You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuning Your M3 Tunes Here

- Thread starter kaylaindy

- Start date

My tune for M3 Sniper .22 cal, 700mm vanilla version with no power add on except the heavy slug liner. I tested the slugs at 50 m only.

Note on precision: after testing the slugs with the 2 type of liners it seems I can get 0.9 MOA (12mm @ 50m) accuracy with the slug liner and 1.2 MOA (17 mm @ 50m) with the Standard Liner. Also I didn’t noticed much difference between .218 slugs and .217.

Note on tuning: what really counts is the Reg 2 pressure and the value of the micro adjustment. Since there is 20 micro “clicks” and 5 macro clicks to move half a graduation on the scale, reading 4,75 means 4,7 plus 2 micro clicks. 4,7 = 4.5 plus 8 micro clicks etc. By playing with the micro knob you can adjust the Macro at any level, therefore IMO what is really relevant comparing the various tunes is the reading on the Quick Tune Scale. Last but not least, it seems at high Reg 2 pressure like 150bars, the valve return spring adjustment has negligible effects: it seems the return spring is too weak for the pressure at 150b.

1 Reg 190b, 2 Reg 150b, Valve adjustment at 5 (one full turn after the 4 th line). Heavy Slug Liner.

Patriot .218 34 gr; Speed 922 fps; E/S: 3; S/D: 1.3; Accuracy 0.8 MOA; Macro 14, Micro 4,75 (2 micro clicks above 4.7)

H&N .217 30 gr; Speed 975 fps; E/S 4; S/D 1.5; Accuracy 0.8 MOA, Macro 13, Micro 4,6

Important: all my E/S and S/D are measured for each 5 slug grouping with a Magnetospeed “bayonet” type chronograph.

Next week I will get the shroud with the Harmonic tuner from Krale, I can’t wait playing with it to increase accuracy. I also bought the slug power kit but I am a bit reluctant (and lazy) to mess up with the internal of this great gun.

Hope it helps. Happy and safe shooting.

Pascal

Note on precision: after testing the slugs with the 2 type of liners it seems I can get 0.9 MOA (12mm @ 50m) accuracy with the slug liner and 1.2 MOA (17 mm @ 50m) with the Standard Liner. Also I didn’t noticed much difference between .218 slugs and .217.

Note on tuning: what really counts is the Reg 2 pressure and the value of the micro adjustment. Since there is 20 micro “clicks” and 5 macro clicks to move half a graduation on the scale, reading 4,75 means 4,7 plus 2 micro clicks. 4,7 = 4.5 plus 8 micro clicks etc. By playing with the micro knob you can adjust the Macro at any level, therefore IMO what is really relevant comparing the various tunes is the reading on the Quick Tune Scale. Last but not least, it seems at high Reg 2 pressure like 150bars, the valve return spring adjustment has negligible effects: it seems the return spring is too weak for the pressure at 150b.

1 Reg 190b, 2 Reg 150b, Valve adjustment at 5 (one full turn after the 4 th line). Heavy Slug Liner.

Patriot .218 34 gr; Speed 922 fps; E/S: 3; S/D: 1.3; Accuracy 0.8 MOA; Macro 14, Micro 4,75 (2 micro clicks above 4.7)

H&N .217 30 gr; Speed 975 fps; E/S 4; S/D 1.5; Accuracy 0.8 MOA, Macro 13, Micro 4,6

Important: all my E/S and S/D are measured for each 5 slug grouping with a Magnetospeed “bayonet” type chronograph.

Next week I will get the shroud with the Harmonic tuner from Krale, I can’t wait playing with it to increase accuracy. I also bought the slug power kit but I am a bit reluctant (and lazy) to mess up with the internal of this great gun.

Hope it helps. Happy and safe shooting.

Pascal

Upvote 0

Just curious if anyone is shooting FX hybrid slugs or any other slugs with the m3 500mm .25 caliber, i haven't seen any tunes for this barrel, although it came shooting the 25 grain pellets perfectly from the factory, I don't mind tuning it myself but tuning suggestions are always nice.

Upvote 0

Hello,

I have the same setup as you. Looking for a good starting point for the 29.5 nsa slugs. Have you found a good tune yet? I have the carbon fiber sleeve installed and just got the harmonic barrel tuner. I was thinking around 960 fps but looking around first.

Thanks for any feedback.

Jeff

I have the same setup as you. Looking for a good starting point for the 29.5 nsa slugs. Have you found a good tune yet? I have the carbon fiber sleeve installed and just got the harmonic barrel tuner. I was thinking around 960 fps but looking around first.

Thanks for any feedback.

Jeff

Upvote 0

Hi Jeff, yes 960 fps should be a good start for developping a tune for the 29.5 or 30 gr slugs. What is also very impressive with the M3 is the very low Standard deviation reached: 1.5. It is only for a 5 shot group but it is pretty consistant for several 5 shots group.

Anyway I have to do it all over again: as an average fashion victim influenced by the excellent videos of Matt Dubber and the likes in S;A, I have succumbed to installing the slug power kit to send Patriot 34 grains above 1000fps... I am still struggling to install it in my M3. I have also received the harmonic tuning shroud. If my M3 survives the operation I'll be back with some new tunes, new SD and new accuracy. The comparison will be interresting.

