I have a compressor and before I changed my oil it used to fill my pcp all the way up to 4500 psi and after I made the oil change it takes forever to fill and it fills only to 4000 psi if I’m lucky

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yong heng compressor not filling

- Thread starter Dcm2010

- Start date

Leaks are the number 1 cause. Hook up a bottle, get pressure in the compressor and bottle, turn off the compressor, pumps, fans, everything and listen for leaks.

Use a spray bottle with soapy water too.

If nothing is found, it is likely the valves on the cylinder head. Time to get mechanical of that's the case.

Use a spray bottle with soapy water too.

If nothing is found, it is likely the valves on the cylinder head. Time to get mechanical of that's the case.

Upvote 0

Already tried the soap and nothing happened, and something I’ve notice is that if I charge my pcp and leave it without releasing the pressure on the line it starts dropping by it self slowly but I can’t find the leak.

Upvote 0

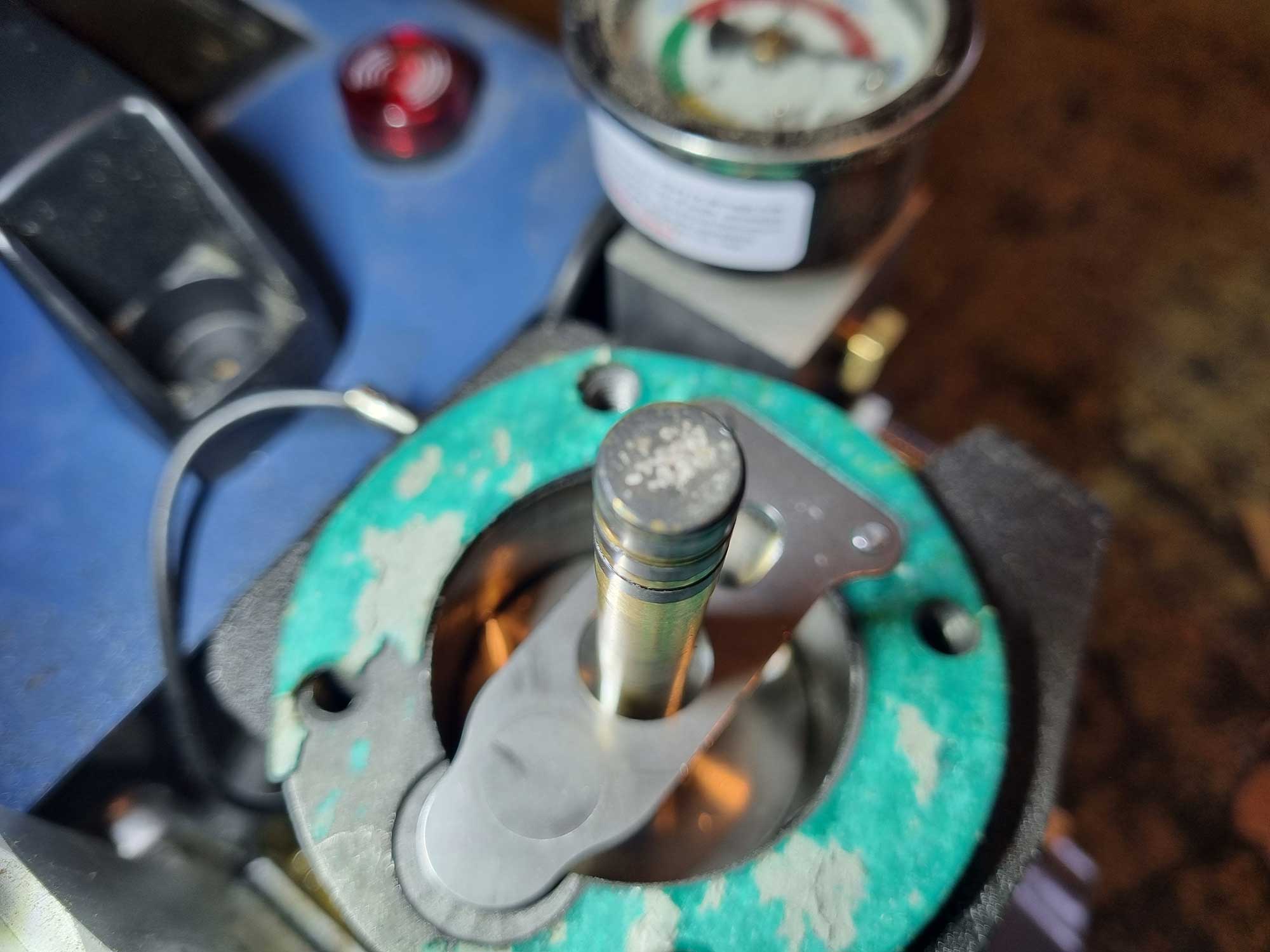

Most PCP compressors include a "dead head" plug (pictured) for leak testing. Install in fill whip end, pressurize system, shut down, check with soapy water bottle for leaks. Check gauge, quick-disconnect fittings and burst disc. Release pressure before re-starting compressor. WM

Upvote 0

"Already tried the soap and nothing happened"

Exactly what was your procedure while leak detecting? Every single fitting, burst disc, drain valves, cylinder screws, HP & LP tubing fittings, etc. have to be checked with leak detector. If you've done that (the correct way) & aren't finding a leak it's likely piston rings or internal problems. There are a plethora of YH maintenance & repair videos on YouTube to help.

Exactly what was your procedure while leak detecting? Every single fitting, burst disc, drain valves, cylinder screws, HP & LP tubing fittings, etc. have to be checked with leak detector. If you've done that (the correct way) & aren't finding a leak it's likely piston rings or internal problems. There are a plethora of YH maintenance & repair videos on YouTube to help.

Upvote 0

It just happened to me today... tried to refill from 160 bar and got up to 250 needed more then an hour and half with 3 cool downs.

