You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Leshiy 2 - 3D print

- Thread starter towle

- Start date

Have you thought or tried to make the top layer having a recessed hex shaped hole that would accept the nyloc nut so that the nut is below the surface. Then a 3/4” x 1/8” cylinder magnet could be glued over top. This would be used to remove and hold the magazine plate for loading the magazine. Makes The Whole process a one handed operation. I also use the magnet to attach the speed loader to a steel washer I attached to the gun, in this case to the Eagle Vision scope rings.

Upvote 0

i could not resist getting a prusa mini so i could try this myself and help support the community, but i am a complete newb and probably won't have time to develop products, at least not unless i win the lottery and retire. anyway, hope to be up an running to at least make something from a file.

Upvote 0

Have you thought or tried to make the top layer having a recessed hex shaped hole that would accept the nyloc nut so that the nut is below the surface. Then a 3/4” x 1/8” cylinder magnet could be glued over top. This would be used to remove and hold the magazine plate for loading the magazine. Makes The Whole process a one handed operation. I also use the magnet to attach the speed loader to a steel washer I attached to the gun, in this case to the Eagle Vision scope rings.

Yes I have thunk about that but...

Would make the print more complicated for some as it may need support material for the hex hole, I want this to be an easy print for all and it is

The upper disc would have to be higher, would ad to the total height...and in printing require extra cooling as the indexing part of the upper disc would be the last printed, as of now all 3 parts is of same height so has time to cool down

If I integrate the nut, the head of the countersunk screw will have to move freely in the lower disc, this will require frequently adjustment of the screw to keep the friction the same - as of now, with the screw head glued to the lower disc and a shim under the lock nut the friction is between the large surface of the 3 discs and hardly change at all

I have a small update to the design, will post later, my X220 is slow as molasses so rendering all calibers takes time..

Upvote 0

i could not resist getting a prusa mini so i could try this myself and help support the community, but i am a complete newb and probably won't have time to develop products, at least not unless i win the lottery and retire. anyway, hope to be up an running to at least make something from a file.

Congrats and have fun with your new hobby!

Upvote 0

OK I see what your saying. I have one from a guy on EBay and his is made with the hex nut recessed. The nut is a nyloc type that keeps the tension when the screw is tensioned up. If the tension loosens the screw can be tightened a little and it’s good again. No need to glue the screw head. The hex nut is small enough that it fits within the the chambers and the height of the base is 1/2” with the nut countersunk flush. The top is 1/4” thick. I am not criticizing your design and I understand why you have made it based on your machines capabilities and other factors that I don’t understand . It’s just that with a magnet attached to the bottom makes the whole reloading a one handed operation when the magazine is still in the gun. I have the original magazines that you need a magnet to remove the black plate to load.

Upvote 0

I was planning on making a full tutorial but I really will not have enough time as I will be very busy and it is very easy anyway.

I will give information as much as possible.

Disclaimer: I hold no responsibility whatsoever if you damage your air gun while using this baffle.

every 3d printer is different so you have to make sure tolerances are good to go before shooting through it.