Sometime I criticise girls at home for being massively influenced by Make Up Artists on the web. I realise with horror I'm just like them about my favorite hobby: rifles air or powder burners. Tsssss...

Anyway I have to do it all over again: as an average fashion victim influenced by the excellent videos of Matt Dubber and the likes in S;A, I have succumbed to installing the slug power kit to send Patriot 34 grains above 1000fps... I am still struggling to install it in my M3. I have also received the harmonic tuning shroud. If my M3 survives the operation I'll be back with some new tunes, new SD and new accuracy. The comparison will be interresting.

Sometime I criticise girls at home for being massively influenced by Make Up Artists on the web. I realise with horror I'm just like them about my favorite hobby: rifles air or powder burners. Tsssss...

Upvote 0

OK I have installed the slug power kit, the hamonic shroud and I am using the FX radar i/o the Magnetospeed. I went to the range this afternoon with great expectations... It was a total desaster. With my best tuneI P reg 2increased from 150 to 170 bar and the spring indicator 4.70 the best speed I could get is 830 fps with E/S of 40 !!! Any other tune result in 700 something fps.

All this to be compared with 930 fps at Preg 150 bar and the spring indicator at 4.70 with and Extreme Spread of 4 fps for the Patriot 34 grains with my vanilla M3 before installing the Slug Power Kit. What gives?

Thanks to my brilliant work installing the power slug kit I managed to transform an accurate M3 into a useless tomato pick. Did anyone had a similar experience or does anybody have a clue about what's going on? Any help will be highly appreciated. Pascal.

All this to be compared with 930 fps at Preg 150 bar and the spring indicator at 4.70 with and Extreme Spread of 4 fps for the Patriot 34 grains with my vanilla M3 before installing the Slug Power Kit. What gives?

Thanks to my brilliant work installing the power slug kit I managed to transform an accurate M3 into a useless tomato pick. Did anyone had a similar experience or does anybody have a clue about what's going on? Any help will be highly appreciated. Pascal.

Upvote 0

Yes I did I just followed the video on installation. This rubber ball may be the problem on the M3 isn't it?

Upvote 0

@MajorSylvester

Yes sir that’s most likely your issue right there! Take that rubber ball out. Also, do not mess with the springs or hammer spacers unless you see an obvious need for them, which you should not.

Here is some backstory on this issue. I love sharing stories btw sometimes I get carried away, this may be one of those times and more appropriate for a different thread but what the heck…

Before installing my pin probe I called FX USA and spoke with one of the techs. He reported that on the FX Impact M3 you only use the pin probe. The other components are for the previous models. Quick shout out to those guys at FX USA, have always taken the time to answer my questions, excellent customer support.

A gentleman, I believe from Denmark, made a post on Facebook. I don’t go on Facebook much these days, only once in a blue moon. Perhaps it was fate I saw his post. He was asking for tuning advise as his fps readings were not the same as other shooters chronograph readings with the same settings. I thought perhaps he was a noob like myself and learning as I am. So gave a general rundown of what I had seen in Mr. Rowes FX masterclass tuning video. I also mentioned that no two guns are alike and while you can swap setting with others you will not match their results exactly. You will get the best results by putting in the time, patience, and lead over the chrony. I thought he was only off by a few fps or so. Nope, he was maxed out and had next to no power like yourself and anything other than max gave approximately the same output.

Helping him troubleshoot and brainstorming together I shared some of my own experiences as a new owner of an Impact. One thing I mentioned was checking the transfer port as I had an issue once. I had tried fx hybrid slugs (not bad in .22 but didn’t like them in .25 personally). So I was re-tuning my gun to shoot pellets again. I didn’t flip the barrel over back to the pellet side as I thought it wouldn’t matter much, it’s now my opinion that is does. I double chambered two rounds by accident and got a pellet stuck in one of the ports on the slug side of the transfer port. Each pellet felt rough going into the breech and my accuracy was trash all of a sudden. After a few quick checks I slid the barrel out and found the issue, the second pellet mashed over the “bridge”. Whoops. Removed it with a pick and continued to tune.

He checked that and other things I can’t quite recall. After a few days he found the issue. He followed a video where the person used all of the components in the slug power kit on the M3. After removing the ball spring and spacers his output jumped right up. He was pushing rounds out at near the speed of sound. I believe he was trying to tune for around 1050fps as I recall writing that was close to supersonic.

Side notes: I see many who strive for velocity and power. My own experience has been that lower velocities have given me better results. This is for me only many do very very well at higher velocities.

I value this thread and the users who have complied data on settings and results, I truly do. It’s very interesting to see how others have set up their guns. However, it should be noted it is only a starting point for consideration. There are many factors that will give you different results. There are many setting that could give you the same fps and fpe. If you just want to shoot sure go ahead set you gun to one of these tunes and shoot. If you want perfection time, patience, and lead over the chrony are going to give you the best tune/shot cycle.

Good luck sir and happy shooting!

Yes sir that’s most likely your issue right there! Take that rubber ball out. Also, do not mess with the springs or hammer spacers unless you see an obvious need for them, which you should not.

