Edit: final configuration..

Preface - I'm not a bling guy, but I started putting together this rifle with a lot of shiny silver parts and decided to call it the BlingVet.

Custom ingredients for this build:

Powerplant - I got this rifle new a while back and the first thing that I did with it was make a new higher performance valve system. The second modification was installing Huma regulator. There's nothing wrong with the factory regs, but they're not setup for as wide of a range of adjustment and I just prefer them in all of my non-FX rifles.

Hammer system - I made a factory-like hammer from A2 tool steel with a PEEK insert at the striker. Running the on the right (in the first photo):

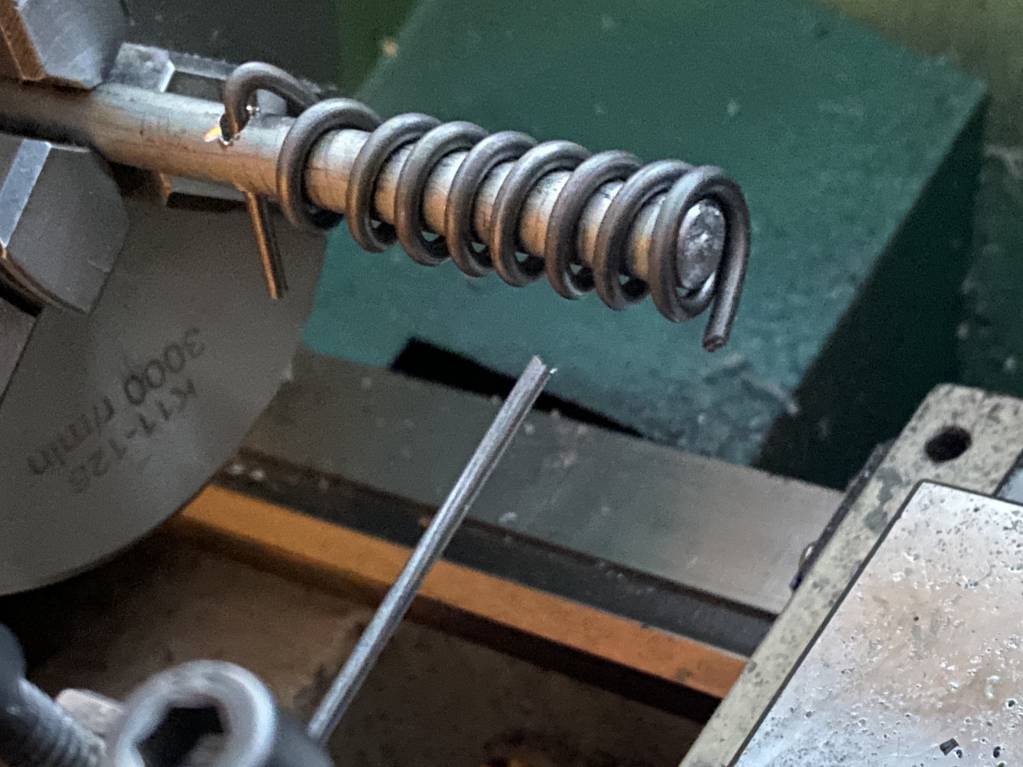

I make my own hammer springs for better control over specifications (it got tiring never having the right compression springs!). No photos making this particular spring, but the process looks like this (this was my first test / mandrel, but I've got the process down much better now lol)..

Moderator insert - I machined this insert to be just a hair over the maximum projectile diameter that I plan to ever shoot from these rifles in .22cal. I do a couple of other things to the baffle system, but this mod alone reduces the shot report signature significantly!!! Being in full control over the concentricity from the breech to the end of the moderator, I can get away with making this opening as small as possible..

(That's lubrication around the edges in the last photo btw)

Biathlon-style, low-profile "no snag" cocking mechanism- the goal here was simple - I wanted a biathlon lever as close to the action as possible. There's nothing more frustrating to me with the Veterans / Crickets than to have that charging lever get snagged on something and it cycles the mag!

This design here definitely mitigates that very well, and it's not SO close that I can't open it. I also machined / polished the big internal linkage piece a fraction larger than the factory component, which keeps it more rigidly in place..

