Some of you may be familiar with my project to try and take the bark off my FX Crown. For those that aren't, that ongoing saga can be found HERE.

After completing the big comparative test of all the common brands of moderators out there, I wanted to experiment with some more unusual moderator designs. Buoyed by my previous testing success, and presumably encouraged by the lack of complaining from people who loaned me moderators for said test, AGN user Custard stepped forward to loan me his Edgun Leshiy so I could experiment with a challenging eccentric bore moderator design. So I want to put out an IMMENSE thank you to Custard. He is an incredibly trusting and generous gentleman to ship his Leshiy across the country to a total stranger, a stranger who is clearly missing a few marbles I might add, for the purposes of experimenting with moderator design. I, for my own part, wanted to experiment with eccentric-bore moderator design, and the Leshiy looked like the most challenging platform on which to do it. So in that regard we are a match for each other it would seem. Your ongoing patience through testing setbacks is also incredibly appreciated, and so while I've expressed my thanks and such privately, I also want to very publicly say thank you and that if at any point you lose your patience with me just say the word and I'll shutter the whole project and just ship your gun back straight away no questions asked.

This Leshiy chronos at 740fps w/ a JSB 18.13gr .22 caliber pellet, or 22 foot pounds using the 250mm barrel. I have no idea if this is typical or not, however developing 2/3rds of the power of a full size air rifle with half the barrel length or less is no small feat. It also uses no small amount of air, and the internal volume of the Leshiy's shroud is TINY. It also is incredibly close to the bottom of the tube, which presents yet more problems. I should also mention that, in stock form, this Leshiy is LOUD, properly loud. I couldn't stand my stock FX Crown with its barrel well away from my ear, and that thing meters, when fully erect , at 254 in my most recent extended shroud test compared to the Leshiy which metered 279. (this test was done the same day as the Leshiy, same everything. It'll also be the last time I ever use the extended FX shroud as a benchmark) That is loud, especially that close to your face. Your neighbors will notice, particularly if you're near sound-reflective surfaces..... like a house.

, at 254 in my most recent extended shroud test compared to the Leshiy which metered 279. (this test was done the same day as the Leshiy, same everything. It'll also be the last time I ever use the extended FX shroud as a benchmark) That is loud, especially that close to your face. Your neighbors will notice, particularly if you're near sound-reflective surfaces..... like a house.

Leshiy Stock Core - 279

The stock Leshiy moderator is a fairly conventional design from the firearm industry, one which relies on cross-jetting in order to function. Given the air-blast we’re dealing with here, it is difficult to say how effective such a design could be, but I have a hard time imagining it is highly effective. As I said, such a design leans on cross-jetting in order to function efficiently, however in this case the angled baffles are both dished and in opposing directions, both of which should limit the design’s efficacy. Furthermore, were it to provide a substantial amount of cross-jetting, it would destabilize the delicate Diabolo pellets we use, so again I can’t imagine it to be that effective.

So what have I come up with to test? Well given that this is round one, the answer is a whole bunch of different things. The purpose of all this is a “scattergun” approach, where you try a bunch of different things and see what seems to work best. From there you have what you need to begin optimizing with purpose, rather than randomly. I will provide a brief overview of the philosophy of each design as well as a rendering below. But there is another catch. I do have an indoor anechoic chamber I set up a couple testing cycles ago to work on the Crown. This is where I like to do optimizing as I can rapid-prototype a design and then quickly test it, and then further tweak the design. The speed of this feedback loop was critical to the rapid design improvement seen in the design which ultimately came to be known as the Levitas. The probem? The action on the Leshiy is so noisy that the not-really-anechoic chamber doesn’t produce good data, it produces garbage. Say bye bye to the rapid iteration process.

And there is another thing: I generally use a rubber damper with cores, as in other platforms it has very well proven efficacy. Unfortunately it does eat some volume. On a lark I decided to do one core test which was otherwise identical but omitted the rubber damper, basically an apples to apples comparison of “does this work.” As it turns out, that was the only core which metered quieter than the stock Leshiy core, definitively answering the question of whether or not the rubber damper belongs in this design. It doesn’t nullify the relative performance of the other cores, they can still be compared to each other, however it does explain why they were all louder than stock.