Here is some backstory on this issue. I love sharing stories btw sometimes I get carried away, this may be one of those times and more appropriate for a different thread but what the heck…

Before installing my pin probe I called FX USA and spoke with one of the techs. He reported that on the FX Impact M3 you only use the pin probe. The other components are for the previous models. Quick shout out to those guys at FX USA, have always taken the time to answer my questions, excellent customer support.

A gentleman, I believe from Denmark, made a post on Facebook. I don’t go on Facebook much these days, only once in a blue moon. Perhaps it was fate I saw his post. He was asking for tuning advise as his fps readings were not the same as other shooters chronograph readings with the same settings. I thought perhaps he was a noob like myself and learning as I am. So gave a general rundown of what I had seen in Mr. Rowes FX masterclass tuning video. I also mentioned that no two guns are alike and while you can swap setting with others you will not match their results exactly. You will get the best results by putting in the time, patience, and lead over the chrony. I thought he was only off by a few fps or so. Nope, he was maxed out and had next to no power like yourself and anything other than max gave approximately the same output.

Helping him troubleshoot and brainstorming together I shared some of my own experiences as a new owner of an Impact. One thing I mentioned was checking the transfer port as I had an issue once. I had tried fx hybrid slugs (not bad in .22 but didn’t like them in .25 personally). So I was re-tuning my gun to shoot pellets again. I didn’t flip the barrel over back to the pellet side as I thought it wouldn’t matter much, it’s now my opinion that is does. I double chambered two rounds by accident and got a pellet stuck in one of the ports on the slug side of the transfer port. Each pellet felt rough going into the breech and my accuracy was trash all of a sudden. After a few quick checks I slid the barrel out and found the issue, the second pellet mashed over the “bridge”. Whoops. Removed it with a pick and continued to tune.

He checked that and other things I can’t quite recall. After a few days he found the issue. He followed a video where the person used all of the components in the slug power kit on the M3. After removing the ball spring and spacers his output jumped right up. He was pushing rounds out at near the speed of sound. I believe he was trying to tune for around 1050fps as I recall writing that was close to supersonic.

Side notes: I see many who strive for velocity and power. My own experience has been that lower velocities have given me better results. This is for me only many do very very well at higher velocities.

I value this thread and the users who have complied data on settings and results, I truly do. It’s very interesting to see how others have set up their guns. However, it should be noted it is only a starting point for consideration. There are many factors that will give you different results. There are many setting that could give you the same fps and fpe. If you just want to shoot sure go ahead set you gun to one of these tunes and shoot. If you want perfection time, patience, and lead over the chrony are going to give you the best tune/shot cycle.

Good luck sir and happy shooting!

Upvote 0

@icycrosshairs, thanks so much for your very detailed and useful explanations it really helps a lot.

It is still a mystery that FX Europe sell their kit WITHOUT informing anyone that, except for the pin probe, it is totally useless for the M3. And even reducing the performance after a difficult surgical disassembly and reassembly of internal critical components. After removing the rubber ball, now I have no power at all. Reg 1 is at 190b Reg 2 at 170b, I press the trigger, I hear a click and no air is leaving the barrel. Maybe that is an issue with the new weaker valve spring but I do not understand why. I'm going to replace it with the original spring and I will remove the spacers. Another surgical operation I do not like. I will just keep the pin probe as suggested. I'll be back to the range next week and post the result. Let's cross fingers.

It is still a mystery that FX Europe sell their kit WITHOUT informing anyone that, except for the pin probe, it is totally useless for the M3. And even reducing the performance after a difficult surgical disassembly and reassembly of internal critical components. After removing the rubber ball, now I have no power at all. Reg 1 is at 190b Reg 2 at 170b, I press the trigger, I hear a click and no air is leaving the barrel. Maybe that is an issue with the new weaker valve spring but I do not understand why. I'm going to replace it with the original spring and I will remove the spacers. Another surgical operation I do not like. I will just keep the pin probe as suggested. I'll be back to the range next week and post the result. Let's cross fingers.

Upvote 0

@MajorSylvester

You’re very welcome sir. That’s odd you have no valve movement after removing the ball. Perhaps because the original valve spring is stronger? I think you may need to turn down your regulators. If the pressure is too high the hammer won’t be able to open the valve. I am by no means an expert with these however, I would degas the gun and drop your regs back down and start the tune process working your way up to higher pressures again.

Not sure if you know this, if you do please don’t take offense sir. You should not make large decreases in regulator pressure with the plenum charged. It is too much force on the regulator piston. Yes you can adjust higher without problems. Yes make small adjustments by turning the adjustment screw in (clockwise) 1/8 turn and firing the gun “shooting down” the pressure however, if you turn it too much it’s not good. It will smoosh the delrin piston in the regulator. To make a substantial decrease on the second regulator you should degas the plenum. Again no offense if you already know this; to degas the gun you unscrew your bottle and then turn the second regulator up (counter clockwise). This will dump the air in the plenum. After the plenum is depressurized you can turn the regulator screw in a few turns to lower the regulator and thread the bottle back on.

If you cannot actuate the valve you will not be able to make small adjustments and “shoot down” the pressure so the second option seems to be the way to go. Unscrew the bottle, adjust the second reg up to dump the plenum, then adjust the second regulator down and thread the bottle back on. Repeat if necessary.