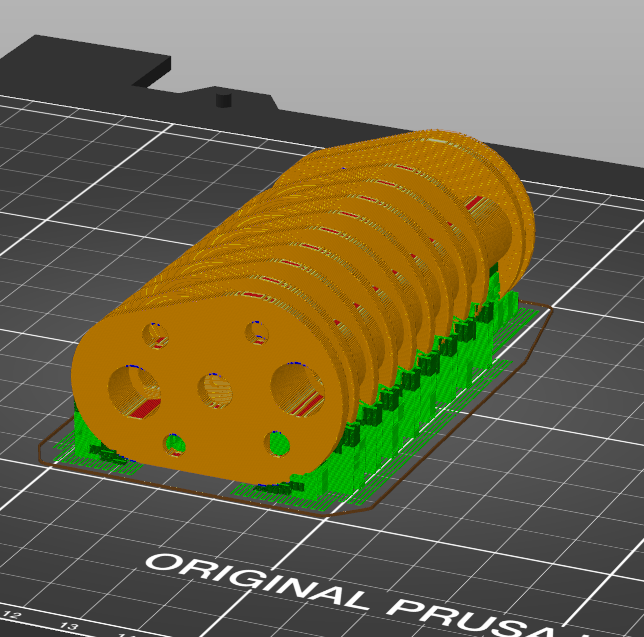

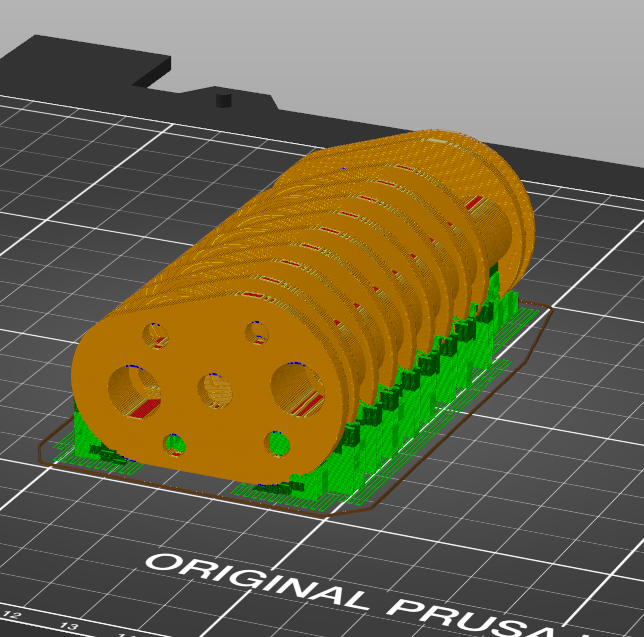

3d Printing Orientation (print horizontally with support on bed):

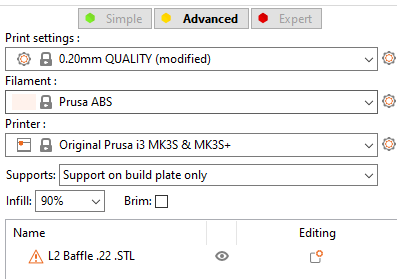

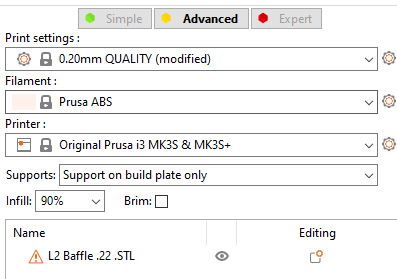

after that clean up the print then use a 4mm Allen key to round off these two holes.