Here is an alternative mechanism that extends the lever out a little more (still much closer than how the factory lever protrudes)..

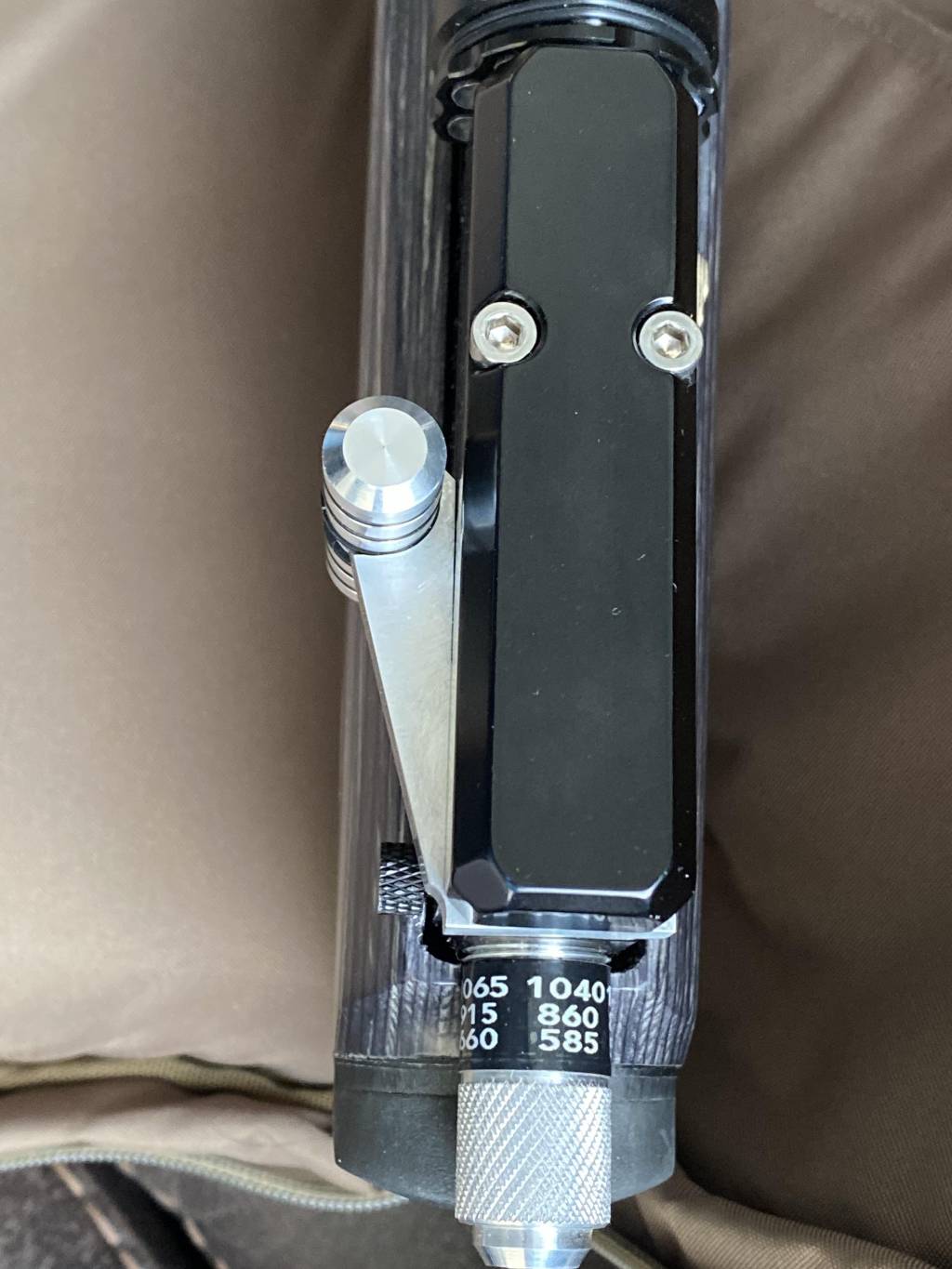

Hammer spring adjuster with "speed dialer" - I whipped that one up in a hurry to test something, but the velocity / "speed" tape works very, very well! (I posted this mod some time ago with my Mutant).

