throwing the larger chunks forwards, away from the person behind the airgun.

So, a little insight about the process I and my development partners follow.

Upvote 0

Rvaugn,

As they say, the devil is in the details. If the moderator has a large volume (specifically the first expansion chamber), then the stress it sees is lower than if the moderator is small. So, the limit for printed inserts is not FPE related, but volume related. Also, the design of the baffles make a difference. The first baffle/s that the air slams into should be made thick, while those further forwards can be made thinner, as they do not work as hard.

I strongly advise you to use a aluminum or CF tube to house the internals, so that the stronger outer tube is the pressure vessel, rather than the printed insert. This is similar to a brass case being supported by a steel chamber in a PB.

If you provide basic dimensions I should be able to tell you if your goal is feasible. I need:

Shroud OD; and if it is stepped, both diameters.

Shroud length ahead of the barrel muzzle; and behind the muzzle. If this is one tube that makes things simpler.

I assume the barrel has a threaded stud. What is the thread diameter, pitch and length?

You can do a lot with a 1.5 to 2" OD tube. Depending on available materials, you may choose a 40 mm OD CF or aluminum tube. from a design perspective, I would ultimately need to know the tube ID as measured, rather than just nominal, as sold.

Considering you expectations, I think you will be disappointed with any length less than 8" ahead of the barrel muzzle.

What is the barrel length on your Raptor, as this affects muzzle pressure?

I would like to run carbon fiber to keep the whole rig as light as possible. I’ll have to measure a bit later today and see how large of a diameter tubing I could run , I’m positive I have room for 1.5” OD at least but I’ll have to confirm that..

I’m fine with doing the assembly and fitting on it, I actually prefer it that way.

Just have to find someone to do the printing, but I have a friend in mind that may be able to help with that also.

My barrel isn’t currently threaded due to me cutting the choke off the end, so I’m going to be running an adapter from Donnyfl similar to what Mackeral5 has on his barrel.

If you could design one for me that would be amazing and I’d be very grateful for that!

I’ll also say I’m not overly concerned about hushing the report but more so with reducing the sound to a level that doesn’t require hearing protection to shoot.

That’s my real goal..

Upvote 0

That’s my real goal..

Sounds reasonable to me.

Hearing safe should be more than feasible with any reasonable shroud.

If you can't locate a printer, I can recommend a guy.

Upvote 0

Sounds reasonable to me.

Hearing safe should be more than feasible with any reasonable shroud.

If you can't locate a printer, I can recommend a guy.

Ok perfect , I’ll pm you a little later in the day and we can talk details of my rifle.

Thanks!

Upvote 0