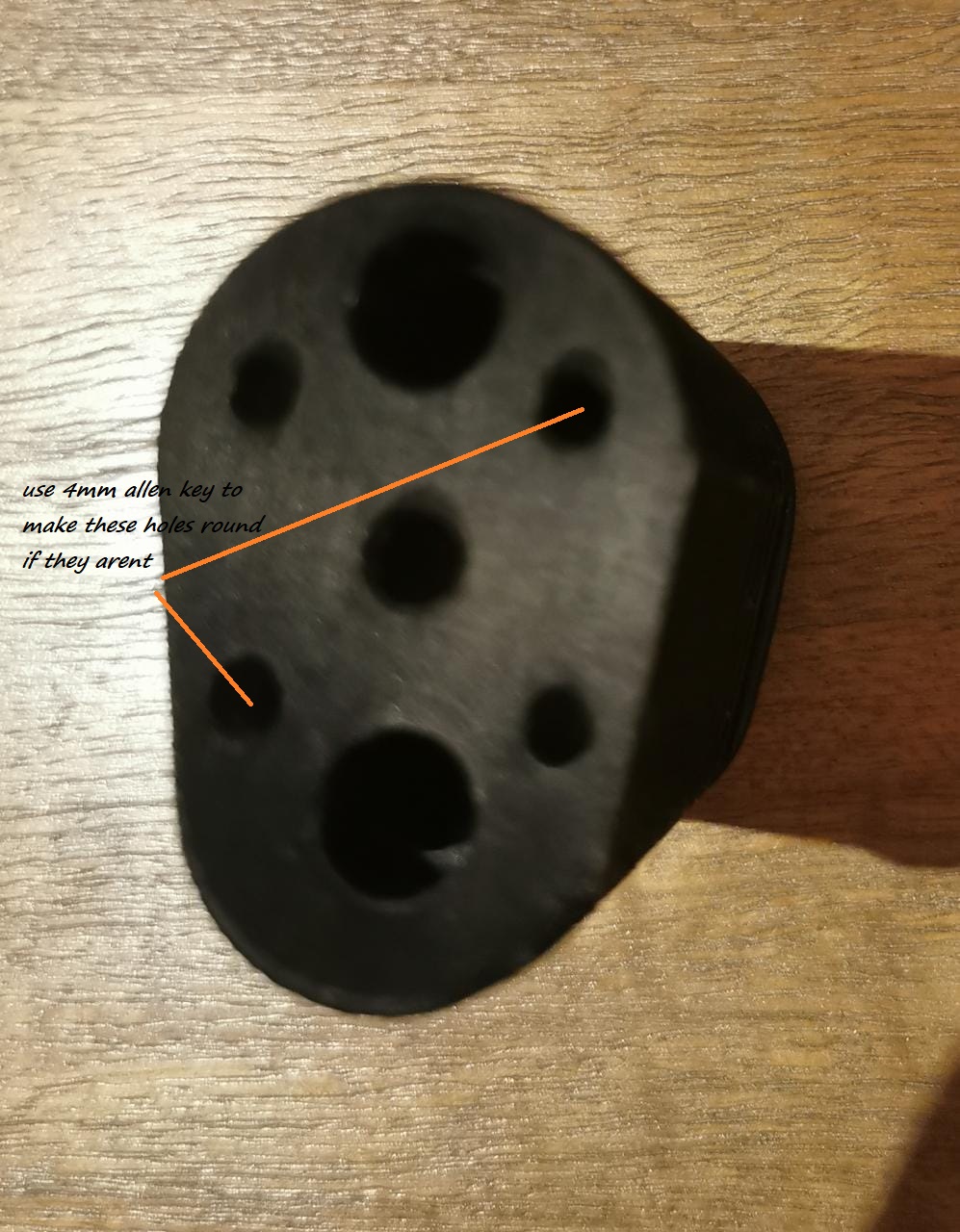

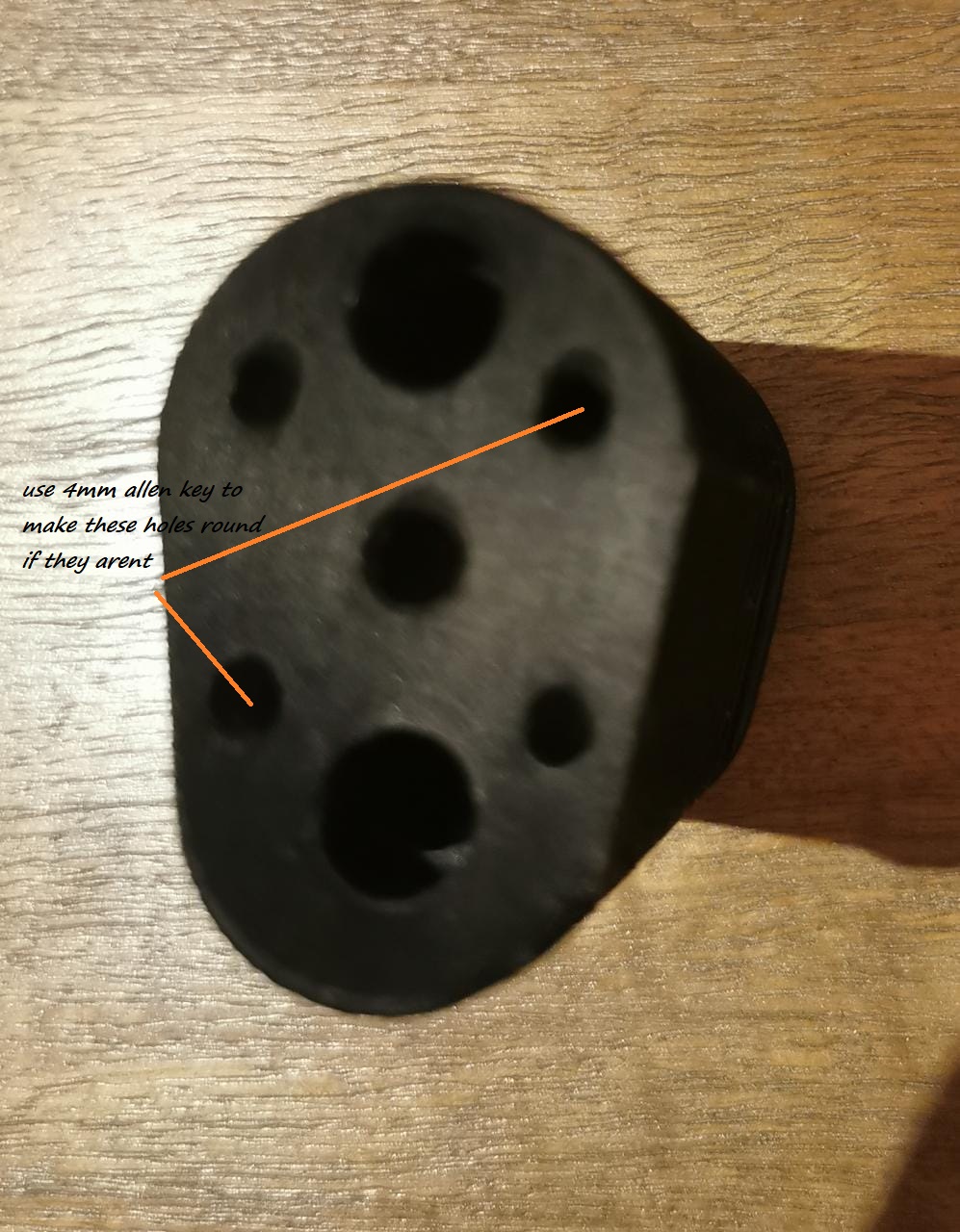

install the baffle and tighten both screws (insert screws from bottom and use a screwdriver to guide them into the hole then tighten using an Allen key from the top)

also ensure the baffle is flush with the front moderator plate (the two small pins should slot into their respective holes.

don't forget to put the O ring.