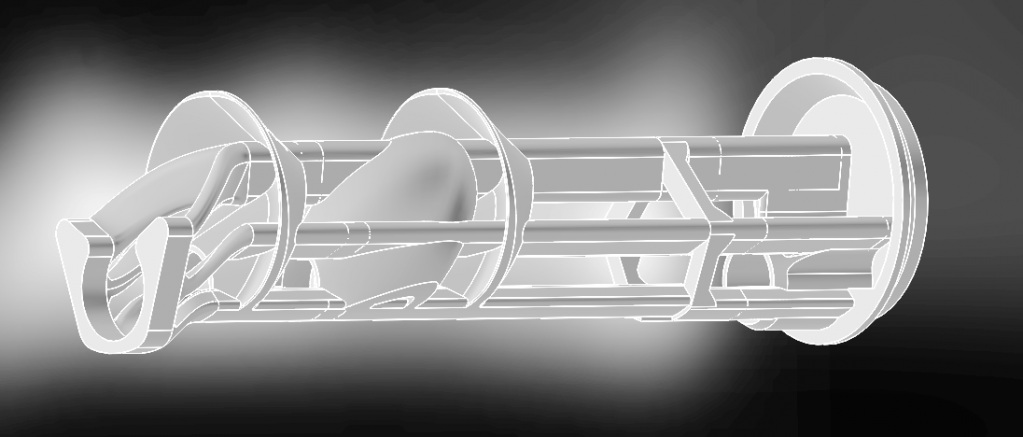

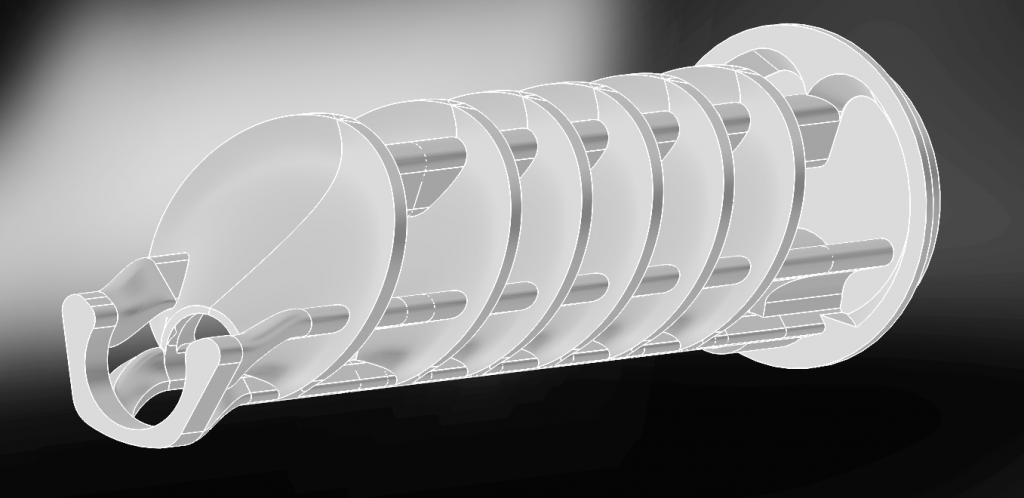

Worth noting are some general characteristics you’ll see repeated over and over again as they’re specific to this application. Visible at the left is the part which grips and justifies the rear of the core around the barrel. Minimalism is the name of the game here, anything that isn’t working is just wasted volume, so cut it out eh? Longitudinally there are struts to maintain the core’s structure. These maintain strength and alignment while helping to disrupt pressure waves in the shroud. I believe they’re a better design option than doing a full tube enclosure design, all else being equal.