The first stage piston rings leaking cannot build up the compression. I can grab the pipe between first to second stage with fingers and it is "cold". The second stage pipe to output is much warmer.

I shall have one complete piston + headset in spare, but I will be ordering a full kit from aliexpress soon.

The first stage piston rings leaking cannot build up the compression. I can grab the pipe between first to second stage with fingers and it is "cold". The second stage pipe to output is much warmer.

I shall have one complete piston + headset in spare, but I will be ordering a full kit from aliexpress soon.

Upvote 0

I just finished installing a new jug, piston/rod assembly, and second stage kit from Ali Express on a Yong Heng gifted to me by my neighbor. I finally pushed it too hard and it wouldn't build pressure past 2400 psi. I suspect it may be a clone, as it does not have the mfg info plate on the side. The new parts did fit perfectly, but I had to use the original hex bolts for the jug, the ones with the kit wouldn't start.

So far so good, have topped off all my bottle guns to 4500 with no issues.

EDIT: This may be an obvious suggestion, but don't forget to make sure any and all bleed valves in the equation aren't leaking.

So far so good, have topped off all my bottle guns to 4500 with no issues.

EDIT: This may be an obvious suggestion, but don't forget to make sure any and all bleed valves in the equation aren't leaking.

Last edited:

Upvote 0

Yesterday I managed to seize that piston rod. Oh well, I have one new full assembly (first and second stage) on order from aliexpress, ETA 2 weeks.It just happened to me today... ...I shall have one complete piston + headset in spare, but I will be ordering a full kit from aliexpress soon.

Today I toke it apart, replaced the cylinders/pistons with one already used earlier years but refurbished the second stage diy and in good shape.

I saw the seizing left some scars on the "crankshaft" rod clean it with 1500 sandpaper, put all together and crank it up.

And seized again. !@%

I will need to replace that "crankshaft" now. I read somewhere back in time that the thread is opposite to brake it loose I shall do moment of inertia ClockWise. Never replaced that one before, is it sitting on a cone or cylindrical with keyway? I will try to polish it until next aliexpress order.

Upvote 0

My YH has been getting slower and slower, but gee it has a poopload of hours on it!!