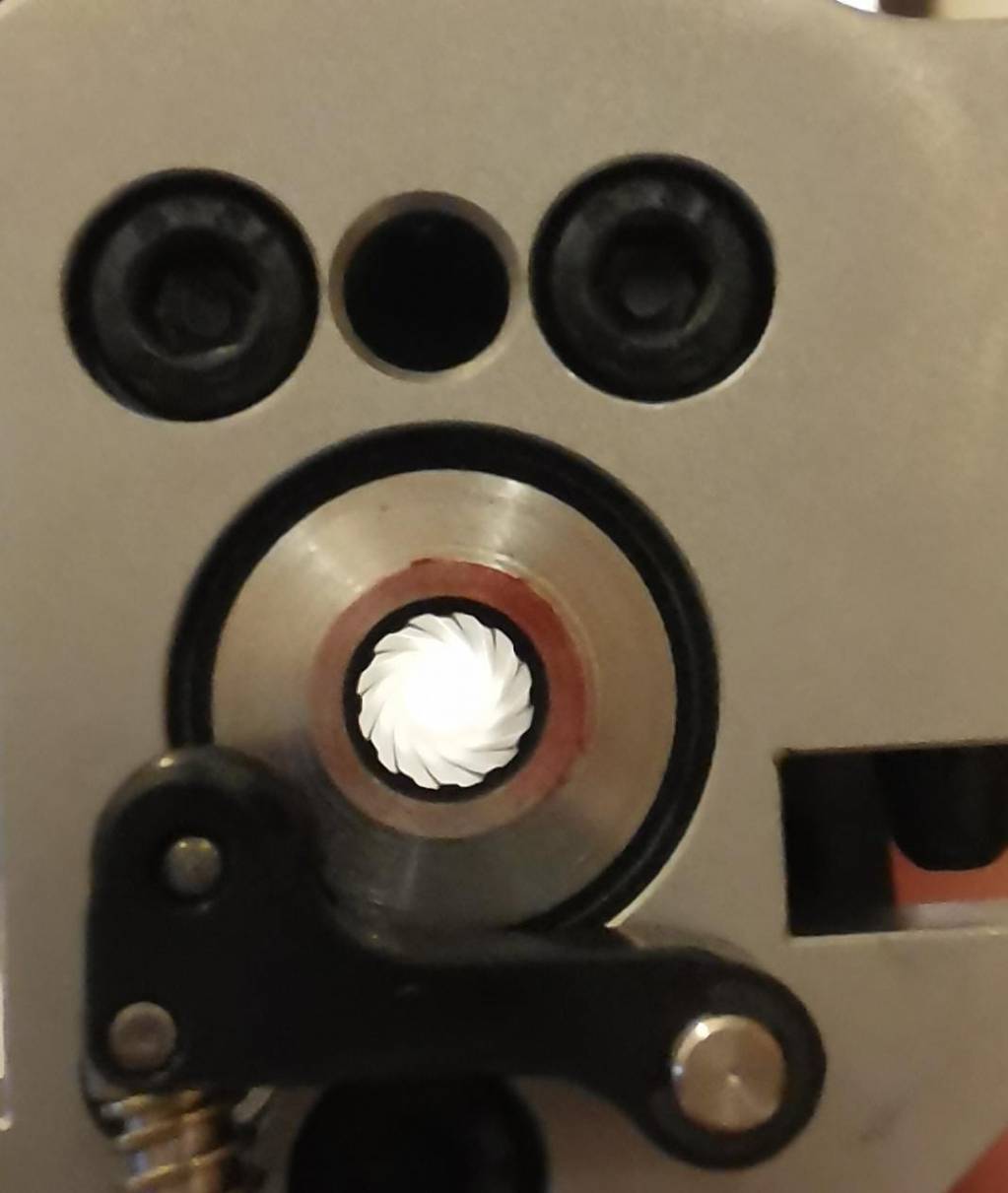

assemble everything then check the barrel from the back side to ensure no obstruction (for my L2 when I look through the baffle I can barely see the edges of the baffle center hole)

keep in mind the center hole tolerance is very tight so ensure everything is ok before test firing.

if you don't want it to be very tight you can widen it by shoving a 5.5mm Allen key (for the .22 caliber) in the center of the baffle and rotate the Allen key to round off the hole and slighting increase the size. ( keep in mind that the tighter the hole tolerance the more reduction in sound )

you can do the same for other calibers with different size Allen keys.

your results may vary based on your power settings.

Enjoy.

View attachment L2 Baffle .22 .1629234735.STL

View attachment L2 Baffle .22 .1629234735.STL

View attachment L2 Baffle .25 .1629234735.STL

View attachment L2 Baffle .25 .1629234735.STL

View attachment L2 Baffle .30 .1629234736.STL

View attachment L2 Baffle .30 .1629234736.STL

I will give information as much as possible.

Disclaimer: I hold no responsibility whatsoever if you damage your air gun while using this baffle.

every 3d printer is different so you have to make sure tolerances are good to go before shooting through it.

3d Printing Orientation (print horizontally with support on bed):

after that clean up the print then use a 4mm Allen key to round off these two holes.

install the baffle and tighten both screws (insert screws from bottom and use a screwdriver to guide them into the hole then tighten using an Allen key from the top)

also ensure the baffle is flush with the front moderator plate (the two small pins should slot into their respective holes.

don't forget to put the O ring.

assemble everything then check the barrel from the back side to ensure no obstruction (for my L2 when I look through the baffle I can barely see the edges of the baffle center hole)

keep in mind the center hole tolerance is very tight so ensure everything is ok before test firing.

if you don't want it to be very tight you can widen it by shoving a 5.5mm Allen key (for the .22 caliber) in the center of the baffle and rotate the Allen key to round off the hole and slighting increase the size. ( keep in mind that the tighter the hole tolerance the more reduction in sound )

you can do the same for other calibers with different size Allen keys.

your results may vary based on your power settings.