On my gun The first reg somewhere around 140 bar and second reg somewhere around 125 bar. I say “around“ because I cannot say for certain that my gauges are calibrated perfectly. I have the standard factory gauge on the bottom and the inexpensive digital gauge on the angle bracket. They both read a little different, factory gauge reads just under 120bar, digital reads 124.9bar.

So my tune for this gun is as follows:

.25cal 700mm stx superior heavy liner with carbon liner sleeve.

Fx pin probe adjusted to max depth without interfering with magazine.

Factory transfer port on slug side. I have an oversized o-ring in the breech rather than the factory o-ring

Factory spring, hammer, and valve configuration

First reg: ~140 bar

Second reg: ~125 bar

macro: 16

Micro: 3.75 on the scale

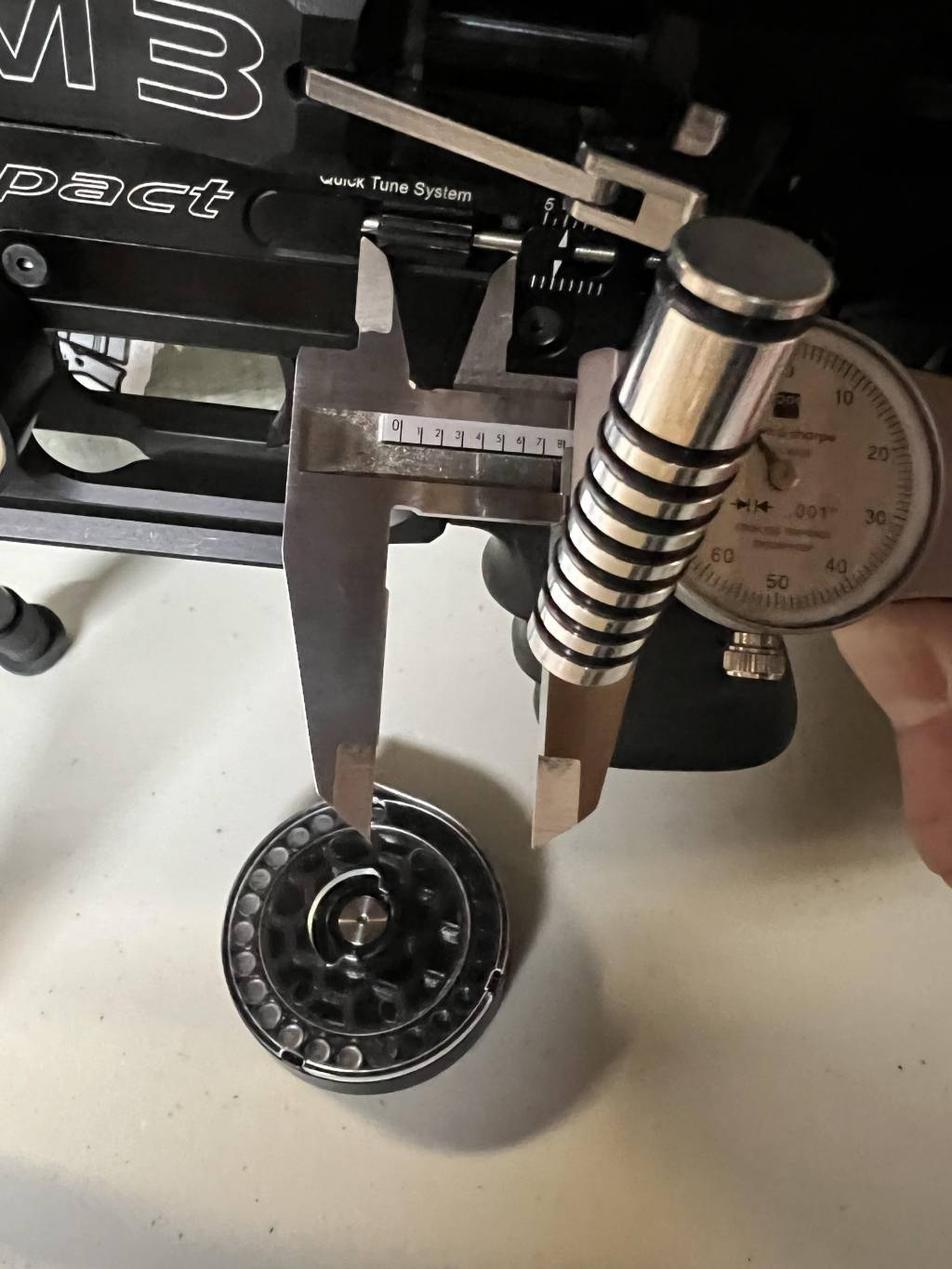

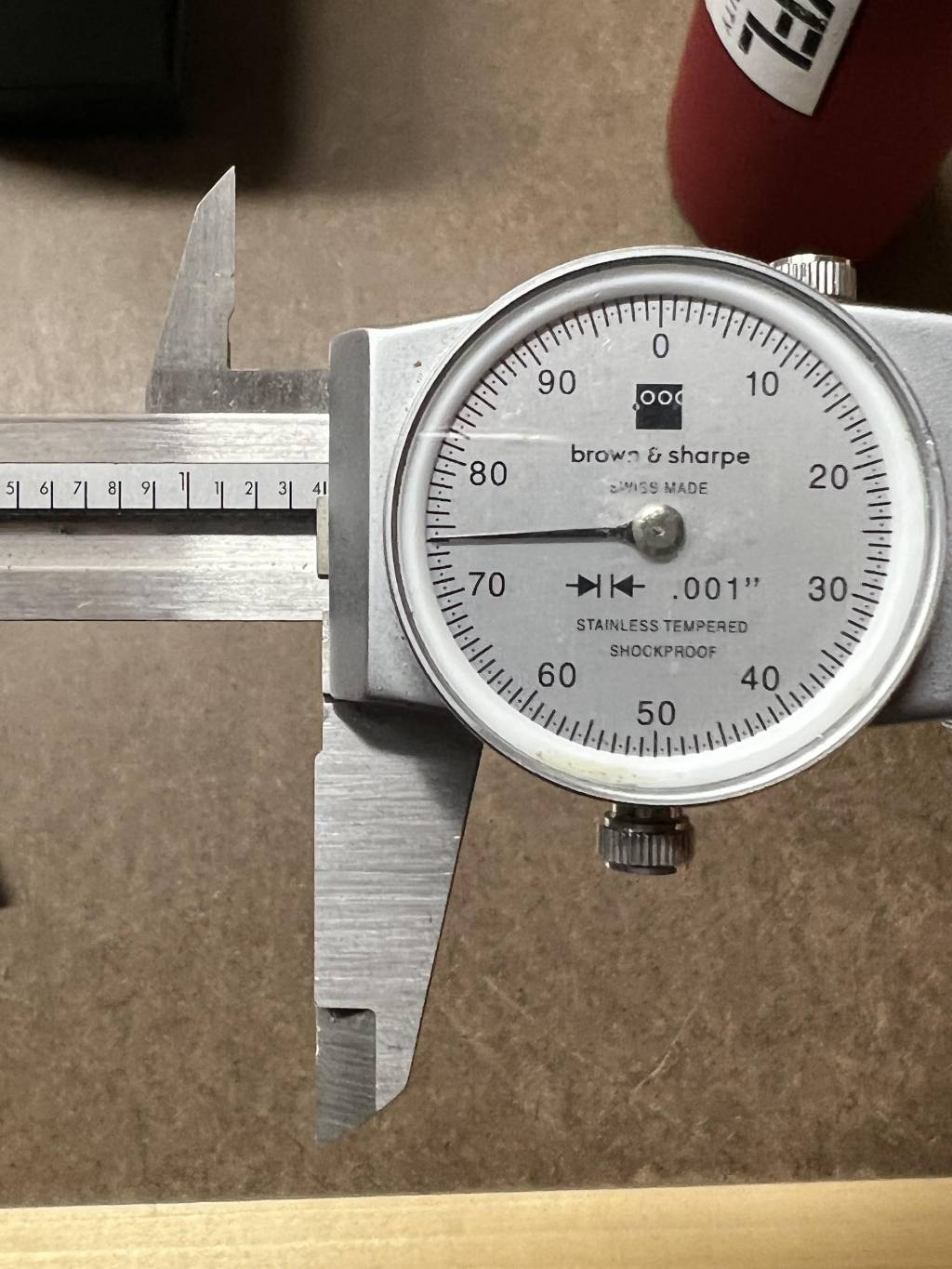

The micro adjuster measures 0.789” from flat spot to flat spot (on my gun)

Valve: just past the fourth line by the width of one line

The valve measures 1.374” from end of valve knob to trigger block (Not the shoulder the actual block) as you can see it’s a poor measurement as my caliper is not perfectly straight.