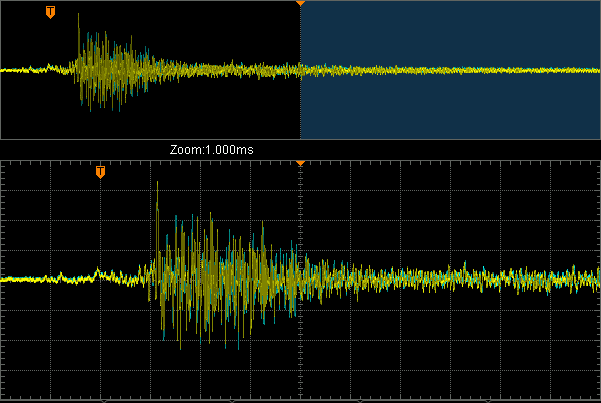

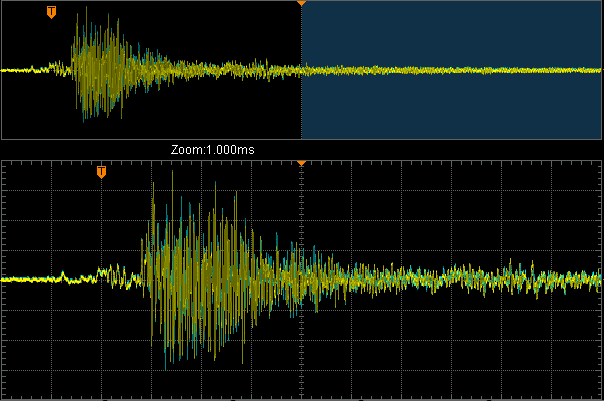

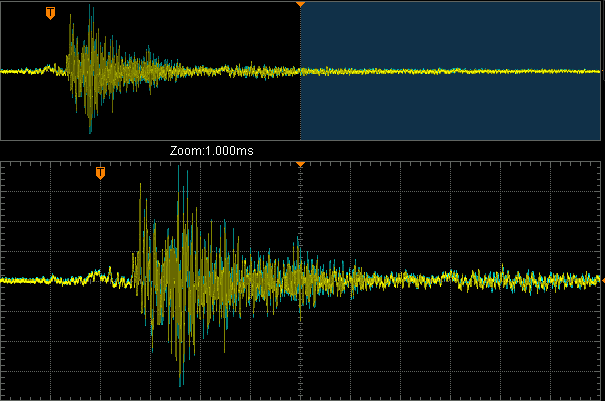

Single Diode - 382

So lets get the obvious out of the way, this is an attempt at an adaptation of the Levitas to the Leshiy. There is an offset blast baffle followed by an eccentric gas diode followed by a skeletal structure to which sound damping material is attached. I’ll be curious to see if it beats the stock moderator, however in this application it almost certainly will not do well compared to the other designs. Why do I say that? The Levitas was optimized on a gun which produces only 1/3rd more power but does it using a barrel which is twice the length, and with the benefit of a shroud’s worth of reflex volume which is considerable. This means the ratio of flow-delaying to sound damping is not even close to proportionate for this design. Never the less it will be interesting to see. Another point of concern here is the fact that the diode really doesn’t actually have much area to operate, and so there is a real possibility it just won’t act like a diode in this form factor.

In short, this didn’t work, clearly. I’m not sure I was expecting it too, but this is why we test things right?