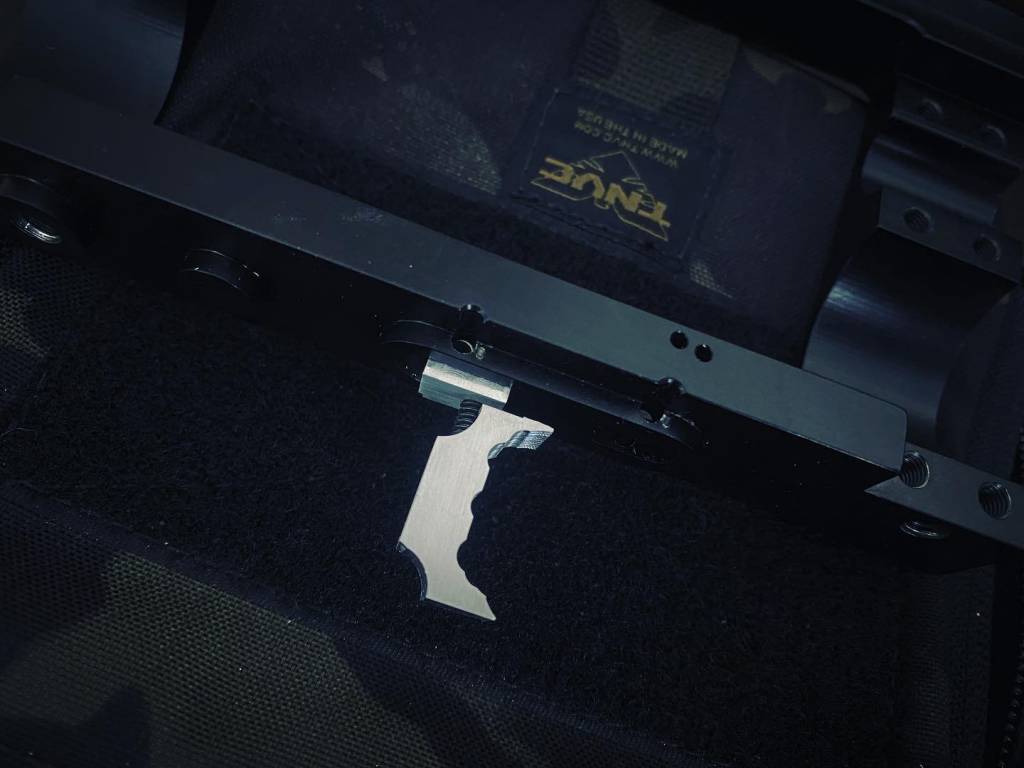

Trigger system with "Space Invader" trigger blade - this was my first attempt at making a trigger. I milled this entire thing by hand, but as I worked through this I realized that I wanted some heavy texturing to the trigger blade, which I milled out to be a precise fit for my trigger finger. It looks sharp, but it's COMFORTABLE!!!! Totally changes the dynamics of the trigger pull!!! There's more leverage with this thing, but I'm much more in tune with each stage now..

Barrel - this is a .22cal choked LW polygonal barrel with a special twist rate for the MRDs and Beasts. Not ready to discuss the details just yet, but I chambered the blank perfect for the Taipans and threaded it for the block.