Enjoy.

Upvote 0

I was planning on making a full tutorial but I really will not have enough time as I will be very busy and it is very easy anyway.

I will give information as much as possible.

Disclaimer: I hold no responsibility whatsoever if you damage your air gun while using this baffle.

every 3d printer is different so you have to make sure tolerances are good to go before shooting through it.

3d Printing Orientation (print horizontally with support on bed):

after that clean up the print then use a 4mm Allen key to round off these two holes.

install the baffle and tighten both screws (insert screws from bottom and use a screwdriver to guide them into the hole then tighten using an Allen key from the top)

also ensure the baffle is flush with the front moderator plate (the two small pins should slot into their respective holes.

don't forget to put the O ring.

assemble everything then check the barrel from the back side to ensure no obstruction (for my L2 when I look through the baffle I can barely see the edges of the baffle center hole)

keep in mind the center hole tolerance is very tight so ensure everything is ok before test firing.

if you don't want it to be very tight you can widen it by shoving a 5.5mm Allen key (for the .22 caliber) in the center of the baffle and rotate the Allen key to round off the hole and slighting increase the size. ( keep in mind that the tighter the hole tolerance the more reduction in sound )

you can do the same for other calibers with different size Allen keys.

your results may vary based on your power settings.

Enjoy.

View attachment L2 Baffle .22 .1629234735.STL

View attachment L2 Baffle .25 .1629234735.STL

View attachment L2 Baffle .30 .1629234736.STL

Thanks for sharing the STL file. Can you upload the final design as well? Like to do a comparison.

Upvote 0

Thanks for sharing the STL file. Can you upload the final design as well? Like to do a comparison.

Sure

Upvote 0

Thanks for sharing the STL file. Can you upload the final design as well? Like to do a comparison.

Sure

View attachment L2 Baffle .22 B .1629290025.STL

View attachment L2 Baffle .25 B .1629290035.STL

View attachment L2 Baffle .30 B .1629290040.STL

sorry if this is a dumb question...

edit: nevermind, i already found the answer...

Upvote 0

Thanks for sharing the STL file. Can you upload the final design as well? Like to do a comparison.

Sure

View attachment L2 Baffle .22 B .1629290025.STL

View attachment L2 Baffle .25 B .1629290035.STL

View attachment L2 Baffle .30 B .1629290040.STL

sorry if this is a dumb question (i don't even have the prusa mini yet) but does the support structure (green part in your picture) need to be printed with a different material, or can i use PETG for the entire print. again i am sorry if this is so basic that i should already know.

Depending on your printer. If your printer has a single Extruder then the support material will be the same filament. Some of the IDEX or Dual Extruder 3D printer can print and use another material as support.

Upvote 0

Thanks for sharing the STL file. Can you upload the final design as well? Like to do a comparison.

Sure

View attachment L2 Baffle .22 B .1629290025.STL

View attachment L2 Baffle .25 B .1629290035.STL

View attachment L2 Baffle .30 B .1629290040.STL

sorry if this is a dumb question (i don't even have the prusa mini yet) but does the support structure (green part in your picture) need to be printed with a different material, or can i use PETG for the entire print. again i am sorry if this is so basic that i should already know.

Depending on your printer. If your printer has a single Extruder then the support material will be the same filament. Some of the IDEX or Dual Extruder 3D printer can print and use another material as support.

thanks! i am just now getting around to watching some youtube videos, lol. luckily i am going to be using a prusa mini, so will likely have similar options that LenaTo shared.

Upvote 0

My print is about 25% through. The print time is around 7 1/2 hours. I used the same PrusaSlicer options except for material. I used PETG instead of ABS. LenaTo said in another post that he was using PETG. Thanks again for the files LenaTo.

Upvote 0

My print is about 25% through. The print time is around 7 1/2 hours. I used the same PrusaSlicer options except for material. I used PETG instead of ABS. LenaTo said in another post that he was using PETG. Thanks again for the files LenaTo.

Enjoy!