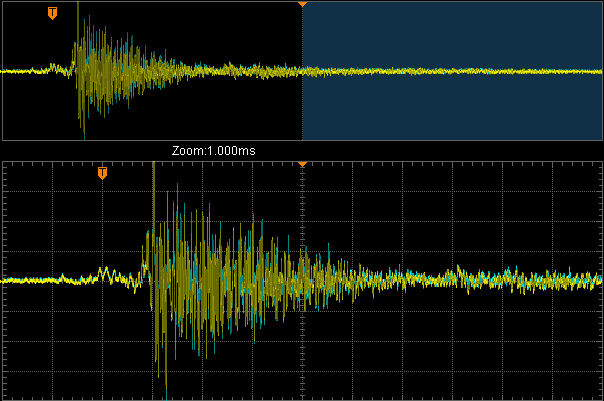

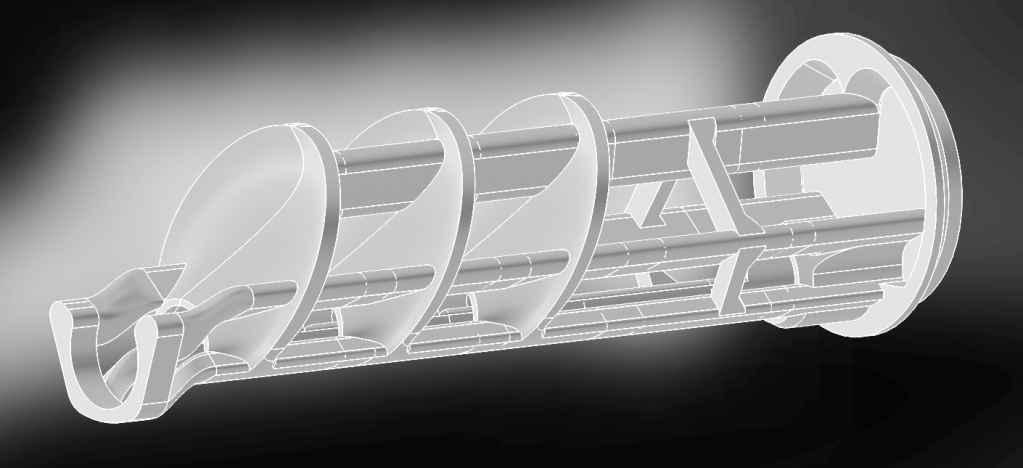

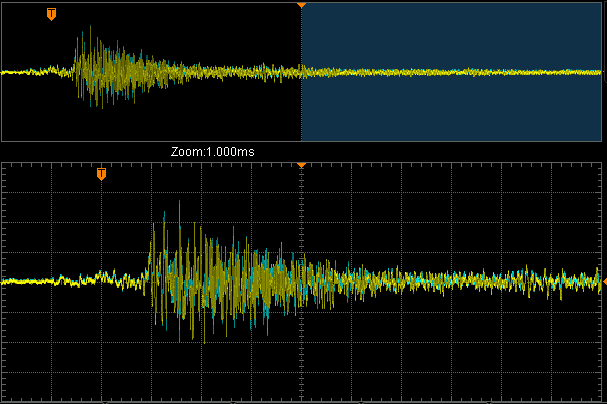

Double Diode - 324

The gas diodes, particularly the eccentric ones, are big. No two ways about it. If they work at all though, in this application two may be better than one? Anyway that was the hypothesis of this core. Again I have no idea if this eccentric of a bore will allow the diode to function at all, so this may be a total flop, but it is worth a shot anyway.

So this clearly worked better than the single diode, and actually was the third best experimental core. However in this application the diodes simply take up too much space and are not as efficient probably because of their eccentric design. It is possible this can be adapted to work better, but for the time being it is being abandoned.