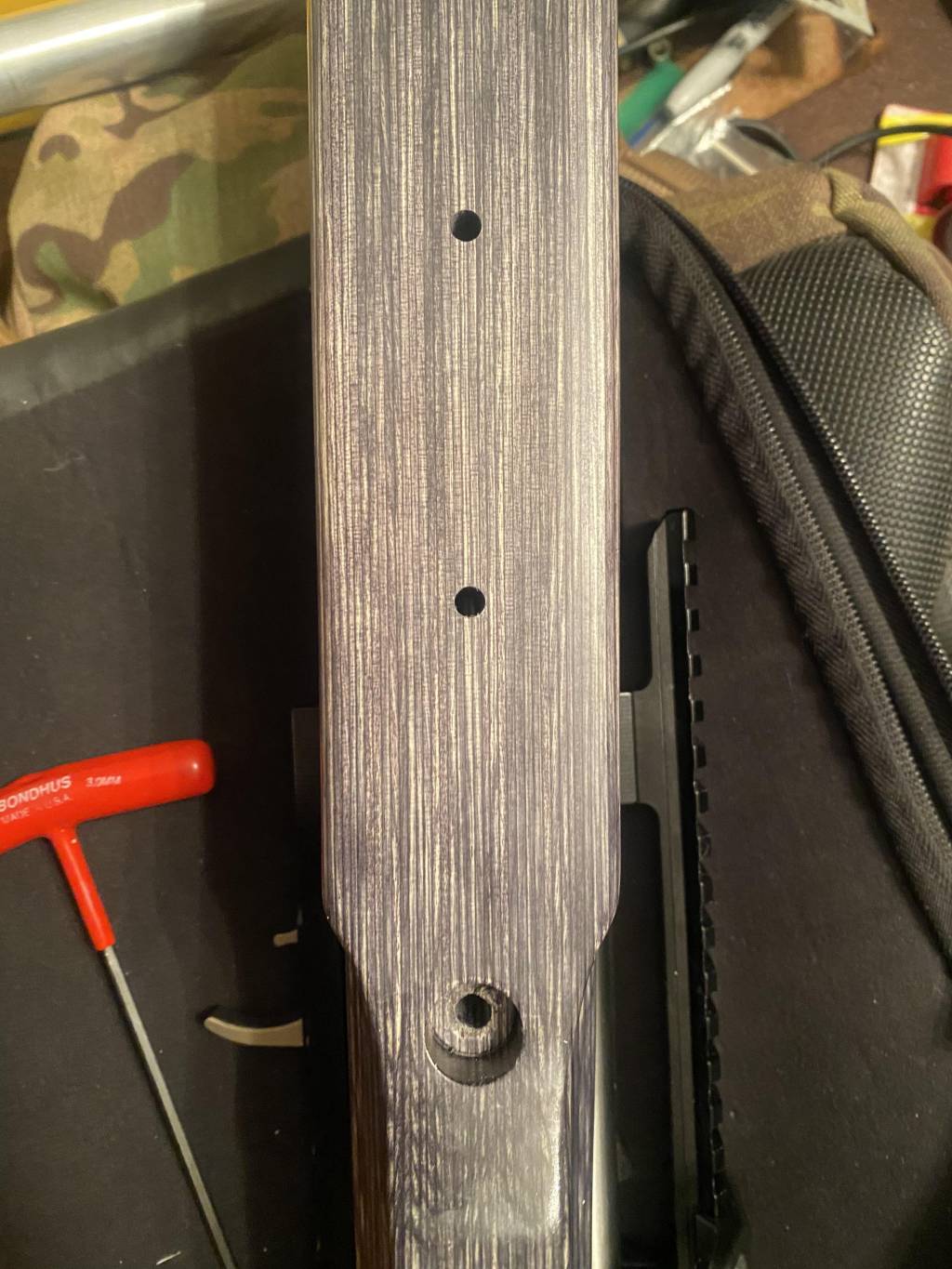

Bipod rail & stock screw bushings - For the rail, I milled down a 20MOA dovetail to Picatinny rail in raw 7075 that I already had. I wanted to keep some of that angle in there so that I could have better resistance on a bench with my bipod legs extended straight down at 90 degrees (thus titling them back a little). This rail system was pre-threaded with 1/4-28 set screws, and that gave me the idea to bypass the need for T-nuts (I usually countersink stocks with T-nuts).

I drilled and threaded the laminate stock to 1/4-28, and cut down some flanged stainless hex bolts with some big flat washers underneath. This threads into the rail and PULLS it snug to the stock. No need for Loctite.. Pretty awesome!!!

Probably left some things out, but I'd say that I'm about 85% done with this rifle. I want to make a glossy twill carbon fiber moderator for it with stainless endcaps. The HST dialer and trigger are just a prototyping tests, so I'll eventually get around to making final parts.

I have only shot it at 23y so far (hitting the range tomorrow), but it put 5 through a pellet sized hole twice when I zeroed it. Hoping that precision translates over at longer ranges!

Preface - I'm not a bling guy, but I started putting together this rifle with a lot of shiny silver parts and decided to call it the BlingVet.