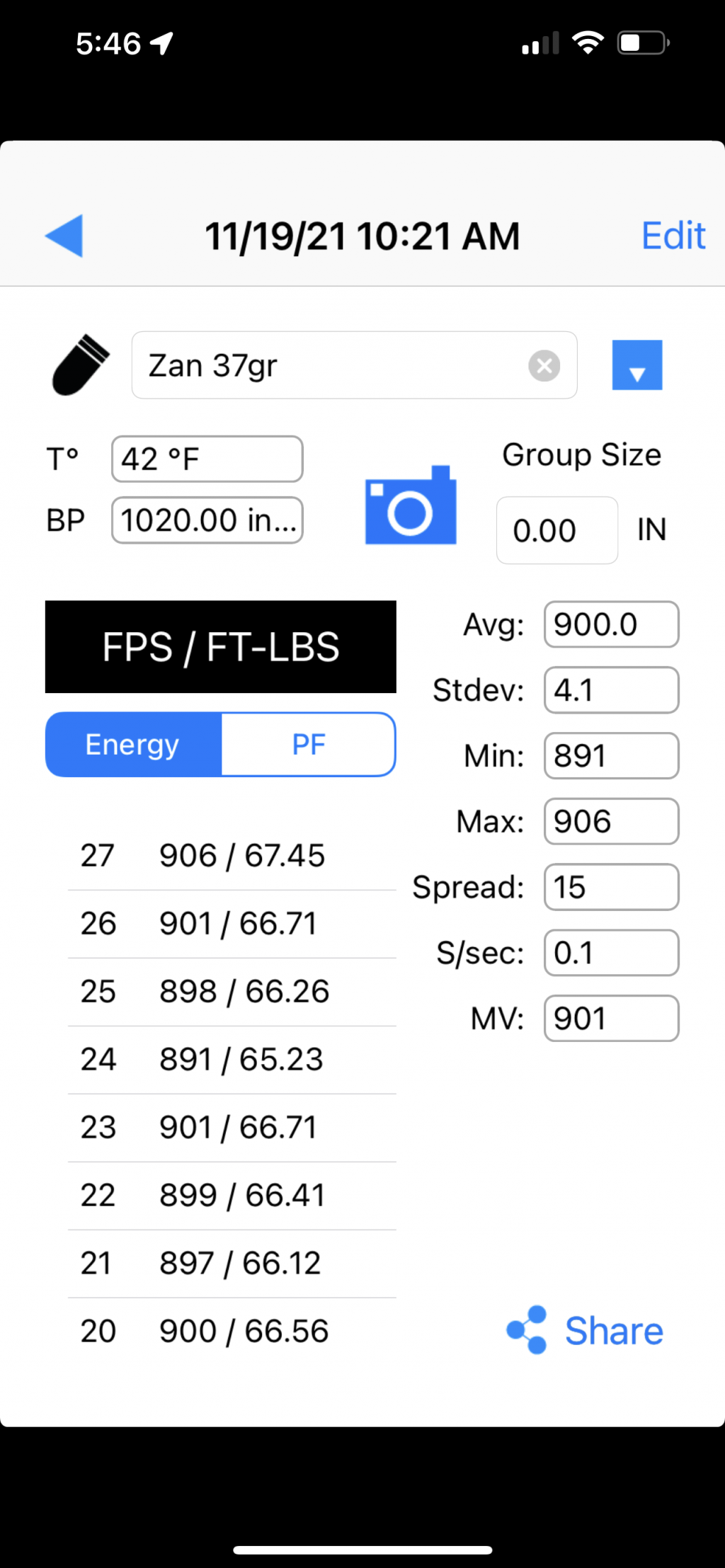

I am shooting 37gr Zân slugs at 891-906 fps with unsorted non lubricated slugs ~15 fps spread over 27 shots. Average velocity ~900fps

Could my tune better? Yes definitely. Am I happy with it? For now yes definitely.