I want to make mine mouse fart quiet.

so in my free time I will work on something that extends the moderator length by ~90mm which allows me to double the baffle length and make more design tweaks to it.

it will also allow for installing longer barrels while retaining the stock moderator.

only thing is I have to figure out how to secure it properly since the existing rods wont reach anymore.

then I will wrap the whole thing in neoprene material to make it look nice.

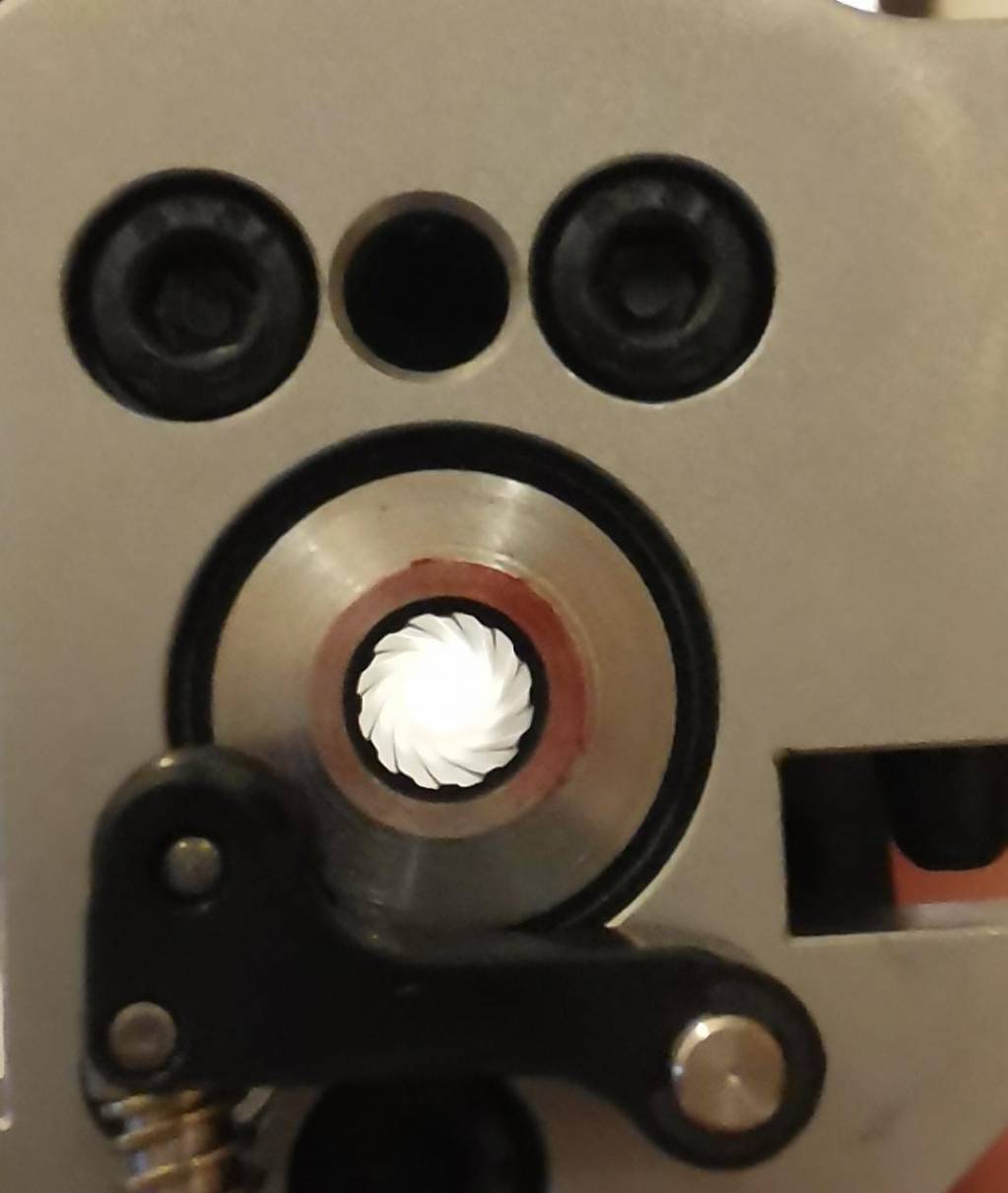

anyone know how to remove the rear moderator plate? is it glued on or something? i can't seem to be able to remove it without possibly damaging it.