Custom ingredients for this build:

- Taipan Veteran (Long)

- High-power valve system (classified)

- Heavier factory-style hammer (A2 tool steel + PEEK)

- Hand-made hammer spring (Stainless spring steel)

- Larger hammer spring tension knob (7075 AL)

- Biathlon-style low-profile lever system (6061 & 7075 AL)

- Kelby canted Picatinny rail (7075 AL)

- Bushings for the stock screws (7075 AL)

- 535mm Polygonal LW .22cal barrel (custom spec for JSB Monster Redesigned & JSB Beasts)

- Complete stainless steel screw overhaul

- Plug insert for the muzzle end of the moderator, greatly reduces shot report (Delrin 150)

- Huma regulator

- Single plenum chamber extension

- New trigger system (6061 AL)

Powerplant - I got this rifle new a while back and the first thing that I did with it was make a new higher performance valve system. The second modification was installing Huma regulator. There's nothing wrong with the factory regs, but they're not setup for as wide of a range of adjustment and I just prefer them in all of my non-FX rifles.

Hammer system - I made a factory-like hammer from A2 tool steel with a PEEK insert at the striker. Running the on the right (in the first photo):

I make my own hammer springs for better control over specifications (it got tiring never having the right compression springs!). No photos making this particular spring, but the process looks like this (this was my first test / mandrel, but I've got the process down much better now lol)..

Moderator insert - I machined this insert to be just a hair over the maximum projectile diameter that I plan to ever shoot from these rifles in .22cal. I do a couple of other things to the baffle system, but this mod alone reduces the shot report signature significantly!!! Being in full control over the concentricity from the breech to the end of the moderator, I can get away with making this opening as small as possible..

(That's lubrication around the edges in the last photo btw)

Biathlon-style, low-profile "no snag" cocking mechanism- the goal here was simple - I wanted a biathlon lever as close to the action as possible. There's nothing more frustrating to me with the Veterans / Crickets than to have that charging lever get snagged on something and it cycles the mag!

This design here definitely mitigates that very well, and it's not SO close that I can't open it. I also machined / polished the big internal linkage piece a fraction larger than the factory component, which keeps it more rigidly in place..

Here is an alternative mechanism that extends the lever out a little more (still much closer than how the factory lever protrudes)..

Hammer spring adjuster with "speed dialer" - I whipped that one up in a hurry to test something, but the velocity / "speed" tape works very, very well! (I posted this mod some time ago with my Mutant).

Trigger system with "Space Invader" trigger blade - this was my first attempt at making a trigger. I milled this entire thing by hand, but as I worked through this I realized that I wanted some heavy texturing to the trigger blade, which I milled out to be a precise fit for my trigger finger. It looks sharp, but it's COMFORTABLE!!!! Totally changes the dynamics of the trigger pull!!! There's more leverage with this thing, but I'm much more in tune with each stage now..

Barrel - this is a .22cal choked LW polygonal barrel with a special twist rate for the MRDs and Beasts. Not ready to discuss the details just yet, but I chambered the blank perfect for the Taipans and threaded it for the block.

Bipod rail & stock screw bushings - For the rail, I milled down a 20MOA dovetail to Picatinny rail in raw 7075 that I already had. I wanted to keep some of that angle in there so that I could have better resistance on a bench with my bipod legs extended straight down at 90 degrees (thus titling them back a little). This rail system was pre-threaded with 1/4-28 set screws, and that gave me the idea to bypass the need for T-nuts (I usually countersink stocks with T-nuts).

I drilled and threaded the laminate stock to 1/4-28, and cut down some flanged stainless hex bolts with some big flat washers underneath. This threads into the rail and PULLS it snug to the stock. No need for Loctite.. Pretty awesome!!!

Probably left some things out, but I'd say that I'm about 85% done with this rifle. I want to make a glossy twill carbon fiber moderator for it with stainless endcaps. The HST dialer and trigger are just a prototyping tests, so I'll eventually get around to making final parts.

I have only shot it at 23y so far (hitting the range tomorrow), but it put 5 through a pellet sized hole twice when I zeroed it. Hoping that precision translates over at longer ranges!