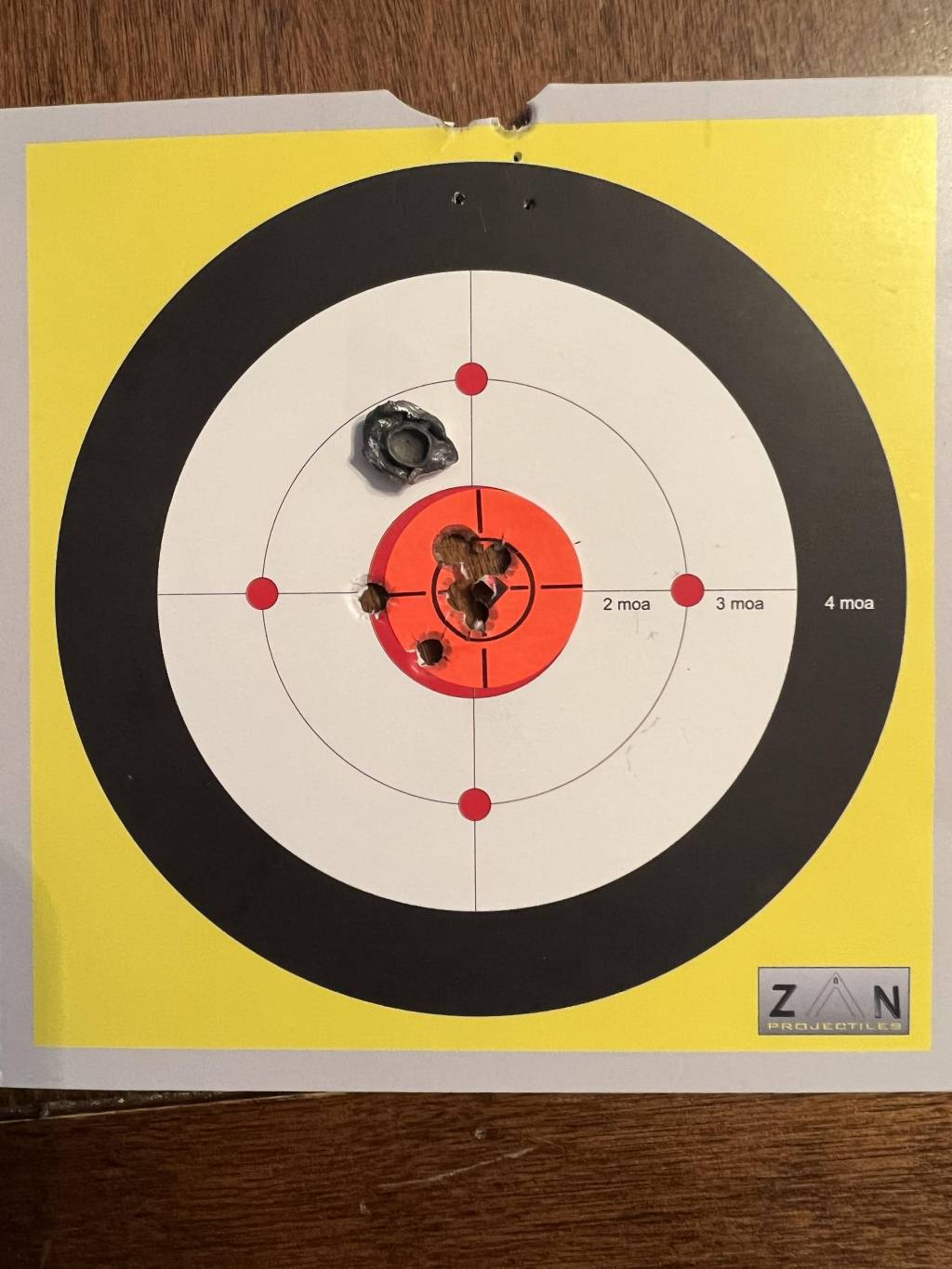

Here’s a group at ~65 yrds:

Regarding my group at 65 yards: the temp was ~40°F outside, my gun was tuned at 68°F in my basement. The top two shots I had my scope adjusted incorrectly perhaps I measured incorrectly with my 200 foot tape measure and it was slightly less than 65 yrds or my scope was off. The second two shots I cannot recall if I adjusted the scope or that was me shaking. When I shot this group I had been awake for ~30 hours working on a final exam/final circuit for my Digital Electronics class. I was burnt out, I needed a break, I was shaking like a leaf in the wind. I had only gotten 3-4 hours sleep the three nights prior to that. All in all not too bad for being an absolute 100% complete mess. I did pass the class with an A and my other classes were all A’s as well! I’m kinda proud of the grades, I had a lot going on in my personal life at home but had a lot of support from a couple members on the forum that I consider friends. God bless them for all the help and the encouragement they gave my wife and myself. I have met so many awesome people on this forum. I am truly grateful for having them in my life.

You’re very welcome sir. That’s odd you have no valve movement after removing the ball. Perhaps because the original valve spring is stronger? I think you may need to turn down your regulators. If the pressure is too high the hammer won’t be able to open the valve. I am by no means an expert with these however, I would degas the gun and drop your regs back down and start the tune process working your way up to higher pressures again.

Not sure if you know this, if you do please don’t take offense sir. You should not make large decreases in regulator pressure with the plenum charged. It is too much force on the regulator piston. Yes you can adjust higher without problems. Yes make small adjustments by turning the adjustment screw in (clockwise) 1/8 turn and firing the gun “shooting down” the pressure however, if you turn it too much it’s not good. It will smoosh the delrin piston in the regulator. To make a substantial decrease on the second regulator you should degas the plenum. Again no offense if you already know this; to degas the gun you unscrew your bottle and then turn the second regulator up (counter clockwise). This will dump the air in the plenum. After the plenum is depressurized you can turn the regulator screw in a few turns to lower the regulator and thread the bottle back on.

If you cannot actuate the valve you will not be able to make small adjustments and “shoot down” the pressure so the second option seems to be the way to go. Unscrew the bottle, adjust the second reg up to dump the plenum, then adjust the second regulator down and thread the bottle back on. Repeat if necessary.

On my gun The first reg somewhere around 140 bar and second reg somewhere around 125 bar. I say “around“ because I cannot say for certain that my gauges are calibrated perfectly. I have the standard factory gauge on the bottom and the inexpensive digital gauge on the angle bracket. They both read a little different, factory gauge reads just under 120bar, digital reads 124.9bar.

So my tune for this gun is as follows:

.25cal 700mm stx superior heavy liner with carbon liner sleeve.

Fx pin probe adjusted to max depth without interfering with magazine.

Factory transfer port on slug side. I have an oversized o-ring in the breech rather than the factory o-ring

Factory spring, hammer, and valve configuration

First reg: ~140 bar

Second reg: ~125 bar

macro: 16

Micro: 3.75 on the scale

The micro adjuster measures 0.789” from flat spot to flat spot (on my gun)

Valve: just past the fourth line by the width of one line

The valve measures 1.374” from end of valve knob to trigger block (Not the shoulder the actual block) as you can see it’s a poor measurement as my caliper is not perfectly straight.

I am shooting 37gr Zân slugs at 891-906 fps with unsorted non lubricated slugs ~15 fps spread over 27 shots. Average velocity ~900fps

Could my tune better? Yes definitely. Am I happy with it? For now yes definitely.

Here’s a group at ~65 yrds:

Regarding my group at 65 yards: the temp was ~40°F outside, my gun was tuned at 68°F in my basement. The top two shots I had my scope adjusted incorrectly perhaps I measured incorrectly with my 200 foot tape measure and it was slightly less than 65 yrds or my scope was off. The second two shots I cannot recall if I adjusted the scope or that was me shaking. When I shot this group I had been awake for ~30 hours working on a final exam/final circuit for my Digital Electronics class. I was burnt out, I needed a break, I was shaking like a leaf in the wind. I had only gotten 3-4 hours sleep the three nights prior to that. All in all not too bad for being an absolute 100% complete mess. I did pass the class with an A and my other classes were all A’s as well! I’m kinda proud of the grades, I had a lot going on in my personal life at home but had a lot of support from a couple members on the forum that I consider friends. God bless them for all the help and the encouragement they gave my wife and myself. I have met so many awesome people on this forum. I am truly grateful for having them in my life.