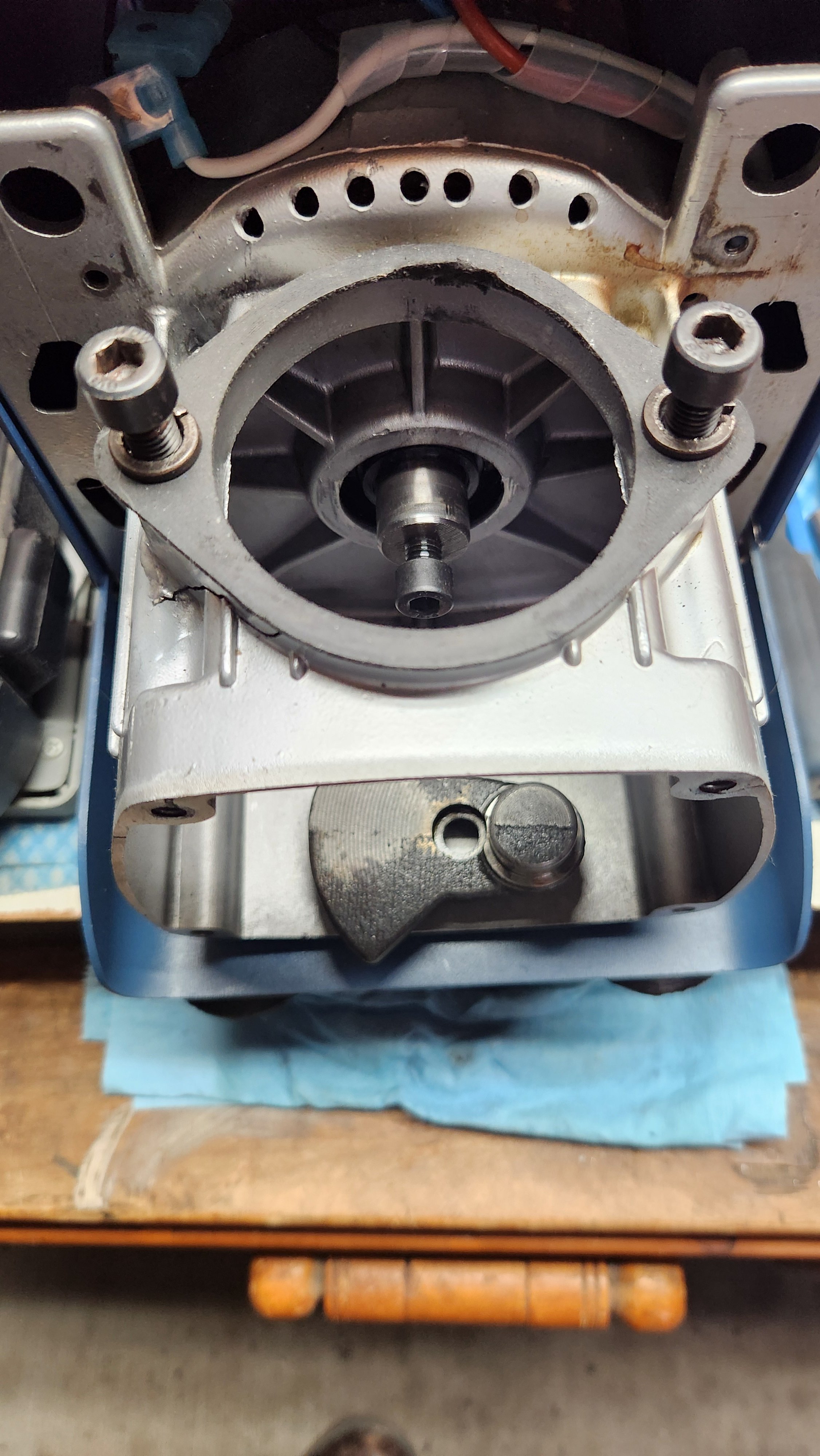

The other day it just would not fill past past 150bar. Took the top off expecting it to look a right mess, but it doesn't look to bad. Obviously there there must be excessive wear so time for a rebuild.