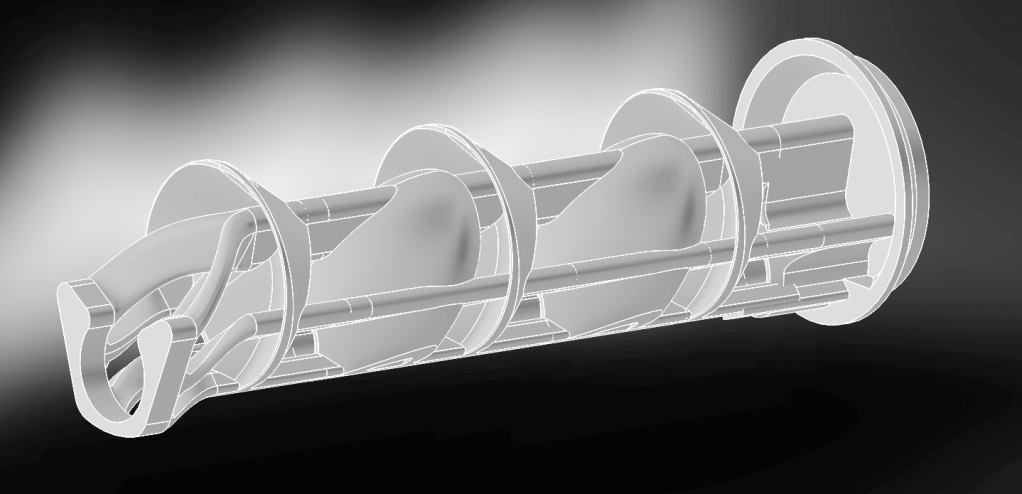

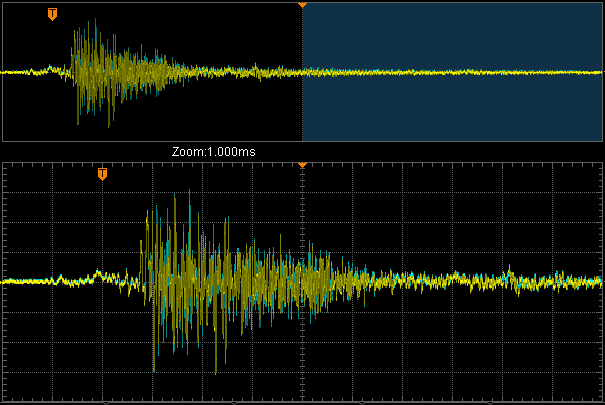

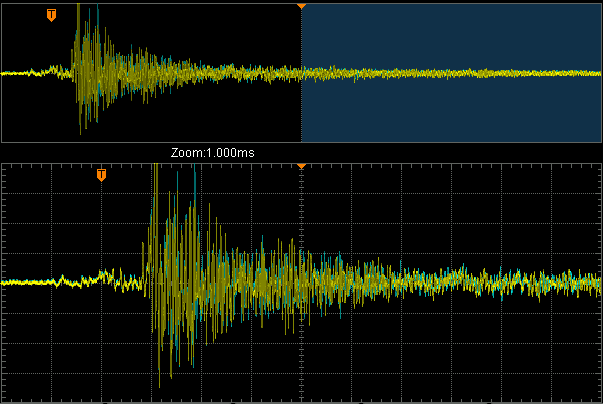

Conical three baffles - 315

The conical baffle is as old as calling them “silencers,” dating all the way back to Hiram Percy Maxim and the first ever commercial silencer. They’ve been working well for over 100 years, why dismiss them now? This uses three reasonably spaced offset conical baffles while still allowing room for sound damping at the terminal end of the core.

This was the best test which had the rubber damper, and designs will likely evolve outward from here. Clearly a combination of flow delaying and sound damping are desirable, even in systems as space-constrained as this. Had I tested this without the rubber damper, my expectation is that it would have been solidly the best performer here.

Four Conical - 357.5

Four Conical NR - 232

This is another design split, asking the question about ratio of flow delay vs. sound damping. This is also the core of which I did the with and without rubber comparison test on. I don’t expect the no-rubber variant to perform well, but it is always worth double checking your assumptions.

The results are stark. While the four conical baffle design was kind of in the middle of the pack, performance-wise, the sans-rubber variant was a runaway leader, beating all the other designs including the factory Leshiy core by a comfortable margin. That is quite an accomplishment given how mediocre this core is compared to the other architectures tested here. Clearly there is a great deal of latent potential to unlock. And that is good, because this test was only slightly quieter than an FX Crown with the factory shroud extended. (that meters 254, also with sustained noise)

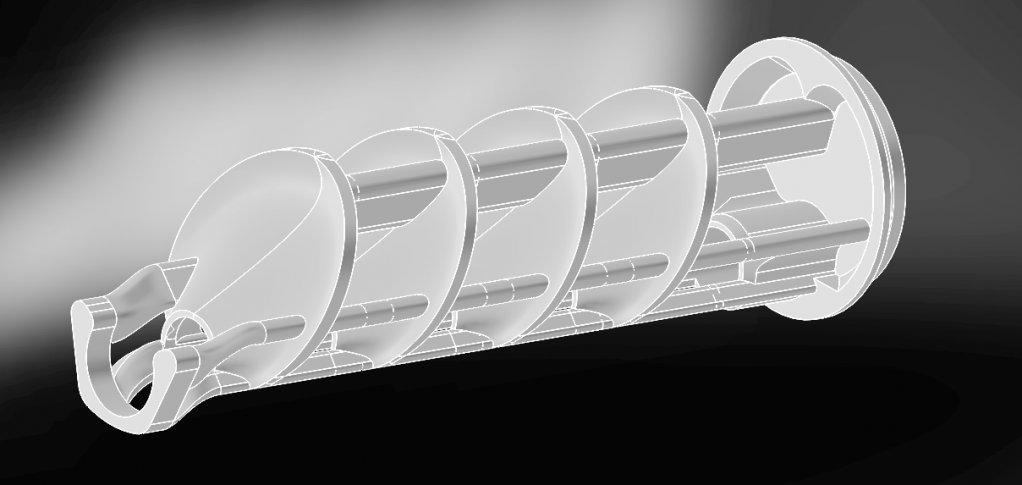

Six Conical Baffles - 419

And the ultimate expression of flow-delaying, as that is pretty much all this design is. 6 unequally spaced conical baffles. If you recall, all the way back at my earliest tests, this design language worked very poorly on the Crown. Hell, it worked very poorly in the big test, just look at how the small Wolf Airguns? moderator performed. But this is not that, so as with all things you turn the dial past where it should be to better know where the happy medium is. I’m writing this before having tested it, however I’m fully prepared to eat my hat if this design is best.