Upvote 0

@majorsylvester I totally agree with you

no oficial guide to install the slug power kit in the M3 from the FX Europe.

So I contact FXUSA an they answer in a short time, and this is ther’s email:

quoute: “Yes, just the pin probe and two spacers. The spring is not for the M3, as the M3 spring is already optimized for power. The rubber ball is not necessary either.” End of quoute FXUSA service.

Só I put the two spacers, but with the two spacers the pcp doesn't cock on the micro 5 position

them I opens the m3 again an out just one spacer, and pin probe nothing more.

sory my english

no oficial guide to install the slug power kit in the M3 from the FX Europe.

So I contact FXUSA an they answer in a short time, and this is ther’s email:

quoute: “Yes, just the pin probe and two spacers. The spring is not for the M3, as the M3 spring is already optimized for power. The rubber ball is not necessary either.” End of quoute FXUSA service.

Só I put the two spacers, but with the two spacers the pcp doesn't cock on the micro 5 position

them I opens the m3 again an out just one spacer, and pin probe nothing more.

sory my english

Upvote 0

In conclusion if i knew what i know today i would not buy the kit, because I ended up buying the huma pin that works for pellets and slugs.

so i bought the kit to use only one spacer on my M3

so i bought the kit to use only one spacer on my M3

Upvote 0

@icycrossair: I've finally solved the no power issue, just repressurized the bottle. Thanks for the detailed explanation about how to change the regulators pressure without messing up the whole system. This is pretty useful. Congrats for this great shooting in such difficult conditions. Also, congratulation s for the A levels in your exams.

@Berto1: Maybe I'm wrong but the fact that your rifle doesn't cock is because the spring has probably achieved its maximum compression with all its spires contacting each others. The addition of the 2 spacers just make achieving the maximum compression earlier. Hence the fact you can't cock anymore at macroweel 5. That was the same for me before I removed the spacers yesterday.

BTW, since one can achieve the maximum spring compression without the spacers, I do not understand the use of the spacers for the M3. Sure it adds more mass hitting the valve BUT no more energy since its speed will be lower. This is due to the fact the maximum potential energy is stored in the spring therefore with spacers or without them the maximum energy will still be the same isn't it? This is just an attemps to explanin something by an air rifle noob, I'm probably missing something? Has someone an explanation for the use of the spacers in the M3?

@Berto1: Maybe I'm wrong but the fact that your rifle doesn't cock is because the spring has probably achieved its maximum compression with all its spires contacting each others. The addition of the 2 spacers just make achieving the maximum compression earlier. Hence the fact you can't cock anymore at macroweel 5. That was the same for me before I removed the spacers yesterday.

BTW, since one can achieve the maximum spring compression without the spacers, I do not understand the use of the spacers for the M3. Sure it adds more mass hitting the valve BUT no more energy since its speed will be lower. This is due to the fact the maximum potential energy is stored in the spring therefore with spacers or without them the maximum energy will still be the same isn't it? This is just an attemps to explanin something by an air rifle noob, I'm probably missing something? Has someone an explanation for the use of the spacers in the M3?

Upvote 0

@MajorSylvester

That’s fantastic you figured it out and got the gun to cycle again! Thank you for the compliment sir!!

That’s fantastic you figured it out and got the gun to cycle again! Thank you for the compliment sir!!

Upvote 0

Yes, the gun is cycling again BUT.... now I am desperate. I'm just back from the range and the issue is the very same. Returning to the vanilla M3 setting (no power kit ball, spring and spacers) I still have the same problem: very low velocity, 700 to 800 fps for .22 34 gr patriot slugs with very high extreme spead. The rifle is set at maximum reg 2 pressure 170b, maximum spring tension (its reads 5.0) valve set 2 turns after the 4th line. The rifle is tuned exactly like in my first post before I installed the kit when the rifle used to sent the 34grs at 922 fps for a reg pressure of 150b. The only difference could be in the C1 from the valve rod wihch protrudes at 6 mm (same setting as the setting recommended by Ernest Rowes video) and I have also left the pin probe for slugs after checking the slug pushed by the pin will leave transfer port clean.

The slug velociy is totally out of control now. And my brain is melting away. I am afraid I need more brainpower and more experience than mine to understand what's going on. Please help!

The slug velociy is totally out of control now. And my brain is melting away. I am afraid I need more brainpower and more experience than mine to understand what's going on. Please help!

Upvote 0

Set up my impact M3 .30 caliber today. 700mm barrel. Finished my tune and hitting quarter size groupings at 50 yards. I have the first Guage said at 150 and the plenum at 120. The front valve is out 4 and 1/2 lines. I have the macro wheel at 16 and the micro at 3 1/2. Shooting an average of 902 ft per second with a standard deviation of 4.2. works just as well with either the FX pellets or the jsb pellets, both at about 44.8 grains.

Upvote 0

I like reading everyone’s tune for different calibers and projectiles, it is a great knowledge library, but if everyone would include the barrel length it would be a great.

Upvote 0