Upvote 0

My print is about 25% through. The print time is around 7 1/2 hours. I used the same PrusaSlicer options except for material. I used PETG instead of ABS. LenaTo said in another post that he was using PETG. Thanks again for the files LenaTo.

Enjoy!

I want to make mine mouse fart quiet.

so in my free time I will work on something that extends the moderator length by ~90mm which allows me to double the baffle length and make more design tweaks to it.

it will also allow for installing longer barrels while retaining the stock moderator.

only thing is I have to figure out how to secure it properly since the existing rods wont reach anymore.

then I will wrap the whole thing in neoprene material to make it look nice.

anyone know how to remove the rear moderator plate? is it glued on or something? i can't seem to be able to remove it without possibly damaging it.

So far I've printed the moderator twice in two different orientations. One was done like yours and the other rotated 90 degrees on the long axis so the wide end is on the build plate. I'll test them this weekend. I'm curious how much clearance are you giving the pellet path in the original design? PETG tends to be a bit gooey to print with and my pellet path was lightly covered over printing following your orientation.

Upvote 0

So far I've printed the moderator twice in two different orientations. One was done like yours and the other rotated 90 degrees on the long axis so the wide end is on the build plate. I'll test them this weekend. I'm curious how much clearance are you giving the pellet path in the original design? PETG tends to be a bit gooey to print with and my pellet path was lightly covered over printing following your orientation.

the .22 baffle hole size is like 6.1 mm and the .25 is 7mm.

if you don't feel confident in the quality of the pellet path you can use an Allen key and force it into the baffle's pellet path all the way through and rotate clockwise and counter clockwise until the pellet path is smooth and rounded off.

for .22 you can use 5.5mm Allen key

for .25 you can use a 6mm Allen key

Upvote 0

i got the mini assembled last night and am trying my first print now (not even trying a sample print). it is telling me over 9 hrs and of course i have no idea what i am doing, lol. i had to calibrate the first level several times to get it low enough (ended up around -1.950 to get it to smoosh a little bit so the solid test section came out "solid".

perhaps it is foolish not to start with a PLA tree frog, but i ain't got time for that!

perhaps it is foolish not to start with a PLA tree frog, but i ain't got time for that!

Upvote 0

My print is about 25% through. The print time is around 7 1/2 hours. I used the same PrusaSlicer options except for material. I used PETG instead of ABS. LenaTo said in another post that he was using PETG. Thanks again for the files LenaTo.

Enjoy!

I want to make mine mouse fart quiet.

so in my free time I will work on something that extends the moderator length by ~90mm which allows me to double the baffle length and make more design tweaks to it.

it will also allow for installing longer barrels while retaining the stock moderator.

only thing is I have to figure out how to secure it properly since the existing rods wont reach anymore.

then I will wrap the whole thing in neoprene material to make it look nice.

anyone know how to remove the rear moderator plate? is it glued on or something? i can't seem to be able to remove it without possibly damaging it.

So far I've printed the moderator twice in two different orientations. One was done like yours and the other rotated 90 degrees on the long axis so the wide end is on the build plate. I'll test them this weekend. I'm curious how much clearance are you giving the pellet path in the original design? PETG tends to be a bit gooey to print with and my pellet path was lightly covered over printing following your orientation.

if you have any pictures of how they came out, especially before you removed the structure and cleaned it up, that would be great and maybe let me know if i am on the right track or taking a ride on the failboat.

Upvote 0

i got the mini assembled last night and am trying my first print now (not even trying a sample print). it is telling me over 9 hrs and of course i have no idea what i am doing, lol. i had to calibrate the first level several times to get it low enough (ended up around -1.950 to get it to smoosh a little bit so the solid test section came out "solid".

perhaps it is foolish not to start with a PLA tree frog, but i ain't got time for that!

Try printing a 3d benchy (you can find it on thingiverse)

If the quality is good

Then you can start printing the baffle using the settings i posted before.

You can use petg or abs for the baffle.

Upvote 0