Thankfully, my hat remains safe….. at least for the time being. This was in fact the loudest design tested this day. So there is the answer to the question nobody was asking: what does too many baffles look like?

So if you're looking for a TL;DR of what does this all mean, the answer is that none of these designs are optimized, and I didn't expect them to be. This is just the first round of testing. I did learn an incredible amount though, and I'll wrap what I learned up into another series of revisions.

For those who are interested, subscribe to this thread, I'll keep updating it as I develop and learn new things.

After completing the big comparative test of all the common brands of moderators out there, I wanted to experiment with some more unusual moderator designs. Buoyed by my previous testing success, and presumably encouraged by the lack of complaining from people who loaned me moderators for said test, AGN user Custard stepped forward to loan me his Edgun Leshiy so I could experiment with a challenging eccentric bore moderator design. So I want to put out an IMMENSE thank you to Custard. He is an incredibly trusting and generous gentleman to ship his Leshiy across the country to a total stranger, a stranger who is clearly missing a few marbles I might add, for the purposes of experimenting with moderator design. I, for my own part, wanted to experiment with eccentric-bore moderator design, and the Leshiy looked like the most challenging platform on which to do it. So in that regard we are a match for each other it would seem. Your ongoing patience through testing setbacks is also incredibly appreciated, and so while I've expressed my thanks and such privately, I also want to very publicly say thank you and that if at any point you lose your patience with me just say the word and I'll shutter the whole project and just ship your gun back straight away no questions asked.

This Leshiy chronos at 740fps w/ a JSB 18.13gr .22 caliber pellet, or 22 foot pounds using the 250mm barrel. I have no idea if this is typical or not, however developing 2/3rds of the power of a full size air rifle with half the barrel length or less is no small feat. It also uses no small amount of air, and the internal volume of the Leshiy's shroud is TINY. It also is incredibly close to the bottom of the tube, which presents yet more problems. I should also mention that, in stock form, this Leshiy is LOUD, properly loud. I couldn't stand my stock FX Crown with its barrel well away from my ear, and that thing meters, when fully erect

Leshiy Stock Core - 279

The stock Leshiy moderator is a fairly conventional design from the firearm industry, one which relies on cross-jetting in order to function. Given the air-blast we’re dealing with here, it is difficult to say how effective such a design could be, but I have a hard time imagining it is highly effective. As I said, such a design leans on cross-jetting in order to function efficiently, however in this case the angled baffles are both dished and in opposing directions, both of which should limit the design’s efficacy. Furthermore, were it to provide a substantial amount of cross-jetting, it would destabilize the delicate Diabolo pellets we use, so again I can’t imagine it to be that effective.

So what have I come up with to test? Well given that this is round one, the answer is a whole bunch of different things. The purpose of all this is a “scattergun” approach, where you try a bunch of different things and see what seems to work best. From there you have what you need to begin optimizing with purpose, rather than randomly. I will provide a brief overview of the philosophy of each design as well as a rendering below. But there is another catch. I do have an indoor anechoic chamber I set up a couple testing cycles ago to work on the Crown. This is where I like to do optimizing as I can rapid-prototype a design and then quickly test it, and then further tweak the design. The speed of this feedback loop was critical to the rapid design improvement seen in the design which ultimately came to be known as the Levitas. The probem? The action on the Leshiy is so noisy that the not-really-anechoic chamber doesn’t produce good data, it produces garbage. Say bye bye to the rapid iteration process.

And there is another thing: I generally use a rubber damper with cores, as in other platforms it has very well proven efficacy. Unfortunately it does eat some volume. On a lark I decided to do one core test which was otherwise identical but omitted the rubber damper, basically an apples to apples comparison of “does this work.” As it turns out, that was the only core which metered quieter than the stock Leshiy core, definitively answering the question of whether or not the rubber damper belongs in this design. It doesn’t nullify the relative performance of the other cores, they can still be compared to each other, however it does explain why they were all louder than stock.

