Been making Custom poppets, seats & generally been modifying valves for years !!

Typically .125" ground shafting pressed into a PEEK head, or Acetal works just fine. No barbs or other tricks required, Loctite 640/680 an option tho not required.

Hole drilled at .120" so the shafts a press fit in until it bottoms out. * Done in a mill vise.

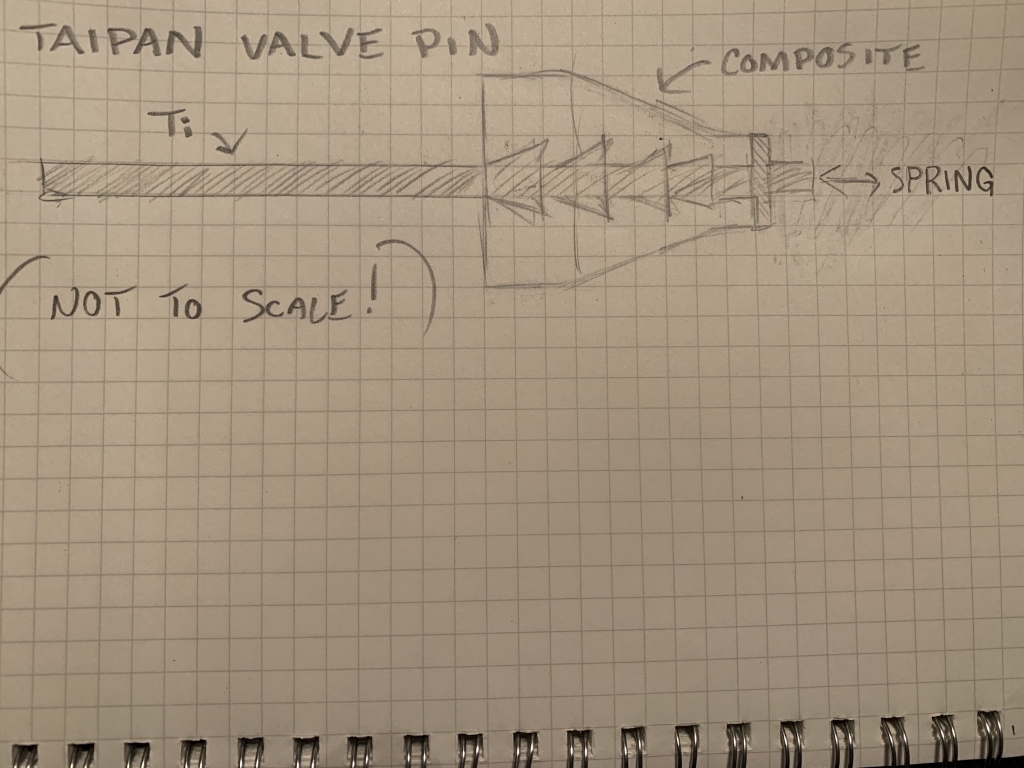

Perfect! I have a tendency to over analyze points of failure and resilience, so bare please with me here lol .. When I start working through the physics involved between the pin and sealing head - the bond would undergo stress from the driving forces from the hammer striking the pin and the collision of the head with the transfer port material as the valve shuts closed (primarily driven by the forces of the valve spring).

In any case, I'm starting to gravitate more towards an all press fit design. I think the head material would have better integrity without being gouged up, although using some 680 would be a

wonderful choice of a bonding agent. I love that stuff! It hadn't crossed my mind to use it (or 640) in this sort of application, so thank you!

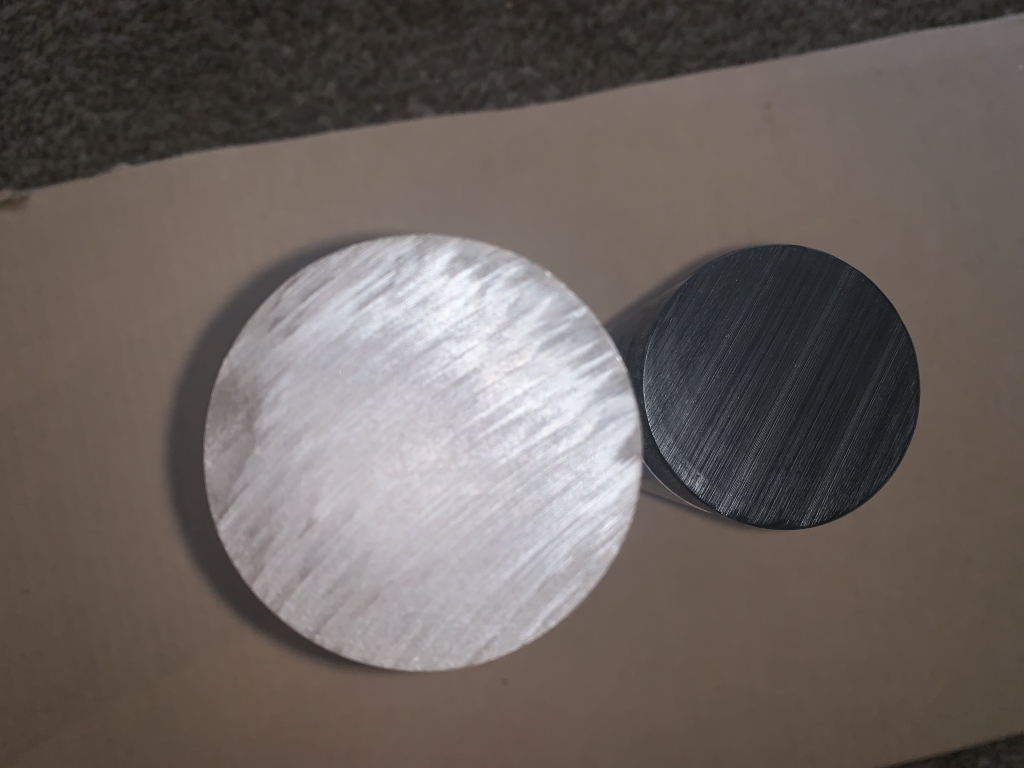

The other thing that I'm overthinking: what are the preferred characteristics of the material used for the sealing surface? The POM-C sealing heads on my valves appear to deform waaaay too quickly. PEEK seems much better (kind of a pain to turn on my lathe). POM-H - I want to test some and see how it holds up over time. That being said, I have a few different varieties stockpiled. Some is waxy, some real slick, and one is was harder than the rest in the materials specifications sheet. I'm thinking the harder black one would be the more appropriate material to use out of the POM-H:

Hard to capture the scratch and impact marks in the photos, but thr taupe colored material is softer and more waxy. I suppose my question then becomes (in simple form): is it better to use a harder or softer material for the sealing head in a PCP valve system, where the regulated pressure exceeds 150bar (full time, compare with say - a 12FPE rig)? Would I be correct in choosing the harder material, given the concerns for deformation?

I appreciate the replies and I really enjoy this sort of discussion