I have always kept a brand new unit for a spare. fired it up today...Good God!!! its fast!!! My old unit must have progressively just got slower and slower and i have just gotten used to it, it did realise it had slowed , but didn't realise just how much!

The other day it just would not fill past past 150bar. Took the top off expecting it to look a right mess, but it doesn't look to bad. Obviously there there must be excessive wear so time for a rebuild.

I have always kept a brand new unit for a spare. fired it up today...Good God!!! its fast!!! My old unit must have progressively just got slower and slower and i have just gotten used to it, it did realise it had slowed , but didn't realise just how much!

Attachments

Upvote 0

Piston rod seized, this is a second time. I tried to sandpaper down the surface but looks like didn't help.

Have a spare pump for parts whenever needed, any idea how to take this crank shaft out without some specialty tool? The screw I brake loose but cannot pull it out.

I would have a good use for it now

The next option is get a new compressor... but closest I can reach is a Tuxing from amazon...

Have a spare pump for parts whenever needed, any idea how to take this crank shaft out without some specialty tool? The screw I brake loose but cannot pull it out.

I would have a good use for it now

The next option is get a new compressor... but closest I can reach is a Tuxing from amazon...

Upvote 0

The piston rod is seizing to the crank? That is such a loose fit to be seizing. I notice there is no “dipper” on the bottom of the crank, did it break off, or did it not have one?

Upvote 0

Look hard at your check valves, the ones connected your SS lines. There easy to get to, so look for corrosion or chipped O-rings or bad Dowty washer, Mine was just cleaned...Already tried the soap and nothing happened, and something I’ve notice is that if I charge my pcp and leave it without releasing the pressure on the line it starts dropping by it self slowly but I can’t find the leak.

Upvote 0

the dipper is on the bottom of the piston rod (not shown in picture)....I notice there is no “dipper” on the bottom of the crank, did it break off, or did it not have one?

My best guess... the plastic spacers (I repeatedly put them in from the very early YH's 2020) shall not be on the dowel.

Upvote 0

What brand oil? Mine blackens any oil used after used but still making good pressure... Thx.Piston rod seized, this is a second time. I tried to sandpaper down the surface but looks like didn't help.

View attachment 463490

Have a spare pump for parts whenever needed, any idea how to take this crank shaft out without some specialty tool? The screw I brake loose but cannot pull it out.

I would have a good use for it now

View attachment 463491

The next option is get a new compressor... but closest I can reach is a Tuxing from amazon...

Upvote 0

Royal Purple, but next oil I want to get something else and hopefully better, no available for pickup I shall internet order.

Today removed the oil and pan again, and with some tinkering finally managed to pull out that crank piece. I removed both the damaged and from my spare YH as well (this pic below) where I am scavenging parts in emergency.

I have two pistons refurbished but both piston rods damaged/seized and can't re-use, need to wait for a new full kit to arrive ETA next week.

Good news that all three of my scba tanks still about 250 bars, I have a good chance to survive couple weeks.

Today removed the oil and pan again, and with some tinkering finally managed to pull out that crank piece. I removed both the damaged and from my spare YH as well (this pic below) where I am scavenging parts in emergency.

I have two pistons refurbished but both piston rods damaged/seized and can't re-use, need to wait for a new full kit to arrive ETA next week.

Good news that all three of my scba tanks still about 250 bars, I have a good chance to survive couple weeks.

Upvote 0

I bought a GX 2, for rifle only backup, to allow time for any slow boat parts to arrive. So far, only pressure gauge on my 2019 YHeng...

Upvote 0

I looked at Cotton's teardown video from 6 years ago. Nice of him to mention the left hand threads on the crank bolt, no?

Upvote 0

Check the pressure gauge, that's the first thing to fail on my yong hengs.Already tried the soap and nothing happened, and something I’ve notice is that if I charge my pcp and leave it without releasing the pressure on the line it starts dropping by it self slowly but I can’t find the leak.

Upvote 0