Worth noting are some general characteristics you’ll see repeated over and over again as they’re specific to this application. Visible at the left is the part which grips and justifies the rear of the core around the barrel. Minimalism is the name of the game here, anything that isn’t working is just wasted volume, so cut it out eh? Longitudinally there are struts to maintain the core’s structure. These maintain strength and alignment while helping to disrupt pressure waves in the shroud. I believe they’re a better design option than doing a full tube enclosure design, all else being equal.

Single Diode - 382

So lets get the obvious out of the way, this is an attempt at an adaptation of the Levitas to the Leshiy. There is an offset blast baffle followed by an eccentric gas diode followed by a skeletal structure to which sound damping material is attached. I’ll be curious to see if it beats the stock moderator, however in this application it almost certainly will not do well compared to the other designs. Why do I say that? The Levitas was optimized on a gun which produces only 1/3rd more power but does it using a barrel which is twice the length, and with the benefit of a shroud’s worth of reflex volume which is considerable. This means the ratio of flow-delaying to sound damping is not even close to proportionate for this design. Never the less it will be interesting to see. Another point of concern here is the fact that the diode really doesn’t actually have much area to operate, and so there is a real possibility it just won’t act like a diode in this form factor.

In short, this didn’t work, clearly. I’m not sure I was expecting it too, but this is why we test things right?

Double Diode - 324

The gas diodes, particularly the eccentric ones, are big. No two ways about it. If they work at all though, in this application two may be better than one? Anyway that was the hypothesis of this core. Again I have no idea if this eccentric of a bore will allow the diode to function at all, so this may be a total flop, but it is worth a shot anyway.

So this clearly worked better than the single diode, and actually was the third best experimental core. However in this application the diodes simply take up too much space and are not as efficient probably because of their eccentric design. It is possible this can be adapted to work better, but for the time being it is being abandoned.

Conical three baffles - 315

The conical baffle is as old as calling them “silencers,” dating all the way back to Hiram Percy Maxim and the first ever commercial silencer. They’ve been working well for over 100 years, why dismiss them now? This uses three reasonably spaced offset conical baffles while still allowing room for sound damping at the terminal end of the core.

This was the best test which had the rubber damper, and designs will likely evolve outward from here. Clearly a combination of flow delaying and sound damping are desirable, even in systems as space-constrained as this. Had I tested this without the rubber damper, my expectation is that it would have been solidly the best performer here.

Four Conical - 357.5

Four Conical NR - 232

This is another design split, asking the question about ratio of flow delay vs. sound damping. This is also the core of which I did the with and without rubber comparison test on. I don’t expect the no-rubber variant to perform well, but it is always worth double checking your assumptions.

The results are stark. While the four conical baffle design was kind of in the middle of the pack, performance-wise, the sans-rubber variant was a runaway leader, beating all the other designs including the factory Leshiy core by a comfortable margin. That is quite an accomplishment given how mediocre this core is compared to the other architectures tested here. Clearly there is a great deal of latent potential to unlock. And that is good, because this test was only slightly quieter than an FX Crown with the factory shroud extended. (that meters 254, also with sustained noise)

Six Conical Baffles - 419

And the ultimate expression of flow-delaying, as that is pretty much all this design is. 6 unequally spaced conical baffles. If you recall, all the way back at my earliest tests, this design language worked very poorly on the Crown. Hell, it worked very poorly in the big test, just look at how the small Wolf Airguns? moderator performed. But this is not that, so as with all things you turn the dial past where it should be to better know where the happy medium is. I’m writing this before having tested it, however I’m fully prepared to eat my hat if this design is best.

Thankfully, my hat remains safe….. at least for the time being. This was in fact the loudest design tested this day. So there is the answer to the question nobody was asking: what does too many baffles look like?

So if you're looking for a TL;DR of what does this all mean, the answer is that none of these designs are optimized, and I didn't expect them to be. This is just the first round of testing. I did learn an incredible amount though, and I'll wrap what I learned up into another series of revisions.

For those who are interested, subscribe to this thread, I'll keep updating it as I develop and learn new things.